Академический Документы

Профессиональный Документы

Культура Документы

MBA Operations and Supply Chain Management Lecture Notes 1

Загружено:

Michael FinleyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MBA Operations and Supply Chain Management Lecture Notes 1

Загружено:

Michael FinleyАвторское право:

Доступные форматы

In-Class Lecture 10/4/2010

Tuesday, September 21, 2010 11:29 PM

MIDTERM WILL BE OPEN BOOK!!!

Went over Page 733 Problem 4 & 5 see lecture notes in mgmt840 section of thumb drive for answers (10-4-2010.xls)

It may be useful to utilize tables of known values so that Excel sheets do not become confusing

Went over Learning Curves 2nd

T(2n)/T(n) = constant (where T = time of production of n units) This is a number usually under 1 If this is true T(n) = T(1)*n^b T(2n)/T(n) = L (where L is learning curve) 2^(b)= L B = log(L)/log(2) Reality may not exactly fit the model

Went over homework third. see lecture notes in mgmt840 section of thumb drive for answers (10-4-2010.xls)

Went over Page 86 Problem 5 next: see homework assignment

Went over Problem 6 from Page 86 next, as a class member had a question about it.

Went over the following problem from Quiz 2

Went over PowerPoint lectures 5-8 Chapter 5 Lecture In a job shop Volume is high and Variety is low Similar production is done over and over (flow-shop) Projects are more specific then the flow-shops 5 types of productions Flow-Shop Project Batch Job-Shop More training Assembly-Line Little's Law is Weight * Rate = Length IE: Rate of Ford cars is 20/hour R = 20/hr (Throughput) Cycle time is 1/20 (ie: 1 every 3 minutes) L (length in the line) L = 100 cars W (weight) W = L/R = 100/20 = 5 hours Sometimes increasing utilization is not the best goal Flowcharts help truly understand everything about a project Performance Measures See things that you may not have seen before If the process is important create the flowchart!!!

2 components, one is the standby for the other. You need to multiply .2 (the failure chance) by .2 .2*.2=0.04 Formula is =P(A fail) * P(B fail)

Cycle Time: 200 parts per day, 8 hour day

8/200=0.04 0.04 *60 = 2.4 per minute

Flowchart Example (from Las Vegas Example in Chapter 5)

These are the standard symbols of flow charts Makes everything easier to understand There can be several stages or one stage Buffer A storage area between stages where output of a stage is placed prior to being used in a downstream stage Blocking Occurs when the activities in a stage must stop because there is no place to deposit the item Starving Occurs when the activities in a stage must sop because there is no work Bottleneck-

Lecture Notes 10-4-2010 Page 1

there is no place to deposit the item Starving Occurs when the activities in a stage must sop because there is no work Bottleneck Stage that limits the capacity of the process Make to order Not made until you order it Customizable Make to stock IE: supermarket, goods are stocked on shelves and you buy them if you want them Inventory = flow time * Throughput rate (make sure to match units) Total average value of inventory Sum of the value of raw materials, work-in-process, and finished goods inventory Inventory turns

Cost of goods sold divided by the average inventory value Days-of-supply Inverse of inventory turns scaled to days Littles law There is a long-term relationship between inventory, throughput, and flow time

Inventory = Throughput rate X Flow time See PowerPoint 5 for a good example of Little's Law on Slides 15-26 Measuring Process Performance:

Lecture Notes 10-4-2010 Page 2

Вам также может понравиться

- Value Chain Management Capability A Complete Guide - 2020 EditionОт EverandValue Chain Management Capability A Complete Guide - 2020 EditionОценок пока нет

- International Strategic Management A Complete Guide - 2020 EditionОт EverandInternational Strategic Management A Complete Guide - 2020 EditionОценок пока нет

- International Marketing Chapter 2Документ42 страницыInternational Marketing Chapter 2wubeОценок пока нет

- Torrington, Hall & Taylor, Human Resource Management 6e, © Pearson Education Limited 2005Документ27 страницTorrington, Hall & Taylor, Human Resource Management 6e, © Pearson Education Limited 2005adil0% (1)

