Академический Документы

Профессиональный Документы

Культура Документы

Amine Acid and Sour Gas Plant Experiences

Загружено:

cymyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Amine Acid and Sour Gas Plant Experiences

Загружено:

cymyАвторское право:

Доступные форматы

Fire Tube Boiler

Fire Tube Boiler

Saturated Steam

MEA Solution

MEA Stripper

Vapor

MEA Reboiler

MEA Solution

LeanMEA Solution

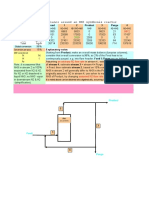

This is the conventional, industrial manner of generating food-grade CO2 in a continuous, steady, and controlled scheme. Note that the 15% MEA (wt.) solution is kept indirectly away from the very hot reboil heat generated by the use of a direct-fired reboiler. Although this method involves the cost of a conventional steam boiler, it eliminates a lot of the degradation products that are formed when MEA comes in contact with temperatures in excess of 300 oF. It also allows for easy and convenient means to ensure a maximum in the fuel combustion to produce as near a stoichiometric quantity of CO2 without worrying about how reboiler heat is affected. The amount of steam produced by this method is well in excess of that required in the MEA Reboiler and this fact enables the process to have sufficient steam available to not only introduce an excess of steam into the reboiler (which ensures that acid gas loadings will be reduced in the Stripper with ease), but it also provides steam for an MEA Reclaimer (which greatly ensures the non-corrosive state of the circulating solution and the efficient operation of the plant.

The application of a cheaper ("low capital investment") direct-fired reboiler in order to save the capital cost of the MEA reboiler reduces the Capital Investment of the plant, but it introduces many serious and expensive maintenance and operating problems for the operator ("owner") of the plant. A direct fired reboiler can accelerate the degradation of MEA into a very corrosive state and cause many corrosion problems in the reboiler as well as in all the rest of the equipment. This is a classical example of getting exactly what you paid for. If the eventual owner is not interested in reducing his operating and maintenance costs and other problems, then he/she doesn't pay attention to such important details that will return to threaten his operating profit margin in the end.

continuous, steady, and

t reboil heat generated a conventional steam A comes in contact with to ensure a maximum in ut worrying about how in excess of that nt steam available to not loadings will be aimer (which greatly ation of the plant.

order to save the capital oduces many serious of the plant. A directand cause many his is a classical example educing his operating such important details

Lean MEA Solution

Nitrogen to Atm.

Flue Gas

LP CO2 + Steam from CO2 Stripper

CW Return

LP Cooler

Nitrogen to Atm. CW Supply

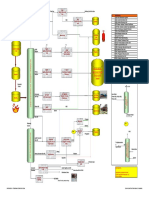

This height, together with H2 should be related to the available pressure in the LP Cooler Separator and give sufficient packing height for efficent scrubbing. H1

Condensate from LP Cooler-Condenser

H2 This height should be sufficiently high to allow effient condensate over flow from the bottom of the exhaust scrubber and allow for taking a solution sample for analysis.

LP CO2 to Purification & Compression

LP Cooler-Condenser

LC

Water-CO2, 5 psig & 228 oF

Rich MEA, 200 oF

Typical Stripper 5/16" Plate, seal welded

35 psig Steam

Condensate

Lean MEA Drain & to Reclaimer

Lean MEA

Some background on MEA use in CO2 removal processes:

During the 1950 and 1960's the Liquid Carbonic Corporation (Chicago, Illinois) was the World's largest producer and distributor of Carbon Dioxide - as a liquefied product ("LiquiFlow") and as a solid ("Dry Ice"). During the 50's, it started to expand its markets in Latin America and decided to install proven, state-of-the-art production plants there. It chose to enter into a purchase/supply arrangement with a company in Dallas, Texas named International Process Equipment Corporation ("IPEC"). IPEC was majority-owned by Mr. Robert Graff who had a recognized and respected reputation for designing and building CO2 removal plants mounted on skids and capable of being easily transported and installed in under-developed locations. During the early 50's Liquid Carbonic engineers bought some surplus, skid-mounted Girdler CO2 generating plants that had been recovered from US Naval ships such as World War II air-craft carriers and they learned about the benefits of the skid-mounted design. The Girdler corporation had specifically designed these units during WWII to function on-board ships to produce CO2 for vital and important fire extinguishers applications on board. These Girdler plants used a direct-fired heater that burned fuel oil directly through a stainless steel helical coil inside the furnace. A 20% wt. MEA solution was circulated within the coil by stainless steel Peerless centrifugal pump. The hot, MEA solution was flashed into bottom of a generator tower packed with Rashig Rings. The generator tower stripped out the absorbed CO2 from the Rich MEA introduced at the top of the Rashig Ring bed. The generator tower operated at 40 psig and this was sufficient pressure to send the Lean MEA in the generator sump to the top of the CO 2 absorber. This design worked very well, but it had notorious amine degradation problems caused by the direct-fired reboiler. This was not a problem for the Navy; they merely dumped the degraded solution at sea and put in fresh MEA on a timed schedule. Liquid Carbonic had two Girdler plants with the above design: One at Maracaibo, Venezuela and another at Lima, Peru. The application of amines for CO2 removal was brought about by the discovery of helium containing carbon dioxide in Thatcher, Colorado, in 1922. Rodger R. Bottoms, a chemist and lieutenant commander in the Navy, developed a process to exploit this helium deposit economically by removing the carbon dioxide. In 1929 he synthesized an amine that removed the carbon dioxide from the helium in laboratory experiments. In 1930 he patented the amine process for the Girdler Corporation for the removal of CO2. In 1935, Robert A. Graff, was working for Mr. Bottoms as his laboratory assistant. They both were employed by the Girdler Corporation. Mr. Graff went on to form the Graff Engineering Company in Dallas, Texas employing all the know-how and experience he had accumulated in his association with R. R. Bottoms and Girdler. Bob Graf actively designed and fabricated amine skid-mounted plants for the Texas-Oklahoma-Louisiana-

New Mexico Oil Patch, removing CO2 and H2S. His plants employed both direct-fired reboilers and steam-heated reboilers. Some unique and innovative features that the IPEC skid-mounted MEA plants incorporated were:

The use of a conventional, fire tube boiler to generate the CO2 gas as well as low pressure steam (35-40 psig). All the steam generated was sent to a U-tube bundle in a kettle Reboiler that formed part of the Stripper (as shown in the illustration above) and all the produced condensate returned to the boiler BY GRAVITY. There was no condensate pump(s), condensate controls, deaerators, or condensate instrumentation. Since Bob Graff needed an MEA heat exchanger and an MEA cooler, he placed these directly below the kettle Reboiler and in doing so, had to raise the reboiler and its steam tube bundle to a height that was normally above the top of the steam boiler. This made the application of condensate gravity return practical and efficient. The CO2 stripper used no "fancy" trays or packing. There were approximately 10 trays used in the IPEC Stripper and each was nothing more than a circular, 5/16" carbon steel plate with a segment cut out. The segment was approximately 15 to 20% of the diameter - depending on the size of the stripper and the CO2 capacity. These Strippers worked well and never needed, inspection or maintenance. The design could not be more simplified. All the condensate produced in the LP Cooler-Condenser down stream of the Stripper was collected a Vapor-Liquid Separator and the condensate was returned to the solution system via the sump of absorber. THERE WAS NO CONDENSATE RETURNED TO THE TOP OF THE STRIPPER AS SO-CALLED "REFLUX". This not only worked very simply and trouble-free, it required no reflux pump, flow meter, vales, controls, and instrumentation. IPEC incorporated an Amine Reclaimer - a means to re-distill a portion of the Lean Amine in order to precipitate out any heavy, polimerized amine products or degradation by-products. This device kept the solution working for very long periods without suffering corrosion in the basic carbon steel material that the plant was constructed out of. Corrosion was effectively kept under control to the degree that the Reclaimer was kept operating. This feature worked very well and practically due to the availability of steam from the boiler. With a direct-fired Reboiler, the use of a Reclaimer is not possible.

