Академический Документы

Профессиональный Документы

Культура Документы

Standard Checklistscorrected

Загружено:

mohan_krishna372Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Standard Checklistscorrected

Загружено:

mohan_krishna372Авторское право:

Доступные форматы

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 1 of 51 DATE OF ISSUE:

NUCLEAR POWER CORPORATION OF INDIA LIMITED (A Go !"o# I$%&' E$!()*)&+(, TARAPUR ATOMIC POWER PRO-ECT-3&4

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

Co$./))(% 01

N'2( & D(+&3$" NPC D(+&3$ G)o/*

PREPARED 04

CHECKED 04

REVIEWED 04

APPROVED 04

ISSUED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 2 of 51 DATE OF ISSUE:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 3 of 51 DATE OF ISSUE:

-T5&+ *'3( &+ &$!($!&o$'661 6(#! 76'$8-

REVISION LOG Revision Details Issue No. Rev.No. Details Date Page No. Preparation Details Prepared by Concurred by Checked by Approved by Reviewed by

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 4 of 51 DATE OF ISSUE:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 5 of 51 DATE OF ISSUE:

-T5&+ *'3( &+ &$!($!&o$'661 6(#! 76'$8CONTENTS SL !I!L" CLA#S" N . Cover sheet Revision log Contents %. Purpose Pre)re*uisites (.% Status o+ other syste,s (.( Syste, Re*uire,ents (.& -anpower re*uire,ents (.. Re*uire,ent o+ special "*uip,ents (.' Re*uire,ent o+ outside agencies (./ 0a1ards 2 precautions $eneral ,ethod Design intents "3pected process para,eters 4ork plan List o+ ,echanical checklists Re+erences 8eri+ication process List o+ anne3ure))))8eri+ication re*uire,ents % & ' PA$" N .

(.

&. .. '. /. 5. 6. 7. %9.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 6 of 51 DATE OF ISSUE:

1"0

P/)*o+(: The purpose of this proce ure is to pro!i e gui e"i#es for Pre$ co%%issio#i#g of %echa#ica" chec&s for TG ' (u)i"iaries*

9"0 9.1

P)(-)(:/&+&!(+: S!'!/+ o# o!5() +1+!(2+: a b c d All erection activities should be co,pleted. !e,porary supports should be re,oved. Calibration: installation and wiring o+ all the instru,ents should be co,pleted as per the approved drawing. A telephone should be available near by and the telephone nu,bers o+ hospital: a,bulance and +ire brigade is displayed.

9"9 S1+!(2 R(:/&)(2($!+

1" 9" 3"

Access to the plant ite, is ade*uate Illu,ination in the plant area is ade*uate. Any other re*uisite sa+ety provision is ade*uate +or the co,,issioning activity. Plant ite, is in clean condition. All necessary locks and keys +or padlocks: interlocks etc. are available. 0ot sur+aces lagged or screened or screened su++iciently to provide protection +or personnel. Co,,issioning o+ process water: D- water has been co,pleted. Co,,unication +acilities should be available between work area 2 control roo,. Depending upon e*uip,ents +ollowing inputs are also needed; %. perating personnel to co)ordinate the activities. i,,ediate

4" ;" <"

=" >"

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page + of 51 DATE OF ISSUE:

(. Power supply +or the actuators. &. Lighting arrange,ent +or oil tank and other operating +loors. .. Portable +ire +ighting e*uip,ents in all the +loors. 5* (!ai"a,i"it- of "a,orator- faci"ities for a#a"-sis of OIL sa%p"es* /. Availability o+ service Air 2 instru,ent air. 5. Availability o+ Co,,unication +acility at working area. 6. <abrication and erection o+ the syste, co,pleted as per drawing. 7. 8isual inspection carried out to check cleanliness o+ the interior o+ the tank. %9. Insulation o+ !urbine 2 piping shall be co,pleted and !$ +loor: !ank 2 operating area co,pletely cleaned 9"3 M'$ *o?() R(:/&)(2($!+: Co,,issioning tea, =,echanical engineer )%: electrical engineer )% 2 C2I engineer )% 2 supporting ,anpower +ro, contractor > one +itter: one electrician two helpers? should be available. a. NPCIL >!$ co,,issioning group +or co)ordination. b. -@s A0"L co,,issioning group +or e3ecution 2 supervision o+ co,,issioning activities 9"4 R(:/&)(2($! o# +*(.&'6 E:/&*2($!+: NIL 9"; R(:/&)(2($! o# o/!+&%( '3($.&(+: NIL 9"< H'@')%+ '$% P)(.'/!&o$+:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page . of 51 DATE OF ISSUE:

!he hydraulic units such as that o+ gland stea, supply 2 leak) o++ valves are e*uipped with positive displace,ent pu,ps. Loosening or tightening o+ any ,echanical ite, should be done a+ter depressuri1ation o+ the syste,. A telephone should be available near by and the telephone nu,bers o+ hospital: a,bulance and +ire brigade is displayed. 4hile testing and adBusting the hydraulic actuator no insulation work shall be allowed. !he operating personnel shall be aware o+ the procedure. /e,ris i# a# arou# s-ste%s sha"" ,e re%o!e *

(pproach0Stair 1ase0P"atfor% 2here!er re3uire are %a e a!ai"a,"e* 4elding @ cutting shall not be carried out in working area.

Provision +or e,ergency stopping o+ electrically operated e*uip,ents +ro, local @ #CA has to be ,ade. Su++icient *uantity o+ sa+ety appliances such as hel,ets: +ace ,ark: hand gloves: Cru, boots: Apron: nose breather are ,ade available +or use at site. !he tea, should be aware o+ operating procedures o+ +ire e3tinguisher to be used +or *uenching ,inor oil +ires. !he tea, should be aware o+ procedure to be +ollowed in case o+ accident involving inBury to personnel. !he tea, should be aware o+ reestablishing the operation in case o+ syste, stoppage due to +ailure o+ power supply.

3" G($()'6 M(!5o%: Please re+er +ollowing checklistsC

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 4 of 51 DATE OF ISSUE:

ANNEXURE NO"1 T'3 No" D'!(: UNIT: Lo.'!&o$: M(.5'$&.'6 .5(.8+ o$ M'$/'661 o*()'!(% '6 (+

S) C5(.8+ N o " %. $eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents (. !he na,eplate legend agrees with the approved NPCIL Plant No,enclature: is clearly visible: securely +i3ed: is durable and correlates with any re,ote labels. &. Installation correct and co,plete to latest drawings. .. !est Reports and other docu,ents veri+ied and +ound in order. '. 0eavy valves are supported properly and independent o+ the pipeline. 8alve should not carry the load o+ the pipeline. /. Direction o+ +low ,arked and correct. 5. Access ade*uate +or adBust,ents: ,aintenance and repairs. 6. Ade*uate locking +acility e3ists. 7. 8alve gland and packing suitable and satis+actory. %9. Check that valve ste, actuating ,echanis, is lubricated with reco,,ended grade o+ grease. %%. <reedo, o+ operation +ully open to +ully closed. Physically check. %(. Position indicator visible and A+ #o/$% A+ 6(#!