- Consumer BehaviourДокумент10 страницConsumer BehaviourPranayОценок пока нет

- AdmasДокумент170 страницAdmasHMichael AbeОценок пока нет

- 02 Entrepreneurship and Economic DevelopmentДокумент11 страниц02 Entrepreneurship and Economic DevelopmentJan MezoОценок пока нет

- Management Theories & PracticeДокумент50 страницManagement Theories & Practicelemlem sisayОценок пока нет

- 18 Ubm 513 Entreprenrurship and Project Management Multiple Choice Questions. Unit-IДокумент31 страница18 Ubm 513 Entreprenrurship and Project Management Multiple Choice Questions. Unit-IManishОценок пока нет

- StudentДокумент16 страницStudentJayne Carly CabardoОценок пока нет

- Course Outline 03Документ6 страницCourse Outline 03Tewodros TadesseОценок пока нет

- MCQ Operations ManagementsДокумент4 страницыMCQ Operations ManagementsRanShibasakiОценок пока нет

- ON Credibility Perception of Consumer Towards Various MediaДокумент33 страницыON Credibility Perception of Consumer Towards Various Mediakalp.desaiОценок пока нет

- 25 Important Staffing Questions and Answers With PDFДокумент6 страниц25 Important Staffing Questions and Answers With PDFwin Zaw TheinОценок пока нет

- Accounting Concepts and ConventionsДокумент19 страницAccounting Concepts and ConventionsSuksham AnejaОценок пока нет

- AAE 3106. Organization Theory 2023Документ161 страницаAAE 3106. Organization Theory 2023Marc Ice creamОценок пока нет

- International Product Policy-SlidesДокумент12 страницInternational Product Policy-SlidesRAVINDRA Pr. SHUKLAОценок пока нет

- 5.2.1 Program Evaluation Review Technique PPT Only PDFДокумент11 страниц5.2.1 Program Evaluation Review Technique PPT Only PDFCecillia Yuliana HalimОценок пока нет

- CH 1 Managerial Accounting BasicsДокумент53 страницыCH 1 Managerial Accounting BasicsIra AdraОценок пока нет

- BIS4225.16 - Knowledge ManagementДокумент24 страницыBIS4225.16 - Knowledge Managementvicrattlehead2013100% (1)

- Material and Labour Cost PPT - Dr.J.MexonДокумент50 страницMaterial and Labour Cost PPT - Dr.J.MexonDr.J. MexonОценок пока нет

- Chapter 3 PlanningДокумент29 страницChapter 3 PlanningDagm alemayehuОценок пока нет

- Scope of Financial ManagementДокумент4 страницыScope of Financial Managementgosaye desalegnОценок пока нет

- 1a1 Plant LocationДокумент14 страниц1a1 Plant LocationDr.V.Bastin JeromeОценок пока нет

- Trends Projection MethodДокумент3 страницыTrends Projection Methodms861000% (1)

- Managerial Economics CH 3Документ32 страницыManagerial Economics CH 3karim kobeissi100% (1)

- Chapter 1 Introduction To EconomicsДокумент22 страницыChapter 1 Introduction To EconomicsBranden Schneider100% (1)

- Chapter1 - Statistics For Managerial DecisionsДокумент26 страницChapter1 - Statistics For Managerial DecisionsRanjan Raj UrsОценок пока нет

- CH 1 StudentДокумент14 страницCH 1 StudentSyedОценок пока нет

- Mock MCQ Test: Subject: Entrepreneurship Development (Ed) Paper Code: Ms 207Документ12 страницMock MCQ Test: Subject: Entrepreneurship Development (Ed) Paper Code: Ms 207Ankit RajОценок пока нет

- Introduction To Linear ProgrammingДокумент34 страницыIntroduction To Linear ProgrammingLahiyruОценок пока нет

- NEW MBS & MBM Thesis Format by TUДокумент22 страницыNEW MBS & MBM Thesis Format by TUMyaavy80% (10)

- Tme 601Документ14 страницTme 601dearsaswatОценок пока нет

- 1.01 Nature of EntrepreneurshipДокумент4 страницы1.01 Nature of EntrepreneurshipKeshawn McBrideОценок пока нет