Addition notes and background:

When I took over the Lima, Peru operation in 1963, I made some major modifications to the existing 150 kg/hr CO2 plant. I converted the two-pass CO2 absorber into a one-pass tower and mounted a scrubber on top to use the LP condensate from the Cooler-Condenser to scrub the exhaust gas exiting the absorber. MEA consumption dropped immediately to 1.0 kg/tonne CO2 produced. I undertook the design and fabrication of a 400 kg/hr CO2 combustion plant using a steam generator and a Chicago-Pneumatic, 3-stage, oil-lubricated reciprocating compressor. I fabricated all the rest of the equipment locally in Peru. I patterned my design using a lot of the IPEC design that I had seen and studied while running the Jamaica Carbonics IPEC plant in Kingston, Jamaica previously before arriving in Peru. I followed Bob Graff's basic concepts with some slight modifications. I employed plain solid Stripper plates, like IPEC. I tried 6 plates and then 10 and found no difference. I also used tunnel caps on six trays and found no difference. I used all the LP condensate to scrub absorber exhaust gas and this plant went on to achieve an MEA consumption of 0.5 kg/tonne CO2 produced - a record in Liquid Carbonic for a pure MEA CO2 plant. I also employed a 12-15% wt. MEA solution instead of 20%wt. and reduced all corrosion within the MEA circulation system. This plant went on to produce efficiently for approximately 24 years before being de-commissioned because it was no longer needed. The only exotic material of construction used in its fabrication was a 304 SS Reboiler tube bundle. After confronting some field practical problems with kettle Reboiler U-tube bundles in Jamaica, I redesigned the Lima Reboiler tube bundle. In Jamaica we discovered that it was practically impossible to obtain a U-Tube bundle perfectly aligned horizontally. Because of fabrication tolerances and measurements as well as bundle deformations and heat distortions, the U-shape ("hair pin") did not maintain itself perfectly while installed. This mean that the top tubes were either sometimes sloped upwards or downwards. This is an important anomaly that is not discussed nor contemplated in heat transfer texts or classrooms when dealing with steam being condensed in a horizontal hair pin. Note that should the hair pin be sloped UPWARDS, formed condensate in the top of the hair pin will have a tendency to drain BACK towards the tube entrance and block the entry of fresh steam. And should the hair pin slope DOWNWARDS, the condensate will simply collect at the bottom of the tube's return and form a liquid blockage there. Either of these effects will hinder and ultimately cause reduced heat transfer and/or haphazard operation of the Reboiler. And this was exactly what was detected in the Jamaican plant operation. It was cured with the substitution of the conventional "U" tube bundle with a "V" type of fabrication - as shown in the illustration below. With this modification, the Jamaican and Lima Reboilers worked exactly as calculated and predicted, with no fluctuation in heat transfer.

It will be noted by those engineers with some amine plant experience that the above designed operations are in distinct difference with designs and fabrications of such illustrious engineering firms like Fluor, Brown & Root, and many others who always propose and build Amine absorbers and Strippers with at least 20+ very sophisticated trays or packings. They also insist on employing a so-called "Reflux" of condensate on the CO2 Stripper. What none of the design or process engineers with these firms have ever been able to explain, prove, or calculate to me is the factual and engineering REASONS for doing what they do. They just do it that way because they have always done it. Yet, they cannot explain the logical and engineering need to have a so-called "Reflux" in what is nothing more than a stripping operation of a non-condensable gas from a liquid solution. What, if any, purpose there is in such a futile attempt is left unspoken. No one has yet to explain why the Reflux is needed at the top of a CO2 (or an H2S) stripper. The real truth is: IT ISN'T - AND NEVER WAS - REQUIRED. The

