Академический Документы

Профессиональный Документы

Культура Документы

Compressor Head Calculations Design Guide

Загружено:

c_nghiaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Compressor Head Calculations Design Guide

Загружено:

c_nghiaАвторское право:

Доступные форматы

PROCEDURE NO.

PAGE

OF

PTD-DGS-125

PREPARED BY

1

DATE

PROCESS TECHNOLOGY PROCEDURES

DEPART.ENT/ SUB&ECT/

Edited from exi ti!" do# $% &.R. B'r!('rt

APPRO1ED BY

A)ri* +,- 2,,,

PROCESS ENG0NEER0NG

&RB

RE10S0ON DATE RE1.

CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

1.0

SCOPE

This design guide1 describes the method used to calculate compressor circuit hydraulics. Refer to the Rotating Equipment Engineering Manual for a detailed description of compressor design and operation. 2.0 RESPONSIBILITIES

The process engineer determines the hydraulic requirements for compressor circuits. 3.0 CODES AND STANDARDS American Petroleum Institute (API !T" #1$ !T" #1( 4.0 DEFINITIONS %entrifugal %ompressors for &eneral Refinery !er'ice Reciprocating %ompressors for &eneral Refinery !er'ice

)isted belo* are the definitions of terms associated *ith calculations for centrifugal and reciprocating compressors using traditional +.!. units. 4.1 Centrif !"# C$%&re''$r'

The API !T" #1$ definitions are sho*n belo* and in ,igure 1. 1. -ormal operating point is the point at *hich usual operation is e.pected and optimum efficiency is desired. This point is usually the point at *hich the !upplier certifies that performance. /. -ormal speed is the speed corresponding to the requirements of the normal operating point. 0. 1ne2hundred2percent speed is the highest speed required for any specified operating point abo'e the normal speed cur'e. If there are no specified operating points that require greater than normal speed3 the 1442percent speed shall be the normal speed. 5. %ompressor rated point is the point on the 1442percent2speed cur'e at the highest capacity of any specified operating point. 6. Ma.imum continuous speed (in re'olutions per minute for compressors dri'en by 'ariable2speed prime mo'ers is the speed at least equal to 146 percent of the

1

Re5. , of t(e De i"! G6ide 7' 'd')ted 7it( mi!im'* #('!"e from ' P' 'de!' do#6me!t- DSG-.P8- 9492

highest speed required by any of the specified operating conditions. Ma.imum continuous speed for constant2speed dri'ers shall be equal to the 1442percent speed. #. Minimum allo*able speed (in re'olutions per minute is the lo*est speed at *hich the manufacturer7s design *ill permit continuous operation. $. Trip speed (in re'olutions per minute is the speed at *hich the independent emergency o'erspeed de'ice operates to shut do*n a prime mo'er (see Table 1 . (. !tability is the difference in capacity (in percentage of rated capacity bet*een the rated capacity and the surge point (and rated gas properties . 8. Turndo*n is the percentage of change in capacity bet*een the rated capacity and the surge2point capacity at the rated head *hen the unit is operating at rated suction temperature and gas composition.

!ource9 API !T" #1$ ,igure 1 : %entrifugal %ompressors 2 "efinitions

Table 1 2 "ri'er Trip !peeds

Trip !peed (percent of ma.imum continuous speed 116 114 146 114 144 114

"ri'er Type

!team turbine -EMA %lass A -EMA %lasses ;3 %3 " &as turbine <ariable2speed motor %onstant2speed motor Reciprocating engine

