Академический Документы

Профессиональный Документы

Культура Документы

Bacillus Polyfermenticus

Загружено:

si275Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bacillus Polyfermenticus

Загружено:

si275Авторское право:

Доступные форматы

J. Microbiol. Biotechnol. (2009), 19(9), 10131018 doi: 10.4014/jmb.0903.

113 First published online 1 June 2009

Characterization of Bacillus polyfermenticus KJS-2 as a Probiotic

Kim, Kang Min1, Myo Jeong Kim1, Dong Hee Kim2, You Soo Park3, and Jae Seon Kang4*

1 2

Department of Smart Foods and Drugs, Inje University, Gyeongsangnam-do 621-749, Korea Research and Development Center, Daewoo Co. Ltd., Gyeongsangnam-do 621-749, Korea Department of Laboratory Biochemistry, Pusan National University School of Medicine, Busan 609-735, Korea 4 Department of Pharmacy, Kyungsung University, Busan 608-736, Korea

3

Received: March 5, 2009 / Revised: March 16, 2009 / Accepted: March 23, 2009

The identification and characterization of Bacillus polyfermenticus KJS-2 (B. polyfermenticus KJS-2) was conducted using TEM, an API 50CHB kit, 16S rDNA sequencing, a phylogenetic tree, and catalase and oxidase testing. The conversion rate of glucose to lactic acid by B. polyfermenticus KJS-2 was found to be 60.714.9%. In addition, treatment of B. polyfermenticus KJS-2 with artificial gastric juice (pH 2.0) and bile acid (pH 6.5) for 4 h resulted in a final viability of 1407.9% and 1083.5%, respectively. Finally, the results of adhesion experiments using Caco-2 cells revealed that the adherence of B. polyfermenticus KJS-2 to Caco-2 cells was approximately 650.6%. Keywords: Bacillus polyfermenticus KJS-2, probiotic, characterization, industrial application

Probiotics are defined as live microbial food ingredients that have a beneficial effect on human health [25]. Lactobacilli, streptococci, bifidobacteria, enterococci, and bacilli species are the bacteria most often used in the production of probiotics. At the very least, a good probiotic should posses the following 5 characteristics: (1) the probiotic should promote growth or increased resistance to disease; (2) the probiotic should be non-toxic and non-pathogenic; (3) the probiotic should be present as viable cells, preferably in large numbers, although there is no known minimum effective dose; (4) the probiotic should be capable of surviving and metabolizing in the gut environment; and (5) the probiotic should be stable and capable of remaining viable for long periods of time under storage and field conditions [8]. Appropriate applications of probiotics have been shown to improve intestinal microbial balance, thereby leading to

*Corresponding author Phone: +82-51-663-4882; Fax: +82-51-663-4809; E-mail: jskang8551002@ks.ac.kr

improved nutritional absorption and reduced pathogenic problems in the gastrointestinal tract [5, 8, 9, 20, 23]. Probiotics have also been applied to a wide range of aquatic organisms, including salmon and shrimp infected with pathogenic bacteria [2, 7, 26]. In 1933, Terakado isolated several endospore-forming rods from the air, four of which were used to make the commercial mixed strain product known as Bispan [18]. These four strains have other morphology. Bispan strains are described in the Japanese Pharmacopoeia as amylolytic bacilli, together with Bacillus subtilis (B. subtilis) and Bacillus mesentericus [18]. However, Bispan strains are distinct from B. subtilis strains because they are capable of producing a larger amount of acetic and lactic acids from glucose and lactose, respectively [14, 15, 18]. Bispan has long been used for the treatment of chronic intestinal disorders, since the live strains in the form of active endospores can successfully reach the target intestine in humans and animals [13]. Although B. polyfermenticus KJS-2 is one of the Bispan strains, there is currently little information regarding this organism. In this study, B. polyfermenticus KJS-2 was isolated from Bispan and then characterized by 16S rDNA sequencing, phylogenetic analysis, catalase and oxidase testing, and TEM observation. In addition, it was evaluated for its ability to metabolize lactic acid, its stability in artificial gastric juice and bile acid, and by a Caco-2 cell in vitro adhesion assay. Furthermore, B. polyfermenticus KJS-2 was evaluated using an API 50CHB kit. The producer strain, B. polyfermenticus KJS-2 KCCM10769P, was maintained at -70oC in tryptic soy broth (TSB, Difco) containing 20% (v/v) glycerol. Working cultures were propagated in TSB with shaking at 37oC. All reagents were purchased from Sigma (St. Louis, MO, U.S.A.). All microorganisms were obtained from the Korea Culture Center of Microorganisms (KCCM) or the Korean Collection for Type Cultures (KCTC).

1014

Kim et al.

