Академический Документы

Профессиональный Документы

Культура Документы

TSBrochureWOFrame

Загружено:

melnemrИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TSBrochureWOFrame

Загружено:

melnemrАвторское право:

Доступные форматы

HYDRA-PNEU CONSULTING.

Steps to Find Design

Information and Logical

Almost Everything HYDRA-PNEU

You Need to Know About CONSULTING.

Trouble Shooting

When a hydraulic circuit quits working the problem must be quickly INTRODUCES

diagnosed and fixed. The responsibility for doing the work usually falls

on the area mechanic. Often the mechanic is not well versed in trouble-

shooting techniques and only has a minimal understanding of fluid

power symbols. This text will attempt to address these areas with infor-

mation on methods of logical trouble-shooting and how to read the

symbols used in fluid power.

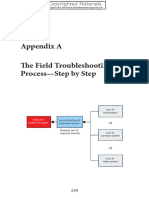

Look Over Machine And Hydraulic

Step 1 Components For Obvious Faults

Low Oil, Bad Wiring, Damaged P arts, Etc.

Question Maintenance Persons About

Step 2 Any Work On The Machine

Prior To Start Of Problem

Question Operator On

Step 3 What Happened When

Problem Started

Step 4

Try To Cycle Machine To See If

Fault Is Related To

Flow, Pressure Or Movement

Trouble

Step 5 Study Circuit Schematic And Note Any

And All Valves That Could Cause The Problem Shooting

Industrial

Step 6 If The Problem Appears To Be An Adjustment

Make Changes And Cycle Again, If Not:

Lower Or Mechanically Contain Suspended Loads

Hydraulics

Step 7 Lockout And Tagout Electrical Circuit

Bleed Off All Trapped Pressurized Fluid

Check Out The Most Obvious Component,

Then The Next Most Obvious Component

Step 8 For Correct Part Number, Damage, Setting, Etc.

Until Finding An Obvious Problem Or

Depleting All The Obvious Components

A Generic Training Book

for Maintenance

Step 9 Adjust, Repair, Replace All Parts

That Are Not Operating As Designed Mechanics and

Step 10 Restart Machine To See If

Technicians that Work on

Problem Is Resolved Fluid Power Systems

Chart 1 General Troubleshooting Procedure

Available Now

Information From the Table of

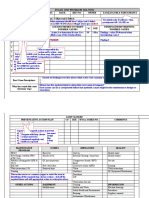

Contents Pressure Compensated Flow

Control Valve Cutaway TSIH Training Book Order

Chapter 1

General Trouble Shooting information and guide- Item # Description Qty Price

lines. Procedures for systematically approaching an ailing

circuit to quickly determine the correct component to work

TS01 Trouble Sht’g Ind’l. Hyd’s. $91.95

on or change. Order total:

Recommended equipment and helpful tools to make Symbol

the Trouble Shooting process faster and easier. Recommen- Indiana Residents add 6% Sales Tax:

dations on how to use the information gleaned from these Adjusting Knob S&H Continental U.S. Free: 6.95

instruments and tools. 150 PSI Bias Spring

Knife Edge Orifice PG2

Chapter 2 Knife Edge Orifice PG1

Contains many Fluid Power circuits with emphasis PG3

on how they work, normal troubles experienced with each

circuit type and ways to diagnose them quickly. All these Name:

circuits are laid out in schematic form and show valve and Co:

actuator changes as they go through normal operations.

Chapter 3 Compensating Spool and Spring Add:

Bypass Check Valve

This chapter covers specific problems that are com- Add:

mon to a given component. Many valves have internal ori-

fices or clearances that can get clogged or wear in such a way Explanation of Function City: St: Zip:

to cause a recognizable symptom to the trained person. Pres- UNI-DIRECTIONAL PRESSURE COMPENSATED FLOW CONTROL Phone:

sure control valves, directional control valves, flow controls

and others are shown in cutaway with an explanation of how Fig. 11B shows a generic cutaway of a pressure compensated uni-

directional flow control that accurately controls flow even when input or output pres- Method of Payment

they work and what to expect in the way of problems. sures change. This type flow control is 2-4 times more expensive than the non-