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 15 of 51 DATE OF ISSUE:

%&. %.. %'. %/. %5. %6. %7.

indicating correctly and set correctly =i+ appropriate? Re,ote indication li,it switch ,ounted securely and set correctly =i+ applicable? Re,ote operating ,echanis, or e3tended valve spindle is securely installed and operates correctly. Ade*uate clearance to wall @ steelwork around hand wheel +or operation. 8alve le+t in DclosedE position Check +or uni+or, bolt si1e and length +or +langes. Check the bonnet and gland leak tightening and valve passing. Check the tightening o+ valve +lange and bonnet bolts.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 11 of 51 DATE OF ISSUE:

ANNEXURE NO"9 T'3 No" UNIT: Lo.'!&o$: D'!(:

M(.5'$&.'6 .5(.8+ o$ E6(.!)&.'661 o*()'!(% '6 (+

S) N o " 1" (.

C5(.8+

A+ #o/$%

A+ 6(#!

&.

.. '. /. 5. 6. 7.

$eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents !he Na,eplate legend agrees with the approved NPCIL Plant No,enclature: is clearly visible: securely +i3ed: is durable and correlates with re,ote labels. Installation is correct; all Boints are properly tight and co,plete to latest drawings. 0eavy valves are supported properly and independent o+ the pipeline. 8alves should not carry the load o+ the pipeline. !est Reports and other docu,ents veri+ied and +ound in order. Direction o+ +low ,arked and correct. Access ade*uate +or adBust,ents: ,aintenance and repairs. 8alve gland and packing suitable and satis+actory. Lubricate valve ste, and actuator gear bo3 with reco,,ended lubricant. -echanical +reeness o+ the valve

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 12 of 51 DATE OF ISSUE:

%9. %%. %(. %&. %.. %'. %/.

shall be checked by operating the valve ,anually in both the directions =open and close?. Position indicator visible and indicating correctly. Li,it switches ,ounted securely and set correctly. "3tended valve spindle: wherever envisaged: is installed and operates correctly. Ade*uate clearance to wall @ steelwork around hand wheel. 0and)gear clutch operation is satis+actory. =i+ +itted?. Leave valve in closed position and disengaged =i+ appropriate? +ro, the electric drive. -otor or solenoid actuator installation including cables and earthing appear to be co,plete.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 13 of 51 DATE OF ISSUE:

ANNEXURE NO"3 T'3 No" UNIT: D'!(: Lo.'!&o$:

M(.5'$&.'6 .5(.8+ o$ P$(/2'!&.'661 o*()'!(% '6 (+

S) N o " %. $eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents !he Na,e Plate legend agrees with the approved NPCIL Plant No,enclature is clearly visible: securely +i3ed: is durable and correlates with re,ote labels. Installation is correct and co,plete to latest drawings. !est Reports and other docu,ents veri+ied and +ound in order. Direction o+ +low ,arked and correct. Access ade*uate +or adBust,ent: ,aintenance and repairs. 8alve gland and packing suitable and satis+actory. Lubrication o+ valve and Actuator Suitable and satis+actory. <reedo, o+ operation: +ully open to +ully closed. -anually operate and physically check i+ possible. Position indicator visible and C5(.8+ A+ #o/$% A+ 6(#!

(.

&. .. '. /. 5. 6. 7.

%9.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 14 of 51 DATE OF ISSUE:

%%. %(.

%&.

%.. %'. %/.

1+* %6. %7.

(9.

(%.

indicating correctly. Li,it switches ,ounted securely and set correctly. Re,ote operating ,echanis, or e3tended valve spindly is securely installed and operates correctly. Ade*uate clearance to wall@steel work around hand wheel and actuator +or operation. Actuator isolating +acility operable. Leave isolated. Power air supply and control signal ,ediu, available and isolated. Ade*uate ,echanical stops +itted to prevent over travel on open or close operation. /rai# or ,"o2out air"i#es a# reco##ect. Connect actuator isolator. "stablish power air and control signal air supplies. pen the valve by giving incre,ental signal air o+ ('F:'9F:5'F and%99F and check the valve operation. bserve +or air leakages and attend the sa,e : i+ any. Repeat the operation in reverse order = %99F to 9F? to check the valve operation in closing direction 8alve reverts to pre) deter,ined position when power air supply +ails=<ail Sa+e Condition?. 4hen control signal supply +ails the valve re,ains in present position or reverts to the pro)deter,ined position

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 15 of 51 DATE OF ISSUE:

((.

as speci+ied. Leave valve in DclosedE position

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 16 of 51 DATE OF ISSUE:

ANNEXURE NO"4 T'3 No" UNIT: D'!(: Lo.'!&o$:

M(.5'$&.'6 .5(.8+ o$ H1%)'/6&.'661 o*()'!(% '6 (+

S) N o " 1"

C5(.8+

A+ #o/$%

A+ 6(#!

(.

&. .. '. /. 5. 6. 7.

%9.

$eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents !he na,eplate legend agrees with the approved NPCIL Plant No,enclature is clearly visible: securely +i3ed: is durable and correlates with re,ote labels =i+ applicable?. Installation correct to latest drawings. !est Reports and other docu,ents veri+ied and +ound in order. Direction o+ +low ,arked and correct. Cover and +lange bolts tight. Access +or adBust,ents: ,aintenance and repairs. 8alve gland packing suitable and satis+actory. Lubrication suitable and satis+actory. <reedo, o+ operation +ully open to +ully closed. -anually operate and physically check i+ possible. Position indicator visible and

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 1+ of 51 DATE OF ISSUE:

%%. %(. %&. %.. %'. %/. %5. %6.

%7.

(9.

indicating correctly. Li,it switches ,ounted securely and set correctly. "3tended valve spindly is installed and operates correctly. Ade*uate clearance to wall @ steelwork around actuator. Counter)balance weight ade*uate. Ade*uate ,echanical stops +itted to prevent over travel on open or close operation. Ra, seal satis+actory and +ree o+ leaks. All pivots satis+actory and pivot pins secure. 0ydraulic pipes coupled. perate 8alve hydraulically +ully opened@ +ully closed condition and cheek +or Li,it switch operation Co,pare ,ini,u, hydraulic pressure re*uired to open and to close with Rated perating pressure. Leave the valve in closed position.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 1. of 51 DATE OF ISSUE:

ANNEXURE NO"; T'3 No" UNIT: D'!(: Lo.'!&o$: M(.5'$&.'6 .5(.8+ o$ S'#(!1 '6 (+

S) N o " 1" $eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents 8alve identi+ication labeling agrees with the approved NPCIL no,enclature: is clearly visible: securely +i3ed and is durable. Installation is co,plete and all Boints are tight. !est Reports and other docu,ents veri+ied and +ound in order. "3pansion cha,ber: i+ +itted: is correct. "scape pipe work below and above roo+ level is correctly installed with provision +or e3pansion @ ,ove,ent. Silencer support structure and anchorage is satis+actory. All drains =e.g. +ro, valve body: e3pansion cha,ber: escape pipe work: silencer body? correctly installed and routed to dirty drains vessel. "scape pipe routed to the sa+e area. C5(.8+ A+ #o/$% A+ 6(#!