The total genomic DNA of B. polyfermenticus KJS-2 was prepared using exponential-phase cells that were cultured in TSB using a salting out procedure for bacterial genomic DNA preparation [16]. Oligonucleotide primers described in Thomas [28] were used to amplify the gene encoding 16S rDNA. PCR amplification was performed in a master mix with a final reaction volume of 50 l that contained 10 l of mixed deoxynucleoside triphosphate (2 mM), 5 l of 10 nTaq-Tenuto reaction buffer (Enzynomics Co., Korea), 3 l of DMSO (dimethyl sulfoxide; Sigma), 1 l of chromosomal DNA (100 ng/l), 1 l of each primer (20 pmol/l), 28 l of ddH2O that had been sterilized by autoclaving, and 1 l of nTaq-Tenuto DNA polymerase (5 U/l; Enzynomics Co., Korea). The total mixture was overlaid with mineral oil and then subjected to the following conditions: denaturation at 95oC for 1 min, annealing at 60oC for 1 min, and extension at 72oC for 1 min, followed by a final extension at 72oC for 7 min. The purified PCR products were then cloned into the pGEM T-easy vector (Promega, U.S.A.), after which 16S rDNA sequencing was performed by Genotec Co. (South Korea) using an ABI Prism 377 DNA sequencer. Nucleotide sequence similarities were then determined using the 16S bacterial cultures Blast Server [1]. A neighbor-joining phylogenetic tree was constructed using MEGA version 2.1 [17]. Catalase and oxidase tests were conducted using the method described by Hanker and Robin [11]. The strains used for the catalase test were Staphylococcus aureus ATCC 25923 (positive control), Streptococcus pyogenes ATCC 12344 (negative control), and B. polyfermenticus KJS-2. Briefly, a loopfull of 16 h-old-culture grown on agar was transferred to a glass test tube containing 0.5 ml of distilled water and mixed thoroughly. Hydrogen peroxide (3%) solution (0.5 ml) was then added and the presence of bubbles was taken to indicate the presence of catalase. The strains used for oxidase test were Pseudomonas aeruginosa ATCC 27853 (positive control), Escherichia coli ATCC 25922 (negative control), and B. polyfermenticus KJS-2. For the oxidase test, the organisms were grown on media, after which two-to-three drops of the reagent N,N,N',N'-tetramethyl-p-phenylenediamine were added to the surface of each organism. A positive test was indicated by a change in color to pink, maroon, and then black within 10-30 sec. A negative test was indicated by a light pink coloration or the absence of coloration. The carbohydrate metabolism of all presumptive B. polyfermenticus KJS-2 isolates was determined using API 50CHB strips (bioMrieux S.A., Marcy-1toile, France). Briefly, isolates were grown on tryptic soy agar (TSA) at 30oC for 18-24 h. The colonies were then suspended in 2 ml of sterile 0.85% saline solution with a concentration sufficient to correspond to McFarland No. 2. Next, 0.1 ml of this suspension was diluted in 10 ml of API 50 CHB medium. The strips were then inoculated, incubated for

24 h at 30oC, and read after 24 h. The results were scored according to the manufacturers instructions and the emerging biochemical profile was identified using the APILAB software, Version 4.0, 2007 (bioMrieux S.A., Marcy-1toile, France) [27]. To evaluate the lactic acid production, B. polyfermenticus SCD and B. polyfermenticus KJS-2 were grown on TSA at 37oC for 16 h. Precultures were then prepared in medium containing 4 ml of PSG medium (10 g polypeptone S, 10 g yeast extract, 20 g glucose, 35 g K2HPO4, per liter) [22]. Two ml of this culture was then used to inoculate a 500-ml screw-capped shake flask containing 200 ml of PSG production medium under anaerobic conditions at 200 rpm. The amount of lactic acid was determined by HPLC (Agilent Technologies, 1100 series, U.S.A.) in conjunction with a refractive index detector under the following conditions: column, MetaCarb 87 H (MetaChem Technologies Inc., Torrance, CA, U.S.A.); column temperature, 25oC; solvent for elution, 0.1 N H2SO4 solution; flow rate, 0.5 ml/min. Prior to measuring the optical purity, the samples were filtered through a 0.2-m pore size polytetrafluoroethylene (PTFE) membrane (JP020, Advantec, Tokyo) to remove extra molecules. B. polyfermenticus KJS-2 was plated onto the agar medium to induce spore formation. The cells were then suspended in sterile distilled water, followed by centrifugation at 6,000 rpm for 10 min at 4oC. The cells were then washed once with sterile distilled water, after which the pellets were fixed with 0.1 M phosphate buffer (pH 7.4) containing 2.5% glutaraldehyde at 4oC for 2 to 4 h. The specimens were then postfixed in 1% osmium tetroxide for 2 h, dehydrated in a graded alcohol series, treated with propylene oxide, and embedded in Epon 812. The resultant blocks were then cut using an LKB ultramicrotome (Nova, Sweden), after which thin-sectioned specimens were mounted on 200 mesh copper grids and stained with uranyl acetate plus lead citrate. The prepared specimens were then observed through a transmission electron microscope (JEM 1200EX II; JEOL, Japan). Approximately 108 CFU/g of spored B. polyfermenticus KJS-2 was suspended in an equal volume of (i) TSB with a pH that had been adjusted to final 2.0 using 1 M HCl (for acid challenge) or (ii) TSB (final pH 6.5) containing 0.3% (w/v) Oxgall. The suspended cells were then incubated aerobically at 37oC for 4 h. At each hour during the incubation period, aliquots of the samples were plated on TSA with an inoculation level of 1% (v/v). The samples were then incubated aerobically at 37oC for 18 h [3]. Caco-2 cells were cultured in Dulbeccos modified Eagles minimal essential medium (DMEM; Gibco, Invitrogen Corporation, U.S.A.) containing 25 mM glucose, 1.0 mM sodium pyruvate, 10% heat inactivated fetal bovine serum (Gibco, Invitrogen Corporation, U.S.A.), 1% nonessential amino acids solutions, and antibiotics (100 U of penicillin