14 Ma.imum allo*able *or=ing pressure is the ma.imum continuous pressure for *hich the manufacturer designed the equipment (or any part to *hich the term is referred *hen it is operating at the ma.imum allo*able temperature. 11 Ma.imum sealing pressure is the highest pressure e.pected at the seals during any specified static or operating conditions and during startup and shutdo*n. 1/ Ma.imum allo*able temperature is the ma.imum continuous temperature for *hich the manufacturer designed the equipment (or any part to *hich the term is referred . 10 !ettling2out pressure is the pressure of the compressor system *hen the compressor is shutdo*n. 15 Inlet cubic feet per minute (I%,M refers to the flo*rate determined at the conditions of pressure3 temperature3 compressibility3 and gas composition3 including moisture3 at the compressor inlet flange. 16 Actual cubic feet per minute (A%,M refers to the flo*rate at flo*ing conditions of temperature and pressure at any gi'en location. ;ecause this term describes flo* at a number of locations3 it should not be used interchangeably *ith I%,M. 1# !tandard cubic feet per minute (!%,M refers to the flo*rate at any location corrected to a pressure of 15.$ pounds per square inch absolute (1.41 bar and a temperature of #4 degrees , (16.6# degrees % *ith a compressibility factor of 1.4 and in a dry condition. 4.2 Re(i&r$("tin! C$%&re''$r'

The API !T" #1( definitions are sho*n belo*.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

1. Rated discharge pressure is the highest pressure required to meet the specified conditions.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

/. Rated discharge temperature is the highest predicted operating temperature resulting from a specified operating condition. 0. !%,M is an abbre'iation for capacity in standard cubic feet per minute at 15.$ pounds per square inch absolute (psia and #4 degrees ,ahrenheit.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

5. I%,M is an abbre'iation for inlet cubic feet per minute determined at suction (compressor inlet flange conditions of pressure3 temperature3 compressibility3 and moisture. I%,M and A%,M (actual cubic feet per minute are identical in meaning (at the inlet conditions . To determine I%,M3 allo*ance shall be made for pressure drop across pulsation suppression de'ices and for interstage =noc=out. 6. Minimum Allo*able !uction Pressure for each stage is the lo*est pressure at the inlet flange belo* *hich the combined rod loading3 or gas loading3 or discharge temperature3 or cran= shaft torque loading *ill e.ceed the ma.imum allo*able during operation at the setpoint pressure of the discharge relief 'al'e and other specified gas conditions for the stage.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

).0

CALCULATION PROCEDURE CO+PRESSORS

CENTRIFUGAL

AND

RECIPROCATING

+sing the %ompressor %ircuit %alculation form3 complete the data section as follo*s9 ).1 Ser,i(e C$n-iti$n'

Enter ser'ice conditions and state the tag number and stage number. ).2 F#$. S/et(0

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

+sing the %ircuit Pressure "rop form3 (E.hibit / 3 construct a flo* s=etch identifying pertinent equipment by item>tag number and sho*ing orifices3 control 'al'es3 and alternate flo* routes. Include dimensions for compressor center line from datum3 line si?es3 static head3 relief 'al'e set pressures3 and bloc= 'al'es. !ho* ele'ations of equipment. ).3 Line Si1in!

%omplete the line si?e calculations using the pro@ect specified method. +se actual routing3 if =no*n3 or the estimated route3 using coordinates of equipment and allo*ing for

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

change of ele'ation3 pipe fittings3 and 'al'ing. estimating the suction line equi'alent length. ).4 C$%&re''$r Differenti"# He"- C"#( #"ti$n'

Particular care should be ta=en in

The compressor differential head calculations shall be performed as follo*s9 1. Enter line "P as calculated abo'e.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

/. "Ps of flo* measurement de'ices shall be actual 'alues obtained from the instrumentation and controls super'ising engineer. ;e sure to consider the use of lo*2pressure2drop de'ices for compressor circuits. 0. Identify the e.changer or equipment and the "P across the unit. These 'alues should be realistic and should be obtained from the heat transfer super'ising engineer. +se only fouled 'alues (allo*able "P . 5. R dynamic "P is the sum of dynamic losses listed abo'e. 6. ,or control 'al'e "P3 consult *ith the instrumentation and controls super'ising engineer to obtain the minimum 'alue that *ill ensure proper control of the

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

25

compressor circuit. &enerally3 these 'alues *ill be appro.imately 16 percent of the total dynamic losses. #. %ompressor suction pressure is obtained by subtracting the total dynamic loss and the control 'al'e "P from the suction 'essel pressure3 allo*ing for static head difference. $. Terminal pressure is the pressure at the end point of the compressor system. This is generally a 'essel3 the @unction *ith another system3 or the battery limit.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