(.

&. .. '. /.

5. 6.

7.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 14 of 51 DATE OF ISSUE:

%9. %%.

Cold setting o+ valve is appropriate to the working pressure =and te,perature?. !esting and setting o+ the sa+ety valve will be as detailed in the appropriate co,,issioning @ testing procedure.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 25 of 51 DATE OF ISSUE:

ANNEXURE NO"< T'3 No" UNIT: M(.5'$&.'6 .5(.8+ o$ T)'*+ D'!(: Lo.'!&o$:

S) N o " 1"

C5(.8+

A+ #o/$%

A+ 6(#!

(.

&.

.. '. /. 5.

$eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents !he na,eplate legend agrees with the approved NPCIL Plant No,enclature is clearly visible: securely +i3ed and is durable and correlates with re,ote labels. Installation is correct: according to drawing and speci+ication; erection co,plete and trap is apparently unda,aged. Direction o+ +low indicated is correct. Lagging co,pleted and satis+actory. !rap was clean be+ore +inal bo3ing. !rap isolated and bypass opened pending energi1ing o+ ,ain plant ite,.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 21 of 51 DATE OF ISSUE:

.*

7.

%9.

6#ti" stea% supp"- is a!ai"a,"e e#sure that f"o2 to rai# e)ists !ia the ,-pass* Close bypass. pen trap isolating valves. Con+ir, that when stea, te,perature is below trap operating te,perature +low e3ists. As stea, te,perature changes: con+ir, operation o+ trap at di++erent te,perature levels. 8eri+y that operating te,perature =rising? and operating te,perature =+alling? co,pares +avorably with the trap te,perature rating: and is recorded.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 22 of 51 DATE OF ISSUE:

ANNEXURE NO"= T'3 No" UNIT: M(.5'$&.'6 .5(.8+ o$ A.!/'!o)+ D'!(: Lo.'!&o$:

S) N o " 1"

C5(.8+

A+ #o/$%

A+ 6(#!

(.

&.

.. '. /. 5.

$eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents !he na,eplate legend agrees with the approved NPCIL Plant No,enclature is clearly visible: securely +i3ed: is durable and correlates with re,ote labels. !he installation is co,plete and correct as per the approved drawings and speci+ications. Precision reduction gearing unit properly lubricated. Local travel indicator: showing open@close positions set correctly. !or*ue@li,it switches are set correctly. !urn the hand wheel a+ter engaging the clutch. !ry hand operation in both directions +or the

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 23 of 51 DATE OF ISSUE:

6.

7. %9.

%%. %(. %&.

%..

%'.

%/. %5.

co,plete length o+ travel to ensure that co,plete asse,bly is per+or,ing properly. Ade*uate access +or adBust,ents ,aintenance and repairers. Ade*uate clearance to wall @ steelwork around hand wheel. All the electrical works are co,plete and check on the e*uip,ents as per SCL co,pleted. Geep the valve in closed position. Check +or the proper tightness o+ the +lange bolts. Check +or the proper visibility o+ ,echanical local indicators +or the travel position Check that the checklist on actuator "lectric ,otor co,pleted as per SCL. Check that setting o+ Li,it Switches @ !or*ue switches are co,pleted and switches are correctly set. Provision +or ,aintenance: adBust,ents and repair is satis+actory. Ade*uate clearance e3ists around hand wheel and wall @ piping. Check that the reco,,ended grade o+ lubricants have been

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 24 of 51 DATE OF ISSUE:

%6.

%7.

(9.

applied to Pri,ary and Secondary reduction gear units. !he #niversal coupling ,ade and lubricated satis+actory with reco,,ended grade o+ grease. Ae+ore operating on "le. Power: engage the clutch lever and ,anually operate the valve with hand)wheel; in the ,arked direction o+ rotation: both ways o+ the valve travel. It ensures the direction ,arked in hand)wheel is correct and the whole asse,bly is per+or,ing Check +or correct phase connection o+ the ,otor actuator. Aring the valve blade in the ,iddle o+ the valve travel ,anually. Press the button in the Close direction bserve $ear Ao3 indicator and actuator indicator. Aoth ,ust travel in the close direction. I+ not then phase connection is wrong and ,ust be corrected. Check +or the correct setting o+ position li,it switches. <or this operate the actuator and see the valve travel to both the e3tre,e ends. !he +inal opening and

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 25 of 51 DATE OF ISSUE:

(%. ((.

(&. (.. ('.

(/.

(5.

closing over the last portion o+ travel ,ust be done using the hand wheel to prove the li,it switch operation. Note the ti,e taken during opening and closing perate the valve ,anually in both the direction +or its +ull travel and check it is +ree. Put valve into inter,ediate position using hand wheel. Switch on ,ains. Put the selector switch on ,anual ,ode. $ive short opening and closing i,pulses and check whether the valve ,oves in correct direction. I+ not then correct the sa,e. perate the valve +or its +ull travel in close and open direction. Check that the li,it switch operates when valve is +ull closed or +ull open. Issue the initial operation certi+icate.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 26 of 51 DATE OF ISSUE:

ANNEXURE NO"> I%($!" No" UNIT: D'!(: Lo.'!&o$: M(.5'$&.'6 .5(.8+ o$ P&*(6&$( +1+!(2+

S) C5(.8+ N o " 1" $eneral conditions satis+y the site Standing Instructions as listed in (.( Syste, Re*uire,ents (. !he na,eplate legend agrees with the approved NPCIL Plant No,enclature is clearly visible: securely +i3ed: durable and correlates with re,ote labels. &. !he installation is co,plete and correct in accordance with the latest approved drawings and speci+ication. .. Access +or adBust,ents ,aintenance and repairs is satis+actory. '. Check that all bosses: +langes and tapping points have been ade*uately ,ade o++. /. Check that all cold pulls: i+ appropriate: have been ,ade and records co,pleted. 5. Check that all +ittings on the pipe work co,ply to the re*uire,ents o+ the relevant drawings +or that

A+ #o/$%

A+ 6(#!

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 2+ of 51 DATE OF ISSUE:

6. 7.

%9.

%%. %(.