BACILLUS POLYFERMENTICUS KJS-2 AS A PROBIOTIC

1015

Table 1. Direct visual estimation of bacterial catalase and oxidase activities. Organisms Positive control Staphyloccus aureus ATCC 25923 Pseudomonas aeruginosa ATCC 27853 Negative control Streptococcus pyogenes ATCC 12344 Escherichia coli ATCC 25922 Test strain Bacillus polyfermenticus KJS-2

a b

Effervescencea Colorb +++ +++ +++

Catalase activity, decomposition of H2O2. Oxidase activity, oxidation of N,N,N',N'-tetramethyl-p-phenylenediamine reagent.

Fig. 1. Transmission electron microscopy observation of B. polyfermenticus KJS-2. VC, vegetative cell; SC, spore coat; ES, endospore.

G per ml and 100 g of streptomycin sulfate per ml). The Caco-2 cells were grown under standard conditions (37oC, 5% CO2) and the medium was replaced every two days. Monolayers of Caco-2 cells, which were used in the adherence assay, were prepared by seeding 6-well tissue culture dishes (Falcon type 3046; Becton Dickinson Labware, Oxnard, CA, U.S.A.) with 9.5104 cells per 4 ml of culture medium. Next, 3.1106 CFU/ml and 2.2106 CFU/ml of B. polyfermenticus KJS-2 and B. polyfermenticus SCD were added to the Caco-2 cells in the culture dishes. The samples were then incubated for 2 h and then washed 3 times with sterile PBS (pH 7.4), after which the number of adhered B. polyfermenticus KJS-2 was determined by plating the diluted B. polyfermenticus KJS-2 suspensions on TSA [10]. B. polyfermenticus KJS-2 was isolated from Bispan. The colony shape of B. polyfermenticus KJS-2 grown on TSA plates was visibly distinguished from those of B. polyfermenticus SCD and other Bacillus. Specifically, B. polyfermenticus KJS-2 produced opaque, dark-yellow colonies with a round and flat shape. Transmission electron microscopy revealed that B. polyfermenticus KJS-2 was characterized as a rod bacterium with a length that ranged from 0.5 to 2 m that formed endospores ranging in size from 0.4 to 0.6 m (Fig. 1). The border of the exosporium, the cortex, the sporederm, and the spore coat of the organism was clear and smooth with no breakage [12]. Table 1 shows the catalase and oxidase activities of the bacteria. Note the correspondence between effervescence and color formation. Although the lowest catalase activity was measured after 16 h of cultivation, the catalase activity was obviously correlated with the accumulation of its specific substrate (H2O2) [11]. In addition, B. polyfermenticus KJS-2 was found to be oxidase positive. The sequence of 16S rDNA from B. polyfermenticus KJS-2 differed from that of B. polyfermenticus SCD

(Accession No. AY149473, GenBank) and from Bacillus subtilis 168 (B. subtilis 168, Accession No. NC000964, GenBank) by three nucleotides out of 1,550. B. polyfermenticus KJS-2 occupied the position of Bacillus amyloliquefaciens (Accession No. CP000560, GenBank) in the phylogenetic tree (>99%). Biochemical characterization of B. polyfermenticus KJS-2 was conducted using an API 50CHB kit. B. polyfermenticus KJS-2 utilized glucose, fructose, mannose, mannitol, sorbitol, -methyl-D-glucoside, amygdalin, arbutin, esculin, salicin, cellobiose, maltose, and sucrose as carbon sources. The percentage of positive results for the carbohydrate tests of our B. polyfermenticus KJS-2 isolates was within the range reported by others [21]. However, the number of carbon sources utilized by B. polyfermenticus KJS-2 was relatively smaller than the number of carbon sources utilized by B. subtilis 168 and B. polyfermenticus SCD (Table 2). The API 50CHB strips were analyzed using the Apiweb software to identify corresponding Bacillus species. B. polyfermenticus KJS-2 was found to be 62% homologous to B. subtilis and Bacillus amyloliquefaciens, whereas it was found to be 97.4% and 99.9% homologous to B. subtilis 168 and B. polyfermenticus SCD, respectively. In the case of carbohydrate utilities obtained from the API 50CHB strips, B. polyfermenticus KJS-2 could be clearly distinguished from B. subtilis 168 and B. polyfermenticus SCD (Table 2). Therefore, B. polyfermenticus KJS-2 was identified as a new strain isolated from Bispan and deposited in the KCCM under Accession No. KCCM10769P. In the anaerobic culture, the conversion rate of glucose to lactic acid by B. polyfermenticus KJS-2 and B. polyfermenticus SCD was 60.714.9% and 58.575.9% after 24 h, respectively. If the pH, dissolved oxygen, and nitrogen source are controlled, the efficiency of lactic acid production may be increased by increasing the fermentation time [22]. Use of Bacillus to produce lactic acid in simple media has previously been reported [6]. The production of lactic acid is expected to induce antimicrobial activity against pathogenic bacteria via a reduction in pH. Therefore,

