Академический Документы

Профессиональный Документы

Культура Документы

1964 AFM Relationship Between Substrate Concentration, Growth Rate and Respiration Rate of E. Coli in Continuous Culture

Загружено:

vewmИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1964 AFM Relationship Between Substrate Concentration, Growth Rate and Respiration Rate of E. Coli in Continuous Culture

Загружено:

vewmАвторское право:

Доступные форматы

Archly fiir Mikrobiologie 48, 1--20 (1964)

Michigan State University, East Lansing, Michigan

Relationship between Substrate Concentration, Growth Rate, and Respiration Rate of Escherichia coli in Continuous Culture*

By I~ARL I~. SIJtIULZE a n d ROBERT S. LIPE With l l Figures in the Text

(Received December 28, 1963)

I n batch culture it is very difficult to establish a relationship between substrate concentration and growth rate for a given type of microorganism. As long as the substrate is in ample supply growth will proceed at a constant maximum rate according to the equation x = Xoek~t (1) or (2) In (X/Xo) = kit and 1 dx ln2 k 1 --- - (3) x dt g where k 1 = specific growth rate, i.e. growth rate per unit cell weight per unit time. x 0 = cell concentration at t = 0. g = mean doubling time or generation time. k 1 will become dependent on the substrate concentration only when most of the substrate has been consumed. At this point the culture has practically reached its maximum density and the remaining substrate concentration changes rapidly, leaving no time for the measurement of growth rates at any specific substrate level. This difficulty can be overcome by the use of the continuous flow culture under complete mixing conditions. Equations defining the cell concentration and the substrate concentration in the reactor as well as the specific growth rate at steady state conditions have been developed by Mo~oD (1950), N o w c K and SZILA~D (1950) and H ~ m m T , ELSWO~TH and T~LLI~G (1956). The equations state t h a t

kl = / I v = I)

(4)

where lq ] v D

= = = =

specific growth rate flow rate of nutrient solution volume of reactor dilution rate = inverse of detention time

* Material contained in this paper was submitted as a thesis in partial fulfillment of the requirements for the P h . D . degree of Dr. R. S. LIVE.

Arch. Nikrobiol., Bd. 48 1

E~L

L. SCHULZE and ROBEI~T S. LIPE:

a~ Y S' S, k~,

= cell concentration in reactor or effluent at steady state conditions = substrate concentration in reactor or effluent at steady state conditions ~ yield factor = unit weight of cells formed per unit weight of substrate

used

= substrate concentration in feed solution = substrate concentration at which k i = k,~/2 = maximum growth rate for the given set of conditions.

From these equations it follows that under steady state conditions 1. the cell concentration in the reactor is determined by the yield factor Y and the difference between ingoing and outgoing substrate concentration (equation 5). The investigator can therefore choose the cell concentration at which he wants to operate merely by varying the substrate concentration in the feed solution. This is important because at high eel1 concentrations the oxygen supply may become a limiting factor for aerobic cultures. 2. the growth rate is equal to the dilution rate as long as steady state conditions are maintained (equation 4). Since the volume of the reactor is constant the growth rate is determined by the feed rate and can be varied simply by varying the feed rate. This provides a convenient means of establishing the relationship between substrate concentration and k 1. Decreasing the feed rate results in a decrease of D = k i and this produces a decrease in substrate concentration due to the increased contact time. Corresponding to a given D or k i value the culture will therefore automatically establish a definite substrate concentration in the reactor as long as the given set of conditions remains unchanged. The system can thus be operated at a series of steady state low substrate concentrations, i.e. in the range where k 1 is dependent on S. The basic balance equation for the reactor is:

d x/dt = kl x - - D x.

(7)

Obviously D cannot exceed the value of kl if steady state is to be maintained. At

D > k~, dx/dt is negative and the cell concentration in the reactor will therefore

decrease progressively with time until eventually no cells are left. This provides a means of establishing k~ from continuous flow data. One has only to increase D to the point where the cell concentration in the reactor begins to show a steady decline. The basic equation relating substrate concentration and k s which has b e e n e m p l o y e d t o d e v e l o p e q u a t i o n (5) a n d (6) is :

T h i s is f o r m a l l y e q u a l t o a n a d s o r p t i o n i s o t h e r m or t o t h e MichaelisM e n t e n e q u a t i o n w h i c h is u s e d in e n z y m e k i n e t i c s . T h e b a c t e r i a l cell is t h u s c o n s i d e r e d as a n e n z y m e m o l e c u l e r e a c t i n g w i t h t h e s u b s t r a t e S. S~ c o r r e s p o n d s t o t h e M i e h a e l i s - M e n t e n c o n s t a n t a n d r e p r e s e n t s t h e subs t r a t e c o n c e n t r a t i o n a t w h i c h t h e r e a c t i o n v e l o c i t y , i.e. t h e g r o w t h r a t e k 1 r e a c h e s i/2 o f i t s m a x i m u m v a l u e . T h e c u r v e is h y p e r b o l i c a n d km w o u l d be r e a c h e d a t i n f i n i t e s u b s t r a t e c o n c e n t r a t i o n . TEISSIER (1936) p r o p o s e d a d i f f e r e n t t y p e of e q u a t i o n

d k i / d S = c (k,~ - - kl)

(9)

(10)

or integrated

k~ = k,. (1 e -ca).

Substrat~ concentration growth and respiration rate in continuous culture

This expression is formally similar to the equation of a first order reaction where ]c I increases with increasing substrate concentration proportionally to k m- k~. Experimental curves demonstrating the relationship between growth rate and substrate concentration have been published by several authors and for several growth limiting factors such as glucose, mannitol and lactose (MO~OD 1942, 1949), tryptophan (NovlcK 1955) and phosphate (ScHuLZE 1956). All these curves are of the same general shape where the growth rate asymptotically approaches a maximum value with increasing concentration of the limiting factor. Either one of the equations

(8) or (10) could r e p r e s e n t these curves. So far a decision b e t w e e n t h e t w o f o r m u l a t i o n s has n o t b e e n m a d e p r o b a b l y d u e to t h e fact t h a t t h e experim e n t a l d a t a were insufficient. P a r t l y because of t h e reason j u s t m e n t i o n e d a n d p a r t l y because t h e Michaelis-Menten e q u a t i o n is m o r e co n v en i en t , t h e d e v e l o p m e n t of t h e continuous flow e q u a t i o n s has been b ased e x c l u s i v e l y on e q u a t i o n (8). I n t h e following an a t t e m p t is m a d e to t e s t t h e v a l i d i t y of e q u a t i o n s (8) a n d (10) b y n u m e r i c a l analysis of e x p e r i m e n t a l data. As a c o n s e q u e n c e n ew s t e a d y s t a t e e q u a t i o n s defining cell- a n d s u b s t r a t e c o n c e n t r a t i o n based on e q u a t i o n (10) will be developed. I n a d d i t i o n t h e e x p e r i m e n t a l d a t a will be used to establish m a t h e m a t i c a l relationships b e t w e e n g r o w t h rate, o x y g e n c o n s u m p t i o n r a t e a n d t h e r a t e of s u b s t r a t e r e m o v a l .

