Академический Документы

Профессиональный Документы

Культура Документы

An Electronic Water Meter Design Using MSP430F41x

Загружено:

rsrtnjОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

An Electronic Water Meter Design Using MSP430F41x

Загружено:

rsrtnjАвторское право:

Доступные форматы

Application Report

SLAA138A MARCH 2002

An Electronic Water Meter Design Using MSP430F41x

Kes Tam ABSTRACT This application report describes how to achieve a reliable and ultralow-power electronic water meter design using the MSP430F41x microcontroller from Texas Instruments. The innovative flow sensor IP and a fault tolerant rotation detection algorithm also are covered. MSP430

Contents 1 2 Introduction ........................................................................................................................................2 Flow Sensor........................................................................................................................................2 2.1 Sensor Structure..........................................................................................................................2 2.2 Sensor Hardware.........................................................................................................................4 3 Rotation Detection Algorithm...........................................................................................................7 3.1 Rotation With No Defective Sensor.............................................................................................7 3.2 Rotation With One Defective Sensor...........................................................................................7 3.3 Jittering on the Same Sensor ......................................................................................................9 4 Ultra-Low Design .............................................................................................................................10 5 Summary...........................................................................................................................................10 6 References........................................................................................................................................10 Appendix A. Hardware Schematic .........................................................................................................11

Figures Figure 1. Figure 2. Figure 3. Figure 4. Figure 5. Figure 6. Figure 7. Figure 8. Figure 9. Flow Sensor Structure .........................................................................................................3 Sensor Schematic Diagram .................................................................................................4 Undamped Oscillation, With No Copper Coating Over the Inductor..............................5 Damped Oscillation, With Copper Coating Over the Inductor ........................................6 Rotation With No Defective Sensor....................................................................................7 Rotation Passing Through a Defective Sensor.................................................................8 Rotation Not Passing Through the Defective Sensor ......................................................8 Rotation Through All Sensors With No Defect..................................................................9 Copper Coating Jittering Around Sensor A ......................................................................9

SLAA138A

Introduction

The patented flow sensor IP from Texas Instruments provides a way to detect water flow with no associated mechanical switch. It uses inductors and metal wheel to detect the water flow. This resolves the reliability problem caused by mechanical wear of a switch. Detail structure, hardware and working principle of the flow sensor are described in Section 2. An intelligent rotation detection algorithm is covered in Section 3. This algorithm can tolerate the failure of any one inductive sensor out of the total three. First, the section covers the way to detect different directions of wheel rotation. Then it discusses the handling of a defective sensor. Section 4 will talk about how to achieve the ultra-low power design. Finally, a summary is given in Section 5. The hardware schematic is included in Appendix A. A software listing based on MSP430F41x can be found on Texas Instruments web site (http://www.ti.com).

2

2.1

Flow Sensor

Sensor Structure

The mechanical structure of the flow sensor is shown in Figure 1. It consists of two mechanical wheel plates mounted on the same axis and driven by a gear assembly. For simplicity, the gear assembly is not shown on the figure. If there is water flow, the gear assembly drives and rotates the two wheel plates together. The two wheel plates should be made of nonconductive material. Half of the wheel plates is coated with copper or other conductive metal. Between the two wheel plates are three inductors placed with 120 degrees of separation. The rotation of the wheel plates is detected by the three inductor sensors when the copper coating passes over them.

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

a. Three-Dimensional View

Inductor

Copper Coating

120

b. Wheel Plate With Copper Coating Figure 1. Flow Sensor Structure

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

2.2

Sensor Hardware

Figure 2 shows the schematic for one inductor sensor only. The inductor in the circuit is mounted between two mechanical wheel plates as shown in Figure 1. Each inductor sensor has its own select line. The trigger line is common and the transistor collector outputs for all inductor sensors are tied together.

Figure 2.

Sensor Schematic Diagram

Driving the corresponding SELECT line low together with a positive pulse on the TRIGGER pin starts an LC oscillation on the selected sensor. Oscillation takes a longer time to die out when the copper coating of the wheel plates is not over the inductor. This is referred to as undamped oscillation. However, if the inductor is covered by the copper coating, the oscillation dies down quickly, as the copper absorbs the energy stored in the inductor. This is referred to as damped oscillation. The oscillation can be observed at the transistor emitter. Both undamped and damped oscillation are shown in Figure 3(a) and Figure 4(a) respectively.