1016

Kim et al.

Table 2. Identification of carbon sources utilized by B. polyfermenticus KJS-2 and two other Bacillus strains with the API 50CHB kit. No 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 Substrates Control Glycerol Erythritol D-Arabinose L-Arabinose Ribose D-Xylose L-Xylose Adonitol -Methyl-D-xyloside Galactose Glucose Fructose Mannose Sorbose Rhamnose Dulcitol Inositol Mannitol Sorbitol -Methyl-D-mannoside -Methyl-D-glucoside N-Acetyl glucosamine Amygdalin Arbutin Esculin Salicin Cellobiose Maltose Lactose Melibiose Sucrose Trehalose Inulin Melezitose Raffinose Starch Glycogen Xylitol Gentiobiose D-Turanose D-Lyxose D-Tagatose D-Fucose L-Fucose D-Arabitol L-Arabitol Gluconate 2 Keto-gluconate 5 Keto-gluconate B. polyfermenticus KJS-2 + + + + + + + + + + + + + B. polyfermenticus SCD + + + + + + + + + + + + + + + + + + + + + + + B. subtilis 168 + + + + + + + + + + + + + + + + + + + -

+: utilized; -: not utilized.

BACILLUS POLYFERMENTICUS KJS-2 AS A PROBIOTIC

1017

be highly specific and depends on both probiotic and pathogenic bacteria [19]. In conclusion, B. polyfermenticus KJS-2 produced lactic acid, remained stable in artificial gastric juice and bile acid, and adhered to Caco-2 intestinal epithelial cells. Taken together, these characteristics indicate that B. polyfermenticus KJS-2 is suitable for industrial use as a probiotic. REFERENCES

1. Altschul, S. F., T. L. Madden, A. A. Schffer, J. Zhang, Z. Zhang, W. Miller, and D. J. Lipman. 1997. Gapped BLAST and PSI-BLAST: A new generation of protein database search programs. Nucleic Acids Res. 25: 3389-3402. 2. Austin, B., L. F. Stuckey, P. A. W. Robertson, J. Effendi, and D. R. W. Griffith. 1995. A probiotic reducing diseases caused by Aeromonas salmonicida, Vibrio anguillarum and Vibrio ordalii. J. Fish. Dis. 18: 93-96. 3. Berrada, N. 1991. Bifidobacterium from fermented milks: Survival during gastric transit. J. Dairy Sci. 74: 409-413. 4. Chou, L. S. and B. Weimer. 1999. Isolation and characterization of acid- and bile-tolerant isolates from strains of Lactobacillus acidophilus. J. Dairy Sci. 82: 23-31. 5. Cole, C. B. and R. Fuller. 1984. A note on the effect of host specific fermented milk on the coliform population of the neonatal rat gut. J. Appl. Microbiol. 56: 495-498. 6. De Boer, J. P., M. J. Teixeira, T. de Mattos, and O. M. Neijssel. 1990. D(-)Lactic acid production by suspended and aggregated continuous cultures of Bacillu laevolacticus. Appl. Microbiol. Biotechnol. 34: 149-153. 7. Douillet, P. A. and C. J. Langdon. 1994. Use of a probiotic for culture of larvae of the Pacific oyster (Crassostrea gigas Thuberg). Aquaculture 119: 25-40. 8. Fuller, R. 1989. Probiotics in man and animals. J. Appl. Bacteriol. 66: 365-378. 9. Goren, E., W. A. De Jong, P. Doornenbal, J. P. Koopman, and H. M. Kennis. 1984. Protection of chicks against Salmonella infection induced by spray application of intestinal microflora in the hatchery. Vet. Quart. 6: 73-79. 10. Greene, J. D. and T. R. Klaenhammer. 1994. Factors involved in adherence of lactobacilli to human Caco-2 cells. Appl. Environ. Microb. 60: 4487-4494. 11. Hanker, J. S. and A. N. Rabin. 1975. Color reaction streak test for catalase-positive microorganisms. J. Clin. Microbiol. 2: 463-464. 12. Huang, X., Z. Lu, X. Bie, F. X. L, H. Zhao, and S. Yang. 2007. Optimization of inactivation of endospores of Bacillus cereus by antimicrobial lipopeptide from Bacillus subtilis fmbj strains using a response surface method. Appl. Microbiol. Biotechnol. 74: 454-461. 13. Jun, K. D., K. H. Lee, W. S. Kim, and H. D. Paik. 2000. Microbiological identification of medical probiotic Bispan strain. Kor. J. Appl. Microbiol. Biotechnol. 28: 124-127. 14. Jun, K. D., H. J. Kim, K. H. Lee, H. D. Paik, and J. S. Kang. 2002. Characterization of Bacillus polyfermenticus SCD as a probiotic. Kor. J. Microbiol. Biotechnol. 30: 359-366.