Materials and Methods

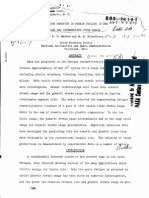

In the experimental apparatus two different pyrex reaction chambers were used; one with a constant culture volume of 1 1 for the higher feed rates and the other with a volume of 31 for the very small feed rates. The temperature of the reaction chamber was maintained at 30 C 0.5 C by means of a constant temperature water bath. The system used for providing the reaction chamber with a constant supply of substrate is labelled system A in Fig. 1. The feed solution was pumped from a 201 storage bottle by means of a Sigmamotor Model T65 pump. By closing clamp A in System A the flow of the feed solution was directed down into a burette and the feed rate was determined as ml/min with the aid of a stop watch. The system used for the aeration of the culture in the reaction chamber is shown as System B in Fig. 1. Compressed air controlled by a pressure regulating valve set at 51,6 mm Hg was passed through a Wet Test meter in order to measure the flow rate and then through a large sterile cotton filter before entering the reaction camber. Two fritted glass diffusors were used as aeration devices. The dissolved oxygen range obtained during the experiments was 0.5--4.8 ppm, in other words, the dissolved oxygen concentration did not decrease below 0.5 rag/1 at any time. The rate of air supply, varied from 1.01 per liter reactor volume per rain at small D values to 3.1 1 per liter reactor volume per rain at the higher D values. The air passing through the unit not only served as an oxygen supply but also as a mixing device to thoroughly mix the incoming substrate with the cell suspension in the reaction chamber. Effluent from the reaction chamber was discharged through a 1/4'+overflow tube which also served as the air exit line. The system for the sampling of culture from the reaction chamber is shown as system C in Fig. 1. In order to obtain a sample clamp B was closed, clamp C was 1"

KArL L. SC~VLZ]~ and ROBERT S. LIFE: opened and the liquid sample drawn into a sample container by means of a vacuum. Clamp C was then dosed, d a m p B opened and the liquid remaining in system C was returned to the reaction chamber. All parts of this apparatus were sterilized in an autoclave at 15 lbs. pressure for at least 30 min. The reaction chamber, aeration system, sampling system, and feed system were sterilized together. The other parts of the apparatus were sterilized separately and connected to the rest of the system by means of three-inch pieces of sterile, heavy rubber tubing. The composition of the nutrient solution was as follows (g/l) : Glucose 1.0; Urea 0.5; KH2PO 4 0.14; MgSO 4 0.03; FeS04 0.005; CaC12 0.01 ; Yeast extract 0.01. The px~ was adjusted to 7.0 by adding 100 ml of 0.1 N sulfuric acid to each 20 1 of the medium.

o~D'JemB

/g

f I.--

,Yj/slemS'

l /2

II

7Fig. 1. Schematic diagram of continuous flow unit. System A: nutrien~ supply, I pump, 2 graduated burette, 3 clamp. System B: air supply, g Wet-Test meter, 5 air filter, 6 needle valve, 7 diffuser. ,System C: sampling, 8 'and 9 clamps, 10 and 11 air filters, 12 two-way stopcock, 13 samDling tube, 14 growth chamber, 15 water bath, 16 overflow line

The amount of each constituent in the medium was such that nitrogen, phosphorus, magnesium, iron, calcium and nutrflites (supplied by the yeast extract) were present in excess. The intention was to make glucose the only growth limiting factor. Initially several strains of bacteria isolated from sewage were tested. However these were found unsuitable because of clumping, sticking to the sides of the reaction chamber, inconsistent growth or a tendency to settle. The organism finally selected was a strain of Escherichia cell obtained from Dr. E. D. DEVE~EUX, Department of Microbiology and Public Health, Michigan State University. After a short adapt a t i o n period this organism was found to be well suited for use in the continuous flow system. Its growth was evenly dispersed with no tendency to clump or to stick t o the sides of the reaction chamber. The following analytical determinations were made daily during the operation of the continuous flow unit: 1. Glucose -- by a photometric adaptation of the Somogyi method as given by NELSON (1944). 2. Cell concentration -- from a calibration curve relating optical density and rag/1 cell dry weight at a wave length of 350 m#. 3. Dissolved oxygen -- according to the standard Winlfler method (Standard Methods for the Examination of Water, Sewage and ~ndustrial Wastes, 1955). 50 ml of sample from the reactor vessel were used for each determination.

Substrate concentration growth and respiration rate in continuous culture

-

4. Oxygen uptake rates in a circular 20 unit Warburg apparatus using the standard procedure recommended by UMBREITeta]. (1957). 5 ml samples of the cell suspension from the reactor were placed in 6 Warburg flasks which were operated in parallel and three manometer readings were taken at 5 or 10 min intervals. For most D-values this procedure was repeated on 2 or 3 successive days. 5. p~ -- PH determinations were made three or four times daily using a Beckman Model H-2 pH-meter. Due %o the production of acid by the organisms it was necessary to adjust the PH of the culture by adding sterile 0.1 N sodium hydroxide solution three to four times daily from a 500 ml bottle connected to the reactor. This procedure maintained the pH in the reactor between 6.4 and 7.0. Contaminationwas checked by frequent microscopic examination of wet mounts and Gram stained preparations of the reactor cell suspension under the oil immersion lens. When contamination did occur the unit was shut down, cleaned, sterilized, and inoculated again with a pure stock culture. On the bacterial cell material total nitrogen was determined according to the A.0.A.C. Official I~Iethods of Analysis (1950). Ash determinations were made in an electric muffle furnace heated to a low red heat (650~ Viable cell counts were obtained by a drop-plate procedure reported by M~LMANN and BROIT~AN(1956). This procedure is based on the premise that colonies will appear on a suitable medium from each culturable cell placed on the medium.

Results

Values for /% were first established from a e r a t e d b a t c h cultures b y p l o t t i n g log cell d e n s i t y versus t i m e as shown i n Fig. 2. The initial substrate c o n c e n t r a t i o n was 980 mg/1 glucose, so t h a t s u b s t r a t a was n o t a l i m i t i n g factor. The first set of d a t a (Flask A) was o b t a i n e d 7 from the original culture of I x, ~ o E. coli used i n s t a r t i n g the .~8 c o n t i n u o u s flow experiments. 2 1 5 .z,,~----8 F o r the second set of d a t a ~Y (Flask B) cell m a t e r i a l which h a d been m a i n t a i n e d i n con-~ t i n u o u s flow culture for a period of 3 m o n t h s was used as in_g" 3 oculum. This served as a check 2 I [ I I I against the possibility of m u #or~'A 2 3 r ,58 7 t a t i o n a l changes in the growth //o's-,.('8 / 2 3 g 5 # f/me-hou~ rate of the E. coli strain d u r i n g :Fig.2 ]~atch culture d e t e r m i n a t i o n o f kin. A) Before c o n t i n u o u s flow culture. The use in continuous flow culture; B) A f t e r use in continuous flow culture slopes of the lines were comp u t e d b y the m e t h o d of least squares a n d resulted i n k m = 0.67 a n d 0.69 for F l a s k A a n d B respectively. A statistical t-test comparing the two slopes showed t h a t the difference b e t w e e n t h e slopes was n o t significant; t = 3.008 as c o m p a r e d to 3.335 at the 1 ~ p r o b a b i l i t y level for 8 degrees of freedom.

KAI~L L. SCHULZE a n d ROBERT S. LIPE:

In experiment No. i the continuous flow unit was operated at a series of D-values ranging from 0.06 to 0.85 per hour by varying the feed rate. Each feed rate except at the highest and lowest level was maintained for 3 days to obtain steady state conditions. Average data for cell- and substrate concentration in the reactor and for the oxygen uptake rates are listed in Table i. In experiment No. 2 the test was repeated with D-values ranging from 0.06 to 0.73 as shown in Table 2. The tables demonstrate

Table 1. Experiment No. 1 Avg. substrate cone. in feed = 964 rag/1 glucose, temp, 30~