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

Ve (undamped)

(a) Transistor Emitter Output

Sensor_out (undamped)

Vref

Comparator_out

(b) Sensor and Comparator Output Figure 3. Undamped Oscillation, With No Copper Coating Over the Inductor

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

Ve (damped)

(a) Transistor Emitter Output

Sensor_out (damped)

Vref

Comparator_out

(b) Sensor and Comparator Output Figure 4. Damped Oscillation, With Copper Coating Over the Inductor

If the amplitude of the oscillation at the emitter is sufficiently high, the transistor is turned on. Figures 3(b) and 4(b) show the sensor output from the collector of the transistor through two diodes. In damped oscillation, the transistor can be turned on only once by the first big spike in the oscillation. The output is then discharged back to VCC at a rate determined by the RC connected to VCC. For undamped oscillation, transistor can be turned on more than one time as the second or even third spike of the oscillation is sufficiently high. Figure 3(b) shows the sensor output for the undamped oscillation, assuming two triggers on the transistor. If the inductor sensor output is compared with Vref, which is around 1/2 V CC, the comparator output is as shown in Figure 3(b) and Figure 4(b). There are two rising edges and two falling edges for undamped oscillation, but only one of each for damped oscillation. By checking the number of rising (or falling) edges, we can know whether it is a damped or undamped oscillation. In other words, we can know whether the copper coating is over the inductor or not.

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

Rotation Detection Algorithm

There are different ways to tell whether the wheel plate is rotating, and if so, in which direction. The algorithm shown here is simple, straightforward, and capable of tolerating one defective inductor sensor.

3.1

Rotation With No Defective Sensor

In Figure 5, the copper coating is passing over sensor A. Before the copper coating reaches sensor A, sensor A is in undamped oscillation. Then it switches to damped oscillation when whole of it is covered by the copper coating. The transition from undamped to damped oscillation tells that the copper coating is passing over a sensor.

C Copper B B

Copper

Figure 5.

Rotation With No Defective Sensor

Because the three sensors are equally separated by 120 degrees, wheel rotation can be converted to a number of flow counts with each count representing 120 degrees, or three counts representing one revolution. A simple rotation conversion algorithm can be developed. Flow count is incremented or decremented by one when the copper coating passes a sensor. The increment or decrement depends on the direction of rotation. The positive direction can be selected to be either clockwise or counterclockwise, according to user preference. The direction of rotation can be determined by the sequence of sensors passed by the copper coating. If all three sensors are working, the latest two sensors in the sequence are enough to determine the direction. Assuming sensors A, B, and C are placed in a clockwise direction as in Figure 5, if the last two sensor outputs are from C and A, then rotation is clockwise. However, if they are from B and A, rotation is counterclockwise.

3.2

Rotation With One Defective Sensor

Suppose sensor C has failed. Figure 6 and Figure 7 show two different rotation directions which pass or do not pass the defective sensor C. Because sensor C is defective, the passing sequences are from B to A in both figures. Just considering the sequence from the undamped to the damped oscillation as described in section 3.1 cannot determine the direction of rotation. To make the determination, the algorithm can be extended by having it check the previously passed sensor to see whether it is still covered by the copper coating.

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

C Copper B Copper A B

Copper

(a) Passing Sensor B

(b) Passing Defective Sensor C

(c) Passing Sensor A

Figure 6.

Rotation Passing Through a Defective Sensor

C Copper B B Copper A

(a) Passing Sensor B

(b) Passing Sensor A

Figure 7.