Fig. 2. Comparison of viability of B. polyfermenticus KJS-2 with artificial gastric juice (pH 2.0) and artificial bile acid (pH 6.5). , pH 2.0; , pH 6.5.

lactic acid producing B. polyfermenticus KJS-2 can be used as a raw material for the production of biodegradable polymers with applications in medical, pharmaceutical, and food industries. Cellular stress begins in the stomach, which has a pH as low as 2.0. To determine the effect of the acidic pH of the stomach on the survival of B. polyfermenticus KJS-2, an in vitro system with a pH of 2.0 was utilized (Fig. 2). When B. polyfermenticus KJS-2 was exposed to pH 2.0, it survived for 4 h and its concentration increased. These results indicate that B. polyfermenticus KJS-2 is not adversely affected by strongly acidic conditions. After the microorganisms pass through the stomach, they enter the upper intestinal tract, where bile salt is secreted into the stomach [4]. Therefore, it is necessary for probiotic lactic acid bacteria to be resistant to bile. Accordingly, we evaluated the sensitivity of B. polyfermenticus KJS-2 to bile by culturing it in TSB containing 0.3% bile (Fig. 2). The results revealed that the level of B. polyfermenticus KJS-2 was maintained in the presence of bile, which indicates that it is relatively resistant to bile. The viability of B. polyfermenticus KJS-2 in artificial gastric juice and bile salt was rarely intended to increase correspondence to B. polyfermenticus SCD and other commercially beneficial bacteria [14]. We investigated the adherence of B. polyfermenticus KJS-2 to Caco-2 cells. The human Caco-2 cell line is one of the best model systems for evaluating the interactions between bacterial and intestinal epithelial cells [24]. In this study, B. polyfermenticus KJS-2 and B. polyfermenticus SCD were adherent to approximately 650.6% and 541.4% of Caco-2 cells, respectively. B. polyfermenticus KJS-2 is used as a probiotic in the normal intestinal microbiota to counteract invasion by pathogenic bacteria. Therefore, the ability of B. polyfermenticus KJS-2 to inhibit the adhesion of pathogenic bacteria is expected to

1018

Kim et al.

15. Kang, J. S., D. J. Jun, W. S. Kim, W. S. Jo, J. Y. Kwon, and K. H. Moon. 2004. Antibacterial activities of Bacillus polyfermenticus SCD against pathogenic bacteria and effects on animals and humans. Yakhak Hoeji 48: 70-74. 16. Kieser, T., M. J. Bibb, M. J. Buttner, K. F. Chater, and D. A. Hopwood. 2000. Streptomyces Genetics, p. 169-171. The John Innes Foundation, United Kingdom. 17. Kumar, S., K. Tamura, I. B. Jakobsen, and M. Nei. 2001. MEGA 2: Molecular evolutionary genetics analysis software. Arizona State University, Tempe, Arizona. 18. Lee, K. H., K. D. Jun, W. S. Kim, and H. D. Paik. 2001. Partial characterization of polyfermenticin SCD, a newly identified bacteriocin of Bacillus polyfermenticus. Lett. Appl. Microbiol. 32: 146-151. 19. Lee, Y. K., K. Y. Puong, A. C. Ouwehand, and S. Salminen. 2003. Displacement of bacterial pathogens from mucus and Caco-2 cell surface by lactobacilli. J. Med. Microbiol. 52: 925930. 20. Lilly, D. M. and R. H. Stillwell. 1965. Probiotics: Growth promoting factors produced by microorganisms. Science 147: 747-748. 21. Logan, N. A. and R. C. Berkeley. 1984. Identification of Bacillus strains using the API system. J. Gen. Microbiol. 130: 1871-1882.

22. Ohara, H. and M. Yahata. 1996. L-Lactic acid production by Bacillus sp. in anaerobic and aerobic culture. J. Ferment. Bioeng. 81: 272-274. 23. Parker, R. B. 1976. Dental office procedures for breaking an infection chain. J. Am. Soc. Prev. Dent. 6: 18-21. 24. Panigrahi, P., B. D. Tall, R. G. Russell, L. J. Detolla, and J. G. Jr. Morris. 1990. Development of an in vitro model for study of non-O1 Vibrio cholerae virulence using Caco-2 cells. Infect. Immun. 58: 3415-3424. 25. Salminen, S. and A. von Wright. 1998. Current probiotics safety assured? Microb. Ecol. Health Dis. 10: 68-77. 26. Sugita, H., N. Mutsuo, K. Shibuya, and Y. Deguchi. 1996. Production of antibacterial substances by intestinal bacteria isolated from coastal crab and fish species. J. Mar. Biotechnol. 4: 220-223. 27. Te Giffel, M. C., R. R. Beumer, P. E. Granum, and F. M. Rombouts. 1997. Isolation and characterization of Bacillus cereus from pasteurized milk in household refrigerators in the Netherlands. Int. J. Food Microbiol. 34: 307-318. 28. Thomas, P. 2007. Isolation and identification of five alcoholdefying Bacillus spp. covertly associated with in vitro culture of seedless watermelon. Curr. Sci. 92: 983-987.