Chapter 4 compensated type but is worth the money when accurate flow is required. Check Money Order Bill Me

Circuits in this chapter help the trouble shooter Flow entering the Inlet Controlled Flow port passes through the Com-

pensator Spool And Spring chamber and on to the adjustable orifice. Back pressure

learn to quickly identify symbols in a schematic drawing. at the orifice builds at the right end of the compensator spool and forces it against the TROUBLE SHOOTING

After identifying the component it must be integrated into the spring. The compensator spring takes approximately 75-150 PSI to compress it so the INDUSTRIAL

circuit to show how its function interacts with other parts. compensator spool moves over enough to restrict flow so pressure on gauge PG2

reads 150 PSI. When pressure at PG2 reads zero PSI then pressure drop across the HYDRAULICS

Chapter 5 orifice is 150 PSI. No matter how much input pressure changes the Compensator

The circuits in this chapter are missing parts or Spool And Spring maintains the 150 PSI drop across the orifice and flow stays con-

lines, have wrong valves in place, have faulty adjustments, stant.

If pressure increases at the outlet, gauge PG3, it adds to spring pressure at

lack power or a combination of problems. the compensator spool and causes pressure at PG2 to increase by the amount of back

It is the student’s job to find the reason for the mal- pressure plus the 150 PSI compensator spring. If outlet pressure climbs to 400 PSI

function called out on the facing page and determine what to then pressure at PG2 would increase to 550 PSI keeping pressure drop across the

orifice at 150 PSI.

do to fix it. When pressure at the inlet or outlet fluctuates the Compensator Spool

Chapter 6 And Spring adjusts flow to the control orifice to maintain a constant pressure drop

across it. When pressure drop remains constant flow also remains constant. The

Chapter 6 shows several multifunction circuits with schematic symbol indicates pressure compensation by the perpendicular arrow on the

a sequence of operation on the facing page. The student must inlet to the orifice.

explain the symptoms of failure for the called out compo- When this type valve is used at low flows it sometimes becomes unstable

when it first receives flow. The Compensator Spool And Spring jumps shut too fast

nents. and too far causing a pressure drop which then allows it to open too far and too fast. It

Chapter 7 take a few seconds for the valve to settle in to a constant flow and could cause prob-

Information and Logical Steps to Find Design Problems

Here are several schematics from the students on lems. To overcome this fault a Spool Over Speed Adjustment (No Jump) screw is or Problems Causing Components in the Shortest Time

added to adjust spool starting position close to the minimum flow setting so it does not

machine in the plant. The circuits must be studied to see how have as far to move at first flow. If the valve is fitted with a Spool Over Speed Ad-

they work and then determine the importance of each part to justment (No Jump) it needs to be changed especially when speeding up the actuator.

HYDRA-PNEU CONSULTING.

the operation. To compensate for viscosity changes primarily due temperature changes a

Knife Edged Orifice replaces the standard needle and orifice. This sharp edged

Chapter 8 restriction causes less change from different viscosity’s and keeps an actuator operat-

This is a set of symbols that meet ISO (International Ph.& Fax: 812-853-3234

ing at the same speed from star up to operating temperature. Temperature compensa-

Stan- dards Organization) criteria and may be used for tion is shown on the schematic symbol as a temperature bulb perpendicular to the inlet Email: fluidpower1@hotmail.com

line to the orifice.

reference in all the foregoing exercises.

Вам также может понравиться

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreОт EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreОценок пока нет

- Functional Analyzing: E N From Hewlett-PackardДокумент12 страницFunctional Analyzing: E N From Hewlett-PackardMohamed BarhomaОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Technical User Support Notes 2Документ15 страницTechnical User Support Notes 2pix patelОценок пока нет

- Troubleshooting JLG T350, T500JДокумент225 страницTroubleshooting JLG T350, T500Jgpe GardunoОценок пока нет

- Dimension L CX Reference Guide en UsДокумент46 страницDimension L CX Reference Guide en Usمسعود المغيريОценок пока нет

- Engine PerformanceДокумент33 страницыEngine PerformanceRuben Cruces LiraОценок пока нет