many IPEC and Girdler plants that were built and operated have proven this throughout the last 70+ years. And I have followed this principle and proved it in all the plants I designed, built, and operated as well. What is really embarrassing is that practically all major text books on gas purification - as well as most authors of journal articles - fail to see or recognize this false and useless engineering design in amine plant design. All that a "Reflux" of condensate can accomplish in the CO 2 stripper is a "scrubbing" of the ascending vapors in the top section of the tower in order to avoid entrainment of MEA in the overheads. But if that is a necessity, then why not design the stripper and its diameter such that there is no entrainment in the first place? The Strippers I operated and designed never produced any entrainment - inspite of the inherent excess steam (water vapor) in the overheads due to using all of the boiler's steam production in the Reboiler tube bundle. Authors such as Kohl, Reisenfeld, Neilsen, Campbell, and Maddox - all intelligent and learned engineers - have failed to detect what is an obvious mistaken design that is useless and does absolutely nothing to improve an amine plant's operation. However, a guy like Bob Graff did spot this in 1950 and incorporated a much simpler and fool-proof method. If one goes to the trouble of using a McCabe-Thiele method of designing a CO2 Stripper, it will be quickly noted that building a CO2 Stripper with 20 trays - whether bubble cap, sieve type, or valve type - is an IGNORANT ENGINEERING OVERKILL. There is definitely no need for so many trays in an MEA Stripper. And thank goodness for that! There are enough troubles and problems to worry about in an MEA process without having to put up with investment, care, and maintenance of so many engineered trays. The latest actors in Amine Plants - such as DEA, MDEA, and even aMDEA - have the characteristic of being selective in absorbing H 2S with preference over CO2 and are actively used in Sour Gas applications. These solutions also demonstrate a propensity for easily having H2S stripped out of solution in the Stripper. Therefore, they should require less trays than even an MEA Stripper.

Вам также может понравиться

- Conversion of SulfinolSM To BASF's aMDEAДокумент12 страницConversion of SulfinolSM To BASF's aMDEAAna Carolina AbrantesОценок пока нет

- Ammonia Equvments DrawingДокумент43 страницыAmmonia Equvments DrawingSaad KhanОценок пока нет

- TEP03 Part4 AbsorptionДокумент28 страницTEP03 Part4 AbsorptionEK63Оценок пока нет

- Hydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)Документ18 страницHydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)yliangcaОценок пока нет

- Hydrocarbon Processing - Specifying Internals in Sour Water Strippers Part 1 (29dec2020) - 3 Jan 2021Документ13 страницHydrocarbon Processing - Specifying Internals in Sour Water Strippers Part 1 (29dec2020) - 3 Jan 2021achraf ahassanОценок пока нет

- Steam Reforming Carbon FormationДокумент26 страницSteam Reforming Carbon FormationBilalОценок пока нет

- Air Separation Unit Atmospheric AirДокумент2 страницыAir Separation Unit Atmospheric Airv.satyanarayana EthaОценок пока нет

- Catacarb Section, Dawood Hercules Fertilizers LimitedДокумент16 страницCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- Part II Cases of Piperazine-Activated MDEA and Generic MDEAДокумент2 страницыPart II Cases of Piperazine-Activated MDEA and Generic MDEAShailesh LohareОценок пока нет

- Molecular Sieve RegenerationДокумент3 страницыMolecular Sieve RegenerationEbby Onyekwe100% (1)

- Antifoam + Activated Carbon Filter For AGRUДокумент1 страницаAntifoam + Activated Carbon Filter For AGRUElton SitumeangОценок пока нет

- Amine Treating UnitДокумент3 страницыAmine Treating UnitBeergson2Оценок пока нет

- Contamination in Amines 2010Документ14 страницContamination in Amines 2010NS MurthyОценок пока нет