Rotation Not Passing Through the Defective Sensor

Considering Figure 6(c) and Figure 7(b), the copper coating is passing and has covered sensor A. In both cases, the previously passed sensor is sensor B. However, in Figure 6(c), sensor B is not covered by the copper coating, whereas it is covered in Figure 7(b). This difference can be used to distinguish the two rotational directions. The algorithm can be modified as follows: at the time the copper coating passes over a sensor, if the previously passed sensor is still covered by the copper coating, there will be no interspersed defective sensor and the direction is given by the previously passed sensor. Otherwise, there is an undetected defective sensor between the previous and current sensors. The direction is given by the defective sensor and the rotation distance is doubled. So for the case in Figure 6, the previous sensor B is not under the copper coating when it passes over sensor A. The direction is determined by the defective sensor C, i.e., from C to A, which is clockwise. The number of flow counts to be incremented or decremented is two. For the case in Figure 7, previous sensor B is under the copper coating, so the direction is determined by the previous sensor B, i.e., from B to A, which is counterclockwise.

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

C Copper B Copper A B

Copper

(a) Passing Sensor B

(b) Passing Sensor C

(c) Passing Sensor A

Figure 8.

Rotation Through All Sensors With No Defect

The extended algorithm still applies in the case of no defective sensors. Figure 8 shows all the cases for the copper coating passing over each sensor. While the copper coating passes over any sensor, the previous sensor is covered by the copper coating, so that the direction is determined by the previous sensor and the flow count is updated by one.

3.3

Jittering on the Same Sensor

C

Copper

Figure 9.

Copper Coating Jittering Around Sensor A

There might be a situation such that the edge of the copper coating stops and stands still or jitters over a particular sensor when there is no water flow. In this case, the sensor completely under the copper coating is always the same one, and no action should be taken. Actually, this situation is same as the case of having two defective sensors. Because of this, two defective sensors are not supported.

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

Ultra-Low Power Design

For water meter application, it is essential to have an ultra-low power design so that a single battery can provide years operation. The sensor hardware discussed on section 2 consumes an extremely low amount of power. For most of the time, the sensors transistors are completely turned off with no current flown. They are turned on to excite the LC oscillation periodically to detect the wheel plate rotation. To minimize the average current, the frequency and the actual excitation time should be kept to a minimum. However, the actual excitation frequency should not be set so slow as to miss any detection. To better cope with this, two different frequencies can be used. A higher frequency is used when the wheel is rotating. If the wheel stops for a set period of time, it will automatically switch to a lower frequency. When the wheel starts rotating again, it will switch back to the higher frequency immediately. The selection of the micro-controller is also critical. The MSP430F41x used here is an ultra-low power microcontroller. It takes very few A in its low-power mode 3 and has extremely fast 6-s wake-up time. The sensor excitation frequencies with and without rotation are 128 Hz and 8 Hz respectively and the excitation time is only 1s. With this configuration, an ultra-low power design can be achieved.

Summary

This application report describes an electronic water meter design that uses no mechanical switch and therefore is more durable. The Texas Instruments patented flow sensor IP has been covered in detail. This includes the mechanical structure, sensor hardware and the detection principle of damped and undamped oscillation. A fault-tolerant rotation detection algorithm has been discussed in detail. Different rotation situations, including defective and normal sensors, have been covered. Finally, the design was implemented using an MSP430F41x from Texas Instruments. The working current was found to be as low as 3 A with no water flow or 16 A with water flow, making it ideal for water meter application.

References

1. MSP430x4xx Family Users Guide, Texas Instruments (SLAU056) 2. MSP430x41x Mixed Signal Microcontroller, Texas Instruments, data sheet (SLAS340) 3. Patent DE19725806, Rotation sensor, e.g. for battery-powered water meter

10

An Electronic Water Meter Design Using MSP430F41x

SLAA138A

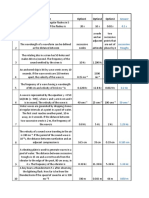

Appendix A. Hardware Schematic

An Electronic Water Meter Design Using MSP430F41x

11

C Vcc Vcc J1 Vcc 100p C1

D Vcc

Water meter

1 Vcc D1 47K R2

1 3 5 7 2 4 6 8 10 12 14

15K

R1

1 D5 D6 Q3 Q2 Q1

R5 2.2K C3 4.7n L1 47u Sensor 1

R4 2.2K C6 4.7n L3 47u Sensor 2

R3 2.2K C4 4.7n L2

C12

BAT1

10u

56p

SW1

R6 1K

11 13

C2

JTAG

2 Vcc 100 R9 47u Sensor 3 D2

100

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

U1 P1.5/TACLK/ACK P1.6/CA0 P1.7/CA1 P2.0/TA2 P2.1 P5.7/R33 P5.6/R23 P5.5/R13 R03 P5.4/COM3 P5.3/COM2 P5.2/COM1 COM0 P2.2/S23 P2.3/S22 P2.4/S21