- Microsoft PowerPoint - Bab 11 Organizational Design by YUN Untuk MHSWДокумент22 страницыMicrosoft PowerPoint - Bab 11 Organizational Design by YUN Untuk MHSWAnnisa KurniaОценок пока нет

- VIRTUSAДокумент6 страницVIRTUSAVaibhav Chauhan100% (1)

- Entrepreneurship - NotesДокумент39 страницEntrepreneurship - NotesKrishnaОценок пока нет

- Debre Berhan UniversityДокумент8 страницDebre Berhan Universitymeron eyasuОценок пока нет

- MBA Operations and Supply Chain Management Lecture Notes 5Документ3 страницыMBA Operations and Supply Chain Management Lecture Notes 5Michael Finley100% (1)

- CH 1-5 OMДокумент71 страницаCH 1-5 OMAbu DadiОценок пока нет

- Assignment On Entrepreneurship and Economic DevelopmentДокумент28 страницAssignment On Entrepreneurship and Economic Developmentgosaye desalegn100% (2)

- Lecture 01 - Introduction To Import ExportДокумент25 страницLecture 01 - Introduction To Import Exportthu tranОценок пока нет

- 18 Ubm 306 Financial Management Multiple Choice Questions. Unit-IДокумент31 страница18 Ubm 306 Financial Management Multiple Choice Questions. Unit-ILaezelie Palaje100% (1)

- @4 Auditing and Assurance Services - WSUДокумент125 страниц@4 Auditing and Assurance Services - WSUOUSMAN SEIDОценок пока нет

- DR.K. BARANIDHARAN MBA POM Case Study 5Документ2 страницыDR.K. BARANIDHARAN MBA POM Case Study 5Dr.K BaranidharanОценок пока нет

- BB MCQДокумент10 страницBB MCQRamnarayan DarakОценок пока нет

- BSNLДокумент25 страницBSNLSaurabh G100% (5)

- CH 5Документ19 страницCH 5Ebsa AdemeОценок пока нет

- Pricing: Prof - Dr.S.Kathirrvelu Eitex, Bdu, EthiopiaДокумент49 страницPricing: Prof - Dr.S.Kathirrvelu Eitex, Bdu, EthiopiaPradeep BiradarОценок пока нет

- PROJECT MANAGEMENT FINAL EXAM-shubham.033Документ7 страницPROJECT MANAGEMENT FINAL EXAM-shubham.033Jæy SäwärñОценок пока нет

- Cert and CPMДокумент11 страницCert and CPMECRCОценок пока нет

- Study Guide For Students in Cost AccountingДокумент41 страницаStudy Guide For Students in Cost Accountingjanine moldinОценок пока нет

- Questions Related To Planning (Chapter 4)Документ14 страницQuestions Related To Planning (Chapter 4)Wilson AdrikoОценок пока нет

- Chapter 10Документ8 страницChapter 10Ayoub BokhabrineОценок пока нет

- The Entrepreneurial & Intrapreneurial Mind-1Документ25 страницThe Entrepreneurial & Intrapreneurial Mind-1J BОценок пока нет

- Management AccountingДокумент38 страницManagement AccountingHari Haran100% (1)

- Chapter 1 An Overview of HRMДокумент4 страницыChapter 1 An Overview of HRMNguyễn GiangОценок пока нет

- Individual Assignment On Chapter One-OBДокумент6 страницIndividual Assignment On Chapter One-OBDawit AsmelashОценок пока нет

- Process AnalysisДокумент26 страницProcess AnalysisSankha BhattacharyaОценок пока нет

- Motion and Time StudyДокумент25 страницMotion and Time Studyjayshah1991Оценок пока нет

- Learning OrganizationsДокумент17 страницLearning OrganizationsMichael FinleyОценок пока нет

- Case Study - New York TimesДокумент5 страницCase Study - New York TimesMichael FinleyОценок пока нет

- MBA Operations and Supply Chain Management Lecture Notes 3Документ6 страницMBA Operations and Supply Chain Management Lecture Notes 3Michael FinleyОценок пока нет

- MBA Operations and Supply Chain Management Lecture Notes 5Документ3 страницыMBA Operations and Supply Chain Management Lecture Notes 5Michael Finley100% (1)