D 1

hr-1 0.059 0.091 0.124 0.177 0.241 0.302 0.358 0.425 0.485 0.546 0.610 0.662 0.725 0.792 0.852

rag/1 5.1 8.3 13.3 20.3 30.4 37.0 43.1 58.0 74.5 96.5 112.0 161.0 195.0 266.0 386.0

cells cone. rag/1 422 429 431 428 421 433 420 420 413 433 426 434 396 311" 156"*

Qo~3 mg/g

cellwt/hr 48.6 74.3 100.0 150.0 202.0 269.0 322.0 356.0 379.0 448.0 478.0

yield factor mg/gkcell wt

per hour 134 203 274 390 534 647 785 917 1,043 1,091 1,220 1,225 i ,420

glucose oxidized

505.0

487.0 500.0 490.0

0.440 0.449 0.453 0.453 0.451 0.467 0.455 0.464 0.465 0.499 O.500 0.540 0.515

34.0 35.0 34.3 35.5 35.8 39.5 38.0 36.2 33.8 38.2 37.0 39.0 32.4

* after 20 hrs operation. ** after 12 hrs operation. 1 avg. from 6 determinations. 2 avg. from 3 determinations. 8 avg. from 36--48 determinations. t h a t s t e a d y state conditions were m a i n t M n e d u p to a D-vMue of a b o u t 0.79. A t higher D-values the cell c o n c e n t r a t i o n i n the reactor b e g a n to decline c o n t i n u o u s l y . This leads to the conclusion t h a t the v a l u e of km should be close to 0.79 u n d e r c o n t i n u o u s flow conditions. This e s t i m a t e for k~ is significantly higher t h a n t h a t f o u n d from b a t c h culture data. As has been p o i n t e d out b y EE~BE~T et al. (1956) the reason for this difference is p r o b a b l y the fact t h a t the actual wash-out rate of cells is less t h a n t h a t g i v e n b y e q u a t i o n (7). E q u a t i o n (7) is based on the a s s u m p t i o n

of instantaneous complete mixing in the reactor. It is reasonable to expect that the experimental apparatus HI only approach these theoretical conditions.

Substrate concentration growth and respiration rate in continuous culture

A plot showing the relationship b e t w e e n growth rate/c 1 a n d s u b s t r a t e c o n c e n t r a t i o n S for r u n ~qo. 1 is given i n Fig. 3. The curve d e m o n s t r a t e s t h a t ]cI increased with increasing s u b s t r a t e c o n c e n t r a t i o n a n d a s y m p t o t i c a l l y ~pproached a m a x i m u m value a t a s u b s t r a t e c o n c e n t r a t i o n of Tuble 2. Experiment No. 2 Avg. substrate cone. in feed 968 mg/l glucose, temp. 30~ D = k~ hr-~ 0.06 0.12 0.24 0.31 0.43 0.53 0.60 0.66 0.69 :0.71 0.73 S rag/1 6.0 13.0 33.0 40.0 64.0 102.0 122.0 153.0 170.0 221.0 210.0 cell cone. rag/1 427 434 417 438 422 427 434 422 430 390 352

0.5'-g.8 0.~ 0.2 '

//0 80

~ I I ~ I

~B

120

1#0

~00

Fig.3. Relationshipbetweensubstrate concentration and growth rate. Comparisonbetween epxerimental data and theoretical curves, o experimentaldata, exp. No. 1

a b o u t 220 mg/1 glucose. ]3elow this level kl was d e p e n d e n t on s u b s t r a t e c o n c e n t r a t i o n . To test the v a l i d i t y of e q u a t i o n s (8) a n d (10) the following w a y was chosen. E q u a t i o n (8) can be r e a r r a n g e d to

1/,~1 = 1I/~,,, + s:I/~,,, x 113

(11)

'This is the e q u a t i o n of a strMght Yme, y = a + bx, where the y-intercept would be equal to 1//c~, the x-intercept = - - 1/S~ a n d the slope b equal to

S~/I~. The curve o b t a i n e d from p l o t t i n g 1/k 1 versus 1/S from the d a t a ,of r u n No. 1 i n this m a n n e r is shown i n Fig. 4. This is e q u i v a l e n t to the Lineweaver-Burke a n d WEBB I958) used i n e n z y m e kinetics. T o o b t a i n the line of best fit the c o n s t a n t s a = 1/k~ a n d b = S~/k,~ were calculated b y the least squares m e t h o d resulting i n /c~ = 0.92 a n d N~ ~ 73. The same procedure was followed using d a t a from r u n No. 2 with the results k~ = 1.05 a n d S~ = 99. The relationship b e t w e e n ]cI a n d

plot (Dixon

according to e q u a t i o n (8) is therefore given b y kl = 0.92 ( 7 - ~ - f f ) or (12)

kl= 1.05(9 ~

(12a)

KARL L. Sc~uLz]~ a n d ROBERT S. LIFE:

I n testing equation (10) the problem again was to determine values for k~ and c from a set of experimental data. Several rather involved methods to obtain these constants have been described (REED and THER~AVLT 1931; T~O~AS 1937; ~OORE et al. 1950). One of the simpler procedures is the method of averages (HO]~LSC~[E~, A ~ O L D and PI]~o]~ 1952). Equation (9) can be rewritten as

dIqld,S : c lc~ - - c k 1

(13)

This is the equation of a straight line y' : a' - - c x' where

y" ~ dI~l/dS; a' ~ c k ~ ; x" = 1cl; c ~

constant.

The y-intercept is equal to a ' ~ c k ~ , the x-intercept ~- k~ and the slope : c. A plot o f L l k l / A S versus kl is shown in Fig. 5, demonstrating t h a t the

0. 012

!

0.010 0.0081

/0/2-

"I

O.OOg

~ ~

o o

0"002f,

0

-//

/ o

/2

/G

20

0.2

Fig, 5, Plot of

0.//

k s k~-I

O.B

0.8

l/~X iO8

]Rig.4. 1)lot of 1]k, ~ersus 1/s

Ak~/ASversus k~

experimental data fit a straight line reasonably well. The line of best fit as obtained b y the method of averages resulted in km ~ 0.76 and c ----0.014 for run No. I and k m = 0.77 and c ---- 0.012 for run No. 2. The relationship between k 1 and S according to equation (10) is therefore given b y ~l = 0.76 (1 -- e-~176~)

or

(14) (14a)

/c1 = 0.77 (1 -- e-~176 ~)

~or comparison with the experimental data from run No. 1 curves employing equations (12) and (14) were plotted as shown in Fig. 3. Both curves fit the experimental data. I n general curve B representing equation (14) shows a closer agreement with the experimental results. The main point however is t h a t the numerical analysis of a set of experi-

Substrate concentration growth and respiration rate in continuous culture

mental data using equation (8) resulted in values for the constants k~ and S~ which could not be verified by the experiment. At a D value of 0.85 (Table 1) no steady state was possible, indicating that k,~ values of 0.92 or 1.05 were considerably out of range. The same was true for the S~ values. According to equation (8), S n represents the substrate concentration at which k1 reaches 1/2 of km. The experimental data show that this point should correspond to about 50 mg/1 glucose, whereas equations (12) and (12a) provide values of 73 and 99 mg/1. I n contrast the kw values of 0.76 and 0.77 obtained from a numerical analysis of the data according to equation (10) agree well with a critical dilution rate near 0.79 as indicated by the loss of steady state conditions. Furthermore equation (10) produces a value of S - = 49 for kI = k w / 2 which is in agreement with the experimental data. According to the boundary conditions equation (5) is not valid for D > kw. However as mentioned previously the net rate of increase or loss of cells from the reactor under complete mixing conditions is given by equation (7). Under the reasonable assumption that at D > k~ the cells continue to grow at a rate equal to kw we obtain:

d x N t = (k,~ - D) x

(15a) (16)

The portion of cells remaining in the reactor after time t will then be

xt/x~ = e ( ~ m - - b ) t

where x, = cell concentration in reactor after time t, rag/l; x~ = initial cell concentration, rag/l; t ~ time, hours. The equation shows that the rate at which the cell concentration decreases in the reactor depends on how much D exceeds kw. I n experiment No. 1 the system was 300 operated at D = 0.85 for 12 hrs starting at an initial cell concentration of 311 mg/J at "~. t = 0. Checks on the cell concentration were E 20o - - o '%'~ ~..,~ made 2.7, 7 and 12 hrs after D had been ~ q increased to 0.85. Using equation (16) theo~ /00 rctical cell concentrations were calculated for k~ = 0.76. The results as shown in r I r J z/ 8 /2 0 Fig.6 demonstrate a fair degree of ?)me, hours agreement between the theoretical curve F i g . 6 . W a s h - o u t o f cells, D ~ 0.85, and the actual decrease in cell concen- k m = 0.76, e x p e r i m e n t No. 1. .... theoretical curve; tration. o experimental data