%&.

syste,. Check that all pipe +alls to drainage points are satis+actory. Con+ir, that all blanks re*uired in the syste, are ade*uately identi+ied and recorded in the Alanks Schedule. Check that drains are provided at all points on the stea, range where water pay collect. Check that stea, traps are +itted with bypass and test connections. Con+ir, that all pipe work that can be touched +ro, walkways etc: and that reaches a te,perature o+ /9 deg C or over is ade*uately lagged. Check that the pipe work syste,: including supports: is +ree to e3pand and contract within its constraints: including +loor collars and wall bo3es. Check that ade*uate nu,ber o+ vents are provided on the pipe at highest points.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 2. of 51 DATE OF ISSUE:

ANNEXURE NO"A T'3 No" UNIT: D'!(: Lo.'!&o$: M(.5'$&.'6 .5(.8+ o$ SUPPORTS

S) N o" C5(.8+ Check that all supports are unda,aged +i3ed and ,ounted vertically: ="3cept where design re*uires the support at a speci+ied angle?. Check that all ,e,bers @ +asteners are installed and tightened correctly. Check that all support loadings have been correctly set and recorded. Con+ir,: where possible: that there is a radial clearance between the pipe and the support clip. Check that all roller and sliding supports are clean: +ree to ,ove and so constructed that dirt and water cannot accu,ulate. Check that all thrust@anchor points are correctly installed. Check that all the supports as re*uired as per the design have been ,ounted. <lush the pipeline A+ #o/$% A+ 6(#!

1"

(.

&.

..

'.

/.

5. 6.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 24 of 51 DATE OF ISSUE:

7. %9.

%%.

properly to open drain to clear o+ all debris +ro, pipe. !est the pipeline hydraulically to the relevant standard. Check that all te,porary supports have been withdrawn. Con+ir, ade*uate support +or s,all bore: hori1ontal pipes that ,ay be stood upon =or ade*uate protection +or the pipes and supports +or syste, not strong each to withstand additional loads?.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 35 of 51 DATE OF ISSUE:

ANNEXURE NO"10 T'3 No" UNIT: D'!(: Lo.'!&o$: M(.5'$&.'6 .5(.8+ o$ T'$8+ & V(++(6+

S) N o " 1" (. &. Access to tanks 2 vessels is ade*uate. Illu,ination in the area near tank is ade*uate. Any other re*uisite sa+ety provision is ade*uate +or the i,,ediate co,,issioning activity. All necessary locks and keys +or padlocks interlocks etc. are available. 0ot sur+aces lagged +or screened su++iciently to provide protection +or personnel. $eneral conditions satis+y the site Standing Instructions as listed in (.(. !he Na,eplate legend agrees with the approved N!PC Plant No,enclature is clearly visible: securely +i3ed is durable and correlates with re,ote labels. Check that the installation and construction is correct to latest drawings and speci+ication. Check that internal and e3ternal access is sa+e and ade*uate. Check that provision +or ,aintenance: repairs: and adBust,ents: to +i3tures and +ittings is ade*uate. Check that all internal ite,s: C5(.8+ A+ #o/$% A+ 6(#!

.. '.

/.

5. 6. 7.

%9.

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 31 of 51 DATE OF ISSUE:

%%. %(.

%&.

%..

%'.

%/.

%5.

%6. %7.

grills: trays +ilter ele,ents etc. are co,plete and secure. Check that +loat valves i+ +itted are correctly installed and operating +reely. Check that tank is internally clean: +ree +ro, debris: and that the internal and e3ternal protective coating is to speci+ication and unda,aged. Check that all e3ternal +ittings: gauges and indicators are correct to speci+ication and securely +itted and supported. #nused bosses to be plugged or blanked o++. Check that all pipe work syste,s connected to the tank are co,plete at least to isolating valve local to tank: and that Boints are correctly ,ade. Check that +illing: over+low: vent and tank e,ptying arrange,ents are co,plete; at least to isolating valve local to tank: and that Boints are correctly ,ade. Check that all Boints are tight. Check that bunds are co,plete and sur+ace drainage arrange,ents are satis+actory. 0ydraulically test tank as appropriate and check +or leaks. Record i+ tank settle,ents are ,ade. Check that heating arrange,ents =stea, heating or electrical heating? is +itted: is to speci+ication and co,plete. Check that lagging and cladding =i+ re*uired? is co,plete to speci+ication. Check that support structure:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 32 of 51 DATE OF ISSUE:

(9. (%.

((. (&. (.. ('.

(/.

(5.

(6. (7.

&9. &%.

ladders and handrails are satis+actory. Check access doors =i+ +itted?. Check that painting o+ approved co lour has been done. Check all valves: switches: pressure switch etc. to their relevant checklists. Are the +ire protection arrange,ents in co,,ission and according to speci+icationH Are all access ,anhole covers +itted satis+actorilyH Can the roo+ ,anhole cover=s? be locked in the open positionH Are there suitable arrange,ents to prevent personnel and e*uip,ent +alling into the tank when the ,anhole is open =hinged lockable grid?H Con+ir, that the vent area is at least %.' ti,es the +illing pipe or suction pipe area =whichever is the greater? and +itted with a . ,, ,esh non)+errous wire cage. <or oil tanks: is the co,bined water draw o++ and clean)out su,p drainage arrange,ent satis+actoryH Are the tank drain valves locked shut with locks having co,,on keysH 0ave oil tank drain valve coupling connectors been +itted with a non)+errous cap: to protect the threads: together with an oil spillage witness hole. Does the =oil? tank +ar, +illing ,ani+old drain line drain to a suitable vessel@pitH Is the tank over+low branch bore greater than that o+ the largest +illing line and is piped to a

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 33 of 51 DATE OF ISSUE:

&(.

&&. &..

&'.

&/. &5.

&6. &7. .9. .%.

suitable pointH <or water !anks: =i+ applicable: has the +loat valve asse,bly been set to operate at the correct water levelH 0ave tank ,i3ers been installed satis+actorilyH =i+ applicable?. !ank 0eating arrange,entsC)Are tank heating ele,ents or coils and ther,ostats installed and connectedH@Check that the control valves in the stea, line +or the heating o+ the oil has been tested +or their correct operation. 0ave the local and re,ote: high and low level alar,s together with the testing +acility been satis+actorily provenH <or oil tanks: has the heater trip and ,i3er trip +acility on receipt o+ low level alar,s been provenH Do the tank earthing arrange,ents co,ply with the re*uire,ents speci+ied +or the particularly si1e o+ the tank. =!anks up to &9, dia: ( opposite spade earth strips; tanks over &9, dia: & e*ually spaced earthing strips?. 0as the tank level indicator been calibratedH !ank calibration certi+icate and charts availableH 0as the tank gauge been +itted satis+actorilyH Are the arrange,ents +or dip scale@tape ,easuring =including the provision o+ a striker plate? and oil sa,pling satis+actory =e.g. weather proo+ing o+ openings?H

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 34 of 51 DATE OF ISSUE:

.(.