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

P4.4/S5 P4.3/S6 P4.2/S7 P4.1/S8 P4.0/S9 P3.7/S10 P3.6/S11 P3.5/S12 P3.4/S13 P3.3/S14 P3.2/S15 P3.1/S16 P3.0/S17 P2.7/S18 P2.6/CAOUT/S19 P2.5/S20

R11

COM2 COM3 COM1 COM0 S14 S13 S12 S11 S10 S9 S8 S7 S6 S5 S4 S3 S2 S1 S0 COM0*

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

R12

1M

1M

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

DVcc P6.3 P6.4 P6.5 P6.6 P6.7 NC XIN XOUT/TCLK NC NC P5.1/S0 P5.0/S1 P4.7/S2 P4.6/S3 P4.5/S4

32.768KHz

AVcc DVss AVss P6.2 P6.1 P6.0 _RST/NMI TCK TMS TDI TDO/TDI P1.0/TA0 P1.1/TA0(i)/MCLK P1.2/TA1 P1.3/SVSOut P1.4

0.1u

C14

100

D4

R8

D3

R7

MSP430F41X

X1

R10

J2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

1M

LCD

T218010

IMPORTANT NOTICE Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are sold subject to TIs terms and conditions of sale supplied at the time of order acknowledgment. TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TIs standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily performed. TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and applications using TI components. To minimize the risks associated with customer products and applications, customers should provide adequate design and operating safeguards. TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI. Reproduction of information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for such altered documentation. Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements. Following are URLs where you can obtain information on other Texas Instruments products and application solutions: Products Amplifiers Data Converters DSP Interface Logic Power Mgmt Microcontrollers amplifier.ti.com dataconverter.ti.com dsp.ti.com interface.ti.com logic.ti.com power.ti.com microcontroller.ti.com Applications Audio Automotive Broadband Digital Control Military Optical Networking Security Telephony Video & Imaging Wireless Mailing Address: Texas Instruments Post Office Box 655303 Dallas, Texas 75265 Copyright 2004, Texas Instruments Incorporated www.ti.com/audio www.ti.com/automotive www.ti.com/broadband www.ti.com/digitalcontrol www.ti.com/military www.ti.com/opticalnetwork www.ti.com/security www.ti.com/telephony www.ti.com/video www.ti.com/wireless

Вам также может понравиться

- Why Sound Heals - Cymatics, Entrainment, Mandalas, Frequencies and DNAДокумент8 страницWhy Sound Heals - Cymatics, Entrainment, Mandalas, Frequencies and DNAnicung100% (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Optical Technology in Current MeasurementДокумент17 страницOptical Technology in Current MeasurementUswa Zainab57% (7)

- Physics Module WavesДокумент40 страницPhysics Module Wavesnickphysics4927100% (2)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetОт EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetРейтинг: 2 из 5 звезд2/5 (1)

- Topic 3 Oscilloscope and Signal GeneratorДокумент24 страницыTopic 3 Oscilloscope and Signal GeneratorChinОценок пока нет

- CapacitorsДокумент10 страницCapacitorsrsrtnj100% (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetОт EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetОценок пока нет

- Introduction To Electrical DrivesДокумент18 страницIntroduction To Electrical DrivesSidali Chaib50% (2)

- Analisis de Vibraciones SKFДокумент118 страницAnalisis de Vibraciones SKFJose EsquedaОценок пока нет

- Intake CalculationsДокумент6 страницIntake Calculationsjameel babooramОценок пока нет

- Digitally Controlled Oscillator ReportДокумент18 страницDigitally Controlled Oscillator ReportVinidhra ShivakumarОценок пока нет

- Daily Intellectual TrainingДокумент36 страницDaily Intellectual TrainingBruno FernandesОценок пока нет

- Waves Worksheet #2: Name: - DateДокумент2 страницыWaves Worksheet #2: Name: - Dateapi-260547045Оценок пока нет