- MBA Operations and Supply Chain Management Lecture Notes 2Документ7 страницMBA Operations and Supply Chain Management Lecture Notes 2Michael FinleyОценок пока нет

- Mastering Microcontrollers Helped by ArduinoДокумент23 страницыMastering Microcontrollers Helped by ArduinoMeri Terihaj100% (2)

- Data Flow Diagrams PDFДокумент9 страницData Flow Diagrams PDFYasmine2410Оценок пока нет

- PT 0817 Cebu Room Assignment PDFДокумент16 страницPT 0817 Cebu Room Assignment PDFPhilBoardResultsОценок пока нет

- Copy Move Forgery Based On DWT-DCTДокумент4 страницыCopy Move Forgery Based On DWT-DCTShiva KeeОценок пока нет

- Deepwater Horizon Accident Investigation Report Appendices ABFGHДокумент37 страницDeepwater Horizon Accident Investigation Report Appendices ABFGHBren-RОценок пока нет

- Status Profile Creation and Assignment To An Order Type in SAP PPДокумент7 страницStatus Profile Creation and Assignment To An Order Type in SAP PPHemant UNICHEMLLPОценок пока нет

- Use Case Diagram For Employee Management SystemДокумент60 страницUse Case Diagram For Employee Management SystemAnant JaiswalОценок пока нет

- 200 Questions AnswersДокумент150 страниц200 Questions AnswersvempadareddyОценок пока нет

- Health Safety StatementДокумент22 страницыHealth Safety StatementShafiqul IslamОценок пока нет

- SW Product SummaryДокумент64 страницыSW Product SummaryFabio MenegatoОценок пока нет

- TabulationДокумент13 страницTabulationWildan PushОценок пока нет

- Quotation 98665Документ5 страницQuotation 98665Reda IsmailОценок пока нет

- Centrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaДокумент26 страницCentrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDobrin PaulОценок пока нет

- Drive ConfigДокумент136 страницDrive ConfigGiangDoОценок пока нет

- Pd5500 Flange CalculationДокумент6 страницPd5500 Flange CalculationMakrand SakpalОценок пока нет

- Seminar Report ON "Linux"Документ17 страницSeminar Report ON "Linux"Ayush BhatОценок пока нет

- Peugeot 3008 BrochureДокумент18 страницPeugeot 3008 Brochuremihai12moveОценок пока нет

- Exterity g44 Serie 1.2 ManualДокумент87 страницExterity g44 Serie 1.2 Manualruslan20851Оценок пока нет

- DC PandeyДокумент3 страницыDC PandeyPulkit AgarwalОценок пока нет

- En 12604 (2000) (E)Документ7 страницEn 12604 (2000) (E)Carlos LanzillottoОценок пока нет

- Hyundai Robex 220LC-9A SpecificationsДокумент14 страницHyundai Robex 220LC-9A SpecificationsKundan DhurveОценок пока нет

- Cold Rolled Steel Sheet-JFE PDFДокумент32 страницыCold Rolled Steel Sheet-JFE PDFEduardo Javier Granados SanchezОценок пока нет

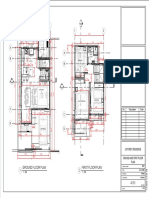

- Floor Plans & ElevationsДокумент6 страницFloor Plans & Elevationsbryan cardonaОценок пока нет

- Phys114 Ps 1Документ11 страницPhys114 Ps 1Reine Amabel JarudaОценок пока нет

- Metalband SawДокумент7 страницMetalband SawRichard JongОценок пока нет

- SA Flight Instructors Training ProceduresДокумент371 страницаSA Flight Instructors Training ProceduresGuilioОценок пока нет

- M Block PDFДокумент45 страницM Block PDFKristina ViskovićОценок пока нет

- CT2000 Manual EN 20151202 PDFДокумент634 страницыCT2000 Manual EN 20151202 PDFKhang NguyenОценок пока нет

- 1450 01 Air Hoists and Trolleys Atlas CopcoДокумент12 страниц1450 01 Air Hoists and Trolleys Atlas Copcomohammed shammiОценок пока нет

- CP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Документ52 страницыCP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Honda almagrorepuestosОценок пока нет