.&.

... .'. ./. .5. .6. .7. '9. '%. '(. '&. '.. ''.

'/.

'5.

Do Aunding arrange,ents +or oil tanks co,ply with the re*uire,ents speci+ied +or the particular duty o+ the tankH Are the bund drainage arrange,ents ade*uate +or stor, water@+ire +ighting water drainageH Is the bund drain valve shut and can it be operated +ro, outside the bunded areaH Is the bund area +ree o+ all debrisH Is the tank base ade*uately drained to prevent accu,ulation o+ li*uid at the base o+ the tankH <ill tank: proving ,anual and auto,atic syste, o+ control =i+ applicable? Record rate o+ +illing; 0eight@,inute Record rate o+ +illingC Iuantity@,inute Record operation level o+ low level alar,s. Record cut in level o+ auto +illing Record cut out level o+ auto +illing Record operation level o+ high level alar,s. Are all Boints leak tightH 4ith all points o+ consu,ption at ,a3i,u, +low and inlet valve shut: ,easureC)Rate o+ e,ptyingC 0eight@,inute@Rate o+ e,ptyingC Iuantity@,inute 8eri+y e3istence o+ statutory test certi+icate and ensure that a copy is available +or station records. 8eri+y e3istence o+ current statutory =insurance? certi+icate

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 35 of 51 DATE OF ISSUE:

'6. '7. /9. /%.

/(. /&.

/..

o+ internal and e3ternal e3a,ination. Check and set all associated valves and ,ountings to appropriate check sheets. Check that drain connections are led to a suitable drainage point. Check that access door readily accessible +or internal inspection. Check that ,ounting o+ pressure gauge: sight glass have been provided a+ter proper calibrations correctly installed: and can be read easily. Check application o+ e3ternal lagging etc. Check vessel is le+t in sa+e condition according to local instructions and environ,ental re*uire,ents. Pressure leak testing ,ay or ,ay not be part o+ the post SRCC co,,issioning procedure.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 36 of 51 DATE OF ISSUE:

ANNEXURE NO"11 T'3 No" UNIT: D'!(: Lo.'!&o$: M(.5'$&.'6 .5(.8+ o$ MAIN OIL TANK

S) N o "

1. GENERAL CONDITIONS SATISFY THE SITE STANDING INSTRUCTIONS AS LISTED IN 2.2 SYSTEM REQUIREMENTS

C5(.8+

A+ #o/$%

A+ 6(#!

(. &. .. '. /. 5.

6.

7.

%9.

Installation o+ ,ain oil tank as per its drawing is co,plete. Check that Strainer has been +itted and cleaned. !ank Level indicator installed and calibrated. il vapour e3hausters have been installed and checked. il piping work is co,plete and checked. Annunciation syste, +or ,a3i,u, and ,ini,u, level indication has been co,,issioned. Check that cleanliness o+ tank thoroughly =Cleaning should be done by cloth and not by cotton waste?. Check integrity o+ +oundations: grouting: anchor bolts: dowels etc. I+ pu,p and ,otor share a co,,on bedplate check that shi,s are +itted under both Check that all drains =$lands: pu,p casing: bed plate etc.? are piped to a suitable destination. Check that pu,p rotates +reely

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 3+ of 51 DATE OF ISSUE:

%%. %(. %&. %.. %'. %/. %5. %6.

%7. (9.

(%.

by hand. Re,ake pu,p coupling: and ensure that all guards are +itted. Check discharge pipe is properly supported as per the approved Drawing. btain a certi+icate +ro, erection@contractor +or the proper cleanliness o+ tank !ank ,ay be charged with oil. Check gland packing: establish gland sealing water +low and adBust gland as necessary. Check bearing lubrication syste, is satis+actory +or operation: and establish +low. Correct grade o+ Lubricating oils and greases have been applied. Check bearing cooling water syste, is satis+actory +or operation: and establish +low. Check that associated instru,ents =pressure gauges etc.? are +itted and in working order a+ter proper calibration. Pri,e pu,p: check +or leakage: and close vents and drains. Run pu,p on closed discharge +or short duration. Record starting and running current and Dno +lowE discharge pressure. Issue Record o+ Initial peration

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 3. of 51 DATE OF ISSUE:

ANNEXURE NO"19 T'3 No" UNIT: D'!(: Lo.'!&o$:

MECHANICAL CHECKS ON Ro!')1 *)o%/.!+ & #&6!()+

S) N o "

1.

C5(.8+

A+ #o/$%

A+ 6(#!

GENERAL CONDITIONS SATISFY THE SITE STANDING INSTRUCTIONS AS LISTED IN 2.2 SYSTEM REQUIREMENTS

(.

&.

.. '. /. 5. 6. 7.

!he na,eplate legend agrees with the approved N!PC Plant No,enclature is clearly visible: securely +i3ed: durable and correlates with re,ote labels. !he installation is co,plete and correct in accordance with the latest drawings and speci+ication. Provision +or adBust,ents ,aintenance and repairs is satis+actory. Reco,,onded grade o+ Lubricating oils and greases have been applied. Con+ir, =where possible and applicable? that oil rings are +ree to re,ove. Check that oil level in bearings can be ade*uately ,onitored. Con+ir, ade*uate +acilities +or +illing and draining the oil. I+ bearings are pressure +ed:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 34 of 51 DATE OF ISSUE:

%9. %%. %(.

%&. %..

%'.

%/.

%5. %6.

%7.

con+ir, that pressure gauges: switches and ther,ocouples been +itted. I+ pressure +ed lubrication: con+ir, that oil +lows to each bearing. Con+ir, that pu,p spindle is +ree to turn. Con+ir, satis+actory coupling align,ent +igures ="rection Case 0istory? and that coupling is ,ade and lubricated satis+actory. I+ li*uid is in+la,,able or corrosive: check that gland spray guards +itted. Con+ir, gland leakage disposal arrange,ents satis+actory +or the +luid being pu,ped. Con+ir, pri,ing and drainage +acilities satis+actory +or the +luid being pu,ped. <or positive displace,ent pu,ps: veri+y that deloader@controller i+ provided +itted and calibrated. Check that all rotating parts ade*uately guarded. Con+ir, that li+ting lugs@eyes are rendered inoperable and =i+ applicable? holes plugged and threads identi+ied. As soon as the pu,p can be operated as part o+ a syste,: run the pu,p +or pre+erably . hours =or at least until bearing te,peratures stabilise? to

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 45 of 51 DATE OF ISSUE:

(9. (%. ((. (&.

(..