- Computational Methods in Power System AnalysisДокумент113 страницComputational Methods in Power System Analysisrsrtnj100% (8)

- Mkm1133 Instrumentation and Control SystemДокумент19 страницMkm1133 Instrumentation and Control SystemNurul Nadia Mohd ZawawiОценок пока нет

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1От EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- Ultrasonics For First Year .B.Tech. StudentsДокумент9 страницUltrasonics For First Year .B.Tech. StudentsSuryasrikar Peruri100% (1)

- BETA Primer Vibration Control StrategiesДокумент35 страницBETA Primer Vibration Control Strategiesdikim100% (1)

- Design and Development of A Fluxgate MagnetometerДокумент5 страницDesign and Development of A Fluxgate Magnetometerdr_oxide2Оценок пока нет

- FR4 Suitability of Different Test Voltages For On Site Cable Testing Rev00Документ34 страницыFR4 Suitability of Different Test Voltages For On Site Cable Testing Rev00Ho Jun XianОценок пока нет

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlОт EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlРейтинг: 5 из 5 звезд5/5 (1)

- Acoustics and PlumbingДокумент14 страницAcoustics and PlumbingCes Dela CruzОценок пока нет

- Tap ChangerДокумент10 страницTap ChangerusefiОценок пока нет

- F 726Документ6 страницF 726costantin2Оценок пока нет

- Dynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Impulse Excitation of VibrationДокумент16 страницDynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Impulse Excitation of VibrationEric GozzerОценок пока нет

- MSD AssignmentДокумент16 страницMSD AssignmentNanda KishoreОценок пока нет

- Speed SensorsДокумент8 страницSpeed Sensorsajd.nanthakumarОценок пока нет

- Index: Page No. List of ContentДокумент20 страницIndex: Page No. List of Contentkolluri ramyaОценок пока нет

- Exp No 3Документ10 страницExp No 3arooj aslamОценок пока нет

- Rajshahi University of Engineering &technologyДокумент4 страницыRajshahi University of Engineering &technologyদিব্যজয় পালОценок пока нет

- ST Micro - An4076Документ14 страницST Micro - An4076smhbОценок пока нет

- Experiment No. 3 Testing A TP Sensor Using An Oscilloscope: ObjectivesДокумент8 страницExperiment No. 3 Testing A TP Sensor Using An Oscilloscope: ObjectivesMustafa AliОценок пока нет

- 12th Electronics Most Likely Questions SetДокумент19 страниц12th Electronics Most Likely Questions SetomdombareОценок пока нет

- Gate OscilatorДокумент4 страницыGate OscilatorfjlpОценок пока нет

- An Automated Method For Measuring Quartz CrystalsДокумент6 страницAn Automated Method For Measuring Quartz CrystalsAnonymous Kti5jq5EJIОценок пока нет

- AVR194 Brushless DC Motor Control Using ATMega32M1Документ16 страницAVR194 Brushless DC Motor Control Using ATMega32M1u776287Оценок пока нет

- Chapter 14Документ15 страницChapter 14Gaurav SharmaОценок пока нет

- Unit-5 EMI CROДокумент24 страницыUnit-5 EMI CROShivam Kumar YadavОценок пока нет

- Sensors Velocity ResolversДокумент17 страницSensors Velocity ResolversAravind ManneОценок пока нет

- EX-604 Electronic Instrumentation Lab FormatДокумент30 страницEX-604 Electronic Instrumentation Lab FormatdeepaknayanОценок пока нет

- Universal Test Bench For Characterization of Distance-Measuring and Strain SensorsДокумент6 страницUniversal Test Bench For Characterization of Distance-Measuring and Strain Sensorssassi amelОценок пока нет

- 3.2 Sensors and TransducersДокумент38 страниц3.2 Sensors and Transducersjohanna shaanyenengeОценок пока нет

- A 10-mW Two-Channel Fully Integrated System-on-Chip For Eddy-Current Position SensingДокумент10 страницA 10-mW Two-Channel Fully Integrated System-on-Chip For Eddy-Current Position SensingkurabyqldОценок пока нет