1,

25

(. "ischarge pressure is the pressure at the discharge no??le of the compressor. It is the sum of the dynamic "P3 the control 'al'e "P3 the static head3 and the terminal pressure. 8. %ompressor differential pressure is the pressure the compressor must add to the fluid to allo* it to flo* to its required destination. It is the difference bet*een the compressor suction pressure (step # and the discharge pressure (step ( . 2.0 CO+PRESSOR TEA+

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

11

25

The compressor team is an organi?ation of members from the technical engineering organi?ation *hose function is to agree on and to fi. information pertinent to the design and procurement of compressor2dri'er units. 1n a specific pro@ect3 this team may be formal or informal. The process engineer is responsible for compressor hydraulics and participates in establishing compressor2dri'er type and number. 3.0 E4HIBITS

The follo*ing e.hibits are referenced in this design guide.

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

12

25

E.hibit 1 /

Title PT"2,RM2111 2 %ompressor %ircuit %alculation ,orm PT"2,RM2114 2 %ircuit Pressure "rop ,orm

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

1+

25

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

18

25

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

15

25

E.hibit 1 2 %ompressor %ircuit %alculation ,orm

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

19

25

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

1:

25

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

1;

25

E.hibit / : %ircuit Pressure "rop ,orm

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

19

25

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

2,

25

PROCEDURE NO.

RE1.

DATE

PAGE OF

PTD-DGS-125 CO.PRESSOR 2EAD CA3CU3AT0ONS DES0GN GU0DE

114,14,2

21

25

E.hibit / : %ircuit Pressure "rop ,orm (%ontAd

Вам также может понравиться

- Sizing Forced Draft Fans For Fired HeatersДокумент5 страницSizing Forced Draft Fans For Fired Heatersdlalameen4471Оценок пока нет

- A Guideline For Design Pressure - Part 2Документ4 страницыA Guideline For Design Pressure - Part 2Said Ahmed SalemОценок пока нет

- Distillation DesignДокумент1 страницаDistillation DesignvicopipОценок пока нет

- Fired Heater Design PDFДокумент12 страницFired Heater Design PDFSterlingОценок пока нет

- Air CoolerДокумент15 страницAir Coolerronny_fernandes363Оценок пока нет

- Steam Jet EjectorДокумент6 страницSteam Jet Ejectorjayanta_198967% (3)

- Reboiler Circuit DebottleneckДокумент8 страницReboiler Circuit DebottleneckstreamtОценок пока нет

- Seleccion de EbullidoresДокумент5 страницSeleccion de EbullidoresDaniela Jurado100% (2)

- Calculate Saturated-Gas Loads For Vacuum SystemsДокумент3 страницыCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberОценок пока нет

- REBOILER CALCULATION GUIDEДокумент12 страницREBOILER CALCULATION GUIDESabba CabbaОценок пока нет

- Effectively Design ACHE'sДокумент22 страницыEffectively Design ACHE'sSeshu BulusuОценок пока нет

- How To Design Overhead Condensing SystemsДокумент7 страницHow To Design Overhead Condensing Systemsstudyendless100% (1)

- Article PSV Specific HeatДокумент6 страницArticle PSV Specific Heatprq123Оценок пока нет

- Specification - Importance of Getting Them RightДокумент6 страницSpecification - Importance of Getting Them RightAnonymous QSfDsVxjZОценок пока нет

- Vertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyДокумент9 страницVertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyPuskar GuptaОценок пока нет

- HYSYS Tutorial PDFДокумент607 страницHYSYS Tutorial PDFsalman hussainОценок пока нет

- Gas Compression IIДокумент13 страницGas Compression IIAnuraag MulpuriОценок пока нет

- Direct Contact Gas-LiquidДокумент7 страницDirect Contact Gas-LiquidgiovanniОценок пока нет

- ENGINEERING DESIGN GUIDELINES Reboiler Rev1.3web PDFДокумент12 страницENGINEERING DESIGN GUIDELINES Reboiler Rev1.3web PDFSamit MitraОценок пока нет

- Thermal Intgration ReboilerДокумент3 страницыThermal Intgration ReboilerChem.EnggОценок пока нет