('. (/. (5. (6. (7. &9. &%. &(. &&. &.. &'.

veri+y that vibration levels are within acceptable li,its. Con+ir, that pu,p pri,e can be established and ,aintained. Con+ir, integrity o+ pu,p glands and seals. Ay care+ully listening to the pu,p noise: establish any obivious signs o+ cavitation. Con+ir, satis+actory operation o+ the deloader@controller =positive displace,ent pu,p?. -onitor =where possible and appropriate? the +ollowing para,eters and record the stable levelsC Pu,p Suction Pressure. Pu,p Discharge Pressure. Pu,p Speed. Pu,p <low Pu,p Inboard Aearing !e,perature Pu,p utboard Aearing !e,perature Pu,p inboard bearing vibration Pu,p utboard bearing 8ibration. -otor Staring Current and Run)#p !i,e =i+ appropriate?. -otor 4inding casing !e,perature. -otor Aearing 8ibration and !e,perature.

CHECKED 04 REVIEWED 04

PREPARED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 41 of 51 DATE OF ISSUE:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 42 of 51 DATE OF ISSUE:

ANNEXURE NO"13 T'3 No" UNIT: Lo.'!&o$: MECHANICAL CHECKS ON S/2* */2*+

S) N o " 1" (. &. .. '. /. 5. 6. 7. %9. %%. %(. %&. %.. %'. Co,ponents and <i3ings secured. All access ladders sa+e. Pu,p discharge pipe work co,plete and satis+actory. Pu,p suction satis+actorily located in su,p well. Pu,p ,otor cable gland satis+actory. Pu,p +ree to rotate. Direction o+ rotation correct. All rotating parts correct. <loat levels +itted and satis+actory. Low level stop operates. 0igh level start operates. All sub,ersible co,ponents ade*uately protected. Su,p internal coating co,plete and correct. Su,p guarded to prevent entry o+ debris. Pipe work to and +ro, su,p ter,inated correctly.

CHECKED 04 REVIEWED 04

D'!(:

C5(.8+

A+ #o/$%

A+ 6(#!

PREPARED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 43 of 51 DATE OF ISSUE:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 44 of 51 DATE OF ISSUE:

ANNEXURE NO"14 T'3 No" D'!(: UNIT: Lo.'!&o$: MECHANICAL CHECKS ON O&6 Ro!')1 *)o%/.!+

S) N o " 1"

C5(.8+

A+ #o/$%

A+ 6(#!

(. &. .. '. /. 5. 6.

7.

%9.

Check that +acilities and access +or re,oval o+ baskets: and ,aintenance generally are convenient and ade*uate. Check that strainer baskets are in position: unda,aged: and are o+ correct ,esh. Carry out strainer change)over to ensure +reedo, o+ ,ove,ent where applicable. "nsure that strainer body and basket are +ree +ro, debris. I+ plant is ,otor driven: con+ir, that direction o+ rotation is correct. Check that position indicators are visible and operating correctly. Check that di++erential pressure gauges are +itted. Check operation o+ pri,ing valve: strainer body drain: and air cocks: +or ease o+ operation as appropriate. Con+ir, that +or an arrange,ent o+ two individual strainers in parallel the valves are interlocked to prevent both strainers being isolated together. Check that points on pipe work back to isolating valves are

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 45 of 51 DATE OF ISSUE:

%%.

%(. %&.

%..

%'.

correctly ,ade: and that isolating valves are closed. 0ydraulically test strainer as appropriate: and check +or leaks. Check that drainage and venting +acilities are ade*uate. Con+ir, the integrity o+ all Boins: glands and seals. Con+ir, that the changeover +acility ade*uately isolates the non)working basket =i+ applicable?. I+ dual individual strainers: in parallel: con+ir, that each strainer can be ade*uately isolated +ro, the syste,: re,oved and cleaned. Con+ir, that: +or ,otor driven strainers: and the baskets rotate satis+actorily.

PREPARED 04

CHECKED 04

REVIEWED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 46 of 51 DATE OF ISSUE:

ANNEXURE NO"1; T'3 No" UNIT: D'!(: Lo.'!&o$: MECHANICAL CHECKS ON C($!)&#/3(+

C5(.8+ N o " 1" (. &. .. '. /. 5. 6. 7. %9. %%. %(. Check +or +reedo, o+ rotation. Check that the si1e o+ S.$. rings is correct +or +luid being handled. Check that seals are correct. Check that cover is secure. Check that bedplate and holding down arrange,ent is secure. Check that drains syste, is co,plete. Check that provision +or containing and draining spillage is ade*uate. Check availability o+ ade*uate water supplies. <lush centri+uge to drain to ensure that the syste, is +ree +ro, debris. Con+ir, that ,otor drives to bowl and pu,p are satis+actory. Check direction o+ rotation o+ centri+uge. Run the centri+uge o++ load: check ,otor current and speed. Run the centri+uge +or a ,ini,u, period o+ one hour. Check +or leaks. Check unit +or vibration. Check instru,ents and alar, A+ #o/$% A+ 6(#!

S)

%&. %..

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 4+ of 51 DATE OF ISSUE:

%'. %/. %5.

syste,. Check bowl discharge operation. Arrange dis,antling: cleaning: re)asse,bly and re)run by centri+uge. Record Initial peration details.

CHECKED 04 REVIEWED 04

PREPARED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 4. of 51 DATE OF ISSUE:

ANNEXURE NO"1< T'3 No" UNIT: MECHANICAL CHECKS ON F&6!()+

S) N o " %. (. &. .. '. /. 5. 6. Check direction o+ +low is correct and is ,arked. Carry out +ilter strea, changeover to ensure +reedo, o+ ,ove,ent where applicable. "nsure that +ilter body and plates are +ree +ro, debris. I+ +ilter plant is ,otor driven: con+ir, that direction o+ rotation is correct. Check that position indicators are visible and operating correctly. Check that di++erential pressure gauges are +itted. Drainage and venting +acilities ade*uateH Con+ir, that +or an arrange,ent o+ two individual +ilters in parallel the valves are interlocked to prevent both +ilters being isolated together. Check that Boints on pipe work back to isolating valves are correctly ,ade: and that isolating valves are closed. Con+ir, cleaning and handling arrange,ents.

CHECKED 04 REVIEWED 04

D'!(: Lo.'!&o$:

C5(.8+

A+ #o/$%

A+ 6(#!

7.

%9.