The yield/actor

The yield factor Y is given by the ratio of the weight of bacterial cells produced to the weight of substrate consumed per unit time. The continuous flow technique provides a very convenient means of establishing

10

K A r L L. SCHUnZV. a n d ROBERT S. L~']~:

Y a t a series of v a r y i n g g r o w t h r a t e s k s. The a m o u n t of s u b s t r a t e cons u m e d is given b y (S' - - S) t i m e s m l feed p e r h o u r a n d t h e a m o u n t of cells p r o d u c e d is given b y t h e cell c o n c e n t r a t i o n 2 t i m e s m l feed p e r hour. T h e flow r a t e s cancel o u t a n d

sz,._ s'----~

(t7)

T h e Y-values o b t a i n e d for r u n No. 1 are l i s t e d in c o l u m n 5 of T a b l e 1. T h e d a t a show t h a t Y i n c r e a s e d f r o m 0.44 a t a k 1 v a l u e of 0.06 to 0.54 a t a k 1 v a l u e of 0.66. This m e a n s t h a t a t low g r o w t h r a t e s 1/]( ~ 2.27 g glucose were c o n s u m e d in t h e p r o d u c t i o n of i g cell m a t e r i a l whereas a t high g r o w t h r a t e s o n l y 1/Y --~ 1.85 g glucose were c o n s u m e d p e r g r a m cell weight p r o d u c e d . I t a p p e a r s t h a t a t high g r o w t h r a t e s s u b s t r a t e was m o r e efficiently c o n v e r t e d t o cell m a t e r i a l . This m a y be r e l a t e d to t h e phenom e n o n of endogenous r e s p i r a t i o n . A similar increase of t h e y i e l d f a c t o r has been d e m o n s t r a t e d b y I ~ E ~ B ~ T (1958 a) for Aerobacter aerogenes a n d for Torula utilis.

Relationship between

k1

and respiration rate

The oxygen consumption rates obtained from Warburg measurements for a series of D values in r u n No. 1 are listed in c o l u m n 4 of T a b l e 1 a n d a p l o t of Qo, versus D is shown in Fig. 7. Since i t was p r e v i o u s l y demons t r a t e d t h a t D ~ k 1 for values u p to 0.79 t h e curve shows t h a t t h e 500 o o r e s p i r a t i o n r a t e was d i r e c t l y prop o r t i o n a l t o t h e g r o w t h r a t e k 1. ~zoo A similar r e s u l t was o b t a i n e d b y o HERB]~T (1958b) for A. aerogenes. 300 T h e curve follows t h e e q u a t i o n

_ /o

200

/00

0

/

02

Qo~ = b + d k1 (18) where Qo~ = oxygen consumption rate, mg OUg cell wtlhr; b = y-intercept, representing Qo~ at k1 = O; d = slope.

0.~ 0.8 08

O=kz; hm~

Nig.7. Relationship between growth rate kl and respiration rate

U s i n g t h e least squares m e t h o d v a l u e s of b = 16 a n d d -----770 were obtained from the experimental d a t a so t h a t (19)

Qo, = 16 ~- 770 kl and ks__ Qo~ - 16 770

(20)

I n general t h e d a t a d e m o n s t r a t e t h a t t h e r e s p i r a t i o n r a t e of b a c t e r i a l cells c a n v a r y over a large scale from 16 m g 02 p e r g r a m cell w e i g h t p e r

Substrate concentration growth and respiration rate in continuous culture

11

hour at k 1 = 0, i.e. when the cells are not growing, to about 500 mg 03 per gram cell weight per hour at the m a x i m u m growth rate. Isolated determinations of the respiration rate in bacterial cultures therefore do not mean much, since the rate depends on the conditions of the culture existing at the time the measurement was made. Thus the respiration rate of 390 mg 02 per gram cell weight per hour at 32~ given by SPEOTO~ (1956) for E. coli would correspond to a growth rate of 0.49 under the experimental conditions described here. I t is believed t h a t Qo, --- 16 represents the endogenous respiration rate of the strain of E. eoli used in the experiments described here. Apparently there exist considerable variations in endogenous respiration rates for different species of bacteria. The value deduced from the curve shown by I~ER]~E~ (1958b) for A. aerogenes is b ~ 100. From this it appears t h a t A. aerogenes has an extremely high endogenous respiration rate. The curve shown in Fig. 7 further demonstrates t h a t Qo, reached its m a x i m u m value at D ~ kr and t h a t Qo, was independent of D at D values larger t h a n k~. This supports the concept t h a t the cells continued to grow at a rate equal to k~ when D was larger t h a n the critical dilution rate D c. I n addition equation (20) shows t h a t it is possible to compute growth rates from respiration rates if the endogenous rate and the slope are known.

Rate o/ substrate uptake

The rate of substrate consumption per gram cell weight per hour can easily be calculated from continuous flow data:

~2 / s' - / 8 (21)

v2

where k~ ---- specific rate of glucose uptake in mg per gram cell weight per hour. The resulting values are shown in column 6 of Table 1. The actual oxygen consumption can then be compared with t h a t required for complete oxidation of the glucose consumed b y the cells. This comparison should provide an estimate of the fraction or percentage of glucose which was oxidized. The data listed in column 7 of Table 1 show t h a t these values varied between 32.4 and 39.5 ~ A plot of the actual rate of oxygen consumption (Qo..) versus the stoiehiometric amount of oxygen required for complete oxidation of the substrate consumed (k2) is shown in Fig. 8. The data fit a curve Qo~ : b x" (21a) where b = slope = fraction of substrate oxidized; x" = oxygen required for complete oxidation of substrate consumed. Using the least squares method the slope was found to be 0.37. This means t h a t independent of the growth rate 37 ~ of the glucose assimilated were actually oxidized in the metabolic process.

12

K A R L L , SCHULZE a n d ROBERT S. LI]?E:

T h e d a t a for k a listed in c o l u m n 6 of T a b l e 1 can also be u s e d t o establish a r e l a t i o n s h i p b e t w e e n g r o w t h r a t e a n d t h e r a t e of s u b s t r a t e u p t a k e . A plot of/c a versus D ~ k 1 is shown in Fig. 9. T h e curve d e m o n s t r a t e s t h a t k S increases in d i r e c t p r o p o r t i o n to t h e g r o w t h r a t e following t h e e q u a t i o n

k,=n+h

k1

(22)

where n ----y-intercept, representing grams of glucose uptake per gram ceil weight per hour at k1 ----0. 5'0O ,h 50O

o o

_ o

1//00 .~ IZO0

O

~

~ J00

Joe

-o c o

I000

" ~ 800 600

200

tl-00

800

800

1000 1200

O~repul'r'eo'for eomflete oxidclt/on/ 1T~I ]mr

:Fig. 0, Relationship between actual rate of oxygen uptake a n d the stoiehiometrie amount of oxygen required for complete oxidation of the substrate assimilated. Slope = 0.87

Fig.9. Relationship between growth rate kl a n d rate of substrate uptake k2

~00

200

, 1 ~ I ~ I ,

02 Fig. 9

a//

08

D=/~ ~ kr-j

h - ~ c o n s t a n t , r e p r e s e n t i n g g r a m s glucose c o n s u m e d p e r g r a m cell weight formed. U s i n g t h e least squares m e t h o d values for n = 0.055 a n d h -= 1.91 were o b t a i n e d so t h a t kS = 0.055 -~ 1.91 k1 (23)