- System Analysis - Noddy GuideДокумент2 страницыSystem Analysis - Noddy Guidegeorge moyoОценок пока нет

- PC450 (LC, HD) - 8 UEN02647-00 TroubleshootingДокумент364 страницыPC450 (LC, HD) - 8 UEN02647-00 Troubleshootingdatphuong100% (1)

- Duster - DCM 1.2-FULL System Workshop Manual.2-FULL System Workshop ManualДокумент90 страницDuster - DCM 1.2-FULL System Workshop Manual.2-FULL System Workshop ManualRamon OjedaОценок пока нет

- Controller Diagnostics: MaintenanceДокумент118 страницController Diagnostics: MaintenanceMichael HunterОценок пока нет

- Digital Assignment-2: Product Development and ManagementДокумент12 страницDigital Assignment-2: Product Development and ManagementSanjit RameshОценок пока нет

- How To Proceed With Troubleshooting (1998.8 - )Документ10 страницHow To Proceed With Troubleshooting (1998.8 - )Jurol MassambaОценок пока нет

- Section 6 TroubleshootingДокумент3 страницыSection 6 TroubleshootingChristian VicenteОценок пока нет

- BOOK Laptop Motherboard Fault FinderДокумент27 страницBOOK Laptop Motherboard Fault FinderJorge Johnny Chipana MachacaОценок пока нет

- TSG DL420-5 (950106-01976e) 20170629 PDFДокумент606 страницTSG DL420-5 (950106-01976e) 20170629 PDFTony Rouillon75% (4)

- Tool Box Talk: Human Induced FailuresДокумент1 страницаTool Box Talk: Human Induced FailuresDIEGO A. TOVAR CHIAОценок пока нет

- AUTO HEADLIGHT BEAM LEVELER SYSTEM DIAGNOSTICS ALdiagДокумент20 страницAUTO HEADLIGHT BEAM LEVELER SYSTEM DIAGNOSTICS ALdiagThomas ZoumbouliasОценок пока нет

- Saht730 DVD Theater Receiver PDFДокумент23 страницыSaht730 DVD Theater Receiver PDFRichard KxorrolokoОценок пока нет

- Fault Code P0089 - The Highs & Lows of Diagnosis: by Clinton BrettДокумент3 страницыFault Code P0089 - The Highs & Lows of Diagnosis: by Clinton BrettPaing Min KoОценок пока нет

- How To Proceed With Troubleshooting (2001.8 - )Документ10 страницHow To Proceed With Troubleshooting (2001.8 - )Jurol MassambaОценок пока нет

- 7 QC Tools TATA Motors PDFДокумент76 страниц7 QC Tools TATA Motors PDFRabi Chhetri Upadhyay50% (2)

- AppendicesДокумент10 страницAppendicesJuan Camilo MolanoОценок пока нет

- Hyster 299YДокумент44 страницыHyster 299YraquelestevezОценок пока нет

- Fault Diagnosis and Testing Unit 222Документ6 страницFault Diagnosis and Testing Unit 222HealthyCut FarmsОценок пока нет

- cc800-815-4200 SeriesДокумент162 страницыcc800-815-4200 SeriesMarcin PstrągowskiОценок пока нет

- An Introduction To Logical TroubleshootingДокумент9 страницAn Introduction To Logical TroubleshootingAnonymous lfw4mfCmОценок пока нет

- Fault F97Документ61 страницаFault F97kelvinalphonce97Оценок пока нет

- Hyundai r510lc 7 TroubleshootingДокумент60 страницHyundai r510lc 7 Troubleshootingmohammed barghothiОценок пока нет

- NC Closure Guideline: Root Cause Corrective Action: Correction (Fix Now)Документ2 страницыNC Closure Guideline: Root Cause Corrective Action: Correction (Fix Now)gopi sanОценок пока нет

- KENR8566 101 Systems Operation Section: Illustration 94Документ2 страницыKENR8566 101 Systems Operation Section: Illustration 94kaswade BrianОценок пока нет