PREPARED 04

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 44 of 51 DATE OF ISSUE:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 55 of 51 DATE OF ISSUE:

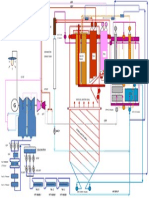

4" D(+&3$ &$!($!+:

;" EB*(.!(% P)o.(++ P')'2(!()+:

<" Wo)8 P6'$:

=" T(+! R(*o)! Fo)2'!:

>" R(#()($.(:

A" V()&#&.'!&o$ P)o.(++:

TAPP-3&4 COMMISSIONING PROCEDURE

COMMISSIONING PROCEDURE FOR PRE-COMMISSIONING MECHANICAL CHECKS OF TG & AUXILIARIES TAPP-3&4-41000-CP-1M

PROCEDURE NO: TAPP 3&4- 41000- CP-1M ISSUE NO:01 REV NO:0

Page 51 of 51 DATE OF ISSUE:

10" L&+! o# A$$(B/)(:

Вам также может понравиться

- Top Drive Encoder System Operation, Reliability, and TroubleshootingДокумент4 страницыTop Drive Encoder System Operation, Reliability, and TroubleshootingJuan Pablo Villazon RichterОценок пока нет

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Документ31 страницаProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzОценок пока нет

- Gas Turbine - Compressor AlignmentДокумент2 страницыGas Turbine - Compressor AlignmentNazmiОценок пока нет

- Start-Up Check ListДокумент3 страницыStart-Up Check ListgustavoespinosamОценок пока нет

- As 3791-1991 Hydraulic HoseДокумент7 страницAs 3791-1991 Hydraulic HoseSAI Global - APAC0% (1)

- Fuel Supply SystemДокумент15 страницFuel Supply SystemPraneshОценок пока нет

- 1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceДокумент2 страницы1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceAbdul Hameed OmarОценок пока нет

- Hydraulic System RequirementsДокумент9 страницHydraulic System RequirementsGuille GiraldoОценок пока нет

- Abrasive Blasting Cop 2013Документ34 страницыAbrasive Blasting Cop 2013Ogala OscarОценок пока нет

- Setting The Hydraulic Block ManifoldДокумент6 страницSetting The Hydraulic Block ManifoldJuan Pablo Villazon RichterОценок пока нет

- Instruction Sheet: W-Series Hydraulic Torque WrenchesДокумент40 страницInstruction Sheet: W-Series Hydraulic Torque WrenchesShag Shaggy100% (1)

- Lesson Valve Maintenance and Valve Packing: Sub-ObjectiveДокумент30 страницLesson Valve Maintenance and Valve Packing: Sub-Objectivemister pogi100% (1)

- 39GC C12 1PD 1 - CarrierДокумент27 страниц39GC C12 1PD 1 - Carrierks aksОценок пока нет

- SPE-68789-MS One PetroДокумент5 страницSPE-68789-MS One PetroAlex ZamanОценок пока нет

- ChecklistДокумент2 страницыChecklistdassayevОценок пока нет

- Accumulator Pressure Test (Offline)Документ3 страницыAccumulator Pressure Test (Offline)aneshseОценок пока нет

- Form For Site Visit BN-12 (25!03!2014)Документ28 страницForm For Site Visit BN-12 (25!03!2014)nadiraОценок пока нет

- Pumps ChecklistДокумент3 страницыPumps ChecklistRaouf AbdelmonemОценок пока нет

- Resume SampleДокумент4 страницыResume SampleKumar Gaurab JhaОценок пока нет

- Berkeley Ownwes ManualДокумент28 страницBerkeley Ownwes ManualMoses Alvarado100% (1)

- Belzona 1111ps EnglДокумент2 страницыBelzona 1111ps EnglNikolay GuerreroОценок пока нет

- 3 s2.0 B9780884156864500508 MainДокумент4 страницы3 s2.0 B9780884156864500508 MainAmal KaОценок пока нет

- Structural Inspection Checklist For FactoryДокумент1 страницаStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- Coiled Tubing TroubleshootingДокумент6 страницCoiled Tubing TroubleshootingMohamed HashemОценок пока нет

- Catalogue 118 JJДокумент132 страницыCatalogue 118 JJkorpaapОценок пока нет

- Mud Pump - High Pressure Lines PDFДокумент7 страницMud Pump - High Pressure Lines PDFKaleem UllahОценок пока нет

- Preventive Maintenance Schedule For FD Fans of "U# 8, D.P.P.S." Equipment: FD Fan # 8AДокумент2 страницыPreventive Maintenance Schedule For FD Fans of "U# 8, D.P.P.S." Equipment: FD Fan # 8ABM UNIT8Оценок пока нет

- Goulds PumpsДокумент44 страницыGoulds PumpscridavarОценок пока нет

- Fa2.5i Fa5i Fa5ti PartsДокумент52 страницыFa2.5i Fa5i Fa5ti Partsmohammad salleh100% (1)

- Quality Checks During OverhaulДокумент17 страницQuality Checks During OverhaulP Koteswara RaoОценок пока нет

- Hose Hanger Installation Operating Procedures Rev.1Документ9 страницHose Hanger Installation Operating Procedures Rev.1HSE PULAI AОценок пока нет

- FC-FXX - 8 Parts List PDFДокумент28 страницFC-FXX - 8 Parts List PDFjulioramcaОценок пока нет

- Boroscope InspectiónДокумент14 страницBoroscope InspectiónXiomara Hurtado FloresОценок пока нет

- I. Velocity Head: Lift, Displacement, Velocity, Buoyancy and Gravity PumpsДокумент26 страницI. Velocity Head: Lift, Displacement, Velocity, Buoyancy and Gravity PumpsAmarjyot SinghОценок пока нет

- Rachael - Turnkey Projects Nigeria and IpodДокумент9 страницRachael - Turnkey Projects Nigeria and IpodparthОценок пока нет

- ChecklistДокумент3 страницыChecklistAndy Noven KrisdiantoОценок пока нет

- Nuflo Turbine Meter Manual PDFДокумент16 страницNuflo Turbine Meter Manual PDFfatsfinderОценок пока нет

- Everpure SSFM 100M 25 orДокумент2 страницыEverpure SSFM 100M 25 orbigcee64Оценок пока нет

- CABOT 750 Equipment ListДокумент21 страницаCABOT 750 Equipment ListOmar Quiñonez100% (1)

- Earth Moving Equipment ChekclistДокумент2 страницыEarth Moving Equipment ChekclistBakri Bin SapilahОценок пока нет

- MNT-INTG-2007OP - Maintenance Welding InspectionДокумент43 страницыMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanОценок пока нет

- Front Loader Maintenance PlanДокумент2 страницыFront Loader Maintenance PlanScribdTranslationsОценок пока нет

- Failure Analysis ReportДокумент9 страницFailure Analysis ReportOka WansyahОценок пока нет

- Electrical Maintenance Standard Operative Procedure - Detailed ProceduresДокумент1 страницаElectrical Maintenance Standard Operative Procedure - Detailed ProceduresamlmrsscontrolОценок пока нет

- Power Slips - General Edition - 5Документ26 страницPower Slips - General Edition - 5brasgОценок пока нет

- N5SC Swivel 1Документ12 страницN5SC Swivel 1Winda FaleviОценок пока нет

- Effect of Metallurgy On Pygas Fouling PDFДокумент6 страницEffect of Metallurgy On Pygas Fouling PDFstreamtОценок пока нет