The c o n s t a n t h r e p r e s e n t s t h e inverse of a y i e l d c o n s t a n t Y' which has been c o r r e c t e d for m a i n t e n a n c e s u b s t r a t e c o n s u m p t i o n . A c c o r d i n g t o this concept t h e a n a l y s i s o f t h e curve in F i g . 9 p r o d u c e s a v a l u e of Y ' = 1/h = 0.52 which is c o n s t a n t over t h e full r a n g e of g r o w t h rates. The specific r a t e of s u b s t r a t e r e m o v a l can therefore be e x p r e s s e d as

k 2 = n + k U Y'

(24)

a n d t h e g r o w t h r a t e can be r e l a t e d to t h e r a t e o f s u b s t r a t e r e m o v a l b y k 1 = Y' (k~ -- n) (25)

Substrate concentration growth and respiration rate in continuous culture

13

By substituting equation (20) into equation (24) the rate of substrate removal can also be related to the rate of oxygen consumption as follows : /~=n-~ Qo~- 16 770Y' (26)

Furthermore since /c1 is related to the substrate concentration by equation (8) or (10) the substrate removal rate can now be expressed in terms of substrate concentration b y

k e=nd:Y'\S~dS/

(27) (28)

or by 4 = n ~ (1 - e-c~) Y

These equations would allow to predict the substrate removal rate at a given substrate concentration if the constants n , Y ' , tc~ and S~ or c are known. Thus for n = 0.055, k~ = 0.76, and Y' = 0.52 a maximum value for the substrate removal rate of ks = 1.51 g glucose per gram cell weight per hour is obtained from equation (24) which is in agreement with the values actually measured as shown in Table 1, column 6. These aspects of microbial activity are very important in the waste treatment field and will be discussed in a separate publication. In the development of continuous flow equations the growth rate is usually assumed to be a constant fraction of the substrate consumption rate dx/dt = - - Y" ds/dt (29) and inversely the rate of substrate consumption is given by

ds/dt = - - d x / Y " dt = - - ]clx/Y"

(30)

Now it appears that equation (30) has to be modified b y a small amount of substrate consumption which is evident even if no growth occurs. I n the case described here this amount would be n = 55 mg glucose per gram cell weight per hour so that

ds/dt = - - (nx ~- I~lx/Y' )

(31) (31 a)

and

ds/xdt = k 2 = - - (n ~- k l / Y ' )

which is identical ~dth equation (24) developed from the curve in Fig. 9. This means that at a substrate removal rate of/c 2 = 0.055, k1 would be zero. I t appears that this is an expression for the "maintenance" supply of bacterial cells since the consumption of 55 mg glucose per gram cell weight per hour would be just enough to sustain the cell metabolism but not enough to allow growth and reproduction. These conclusions received additional support from the investigation of the behaviour of the continuous flow culture at very low feed rates.

14

KArL L. SC~ULZ]~ and ~:~OBERT S. LIPE:

C o n t i n u o u s / l o w culture at low D v a l u e s

From equation (5) it follows that the cell concentration in the reactor should reach its maximum value as D approaches zero : x = Y S'. I n experiment No. 3 the continuous flow unit was operated at decreasing feed rates so that the D values ranged from 0.081 to 0.011 per hour. The results are listed in Table 3. The data indicate that steady state conditions were maintained down to a D value of 0.02 which corresponds to a k 1 value of 0.02, a generation time of In 2 / k 1 = 34.6 hours and a retention time of l I D = 50 hrs. As expected the substrate concentration in the

Table 3. Experiment No. 3 Continuous flow culture at low D values. Avg. substrate conc. in feed 966 rag/1 glucose. Avg. pI~ in reactor 6.6 days of operation 1 st 3rd 5th 7th 12th 17th 22 nd 31 st 37 t h

Dlhr

0.081 0.062 0.052 0.02 0.02 0.011 0.011 0.011 0.011

cell conc. mg/1 438 422 442 422 434

380

rag/1 6.2 5.0 4.1 O-- 1 O-- 1

0 -- 1

rate of substrate supply mg/g cell wt/hr 178 142 116

46

45

steady

state

355 314 293

0--1 0--1 0--1

28 30 34 36

nonsteady state

reactor decreased to near zero. The unit was operated for 5 days under these conditions. When the feed rate was decreased to D = 0.011, the eel1 concentration began to drop off to 380 rag/1 after 5 days and to 293 mg/l after 25 days of operation. Apparently under these conditions the rate of loss of cells was greater than the rate of reproduction and k~ must have decreased to a value near zero. The rate of substrate supply in mg glucose per gram cell weight per hour as found by D S' 103/2 is given in column 5 of Table 3. According to these data steady state operation at least for 5 days was possible down to a supply rate of 45 nag glucose per gram cell weight per hour. When the supply rate decreased to 28 mg glucose per gram cell weight per hour at D =- 0.011 the growth rate approached zero. The supply rate in this case can be set equal to the removal rate since practically no substrate was lei~ in the effluent. Apparently under these conditions the rate of substrate supply was not sufficient to allow cell reproduction even at a rate of k1 = 0.011. Going back to the results obtained from a plot of k 1 versus k2 in Fig. 9 it will be noted that a basic substrate removal rate of n = 55 mg glucose per gram cell weight per hour was indicated at k1 = 0. ttere in experiment No. 3 the loss of steady

Substrate concentration growth and respiration rate in continuous culture

15

state conditions occurred as soon as less than 45 mg glucose per gram cell weight per hour were consumed. Thus these data support the idea t h a t a certain minimum consumption rate of the energy supplying substrate is needed just to maintain the cells and t h a t active growth begins at consumption rates above this level. Evidently additional experiments would be needed to determine the exact value of n, i.e. whether it would be closer to 55 or to 45 mg glucose per gram cell weight per hour. Recently MARR, NILSO~ and CLA~K (1963) investigated the maintenance requirement ofE. coli by using a somewhat different modification of equation (29) : dx/dt + ax = Y" ds/dt (32) where " a " has the dimension of reciprocal time and is designated as the specific maintenance rate. Dividing equation (32) b y x yields: dx/x dt + a = Y" ds/x dt (33) Since d x / x d t = k I and d s / x d t ---- k 2 we obtain a = Y'k2 -- k1 From equation (31 a) : (36)

n = k z - - k~/Y" = a / Y " (35) Thus it turns out t h a t our specific maintenance consumption rate n and the specific maintenance rate a can be easily converted into each other b y the yield coefficient Y'. Assuming Y' to be 0.52 we obtain a =- Y ' n - - 0.028 for the strain of E . coli used in our experiments. M A ~ et al. (1963) listed a ~- 0.018 for E . coli strain M L 3 0 and 0.028 for strain P S . The agreement between these values is surprisingly close. Apparently a represents the minimum value for the dilution rate D at which steady state is possible in a given case. Regardless of the specific value of n which m a y be obtained in any individual case, the experimental data show t h a t equation (5) is valid only between certain limits of D, in the case described here between D ~ 0.02 and D e ~ 0.76. Application o[ s t e a d y state e q u a t i o n s to e x p e r i m e n t a l d a t a

As mentioned previously the development of equations (5) and (6) defining steady state cell- and substrate concentrations was based on equation (8). Since it was found t h a t equation (10) fits the relationship between k 1 and substrate concentration better, new equations for 2 and ~' were developed using equation (10) as a basis. Solving equation (10) for S yields : k~

? -

(361

and substituting equation (36) for S in equation (5) results in: 2 = Y S'

[ 1~

(37)

16

K A R L L . SC~VLZE a n d

I%OB~RmS.