- What Is FRACASДокумент6 страницWhat Is FRACASVennila RangithОценок пока нет

- Codigo de Falha Nova B 60ZДокумент82 страницыCodigo de Falha Nova B 60ZLuiz Henrique LimaОценок пока нет

- Treadmill Service ManualДокумент111 страницTreadmill Service ManualBashar MohammadОценок пока нет

- Fault Finding in Thyristor EquipmentДокумент10 страницFault Finding in Thyristor EquipmentMahmoud El-abdОценок пока нет

- Engine 12V140E-3 Series: 40 TroubleshootingДокумент48 страницEngine 12V140E-3 Series: 40 TroubleshootingЕгорОценок пока нет

- Cruise Control Izusu CamionesДокумент12 страницCruise Control Izusu CamionesAnonymous KOtSfT6qОценок пока нет

- Section 6 TroubleshootingДокумент3 страницыSection 6 TroubleshootingHậu MinhОценок пока нет

- Balanceamento em CampoДокумент15 страницBalanceamento em CampoFabio Silveira CamposОценок пока нет

- Inst - OP TD V3.05 Rev.1 PDFДокумент57 страницInst - OP TD V3.05 Rev.1 PDFshri_palaniОценок пока нет

- Manual Parts Xerox WorkCentre 5632 5645 5655 5645 5675 5665 5687Документ2 321 страницаManual Parts Xerox WorkCentre 5632 5645 5655 5645 5675 5665 5687Miguel Angel100% (1)

- Compressor Trouble ShootingДокумент41 страницаCompressor Trouble ShootingsyammcОценок пока нет

- BTH 780 Reliability Engineering: Topic: Maintenance, Maintainability & AvailabilityДокумент38 страницBTH 780 Reliability Engineering: Topic: Maintenance, Maintainability & AvailabilityNeuky ElsОценок пока нет

- 1 - Basics of Condition Based MaintenanceДокумент16 страниц1 - Basics of Condition Based MaintenanceMohamed Hassan AhmedОценок пока нет

- Six-Step Troubleshooting ProcedureДокумент1 страницаSix-Step Troubleshooting ProcedureNoneya BidnessОценок пока нет

- Six StepsДокумент5 страницSix StepsAlex VulpeОценок пока нет

- How To Troubleshoot Ecu Controlled Systems: General InformationДокумент10 страницHow To Troubleshoot Ecu Controlled Systems: General InformationDanilo Jr. MontealegreОценок пока нет

- SG 110 1Документ13 страницSG 110 1Chris GodwinОценок пока нет

- Failure Mode and Effect AnalysisДокумент25 страницFailure Mode and Effect AnalysislokelooksОценок пока нет

- W414800a LMI NARANJAДокумент84 страницыW414800a LMI NARANJAJhon B HerreraОценок пока нет

- Failure Mode and Effects AnalysisДокумент5 страницFailure Mode and Effects AnalysisSamantha IsabelОценок пока нет

- Section 6 TroubleshootingДокумент58 страницSection 6 TroubleshootingRafał DworakОценок пока нет

- Stage 1 - Noddy GuideДокумент3 страницыStage 1 - Noddy Guidegeorge moyoОценок пока нет

- 1.2 Quarter - Amplitude - Damping - Control - Notes PDFДокумент2 страницы1.2 Quarter - Amplitude - Damping - Control - Notes PDFchris FinlandОценок пока нет

- Three Primary Steps in Maintenance Reliability EngineeringДокумент51 страницаThree Primary Steps in Maintenance Reliability EngineeringPablo Scott100% (1)

- The Top 3 Condition Monitoring KPIsДокумент10 страницThe Top 3 Condition Monitoring KPIssatya krishna chagantiОценок пока нет

- Diagnosti ControladorДокумент198 страницDiagnosti ControladorMONTACARGAS AVS100% (1)

- Solucionar Problema en Rapitpoint Maquina de GasesДокумент2 страницыSolucionar Problema en Rapitpoint Maquina de GasesAndres TorresОценок пока нет

- Group 3Документ3 страницыGroup 3Graig BalagtasОценок пока нет

- 6 1 PDFДокумент4 страницы6 1 PDFTaha RdmanОценок пока нет