- FCC GCU Stripper RevampДокумент5 страницFCC GCU Stripper RevampRavi NookalaОценок пока нет

- 05 - 2 Heat Balance - Practice Problem - InstructorДокумент31 страница05 - 2 Heat Balance - Practice Problem - Instructorsawitri diah ayu komala100% (2)

- Shift CatalystДокумент8 страницShift Catalystraju100% (3)

- 4 Fundamentals of Gas Sweetening by K F Butwell and L Kroop PDFДокумент32 страницы4 Fundamentals of Gas Sweetening by K F Butwell and L Kroop PDFnasreenakhtariОценок пока нет

- Celanese PFD of MethanolДокумент1 страницаCelanese PFD of MethanolJessica CehОценок пока нет

- RT PDFДокумент2 страницыRT PDFsri9987Оценок пока нет

- Atmospheric CO2 To MethanolДокумент16 страницAtmospheric CO2 To MethanolMUTHU KESHAV KОценок пока нет

- SelexolДокумент2 страницыSelexolandrez627Оценок пока нет

- GTC Lidong TrainingДокумент90 страницGTC Lidong TrainingBladeDongОценок пока нет

- Amine Filtration in Natural Gas Processing Operations.Документ6 страницAmine Filtration in Natural Gas Processing Operations.Pervaiz RizviОценок пока нет

- Documents - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront EndДокумент28 страницDocuments - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront Endnafees ahmadОценок пока нет

- Drier Bed SizingДокумент14 страницDrier Bed SizingvkumaranОценок пока нет

- Ammonia Synthesis Material Balence CalulДокумент1 страницаAmmonia Synthesis Material Balence CalulDhruv RanaОценок пока нет

- Gbhe Ammonia Co2 Removal Systems WSV PDFДокумент20 страницGbhe Ammonia Co2 Removal Systems WSV PDFAaserElkenanyОценок пока нет

- Comtaminents in Amine Gas Treating UnitДокумент13 страницComtaminents in Amine Gas Treating Unitarvindgupta_2005Оценок пока нет

- CEeNews2 04 PDFДокумент6 страницCEeNews2 04 PDFJohn AnthoniОценок пока нет

- API 12j SizingДокумент1 страницаAPI 12j SizingAdewunmi OlufemiОценок пока нет

- MDEAДокумент13 страницMDEAAbdulla Alsowaidi100% (1)

- A Guide of Refinery ProcessДокумент1 страницаA Guide of Refinery ProcessSubramani DuraikannuОценок пока нет

- Process DescriptionДокумент6 страницProcess Descriptionافكر اشتري كورياОценок пока нет

- Distillation Column ReboilerДокумент13 страницDistillation Column ReboilerLouie GresulaОценок пока нет

- Reclamation Q & AДокумент11 страницReclamation Q & AchomiОценок пока нет

- Aiche-36-021Equipment Performance of AmmoniaДокумент9 страницAiche-36-021Equipment Performance of AmmoniaHsein Wang100% (1)

- Viscosities of Pure and Aqueous Solutions of Monoethanolamine (MEA), Diethanolamine (DEA) and N-Methyldiethanolamine (MDEA)Документ8 страницViscosities of Pure and Aqueous Solutions of Monoethanolamine (MEA), Diethanolamine (DEA) and N-Methyldiethanolamine (MDEA)Shahid HussainОценок пока нет

- Simulation of Ammonia Production From Synthesis GaДокумент12 страницSimulation of Ammonia Production From Synthesis Gasagar dasguptaОценок пока нет

- Calculation Procedure For Determination of Approach To Equilibrium For The Methane Reforming ReactionДокумент11 страницCalculation Procedure For Determination of Approach To Equilibrium For The Methane Reforming ReactionmadhunaОценок пока нет

- Comparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnДокумент7 страницComparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnianphilanderОценок пока нет