Вам также может понравиться

- Fungicides, Nematocides and Soil Fumigants, Rodenticides and Food and Feed Additives: Analytical Methods for Pesticides, Plant Growth Regulators, and Food Additives, Vol. 3От EverandFungicides, Nematocides and Soil Fumigants, Rodenticides and Food and Feed Additives: Analytical Methods for Pesticides, Plant Growth Regulators, and Food Additives, Vol. 3Оценок пока нет

- Sustainable Crop Production and Soil Health Management Through Plant Growth-Promoting RhizobacteriaДокумент32 страницыSustainable Crop Production and Soil Health Management Through Plant Growth-Promoting Rhizobacteriasiamak77Оценок пока нет

- Genetic Algorithms: A TutorialДокумент20 страницGenetic Algorithms: A TutorialJesse VincentОценок пока нет

- Functional Foods and Their Role in Cancer Prevention and Health PromotionДокумент30 страницFunctional Foods and Their Role in Cancer Prevention and Health PromotionSílfide XanatОценок пока нет

- The Art of Fermentation Press ReleaseДокумент2 страницыThe Art of Fermentation Press ReleaseChelsea Green PublishingОценок пока нет

- Science Magazine 5848 2007-10-12Документ159 страницScience Magazine 5848 2007-10-12sumersoft1Оценок пока нет

- MicotoxineДокумент128 страницMicotoxineAdriana CristinaОценок пока нет

- Compendium of The Microbiological Spoilage of Foods and BeveragesДокумент1 страницаCompendium of The Microbiological Spoilage of Foods and BeveragesDavid Stiven RОценок пока нет

- E2871-13 Standard Test Method For Evaluating DisinfectДокумент6 страницE2871-13 Standard Test Method For Evaluating DisinfectA MusaverОценок пока нет

- Microbe ListДокумент2 страницыMicrobe ListSkye AllisonОценок пока нет

- PCR Protocol For Fish and Seafood Authentication - MSC ThesisДокумент65 страницPCR Protocol For Fish and Seafood Authentication - MSC Thesisdwivanjava00100% (4)

- Rapid Methods For The Detection of Foodborne Bacterial PathogensДокумент19 страницRapid Methods For The Detection of Foodborne Bacterial PathogensIoana MoldovanОценок пока нет

- Vitamin Analysis: Definition and ImportanceДокумент18 страницVitamin Analysis: Definition and ImportanceManjusha KondepudiОценок пока нет

- Spice Microbiological ProfilesДокумент6 страницSpice Microbiological ProfilesainnurkhalisОценок пока нет

- Manual On Simple Methods of Meat Preservation 1Документ11 страницManual On Simple Methods of Meat Preservation 1Poorani ArunachalamОценок пока нет

- Rice Fortification Success Stories in 9 Countries PDFДокумент16 страницRice Fortification Success Stories in 9 Countries PDFjavedafridiОценок пока нет

- 9 - Potassium Solubilizing Microorganisms For Sustainable AgricultureДокумент338 страниц9 - Potassium Solubilizing Microorganisms For Sustainable AgricultureTábatha VasconcelosОценок пока нет

- Codex HACCP and Hazard Analysis For Risk Based Measures White Paper 11 July 2018Документ26 страницCodex HACCP and Hazard Analysis For Risk Based Measures White Paper 11 July 2018Alvaro MontañoОценок пока нет

- Somogyi NelsonДокумент6 страницSomogyi NelsonPhichamon NoisuwanОценок пока нет

- Methods in Gut Microbial Ecology For RuminantsДокумент235 страницMethods in Gut Microbial Ecology For Ruminantssachin kumarОценок пока нет

- 3m Petrifilm Rapid Yeast Mold Count PlateДокумент2 страницы3m Petrifilm Rapid Yeast Mold Count PlateLugher VaqueroОценок пока нет

- The Effect of Air-Drying, Freeze-Drying and StorageДокумент11 страницThe Effect of Air-Drying, Freeze-Drying and Storagemarine2006Оценок пока нет

- Algae Organisms For Imminent Biotechnology Challenges and Opportunities in The Present Era of Marine Algal ApplicationsДокумент40 страницAlgae Organisms For Imminent Biotechnology Challenges and Opportunities in The Present Era of Marine Algal ApplicationsSilviu-Laurentiu BadeaОценок пока нет