- Laser ExtensometroДокумент26 страницLaser Extensometroalfgraga6043Оценок пока нет

- Describe The Construction of A Electromagnetic Velocity Sensor and Explain Its WorkingДокумент8 страницDescribe The Construction of A Electromagnetic Velocity Sensor and Explain Its WorkingJiten Thakur100% (1)

- Feedback Devices MazurkiewiczДокумент6 страницFeedback Devices MazurkiewiczKamlesh TewariОценок пока нет

- 07-Speed Trainer Magnetic PhotoДокумент16 страниц07-Speed Trainer Magnetic Photohydromec_indiaОценок пока нет

- Rotor Rso Reflectometer TYPE TDR100 and TDR100RBДокумент38 страницRotor Rso Reflectometer TYPE TDR100 and TDR100RBDevas ShuklaОценок пока нет

- A Design of SCR Three-Phase AC-Voltage Regulator Simplify Circuitry Based On STM32 MCUДокумент7 страницA Design of SCR Three-Phase AC-Voltage Regulator Simplify Circuitry Based On STM32 MCUibrahimОценок пока нет

- Cable Fault DetectorДокумент25 страницCable Fault DetectorHarshalОценок пока нет

- Experiment in ElectronicsДокумент8 страницExperiment in ElectronicsPercival Cylas CabralesОценок пока нет

- 4k Manual r1Документ21 страница4k Manual r1agudpagudpОценок пока нет

- Flow Metering Tutorial Part 2 Pulse BaseДокумент7 страницFlow Metering Tutorial Part 2 Pulse BasesalemОценок пока нет

- Vehicle Electrical GaugesДокумент13 страницVehicle Electrical GaugesSimon Mwangi kabauОценок пока нет

- Brushed DC Sensorless FeedbackДокумент3 страницыBrushed DC Sensorless FeedbackHoon Miew JieОценок пока нет

- AN295036 Current Sensor ICs in Current Divider ConfigurationsДокумент11 страницAN295036 Current Sensor ICs in Current Divider ConfigurationsmicroperuОценок пока нет

- A Smart Preamplifier For Real-Time Turbine Meter DiagnosticsДокумент4 страницыA Smart Preamplifier For Real-Time Turbine Meter DiagnosticsamrandconanОценок пока нет

- Oscilloscope Guide - How Oscilloscopes Work - BK PrecisionДокумент7 страницOscilloscope Guide - How Oscilloscopes Work - BK PrecisionmedhyalОценок пока нет

- A Beam-Forming Transmit ASIC For Driving Ultrasonic Arrays: John V. Hat®eld, Kwet Seng ChaiДокумент7 страницA Beam-Forming Transmit ASIC For Driving Ultrasonic Arrays: John V. Hat®eld, Kwet Seng ChaitoloiceОценок пока нет

- AVR492: Brushless DC Motor Control Using AT90PWM3: Application NoteДокумент26 страницAVR492: Brushless DC Motor Control Using AT90PWM3: Application NotenicoletabytaxОценок пока нет

- Mahalakshmi: Unit - Iv - Storage and Display DevicesДокумент18 страницMahalakshmi: Unit - Iv - Storage and Display Devicestareq omarОценок пока нет

- AssignmentДокумент39 страницAssignmentMaharnab Paul MugdhaОценок пока нет

- Question Yyybank For Unit I of MechatronicsДокумент3 страницыQuestion Yyybank For Unit I of Mechatronicschetan patilОценок пока нет

- Controllable Rectified Three-Phase DC Supply: Kerstin LindströmДокумент14 страницControllable Rectified Three-Phase DC Supply: Kerstin Lindströmdormo715Оценок пока нет

- System1 Plots - Machinery-Diagnostic - Part1Документ16 страницSystem1 Plots - Machinery-Diagnostic - Part1Thyagaraju PalisettyОценок пока нет

- Measurement and Analysis of Vibrations of Electric Motors On Board Container ShipsДокумент12 страницMeasurement and Analysis of Vibrations of Electric Motors On Board Container ShipsLeon PanaОценок пока нет

- Report Tinkering Lab (1) DFGДокумент17 страницReport Tinkering Lab (1) DFGNEELKANTH MARANDIОценок пока нет