- Presentation Slides - Amine Sweetening Process FlowsДокумент10 страницPresentation Slides - Amine Sweetening Process FlowsEslam ShiblОценок пока нет

- DRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEOДокумент7 страницDRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEOMohsen ArdestaniОценок пока нет

- Understanding Gas Treatment FundamentalsДокумент8 страницUnderstanding Gas Treatment Fundamentalsazotik1985Оценок пока нет

- SAS Engineering Process PackagesДокумент54 страницыSAS Engineering Process PackagesDewa Yuniardi FullОценок пока нет

- Catalyst PoisonsДокумент21 страницаCatalyst PoisonsXuanMaiBuiОценок пока нет

- Product Data Sheet - MDEAДокумент4 страницыProduct Data Sheet - MDEACHANADAS100% (1)

- Amine Sweetening Unit Simplified Design EquationsДокумент20 страницAmine Sweetening Unit Simplified Design EquationsPragathees Waran100% (1)

- Catalytic Reforming: 2011 Refining Processes HandbookДокумент3 страницыCatalytic Reforming: 2011 Refining Processes HandbookGaspar BlaserОценок пока нет

- Auto Thermal Reactor:: Secondary ReformerДокумент6 страницAuto Thermal Reactor:: Secondary ReformerAtif MehfoozОценок пока нет

- Automated Operation of Topsoe Steam Reformers LTMДокумент8 страницAutomated Operation of Topsoe Steam Reformers LTMrajuОценок пока нет

- Dow Solvent Technologies For CO 2 RemovalДокумент25 страницDow Solvent Technologies For CO 2 RemovalWajid NizamiОценок пока нет

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechДокумент31 страницаEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- Sour Water Strippers - Design and OperationДокумент6 страницSour Water Strippers - Design and Operationyusoffd100% (3)

- TRCO Changes of Cryogenic Amine Plants 20110912Документ18 страницTRCO Changes of Cryogenic Amine Plants 20110912johnjoswОценок пока нет

- Engro Fertilizer ReportДокумент46 страницEngro Fertilizer ReportSher Muhammad100% (1)

- FTДокумент29 страницFTNitin HansaliaОценок пока нет

- W VishДокумент52 страницыW VishVikram Kumar VishОценок пока нет

- CO2 RemovalДокумент8 страницCO2 RemovalVinh PhamthanhОценок пока нет

- Acrylic Acid 2Документ36 страницAcrylic Acid 2Virbhadrasinh PuwarОценок пока нет

- MM Refrigeration-IIAR 2006 Conference-CO2 Cascade Refrigeration SystemsДокумент40 страницMM Refrigeration-IIAR 2006 Conference-CO2 Cascade Refrigeration SystemsHarsha Vardhan BОценок пока нет

- Installed Flow CharacteristicsДокумент4 страницыInstalled Flow CharacteristicscymyОценок пока нет

- Live Solution Tank ExampleДокумент6 страницLive Solution Tank ExamplecymyОценок пока нет

- Counter Current Heat Exchanger CarnahanДокумент4 страницыCounter Current Heat Exchanger CarnahancymyОценок пока нет

- Air Standard Cycle - Off Design 2: W - AC (KJ/S)Документ8 страницAir Standard Cycle - Off Design 2: W - AC (KJ/S)cymyОценок пока нет

- Problem 8.6 L (160.67F)Документ3 страницыProblem 8.6 L (160.67F)cymyОценок пока нет

- Combustion Equilibrium Calculations: A1 A2 A3 A4Документ6 страницCombustion Equilibrium Calculations: A1 A2 A3 A4cymyОценок пока нет

- Nox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetДокумент13 страницNox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetcymyОценок пока нет

- Air Standard Cycle - Design Conditions: W - AC (KJ/S)Документ6 страницAir Standard Cycle - Design Conditions: W - AC (KJ/S)cymyОценок пока нет