- VIBXPERT Catalog - English PDFДокумент72 страницыVIBXPERT Catalog - English PDFMuammad SanwalОценок пока нет

- Product Presentation - Oct 2016Документ143 страницыProduct Presentation - Oct 2016Dwi PutraОценок пока нет

- Encoder: Technical Manual 222115-001 40223723-SeriesДокумент34 страницыEncoder: Technical Manual 222115-001 40223723-SeriesAndres NavarroОценок пока нет

- Lesson Centrifugal PumpДокумент14 страницLesson Centrifugal Pumpmister pogiОценок пока нет

- Crusher InspectionДокумент13 страницCrusher InspectionAtiq Ur RehmanОценок пока нет

- Basic Introduction of Coal Handling SystemДокумент7 страницBasic Introduction of Coal Handling SystemHerman AbdullahОценок пока нет

- Crosby ShacklesДокумент6 страницCrosby Shacklessabah8800Оценок пока нет

- Lovol 1004Документ2 страницыLovol 1004Dhee DoodzОценок пока нет

- Specification For PE Pipes FittingsДокумент32 страницыSpecification For PE Pipes FittingsFlorian_AngererОценок пока нет

- Barring GearДокумент30 страницBarring GearJeffrey MuellerОценок пока нет

- PrestartupДокумент155 страницPrestartupvasanthasenanОценок пока нет

- U-00034-PR-CRT-0001 - Rev.AДокумент46 страницU-00034-PR-CRT-0001 - Rev.AthinhviproОценок пока нет

- Report Lube Oil FlushingДокумент10 страницReport Lube Oil Flushingmohan_krishna372Оценок пока нет

- 660 MW SupercrticalДокумент1 страница660 MW Supercrticalmohan_krishna372Оценок пока нет

- Understanding NAS Values in Engine OilsДокумент2 страницыUnderstanding NAS Values in Engine Oilsmohan_krishna372Оценок пока нет

- Sachin Patel: ObjectiveДокумент4 страницыSachin Patel: Objectivemohan_krishna372Оценок пока нет

- Details For Transportation and Dispatch:: Energy Sector 2-84700-76771-00Документ5 страницDetails For Transportation and Dispatch:: Energy Sector 2-84700-76771-00mohan_krishna372Оценок пока нет

- GeneratorДокумент18 страницGeneratorDSGОценок пока нет

- GERB Spring Loaded DECK InfДокумент14 страницGERB Spring Loaded DECK Infmohan_krishna372100% (1)

- DiscussionsДокумент2 страницыDiscussionsmohan_krishna372Оценок пока нет

- Condenser ErectionДокумент51 страницаCondenser Erectiongeorge israel100% (1)

- SW Miniatura Omron D2VW-5L2-1MДокумент8 страницSW Miniatura Omron D2VW-5L2-1MVICTOR LOPEZОценок пока нет

- MPS-PA Solutions 709743 enДокумент160 страницMPS-PA Solutions 709743 enNemanja Davidovic0% (1)

- 7PA23511 Datasheet enДокумент2 страницы7PA23511 Datasheet enJorge Morgado EscobarОценок пока нет

- VC Series: 2 - Way, Balanced Hydronic ValvesДокумент4 страницыVC Series: 2 - Way, Balanced Hydronic ValvesArun SivaОценок пока нет

- PEC KK Series PotentiometersДокумент3 страницыPEC KK Series PotentiometersAlexandre S. CorrêaОценок пока нет

- Product Sheet: Load ComputerДокумент8 страницProduct Sheet: Load ComputerSaravanan MathiОценок пока нет

- FX-2000 SERIES Programmable Modules: RAX-LCD Remote Shared DisplayДокумент2 страницыFX-2000 SERIES Programmable Modules: RAX-LCD Remote Shared DisplayAli OsmanОценок пока нет

- Tablero Controlador FIRETROL FTA1300Документ2 страницыTablero Controlador FIRETROL FTA1300Accesorios y SistemasОценок пока нет

- Delphin HelpДокумент2 041 страницаDelphin HelpshansariОценок пока нет

- Technical Manual VVH40C-DSK - G14-0048Документ28 страницTechnical Manual VVH40C-DSK - G14-0048mantenimientokmdОценок пока нет

- Features: Song ChuanДокумент5 страницFeatures: Song ChuanAlberto CovarrubiasОценок пока нет

- Design and Implementation of An Automatic Soil Moisture Sensor Irrigation SystemДокумент5 страницDesign and Implementation of An Automatic Soil Moisture Sensor Irrigation SystemWARSE JournalsОценок пока нет

- Oisd RP 157Документ34 страницыOisd RP 157navjot singh75% (4)

- Ami Ro System IomДокумент36 страницAmi Ro System IomLiney Gutiérrez OrozcoОценок пока нет

- Blue Smart ManualДокумент139 страницBlue Smart ManualpedroserusОценок пока нет

- Pump Goveror Class OneДокумент38 страницPump Goveror Class OneEolo RojasОценок пока нет

- Electrical SafetyДокумент40 страницElectrical Safetykazooed100% (1)

- Proact™ Ii Digital Speed Control System: Technical SupplementДокумент18 страницProact™ Ii Digital Speed Control System: Technical SupplementTariqMaqsoodОценок пока нет

- HOWO Electrical Diagrams PDFДокумент24 страницыHOWO Electrical Diagrams PDFMTK201689% (36)

- Door Interlock Switch D2DДокумент8 страницDoor Interlock Switch D2DMuhamad PriyatnaОценок пока нет

- LP112 InstructionsДокумент2 страницыLP112 InstructionscockybundooОценок пока нет

- Mektek2 Manual Jan 08 PDFДокумент45 страницMektek2 Manual Jan 08 PDFzokiОценок пока нет

- Pro LH InstructionManualДокумент40 страницPro LH InstructionManualMicanan SystemsОценок пока нет

- EAO MC 18 Main-Catalogue ENДокумент42 страницыEAO MC 18 Main-Catalogue ENrudy pumacahuaОценок пока нет

- Circuit Diagram of Hall EffectДокумент10 страницCircuit Diagram of Hall EffectEvaldas StankeviciusОценок пока нет

- EW &WP Lab EE-108 (2021-22) QPДокумент4 страницыEW &WP Lab EE-108 (2021-22) QPHarimadhavareddy YenireddyОценок пока нет

- 140-RAI AM AlphaRudder MFM (MED) InstOper Manual 22-8-2019 PDFДокумент76 страниц140-RAI AM AlphaRudder MFM (MED) InstOper Manual 22-8-2019 PDFSunil KumarОценок пока нет

- MMI 813.1 Gas Burner Automatic Safety ControlДокумент4 страницыMMI 813.1 Gas Burner Automatic Safety ControlBode JuniorОценок пока нет