- Reboilers SelectionДокумент4 страницыReboilers SelectionPramod Dixit100% (1)

- IFP Materials PDFДокумент20 страницIFP Materials PDFProcess EngineerОценок пока нет

- Compressor How To Select For Varios Services (HP)Документ2 страницыCompressor How To Select For Varios Services (HP)Ricardo BecОценок пока нет

- Sloley - Properly Design Thermosyphon ReboilersДокумент14 страницSloley - Properly Design Thermosyphon Reboilersbltzkrig100% (4)

- CompressorДокумент27 страницCompressorsoxal100% (1)

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsДокумент10 страницEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyОценок пока нет

- Select The Right ReboilerДокумент2 страницыSelect The Right ReboilerSteven A McMurray100% (2)

- Understand Heat Flux Limitations On Reboiler Design PDFДокумент10 страницUnderstand Heat Flux Limitations On Reboiler Design PDFthawdarОценок пока нет

- Section 06B - PumpsДокумент62 страницыSection 06B - PumpsRajesh KumarОценок пока нет

- Gas Blow-By From A Production Separator To Tank PDFДокумент7 страницGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- EIEPD Design CriteriaДокумент125 страницEIEPD Design CriteriaLale AğayevaОценок пока нет

- IFP Materials PDFДокумент40 страницIFP Materials PDFProcess EngineerОценок пока нет

- EjectorsДокумент7 страницEjectorsashirwad shetty50% (2)

- DespresurizaciónДокумент3 страницыDespresurizaciónmatrix69Оценок пока нет

- Column-Base and Arrangements: ReboilerДокумент27 страницColumn-Base and Arrangements: ReboilerPacyfik Kameron100% (1)

- Reboiler HydraulicДокумент3 страницыReboiler Hydraulic54yreyeОценок пока нет

- Estimating Costs of Shell and Tube Heat ExchangersДокумент12 страницEstimating Costs of Shell and Tube Heat Exchangershwang2Оценок пока нет

- Tower Design & Spec.Документ25 страницTower Design & Spec.MuruganОценок пока нет

- Doc. No.: PDG-MUM-XXX Rev. 0 Relief Valve Sizing Philosophy Page 1 of 10Документ10 страницDoc. No.: PDG-MUM-XXX Rev. 0 Relief Valve Sizing Philosophy Page 1 of 10kishna009Оценок пока нет

- Fired Heater Design and CalcДокумент35 страницFired Heater Design and CalcDavidMBBSОценок пока нет

- Realistic control valve pressure dropsДокумент5 страницRealistic control valve pressure dropsJames Harden100% (1)

- Sizing, Specifying and Selecting Centrifugal Pumps (CE) PDFДокумент5 страницSizing, Specifying and Selecting Centrifugal Pumps (CE) PDFjdgh1986100% (1)

- Optimizing Pressure Relief SystemsДокумент6 страницOptimizing Pressure Relief SystemssgrsthОценок пока нет

- Fired Heater ModelingДокумент19 страницFired Heater ModelingAhmed Elhady100% (1)

- Training on Flare Systems Design and RegulationsДокумент93 страницыTraining on Flare Systems Design and Regulationssada sivaОценок пока нет

- 1.3.9 Rating Heat ExchangerДокумент18 страниц1.3.9 Rating Heat ExchangerMelva NainggolanОценок пока нет

- Jan11 GSO PDFДокумент10 страницJan11 GSO PDFChakravarthy BharathОценок пока нет

- HRSG Understand The BasicsДокумент14 страницHRSG Understand The BasicsMazen Darwish100% (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОт EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОценок пока нет

- Centrifugal Compressor Performance CalculationsДокумент4 страницыCentrifugal Compressor Performance CalculationsFreddy RoaОценок пока нет

- Sop For Fan SizingДокумент3 страницыSop For Fan SizingVeerabhadra Rao Korimilli100% (3)

- Air Dryyer PDFДокумент15 страницAir Dryyer PDFrajishrrrОценок пока нет

- Kadrabad Modinagar 2013-2014 Department of Mechanical EngineeringДокумент24 страницыKadrabad Modinagar 2013-2014 Department of Mechanical Engineeringlokesh_045Оценок пока нет