- CXC - 054 - 2004e - Code of Practice On Good Animal FeedingДокумент12 страницCXC - 054 - 2004e - Code of Practice On Good Animal FeedingIvan PopovicОценок пока нет

- Determination of Vitamin B6 in Foods by HPLCДокумент6 страницDetermination of Vitamin B6 in Foods by HPLCDaniel Dávila MartinezОценок пока нет

- Contributions To The Genus: FusariumДокумент179 страницContributions To The Genus: Fusariumchristopher suarez100% (3)

- Phytic Acid Extraction From Rice BranДокумент8 страницPhytic Acid Extraction From Rice BranneharockОценок пока нет

- Southern Organic Resource GuidДокумент138 страницSouthern Organic Resource Guidvas_liviuОценок пока нет

- Determination of Phytase Activity in Feed by A Colorimetric Enzymatic Method: Collaborative Interlaboratory StudyДокумент5 страницDetermination of Phytase Activity in Feed by A Colorimetric Enzymatic Method: Collaborative Interlaboratory StudyTalhaОценок пока нет

- A Pi 20 Ne InstructionsДокумент4 страницыA Pi 20 Ne InstructionsNayely Diego de MartinezОценок пока нет

- Food Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationОт EverandFood Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationОценок пока нет

- Nutraceuticals Functional Foods: Handbook ofДокумент13 страницNutraceuticals Functional Foods: Handbook ofshekharОценок пока нет

- FungicidesДокумент548 страницFungicideshalmasti73730% (1)

- Code of Hygienic PracticeДокумент29 страницCode of Hygienic Practicenitu_gОценок пока нет

- FAO Herbs and Spice ProductsДокумент10 страницFAO Herbs and Spice ProductsUsman CheemaОценок пока нет

- Emerging Technologies and Management of Crop Stress Tolerance: Volume 1-Biological TechniquesОт EverandEmerging Technologies and Management of Crop Stress Tolerance: Volume 1-Biological TechniquesОценок пока нет

- Isolation and Detection of Salmonella in FoodДокумент34 страницыIsolation and Detection of Salmonella in FoodGuada BonusОценок пока нет

- Pesticides Residues Regulation CSAДокумент80 страницPesticides Residues Regulation CSASamantha HoОценок пока нет

- Food Toxicology PDFДокумент11 страницFood Toxicology PDFMoh ZuhriОценок пока нет

- Fermented Frutis and VegetablesДокумент102 страницыFermented Frutis and VegetablesLyant Sakowati100% (2)

- Antinutritional Factors Present in Plant-Derived Alternate Fish Feed Ingredients and Their Effects in FishДокумент31 страницаAntinutritional Factors Present in Plant-Derived Alternate Fish Feed Ingredients and Their Effects in FishAamir MaqboolОценок пока нет

- Yeast Extract: A Potential Substitute of Salt in Baked CrackersДокумент9 страницYeast Extract: A Potential Substitute of Salt in Baked CrackersIJEAB JournalОценок пока нет

- Of Basal MediumДокумент2 страницыOf Basal MediumSandeep Kumar SaklaniОценок пока нет

- Hypobaric Storage in Food Industry: Advances in Application and TheoryОт EverandHypobaric Storage in Food Industry: Advances in Application and TheoryОценок пока нет

- Laboratory Manual For The Microbiological Analyses of Public Drinking Water 2001Документ74 страницыLaboratory Manual For The Microbiological Analyses of Public Drinking Water 2001vk100Оценок пока нет

- Full ThesisДокумент40 страницFull ThesisIskriblihahaОценок пока нет

- Eu PDFДокумент36 страницEu PDFhasmikОценок пока нет

- Hygicult Guide To Monitoring CleanlinessДокумент36 страницHygicult Guide To Monitoring Cleanlinessroem1104100% (1)

- Acrylamida Reporte 2006Документ36 страницAcrylamida Reporte 2006Helton SilvaОценок пока нет

- Bacilli and Agrobiotechnology - PhytostimulationДокумент334 страницыBacilli and Agrobiotechnology - PhytostimulationNelver MorenoОценок пока нет

- Disinfectants Evaluation GuidelinesДокумент44 страницыDisinfectants Evaluation Guidelinesamerican_guy10Оценок пока нет

- Microbiology of Sewage and WastewaterДокумент13 страницMicrobiology of Sewage and WastewaterShekh Muhsen Uddin AhmedОценок пока нет

- FSD 17933Документ36 страницFSD 17933Agatha lestariОценок пока нет

- The Microbiological Safety of Minimally Processed VegetablesДокумент22 страницыThe Microbiological Safety of Minimally Processed VegetablesDiego Alberto CastellanosОценок пока нет

- Determination of Vitamin b6 by Means of DifferentialДокумент7 страницDetermination of Vitamin b6 by Means of DifferentialthuОценок пока нет

- CONDA Industrial Microbiology MediaДокумент26 страницCONDA Industrial Microbiology MediaMaurya GuptaОценок пока нет

- Global Cheesemaking Technology: Cheese Quality and CharacteristicsОт EverandGlobal Cheesemaking Technology: Cheese Quality and CharacteristicsОценок пока нет