- Inst Unit Wise QuestionsДокумент3 страницыInst Unit Wise QuestionsPathan MehemudОценок пока нет

- Microwave Manual 2017Документ72 страницыMicrowave Manual 2017manjuri karОценок пока нет

- Emi Question BankДокумент5 страницEmi Question BankleelavathyОценок пока нет

- Aquamatej User Manual: Serial NumberДокумент27 страницAquamatej User Manual: Serial NumberArun Kumar KarОценок пока нет

- Telugu Grammer LessonДокумент17 страницTelugu Grammer LessonrsrtnjОценок пока нет

- DC DC Power SuppliesДокумент33 страницыDC DC Power SuppliesrsrtnjОценок пока нет

- Nonlinear - Local ControllabilityДокумент12 страницNonlinear - Local ControllabilityrsrtnjОценок пока нет

- Implementing An Electronic Watt-Hour Meter With MSP430FE42x (A) /FE42x2Документ32 страницыImplementing An Electronic Watt-Hour Meter With MSP430FE42x (A) /FE42x2rsrtnjОценок пока нет

- Current-Transformer Phase-Shift Compensation and CalibrationДокумент7 страницCurrent-Transformer Phase-Shift Compensation and CalibrationrsrtnjОценок пока нет

- Microchip SPICE Models 01256aДокумент12 страницMicrochip SPICE Models 01256arsrtnjОценок пока нет

- Ts FindДокумент0 страницTs FindrsrtnjОценок пока нет

- RFID Manual PDFДокумент16 страницRFID Manual PDFAngelus Vincent GuilalasОценок пока нет

- Rr311003 Industrial InstrumentationДокумент5 страницRr311003 Industrial InstrumentationSrinivasa Rao GОценок пока нет

- Hazard Risk MapsДокумент5 страницHazard Risk MapsHarrison Jara InfantesОценок пока нет

- พอฤทัย วิริยะภาค26 3.5Документ2 страницыพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคОценок пока нет

- Narayana Physics Module With Exercise-908-987Документ40 страницNarayana Physics Module With Exercise-908-987vihasithsanamОценок пока нет

- T320XVN02.0 SKD AuoДокумент23 страницыT320XVN02.0 SKD AuoVenkatesh SubramanyaОценок пока нет

- Waves and Light H HMWK 1Документ3 страницыWaves and Light H HMWK 1knoxphysicsОценок пока нет

- Classification of Radio WavesДокумент4 страницыClassification of Radio WavesmayankfirstОценок пока нет

- Acoustics 101 For Architects (Michael Fay)Документ49 страницAcoustics 101 For Architects (Michael Fay)Carlorel AnteОценок пока нет

- 20 Electronics Interview Questions and AnswersДокумент21 страница20 Electronics Interview Questions and AnswersChandra Mathi100% (1)

- Astm E1170Документ10 страницAstm E1170Mutyaba Johnson100% (1)

- KET-3000W4 S-Mini AC Drive ManualДокумент127 страницKET-3000W4 S-Mini AC Drive ManualShashikant PatilОценок пока нет

- Answer52022 SPAK20230524103233Документ89 страницAnswer52022 SPAK20230524103233NifemiОценок пока нет

- Andrew Harvey HSC Preliminary Course Physics NotesДокумент53 страницыAndrew Harvey HSC Preliminary Course Physics NotesnickbarnОценок пока нет

- Electromagnetic Buzzers Pin Terminal SD Series: Conformity To Rohs DirectiveДокумент4 страницыElectromagnetic Buzzers Pin Terminal SD Series: Conformity To Rohs DirectiveYugi Abdul LathifОценок пока нет

- Site Effect Evaluation Using Spectral Ratios With Only One StationДокумент15 страницSite Effect Evaluation Using Spectral Ratios With Only One StationJavier MtОценок пока нет

- Chapter 16 - Electronics and Information and Communication Technology (Ict)Документ17 страницChapter 16 - Electronics and Information and Communication Technology (Ict)Cikgu Shaiful KisasОценок пока нет

- Datasheet: Intelilite Mrs 11Документ4 страницыDatasheet: Intelilite Mrs 11widiОценок пока нет