- Rotary Screw CompressorsДокумент22 страницыRotary Screw Compressorsganeshdhage100% (2)

- Flare Header Sizing Design GuideДокумент3 страницыFlare Header Sizing Design Guidec_nghia100% (1)

- Bristol Scroll Compressors GuidelinesДокумент18 страницBristol Scroll Compressors GuidelinesBrian DohertyОценок пока нет

- Vietnam HPP Low-Pressure Air System CalculationДокумент11 страницVietnam HPP Low-Pressure Air System CalculationVõ Duy GiaОценок пока нет

- 1.1 Control Philosophy CAS-1 NMDCДокумент36 страниц1.1 Control Philosophy CAS-1 NMDCkoushik42000Оценок пока нет

- Applied SciencesДокумент15 страницApplied SciencesCanan KamışlıОценок пока нет

- Compressors Course-Chapter 3Документ19 страницCompressors Course-Chapter 3Abdallah SayedОценок пока нет

- Feb 10Документ38 страницFeb 10c_nghiaОценок пока нет

- Dec 08Документ31 страницаDec 08c_nghia100% (1)

- Heat Exchanger Student HandoutДокумент39 страницHeat Exchanger Student HandoutkotiОценок пока нет

- Feb 10Документ29 страницFeb 10c_nghia100% (1)

- Dec 07Документ55 страницDec 07c_nghia100% (1)

- Nov 09Документ23 страницыNov 09c_nghiaОценок пока нет

- Feb 10Документ41 страницаFeb 10c_nghiaОценок пока нет

- Feb 10Документ50 страницFeb 10c_nghiaОценок пока нет

- Feb 10Документ59 страницFeb 10c_nghiaОценок пока нет

- Instrument Signal LineДокумент62 страницыInstrument Signal Linedewking198875% (4)

- Feb 10Документ46 страницFeb 10c_nghiaОценок пока нет

- Dec 07Документ44 страницыDec 07c_nghiaОценок пока нет

- Feb 10Документ55 страницFeb 10c_nghiaОценок пока нет

- Jul 98Документ38 страницJul 98c_nghia100% (2)

- Jan 10Документ45 страницJan 10c_nghia100% (1)

- Sep 02Документ44 страницыSep 02c_nghiaОценок пока нет

- Jul 08Документ61 страницаJul 08c_nghiaОценок пока нет

- Mar 09Документ30 страницMar 09c_nghia100% (1)

- Jul 97Документ41 страницаJul 97c_nghiaОценок пока нет

- Jul 97Документ35 страницJul 97c_nghiaОценок пока нет

- Sep 09Документ24 страницыSep 09c_nghia50% (2)

- Nov 09Документ30 страницNov 09c_nghiaОценок пока нет

- Dec 08Документ45 страницDec 08c_nghia100% (1)

- Jan 98Документ30 страницJan 98c_nghiaОценок пока нет

- Jul 97Документ28 страницJul 97c_nghiaОценок пока нет

- Dec 98Документ25 страницDec 98c_nghia100% (1)

- May 2011Документ33 страницыMay 2011c_nghia100% (1)

- Sep 02Документ19 страницSep 02c_nghia100% (1)

- Jul 97Документ68 страницJul 97c_nghia100% (1)

- Jan 10Документ44 страницыJan 10c_nghiaОценок пока нет

- Dell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionsДокумент14 страницDell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionseriquewОценок пока нет

- Chapter 5: Operating System, Quiz With AnswersДокумент14 страницChapter 5: Operating System, Quiz With AnswersAden Kheire Mohamed100% (1)

- Sisweb Sisweb Techdoc Techdoc Print Pag - pdf1Документ91 страницаSisweb Sisweb Techdoc Techdoc Print Pag - pdf1MatiussChesteerОценок пока нет

- The Use and Misuse of SEMДокумент30 страницThe Use and Misuse of SEMPPDTBM renОценок пока нет

- V Single Vane Pumps: 1 - "F3" 2 - Pump TypeДокумент14 страницV Single Vane Pumps: 1 - "F3" 2 - Pump TypeJose Leandro Neves FerreiraОценок пока нет