- Detecting Pesticide Residues On Museum ObjectsДокумент18 страницDetecting Pesticide Residues On Museum ObjectsmackerelfishОценок пока нет

- Musculoskeletal Cancer Surgery - Malawer PDFДокумент592 страницыMusculoskeletal Cancer Surgery - Malawer PDFanggita100% (1)

- Kripps' StoryДокумент2 страницыKripps' StorylwnapierОценок пока нет

- Crisis CounsellingДокумент28 страницCrisis CounsellingPooja varmaОценок пока нет

- How To Cheer Someone UpДокумент10 страницHow To Cheer Someone UpPrem sharmaОценок пока нет

- Rehydration, Hangover and Vitamin TherapyДокумент2 страницыRehydration, Hangover and Vitamin TherapyKadek SeptiawanОценок пока нет

- Prosthetic Considerations: R Mericske-SternДокумент11 страницProsthetic Considerations: R Mericske-SternpmodontologiaОценок пока нет

- JumpSTART Training Presentation Instructor Course 2016 FinalДокумент109 страницJumpSTART Training Presentation Instructor Course 2016 FinalvictorioОценок пока нет

- ABRSM Exam TipsДокумент10 страницABRSM Exam TipsLou Smith100% (1)

- Types of Diagnosis:: Problem-Focused Nursing Diagnoses Have Three Components: (1) Nursing DiagnosisДокумент4 страницыTypes of Diagnosis:: Problem-Focused Nursing Diagnoses Have Three Components: (1) Nursing DiagnosisDaisy MellaОценок пока нет

- Black AdonisДокумент4 страницыBlack Adonisapi-74769985Оценок пока нет

- Measles Fact SheetДокумент1 страницаMeasles Fact Sheetapi-286128974Оценок пока нет

- Philippine Oncology Nurses Association Registration: Basic Chemotherapy CourseДокумент2 страницыPhilippine Oncology Nurses Association Registration: Basic Chemotherapy CourseFret Ramirez Coronia RNОценок пока нет

- Implant OlogyДокумент76 страницImplant OlogyTaher RupawalaОценок пока нет

- Pre EclampsiaДокумент15 страницPre EclampsiaSiska FriedmanОценок пока нет

- Meyer-Grieve James Et AlДокумент9 страницMeyer-Grieve James Et Aljolamo1122916Оценок пока нет

- Management of Failed Block - Harsh.Документ48 страницManagement of Failed Block - Harsh.Faeiz KhanОценок пока нет

- 11.efficacy and Stability of The Alar Base Cinch SutureДокумент4 страницы11.efficacy and Stability of The Alar Base Cinch SutureFabian Camelo OtorrinoОценок пока нет

- Single Phase Correction of Tongue Thrust Habit AloДокумент7 страницSingle Phase Correction of Tongue Thrust Habit AloAkhil SinghОценок пока нет

- BPD Concept MapДокумент3 страницыBPD Concept Mapsammillepointer86Оценок пока нет

- PLR Journey Preview PDFДокумент18 страницPLR Journey Preview PDFmoumonaОценок пока нет

- Gut and Psychology Syndrome - Natural Treatment For Autism, Dyspraxia, A.D.130015Документ5 страницGut and Psychology Syndrome - Natural Treatment For Autism, Dyspraxia, A.D.130015liza lizaОценок пока нет

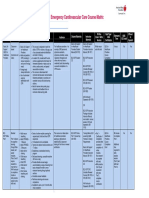

- Emergency Cardiovascular Care Course MatrixДокумент15 страницEmergency Cardiovascular Care Course MatrixJesus M. Espinosa EchavarriaОценок пока нет

- Case Report FinalДокумент21 страницаCase Report FinalAyen FornollesОценок пока нет

- Child Psychopathology: Child Psychopathology Is The Manifestation of Psychological Disorders in Children andДокумент7 страницChild Psychopathology: Child Psychopathology Is The Manifestation of Psychological Disorders in Children andMarvellous MunhuwaОценок пока нет

- Collaborative Couple Therapy: Page Pr/gurman3.htm&dir Pp/fac&cart - IdДокумент39 страницCollaborative Couple Therapy: Page Pr/gurman3.htm&dir Pp/fac&cart - IdCarlos InfanteОценок пока нет

- ORMCO Case StudiesДокумент36 страницORMCO Case StudiesDominikaSkórkaОценок пока нет

- CHECKLISTДокумент7 страницCHECKLISTMichelle CardeñoОценок пока нет

- Acupuncture Standards China Baoyan 2009Документ50 страницAcupuncture Standards China Baoyan 2009Marlon RamirezОценок пока нет

- Wallen Et Al-2006-Australian Occupational Therapy JournalДокумент1 страницаWallen Et Al-2006-Australian Occupational Therapy Journal胡知行Оценок пока нет

- Therapeutic CommunicationДокумент7 страницTherapeutic CommunicationJoseph Rommel Castro CortezОценок пока нет