- Problem 10.9bДокумент2 страницыProblem 10.9bcymyОценок пока нет

- SI - Real Gas - Design: VariablesДокумент9 страницSI - Real Gas - Design: VariablescymyОценок пока нет

- Air Standard Cycle With HRSG Supplemental Firing: Overall Energy Balance MethodДокумент6 страницAir Standard Cycle With HRSG Supplemental Firing: Overall Energy Balance MethodcymyОценок пока нет

- Linear Data Reconciliation: Narasimhan and Jordache (2000)Документ1 страницаLinear Data Reconciliation: Narasimhan and Jordache (2000)cymyОценок пока нет

- Mass Flowrates and Weight %: Styrene FlowsheetДокумент1 страницаMass Flowrates and Weight %: Styrene FlowsheetcymyОценок пока нет

- Example 6.16aДокумент1 страницаExample 6.16acymyОценок пока нет

- Knopf: Ammonia Process FlowsheetДокумент1 страницаKnopf: Ammonia Process FlowsheetcymyОценок пока нет

- Example 5.6aДокумент1 страницаExample 5.6acymyОценок пока нет

- 0.25 Reaction N + 3H NH: Ammonia Material Balance Using Gauss Jordan Elimination and Newton RaphsonДокумент1 страница0.25 Reaction N + 3H NH: Ammonia Material Balance Using Gauss Jordan Elimination and Newton RaphsoncymyОценок пока нет

- Feed Reactor in Reactor Out Product Vapor Out Recycle Purge RHSДокумент1 страницаFeed Reactor in Reactor Out Product Vapor Out Recycle Purge RHScymyОценок пока нет

- Problem 5.6a Ammonia Process - Energy Balance For Mixer Into R2Документ1 страницаProblem 5.6a Ammonia Process - Energy Balance For Mixer Into R2cymyОценок пока нет

- X (0) X (1) X (2) RHS X X X: Newton-Raphson Method All VBA CodeДокумент1 страницаX (0) X (1) X (2) RHS X X X: Newton-Raphson Method All VBA CodecymyОценок пока нет

- Turbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetДокумент14 страницTurbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetcymyОценок пока нет

- CGAM Problem - Ideal Gas: Variables PhysicalДокумент6 страницCGAM Problem - Ideal Gas: Variables PhysicalcymyОценок пока нет

- Trigger 0 (Either 0 To Reset or 1 To Iterate) Iterations 0.00000000 Reaction Iteration Count X 10Документ1 страницаTrigger 0 (Either 0 To Reset or 1 To Iterate) Iterations 0.00000000 Reaction Iteration Count X 10cymyОценок пока нет

- Multiple Unit Operations: Linear Data ReconciliationДокумент1 страницаMultiple Unit Operations: Linear Data ReconciliationcymyОценок пока нет

- Cvode: Initial y ComponentsДокумент1 страницаCvode: Initial y ComponentscymyОценок пока нет

- Turbine Combustion Kinetics PFR-1 : CVODE Starts at Line 100 On EXCEL SheetДокумент14 страницTurbine Combustion Kinetics PFR-1 : CVODE Starts at Line 100 On EXCEL SheetcymyОценок пока нет

- Problem 5.5dДокумент16 страницProblem 5.5dcymyОценок пока нет

- Example 3.10Документ1 страницаExample 3.10cymyОценок пока нет

- Western Indian PlywoodДокумент77 страницWestern Indian PlywoodtawahidОценок пока нет

- Procedure of Boiler Acid Cleaning: and Flushing & PassivationДокумент4 страницыProcedure of Boiler Acid Cleaning: and Flushing & PassivationSteve Wan100% (2)

- IAWPS GUIDELINES ON Instrumentation-2015Документ25 страницIAWPS GUIDELINES ON Instrumentation-2015prakashОценок пока нет