- StudenttextДокумент15 страницStudenttextapi-195130729Оценок пока нет

- Grand Vitara 2012 2013Документ193 страницыGrand Vitara 2012 2013Favio Alejandro Herrera ZapataОценок пока нет

- LCD Interfacing PDFДокумент37 страницLCD Interfacing PDFPeeyush Kp100% (1)

- Spe 58987 Propped Fracturing in Gas Carbonate Formations MexicoДокумент12 страницSpe 58987 Propped Fracturing in Gas Carbonate Formations MexicoJose Gregorio FariñasОценок пока нет

- AAL1 and Segmentation and Reassembly LayerДокумент18 страницAAL1 and Segmentation and Reassembly Layeroureducation.inОценок пока нет

- Projectile LoomДокумент23 страницыProjectile Loommehedi111560% (5)

- CHAPTER 6 Coordinate Geometry Module ExercisesДокумент15 страницCHAPTER 6 Coordinate Geometry Module ExercisesBid Hassan75% (8)

- 11.rolling Disc SolutionДокумент12 страниц11.rolling Disc SolutionAlimin AnniОценок пока нет

- Uncontrolled: Direct Shear Test of Soils Under Consolidated Drained ConditionsДокумент9 страницUncontrolled: Direct Shear Test of Soils Under Consolidated Drained ConditionsMohannad QutubОценок пока нет

- J Gen Physiol-1952-Hershey-39-56Документ18 страницJ Gen Physiol-1952-Hershey-39-56api-277839406Оценок пока нет

- Probset 8Документ7 страницProbset 8Adrian PamintuanОценок пока нет

- MT Slides Logistics (14 NovДокумент24 страницыMT Slides Logistics (14 NovRyan Tw ChoumingОценок пока нет

- GR/KWH, KG/HR or Tons/Month.: ScopeДокумент5 страницGR/KWH, KG/HR or Tons/Month.: ScopeThaigroup CementОценок пока нет

- PHYSICS O-LEVEL PAST PAPER QUESTIONS ON MOMENTSДокумент7 страницPHYSICS O-LEVEL PAST PAPER QUESTIONS ON MOMENTSelty TanОценок пока нет

- Maths Class VIII: Chapter As Per NCERT LessonsДокумент1 страницаMaths Class VIII: Chapter As Per NCERT Lessonsabhijeet_sangwanОценок пока нет

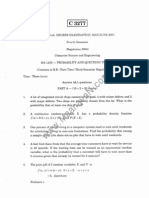

- PQT MJ07Документ6 страницPQT MJ07Raguraman BalajiОценок пока нет

- Signal and Telecommunication - 1Документ83 страницыSignal and Telecommunication - 1srinathОценок пока нет

- A Stated-Preference Study of The Willingness-To-Pay To Reduce Traffic Risk in Urban vs. Rural RoadsДокумент13 страницA Stated-Preference Study of The Willingness-To-Pay To Reduce Traffic Risk in Urban vs. Rural RoadsSantanu KumarОценок пока нет

- Recurrent Neural Network-Based Robust NonsingularДокумент13 страницRecurrent Neural Network-Based Robust NonsingularDong HoangОценок пока нет

- Calcs HETPДокумент50 страницCalcs HETPChemEngGirl89Оценок пока нет

- Charger Energic Plus (Catalog)Документ24 страницыCharger Energic Plus (Catalog)sugar44Оценок пока нет

- Faraday Rotation + Verdet Constant PosterДокумент1 страницаFaraday Rotation + Verdet Constant PosterAndrew PalmerОценок пока нет

- CCR Load Calculator 2014-03-13Документ35 страницCCR Load Calculator 2014-03-13Danielle FowlerОценок пока нет

- openPDC DM-Tools Usage Examples GuideДокумент5 страницopenPDC DM-Tools Usage Examples GuidealantmurrayОценок пока нет

- Class XII Computer Project - Hotel ManagementДокумент29 страницClass XII Computer Project - Hotel ManagementLakshmi Puthiyedath71% (7)