LIP~:

These equations should define the substrate concentration and the cell concentration in the reactor or effluent for any D value between 0.02 and D = / c ~ ff the constants ]ca, Y, and c are known. I n Figs. 10 and 11 the theoretical curves for S and 2 are compared with the corresponding experimental data from run No. 1. The curves demonstrate that the equations predict the substrate concentration in the effluent and the cell concentration in the reactor in good

800

6'00

"~/dOg

I''

% ZOO

02

Oq

08

~08

." %.r

Fig. 11

,I:.

Fig, 10

Fig. 10. Comparison of S values, computed from equation (36) ; o experimental d a t a Fig. 11. Comparison of s v a l u e s . - - c o m p u t c d from equation (37); . . . . . corrected for maintenance requirement, equation (42); o experimental d a t a

agreement with the experimental results. The agreement between experimental and theoretical substrate concentration is especially close. The discrepancies between the theoretical and the experimental cell concentrations are probably related to the fact that in equation (37) an average value for the yield factor was used, whereas, actually the yield factor decreased with decreasing D values. I f in addition to equation (10) equation (31) is also accepted this would necessitate a modification of equation (37). The balance equation ior the net rate of change of substrate concentration in the reactor used so far

was

increase = input -- output -- consumption

ds/dt ~ DS" -- DS -- klx/Y

(38) (39)

This would now be modified by the minimum consumption factor n:

ds/dt : DS" -- DS dsldt - - x ( n -~ k l / Y ' ) = 0

For steady state conditions where

we obtain

(40)

D (s' - ~) = ~ (~ + 4 / Y ' )

Solving for 2 and introducing k1 = D yields

:Y' (s, - ~)

--

n Y'

D ~-1

(41)

Substrate concentration growth and respiration rate in continuous culture Substituting equation (36) into (41) produces Y' S' = k~ n Y" D +1 D _

17

(42)

The equation is identical with equation (37) except for the correction factor (n Y'/D) @ 1. Using the constants evaluated previously n Y'=0.028. For high D values the correction would be small whereas at low D values the correction factor would decrease the cell concentration significantly. This is in general agreement with the experimental data. Using the same values for Y', 1% and c, ~5was computed according to equation (42) and the resulting curve plotted as a dotted line in Fig. 11. The graph demonstrates t h a t the introduction of the correction factor for maintenance substrate consumption produced an improved agreement between the theoretical and the experimental cell concentration. The analysis of the cell material grown in the reactor showed t h a t the average cell density of 422 mg/1 dry weight corresponded to 7 l0 s viable cells per ml. The nitrogen content was 12.1~ of dry weight and the ash a m o u n t e d to 8.5 ~ of dry weight.

Discussion Graphical and numerical analysis demonstrated t h a t the application of the Teissier equation resulted in close agreement with the experimental data, whereas, the application of the 5!ichaelis-?v[enten equation produced values for the constants k~ and S~ which could not be verified. Usually it is assumed t h a t Sn, the substrate concentration at which the growth rate reaches k~/2 has a very low value. Mo~-oD (1942) obtained S n = 2, 4 and 20 mg/l for mannitol, glucose and lactose respectively and t t E ~ E R T eta]. (1956) computed S~ = 12.3 mg/1 for glycerol as limiting substrate. I f S is computed from the newly developed equation (36) for D = k 1 = k~/2 a value of 49 rag/1 is obtained which is in agreement with the experimental data. Apparently the value of S~ depends on the type of substrate which constitutes the limiting growth factor and on the type of organism which is cultivated. Equation (36) can also be used to estimate the substrate concentration at which the m a x i m u m growth rate is attained and above which the growth rate becomes independent of the substrate concentration. For D = k~ the substrate concentration would be infinite. ]{owever, for practical purposes it would be sufficient to obtain the substrate concentration at which k 1 reaches 95 ~ of its m a x i m u m vahie. The resulting value of S is 214 mg/1 glucose which is in agreement with the experimental data.

Arch. ~{ikrobiol., ]~d. 48 2

18

KARLL. SC~VLZEand ROBERTS. LI~E:

Based on experimental work by MoNoI) (1942) it is usually assumed that the yield factor is constant and independent of the growth rate. I t is noteworthy, however, that all the yield factors determined by MONOD were relatively low, i.e. Y ---- 0.23 for E. coli with glucose as limiting substrate. In other words, 4.35 g of glucose were consumed in the formation of 1 g cell material whereas, in the case reported here only an average of 1.93 g of glucose were consumed in the formation of I g cell material. I t is possible, therefore, that the nutrient medium used b y ~O~OD was incomplete and that other limiting factors besides the carbohydrate were present. The fact that independent of the growth rate only 37 ~ of the glucose consumed were oxidized is in agreement with data reported by Po~GEs et al. (1956). These authors found in Warburg experiments with mixed bacterial cultures and skim milk as a substrate that at the point of complete substrate removal 37 ~ of the theoretical oxygen demand had been exerted. Based on this and on a simplified empirical molecular formula for bacterial cell substance they developed the following equation for the bacterial growth process: 8 (Ctt~O) -~ 302 -~ NH~-+ C~HTNO~~- 3C02 -~ 6H20 According to this equation in the consumption of 100 g carbohydrate 40 g 02 are respired and 47.1 g cell material are produced. This corresponds to 3/s or 37.50/0 of the amount of oxygen required for complete oxidation of the carbohydrate consumed and to a yield factor of Y' ~- 0.471. Since the empirical formula represents organic cell material without ash the yield factor would have to be increased to Y' -~ 0.51 ff an ash content of 8.50/0 is considered. This agrees well with the yield constant of 0.52 obtained from graphical analysis of substrate uptake data. In connection with the Warburg measurements calculation shbws that the supply of glucose present in the samples taken from the reactor should be exhausted in 5 to 13 rain at the prevailing rates of substrate removal. There is no doubt that in time the respiration rates of these cells would have declined toward the endogenous level. However the Warburg data showed that no significant decrease of the respiration rates occurred in the 15 to 30 rain period during which readings were taken. This leads to the conclusion that a certain amount of intracellular storage of substrate must be involved in the respiratory process. With regard to the cessation of cell reproduction at very low D values only few similar observations have been reported in the literature (HE~BERT 1958 b ; NOVICK 1958 ; JANNASCH 1963). OVICK (1958) mentioned that no steady state was possible when cultivating a tryptophane requiring mutant of E. coli at D values below 0.03. As an explanation, Novice: assumed that the bacteria went into a kind of lag state. MoNoD

Substrate concentration growth and respiration rate in continuous culture

19

(1942) had postulated t h a t theoretically a minimum substrate concentration (concentration d'entretien) should exist which would allow only maintenance of the cells. However, such a minimum substrate concentration could not be proven experimentally. Now it appears t h a t not the substrate concentration as such is the critical point but the minimum rate of substrate uptake below which the cells would not be capable of reproduction.

Summary

Using a continuous flow technique the relationship between growth rate and substrate concentration was investigated with glucose as the limiting factor of a culture of Escherichia coli. Graphical and numerical analysis of the experimental data demonstrated t h a t the application of the Nichaehs-Menten equation produced erroneous results, whereas, the constants obtained from the Teissier equation were in agreement with the experimental data. On this basis, new equations defining the steady state cell and substrate concentration in continuous flow cultures were developed and tested against experimental data. Comparison of the specific growth rates, substrate uptake rates and oxygen consumption rates demonstrated t h a t all were directly proportional to each other and could be related to each other b y mathematical equations. Specifically it was shown t h a t as the growth rate increased from 0.06 to k~ = 0.76 the substrate uptake rate increased from 134 to 1420 mg glucose per gram cell weight per hour and the oxygen consumption rate increased from 48.6 to 505 mg 02 per gram cell weight per hour. Independent of the growth rate 37 ~ of the carbohydrate consumed were oxidized. The yield factor varied from 0.44 at low growth rates to 0.54 at high growth rates. Analysis of the growth rate-substrate uptake rate relationship indicated t h a t a minimum substrate uptake rate of 55 mg glucose per gram cell weight per hour existed below which cell reproduction would cease. This was supported b y the fact t h a t steady state conditions could not, be maintained in the culture at D values below 0.02 when the substrate supply rate decreased below 45 mg glucose per g r a m cell weight per hour.