- Rishu NewДокумент37 страницRishu NewAbhay AswalОценок пока нет

- Bidang Keahlian Teknika (Att-Ii) Tingkat ManajemenДокумент7 страницBidang Keahlian Teknika (Att-Ii) Tingkat ManajemenGopi SivasamyОценок пока нет

- VWH 400 Marine Boiler ManualДокумент130 страницVWH 400 Marine Boiler ManualPavarut SanjitОценок пока нет

- The Case For Blue HydrogenДокумент9 страницThe Case For Blue HydrogenAnjani100% (1)

- High Pressure FGSSДокумент5 страницHigh Pressure FGSSYoon SDОценок пока нет

- Takoradi Cooling ReportДокумент73 страницыTakoradi Cooling ReportAdil DemiralpОценок пока нет

- Mep QB Jan 2010 Apr 2016Документ37 страницMep QB Jan 2010 Apr 2016Harish KumarОценок пока нет

- Glow Worm Flexicom SX Boiler User GuideДокумент16 страницGlow Worm Flexicom SX Boiler User Guidehallgate1Оценок пока нет

- ThermoДокумент3 страницыThermoSara FloresОценок пока нет

- Acmas Product CatalogДокумент40 страницAcmas Product CatalogSeetanshu AwasthiОценок пока нет

- Statim 2000 & 5000 - SM R3Документ20 страницStatim 2000 & 5000 - SM R3Luis EsparzaОценок пока нет

- 07 Sarkki FosterWheeler PDFДокумент23 страницы07 Sarkki FosterWheeler PDFJose Roberto Vicencio CisternasОценок пока нет

- Babcock Btube Failure AnalysisДокумент8 страницBabcock Btube Failure AnalysisaakashtrivediОценок пока нет

- O&M Boiler and Aux NITДокумент136 страницO&M Boiler and Aux NITefficiencycell edomgОценок пока нет

- Expansion Tank Sizing Calculation Hydronic SystemДокумент16 страницExpansion Tank Sizing Calculation Hydronic SystemNay Myo OoОценок пока нет

- CV Zeeshan RehmanДокумент4 страницыCV Zeeshan RehmanStameco EnergyОценок пока нет

- Man B&W 6L23/30A Project GuideДокумент166 страницMan B&W 6L23/30A Project GuideArtemiy100% (6)

- Boiler Soot BlowerДокумент35 страницBoiler Soot BlowerParthiban Karuna0% (1)

- Liqui-Cel Technical Brief Ammonia in Flue Gas Condensate For Biomass Power Stations LC-1004 CelumДокумент2 страницыLiqui-Cel Technical Brief Ammonia in Flue Gas Condensate For Biomass Power Stations LC-1004 CelumOkko NОценок пока нет

- After Burning Phenomenon As The Cause of HP and MP Steam Superheater Tube Burst During Plant Start Up 2002Документ6 страницAfter Burning Phenomenon As The Cause of HP and MP Steam Superheater Tube Burst During Plant Start Up 2002varatharajan g rОценок пока нет

- Clyde Bergemann PDFДокумент6 страницClyde Bergemann PDFenjineringОценок пока нет

- Recovery Boiler Water Treatment: January 2007Документ44 страницыRecovery Boiler Water Treatment: January 2007thiagoОценок пока нет

- Electric Boilers: Learning OutcomeДокумент8 страницElectric Boilers: Learning OutcomeKaustabha DasОценок пока нет

- KKS Missing ListДокумент15 страницKKS Missing ListKasthuri CoimbatoreОценок пока нет

- Additional Work Cost Data 15.12.17 PDFДокумент141 страницаAdditional Work Cost Data 15.12.17 PDFdhiwakarОценок пока нет

- 2e Handing Over Note Satinder Pal SinghДокумент14 страниц2e Handing Over Note Satinder Pal SinghSriram SridharОценок пока нет

- ASHRAE Terminology - Complete ListДокумент382 страницыASHRAE Terminology - Complete ListJose Luis ZIMICОценок пока нет