References

Dixon, M., and C. E. W~BB: Enzymes, p. 21. Academic Press Inc. (1958). HE~BnUT, D. : Continuous culture of microorganisms; some theoretical aspects. In: Continuous Cultivation of Microorganisms; A Symposium, p. 45--52. Prague: Czechoslovak Academy of Sciences (1958a). -- VII. Int. Congr. Microbiol. Syrup. 381--396, Stockholm (1958b). -- g. ELSWORTU,and R. TELLING:The continuous culture of bacteria; a theoretical and experimental study. J. gen. Microbiol. 15, 601--622 (1956). HOELSC~R, 1~., J. A~0LD, and H. Piracy: Graphic aids in engineering computation, p. 36. New York: McGraw-Hill 1952.

2*

20

Sc~ul~z]~and LIpS.: Substrate concentration growth and respiration rate

JA~INASClZ,H. W. : ]3akterielles Wachstum bei geringen Substratkonzentrationen. Arch. Mikrobiol. 45, 323--342 (1963). MAI~A~II~, W. L., and S. A. ]31~OITMA~ : A surface plating technique for determining bacterial population in milk. Amer. J. publ. Hlth 46, 1018--1020 (1956). MA~I~, A. G., E. H. NILSO~I, and D. J. CI~AI~K:The maintenance requirement of Escherichia coli. Ann. N.Y. Acad. Sci. 102, 536 (1963). Moron, J. : Recherches sur la croissance des cultures baeteriennes. 210 pp. Paris: Hermann and Cie. 1942. The growth of bacterial cultures. Ann. Rev. Mierobiol. 3, 371--394 (1949). La technique de culture continue; Th6orie et applications. Am1. Inst. Pasteur 79, 390--410 (1950). MOOl~E,E., H. T~olviAs, and W. S~ow: Simplified method for analysis of B.O.D. data. Sewage Ind. Wastes 22, 1343--1353 (1950). :NELson, N. : A photometric adaptation of the Somogyi method for the determination of glucose. J. biol. Chem. 153, 375--380 (1944). :NOVlCX,A. : Growth of bacteria. Ann. Rev. Microbiol. 9, 97--110 (1955). - - Genetic and physiological studies with the chemostat. In: Symposium on continuous cultivation of microorganisms, p. 29. Prague: Czechoslovak Academy of Sciences 1958. --, and L. SZILARD:Experiments with the chemostat on spontaneous mutation of bacteria. Proe. nat. Acad. Sci. (Wash.) 36, 708--719 (1950). Official methods of analysis. 7th ed., 910 pp. Washington 4, D.C. : Assoc. of Official Agricultural Chemists 1950. POl~GEs, N., L. JASEWlCZ,and S. Hoovm~: Principles of biological oxidation. In: Biological treatment of sewage and industrial wastes. Vol I., p. 35--48. New York: Reinhold Publ. Co. 1956. :REED, L. J., and E. J. T]t~XlAIILT:The statistical treatment of reaction velocity data. g. Phys. Chem. 35, 950--971 (1931). ;ScgvLZ~, K. L. : The effect of phosphate supply on the rate of growth and fa~ formation in yeasf0s. App]. Microbiol. 4, 207--210 (1956). ;SPEcTOl~,W. S. : Handbook of biological data. Phil., Pa. : W. ]3. Saunders Co. 1956. ~Standard Methods for the Examination of Water, Sewage and Industrial Wastes, 10Lh Ed. New York: Amer. Publ. Health Assoc., Inc. 1955. T]~ISSI]m,G.: Les lois quantitatives de la croissance. Ann. Physiol. physieochim. biol. 12, 527--586 (1936). T~o~As, H. H.: The slope method of evaluating the constants of the first stage biochemical oxygen demand curve. Sewage Works J. 9, 425--430 (1937). U~BI~IT, W., R ]3tmt~IS, and J. STAVSSm~: Manometric Techniques. 338 pp. Minneapolis, Minn. : Burgess Publ. Co. 1957.

-

Dr. K. L. Sc~uLz]~, Associate Professor, Division of Engineering Research, Michigan State University, East Lansing, Michigan, U.S.A. Dr. R. S. L1TE, Assistant Professor, Science Department, Southwest Missouri State College, Springfie]d, Missouri, U.S.A.

Вам также может понравиться

- 03 Chapter 03 AnswersДокумент5 страниц03 Chapter 03 AnswersDavion Stewart0% (1)

- Baranyi Et Al 1993 A Non-Autonomous Differential Equation To Model Bacterial Growth PDFДокумент17 страницBaranyi Et Al 1993 A Non-Autonomous Differential Equation To Model Bacterial Growth PDFCarlos AndradeОценок пока нет

- Growth KineticsДокумент3 страницыGrowth KineticsSanthosh KalashОценок пока нет

- Johnv. Elackay, Gleiss.: Apo2ChДокумент7 страницJohnv. Elackay, Gleiss.: Apo2ChagyaaОценок пока нет

- (Received: Biochimica Et Biophysica ActaДокумент11 страниц(Received: Biochimica Et Biophysica ActaCynthia MartinezОценок пока нет

- General Linking E. Coli Media CultureДокумент27 страницGeneral Linking E. Coli Media CultureFriska Amanda Nur LailiyahОценок пока нет

- Fermentation PDF NotesДокумент24 страницыFermentation PDF NotesJay-zee Shandu100% (5)

- Pnas00161 0050Документ8 страницPnas00161 0050Jonathan MoralesОценок пока нет

- Industrial Wastewater Treatment ThesisДокумент8 страницIndustrial Wastewater Treatment Thesisafktlrreerdihj100% (2)

- Physical Dependence On and Tolerance To Alcohol in The RatДокумент8 страницPhysical Dependence On and Tolerance To Alcohol in The RatJef_8Оценок пока нет

- Why Are Organisms Usually Bigger in Colder Environments? Making Sense of A Life History PuzzleДокумент5 страницWhy Are Organisms Usually Bigger in Colder Environments? Making Sense of A Life History PuzzleWater PigОценок пока нет

- Transient Growth KineticsДокумент14 страницTransient Growth KineticsCeeEeeОценок пока нет

- BARTON Protein Denaturation and Tertiary StructureДокумент2 страницыBARTON Protein Denaturation and Tertiary StructureIna de La FuenteОценок пока нет

- ChE514A Cell Kinetics and Fermenter DesignДокумент116 страницChE514A Cell Kinetics and Fermenter DesignAnonymous 0zrCNQ55% (11)

- Assessmentof Fetal Lungmaturity:Lecithin/ Sphingomyelinratiovs. Cortisoland Foam-Test AssaysДокумент4 страницыAssessmentof Fetal Lungmaturity:Lecithin/ Sphingomyelinratiovs. Cortisoland Foam-Test AssaysPatrick RamosОценок пока нет

- Landahl 1958Документ23 страницыLandahl 1958Mirela CiobanescuОценок пока нет

- CHEMOSTATДокумент2 страницыCHEMOSTATSamantha SwiftОценок пока нет

- Generate Bacterial Growth CurveДокумент63 страницыGenerate Bacterial Growth CurveHassan SheikhОценок пока нет

- A Simplified Method of Phytoplankton Counting: British Phycological JournalДокумент15 страницA Simplified Method of Phytoplankton Counting: British Phycological JournalAlejandro Giraldo ObregónОценок пока нет

- Batch Cellular KineticsДокумент7 страницBatch Cellular KineticsGarion CharlesОценок пока нет

- Mathematical Modeling of Intestinal Bacteria - Host InteractionsДокумент13 страницMathematical Modeling of Intestinal Bacteria - Host InteractionsDanielillo MirandaОценок пока нет

- Microbial Growth and Product FormationДокумент26 страницMicrobial Growth and Product FormationDP PurwadiОценок пока нет

- Abstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeДокумент55 страницAbstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeZarra FaktОценок пока нет

- Chemostat TheoryДокумент28 страницChemostat TheoryManavi AbrolОценок пока нет

- Lab Review 13 LabsДокумент37 страницLab Review 13 LabsPurePureMilkОценок пока нет

- Practical 12Документ7 страницPractical 125408 ManshaОценок пока нет

- Article of TempetatureДокумент16 страницArticle of TempetatureIrma SatyaОценок пока нет

- PNAS 1991 Eghbali 10701 5Документ5 страницPNAS 1991 Eghbali 10701 5Kash EvangelinaОценок пока нет

- Understanding Microbial Growth Kinetics in Batch FermentationДокумент16 страницUnderstanding Microbial Growth Kinetics in Batch FermentationI-hana D'yana100% (1)

- ACTION OF X-RAYS ON MAMMALIAN CELLSДокумент17 страницACTION OF X-RAYS ON MAMMALIAN CELLSEdward Ventura BarrientosОценок пока нет

- 8 Fed-Batch-Culture & ContinousДокумент30 страниц8 Fed-Batch-Culture & ContinousHasna MazidahОценок пока нет

- Protection Against Acetaldehyde Toxicity in The Rat by L-Cysteine, Thiamin and L-2-Methylthiazolidine-4-carboxylic Acid 1)Документ6 страницProtection Against Acetaldehyde Toxicity in The Rat by L-Cysteine, Thiamin and L-2-Methylthiazolidine-4-carboxylic Acid 1)Apocalypto StatumОценок пока нет

- Thermodynamics of Microbial Growth and MetabolismДокумент17 страницThermodynamics of Microbial Growth and MetabolismJeimy MaciasОценок пока нет

- Ideal Bioreactor EngineeringДокумент60 страницIdeal Bioreactor EngineeringAyesha RalliyaОценок пока нет

- Microbial EcologyДокумент17 страницMicrobial Ecologynhanhnafi5Оценок пока нет

- Application of Derivatives in Biomathematics PDFДокумент4 страницыApplication of Derivatives in Biomathematics PDFhafeez ahmed0% (1)

- Mic 21 1 40Документ11 страницMic 21 1 40Mohd Hafiz AhmadОценок пока нет

- Redfield Proportions are Optimal for Benthic Microalgal GrowthДокумент8 страницRedfield Proportions are Optimal for Benthic Microalgal GrowthCornelius HanungОценок пока нет

- Analysis of Detergent-Free Lipid Rafts Isolated From CD4 T Cell Line: Interaction With Antigen Presenting Cells Promotes Coalescing of Lipid RaftsДокумент13 страницAnalysis of Detergent-Free Lipid Rafts Isolated From CD4 T Cell Line: Interaction With Antigen Presenting Cells Promotes Coalescing of Lipid RaftsHeather BenjaminОценок пока нет

- (Received April 1988 Revision 26 Sept. 1988) : Minerals Engineering, Vol. 2, No. 2, Pp. 217-227, 1989Документ11 страниц(Received April 1988 Revision 26 Sept. 1988) : Minerals Engineering, Vol. 2, No. 2, Pp. 217-227, 1989alinoriОценок пока нет

- Archives of Pharmacology: Renal Handling of Oxalate A Micropuncture Study in The RatДокумент5 страницArchives of Pharmacology: Renal Handling of Oxalate A Micropuncture Study in The RatCLPHtheoryОценок пока нет

- Drying Technology: Please Scroll Down For ArticleДокумент32 страницыDrying Technology: Please Scroll Down For ArticlegetsweetОценок пока нет

- PIIS0022030261898548Документ11 страницPIIS0022030261898548TYSON PETRO JONATHANОценок пока нет

- New Microsoft Office Word DocumentДокумент27 страницNew Microsoft Office Word DocumentAlok PandeyОценок пока нет

- Cell Growth Lab Report Final DraftДокумент10 страницCell Growth Lab Report Final DraftKeithen CastОценок пока нет

- aa9a661c-bda5-4604-9a88-1d031359ee5fДокумент121 страницаaa9a661c-bda5-4604-9a88-1d031359ee5fNegese TeklearegayОценок пока нет

- 5 Bioprocess Engineering Ch 5Документ65 страниц5 Bioprocess Engineering Ch 5Abebe BesoОценок пока нет

- J Exp Med-1922-Warren-187-202Документ16 страницJ Exp Med-1922-Warren-187-202Anggun PermatasariОценок пока нет

- ToxicokineticsДокумент18 страницToxicokineticsSilvyОценок пока нет

- Lab 6Документ18 страницLab 6kaimanwatsoN100% (2)

- 5 Biochemical Engineering CH 5Документ64 страницы5 Biochemical Engineering CH 5Barnabas YohannesОценок пока нет

- 1934 - Gorfain - The Effect of Different Concentrations of Acetylcholine and HistaminДокумент7 страниц1934 - Gorfain - The Effect of Different Concentrations of Acetylcholine and HistamindnasdajkdnajfkОценок пока нет

- Toxicology and Applied Pharmacology: Kevin R. Smith, David Leonard, Jacob D. Mcdonald, Yohannes TesfaigziДокумент8 страницToxicology and Applied Pharmacology: Kevin R. Smith, David Leonard, Jacob D. Mcdonald, Yohannes TesfaigziCárdenas EfrainОценок пока нет

- Paper2005 PDFДокумент4 страницыPaper2005 PDFJoshua GatesОценок пока нет

- The Surface Tension of Mixtures of Methanol Acetonitrile Tetrahydrofuran Isopropanol Tertiary Butanol and Dimethyl Sulfoxide With Water at 25 C PDFДокумент22 страницыThe Surface Tension of Mixtures of Methanol Acetonitrile Tetrahydrofuran Isopropanol Tertiary Butanol and Dimethyl Sulfoxide With Water at 25 C PDFKatipot InkongОценок пока нет

- Binary Systems: Solubilities of Inorganic and Organic Compounds, Volume 1P1От EverandBinary Systems: Solubilities of Inorganic and Organic Compounds, Volume 1P1H. StephenОценок пока нет

- Cocinando HuevoДокумент14 страницCocinando HuevovewmОценок пока нет

- PQ Formulary PDFДокумент16 страницPQ Formulary PDFjcriveroОценок пока нет

- Complete Formulas PDFДокумент46 страницComplete Formulas PDFramu_uppada67% (6)

- Cascara de LimonДокумент8 страницCascara de LimonvewmОценок пока нет

- 1964 AFM Relationship Between Substrate Concentration, Growth Rate and Respiration Rate of E. Coli in Continuous CultureДокумент20 страниц1964 AFM Relationship Between Substrate Concentration, Growth Rate and Respiration Rate of E. Coli in Continuous CulturevewmОценок пока нет

- 1964 AFM Relationship Between Substrate Concentration, Growth Rate and Respiration Rate of E. Coli in Continuous CultureДокумент20 страниц1964 AFM Relationship Between Substrate Concentration, Growth Rate and Respiration Rate of E. Coli in Continuous CulturevewmОценок пока нет

- 1993 CRB Lignocellulose Biotechnology Current and Future Prospects DaniaДокумент22 страницы1993 CRB Lignocellulose Biotechnology Current and Future Prospects DaniavewmОценок пока нет

- Production of Xylanases by Immobilized Aspergillus SP Using Lignocellulosic WasteДокумент2 страницыProduction of Xylanases by Immobilized Aspergillus SP Using Lignocellulosic WastevewmОценок пока нет

- Barberel ThesisДокумент278 страницBarberel ThesisvewmОценок пока нет

- Libro. AlemanДокумент127 страницLibro. AlemanvewmОценок пока нет