Академический Документы

Профессиональный Документы

Культура Документы

Duct Design

Загружено:

Faquruddin AliИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Duct Design

Загружено:

Faquruddin AliАвторское право:

Доступные форматы

Ventilate Right Ventilate Right

New and Existing California Homes

Ventilation Guide for

Step 6Design the Duct System

When installing ventilation equipment, it is important to use large enough duct to achieve the rated flow of the ventilation system that you have designed. If the duct system is inadequate or poorly designed, no fan will deliver its rated air flow. You may need to use larger duct than you have in the past to actually get desired airflows. Virtually all fans provide more airflow with less noise when the duct is up-sized an inch or two, when smooth duct is used, and when duct runs are as straight as possible.

The larger the duct diameter, the greater the airflow. Replace 3" duct with 4" or 6" duct. Smooth, rigid duct delivers better airflow than metal flex duct. Metal flex duct performs better than plastic flex duct. Whenever possible, avoid designing a bend or elbow within two feet of the fan to minimize static pressure and fan noise. With metal duct, use wide-sweep elbows or bends to reduce the resistance to airflow. A fan with a 4" duct connection will perform much better with an adapter and 6" duct. Change out the wall cap or roof jack to a larger one at the same time, if possible.

When designing ducting for the whole-building ventilation system, it's important to be conservative. After the fan and ducting are installed, the whole-building fan must deliver at least the airflow required by ASHRAE Standard 62.2 (Step 3), so do everything possible to ensure good air flow. Attempting to use an existing fan and ductwork may be difficult, since most older fans were rated at lower static pressure: 0.1 in. w.c. instead of 0.25 in. w.c. Also, many older fans were ducted with 3 or 4 ducting, which usually decreases fan performance. The following are ways to design for good airflow in a whole-building ventilation system:

Use the largest possible duct diameter, preferably in smooth rigid duct rather than flex duct. Use the Prescriptive Duct Chart to estimate maximum duct lengths that will deliver the desired air flow. Choose a fan that is certified at 0.25 in. w.c. (not 0.1 in. w.c., which was the old standard for fan certification).

Avoid long duct runs and tight or multiple turns.

ASHRAE Standard 62.2 provides a table of maximum duct lengths to use to create no more than 0.25 in. w.c. of static pressure, which is the rating point for certified fans. Usually, using this table and good installation practices will provide the desired airflow. Table 5.3 shows the maximum combination of duct type, size, and fittings using the Equivalent Duct Length (EDL) method. Note that you must deduct 15 feet for each elbow in the duct system. One wall cap is assumed, so no deduction is made for the terminal device.

ASHRAE Std. 62.2 Table 5.3: Prescriptive Duct Sizing Chart

Maximum Length in Feet Fan Rating in cfm Certified @ 0.25 in. w.c. Flex Duct (cfm) 50 80 100 125 50 Smooth Duct (cfm) 80 100 125

Duct Diameter (inches)

n/a = not allowed: No use of this duct diameter will meet ASHRAE Standard 62.2 requirements. This table assumes no elbows. Deduct 15 feet (5 m) of allowable duct length for each elbow.

3 4 5 6 7 and above

n/a 70 no limit

n/a 3 70

n/a n/a 35 135

n/a n/a 20 95

5 105 no limit

n/a 35 135

n/a 5 85

n/a n/a 55 145

no limit no limit

no limit no limit no limit

no limit no limit no limit no limit no limit no limit no limit no limit

Ductwork Can Distribute Pollutants Throughout the House

Sometimes HVAC equipment or ducting is located in places where the air is polluted. If connections and ductwork are not well sealed, harmful pollutants may be pulled into leaky ducts and delivered throughout the house. Make sure all heating, cooling, and ventilation ducting is well sealed, especially in areas such as:

a garage where cars idle or toxic chemicals are stored an attic with loose-fill insulation, fumes from asphalt shingles, or rodent presence a damp crawlspace a basement hobby area

Locate Outdoor Air Intakes Carefully

If outdoor air intakes are located near pollutant sources, the ventilation air brought into a home can make indoor air quality problems worse. Locate outdoor air intakes at least 10 ft from pollutant sources such as:

barbeques trash cans dog runs busy streets combustion appliance vents or clothes dryer vents exhaust vents from fans places where a car idles

Title 24 Requirement

ASHRAE 62.2-2007 & ASHRAE 62.2-2010

When designing ducting for local exhaust ventilation, use the Prescriptive Duct Chart. Bath fans and kitchen range hoods can be sized prescriptively. As long as you meet the local exhaust ventilation requirements (Step 2) by installing the proper size fan and ducting, the local exhaust requirement is met.

Title 24 Requirement

ASHRAE 62.2-2007

When the air handler or return duct is located in thegarage, the ductwork for the HVAC system must be sealed to have air leakage of no more than 6% of the air handler airflow when measured at 0.1 in. w.c. (25 Pa, whether or not the air handler is used for ventilation.

ASHRAE 62.2-2010

When the air handler or return duct is located outside the pressure boundary, the ductwork for the HVAC system must be sealed to have air leakage of no more than 6% of the air handler airflow when measured at 0.1 in. w.c. (25 Pa), whether or not the air handler is used for ventilation.

Best Practice Recommendations

If you have flow testing equipment, its a good idea to measure the airflow of all fans, even if the code doesnt require it. Flow testing allows you to identify and solve problems with airflow rates and installation.

Seal all ductwork for HVAC equipment, no matter where it is located.

Вам также может понравиться

- Correct Duct SizingДокумент3 страницыCorrect Duct Sizingnim_gourav1997100% (1)

- G7.1 Air Conditioning EquipmentДокумент12 страницG7.1 Air Conditioning EquipmentAlex ChoongОценок пока нет

- Drainage - Junctions in DrainsДокумент2 страницыDrainage - Junctions in Drainsmeeng2014Оценок пока нет

- Fire Protection Systems PDFДокумент26 страницFire Protection Systems PDFabdullah sahibОценок пока нет

- Chapter 7 (ACMV)Документ140 страницChapter 7 (ACMV)engkankwОценок пока нет

- 3.ACMV (Air Cooled Split Unit) - PDFДокумент3 страницы3.ACMV (Air Cooled Split Unit) - PDFIswadi Bin ZulkarnainОценок пока нет

- Patna Merto ProjectДокумент37 страницPatna Merto ProjectSonu RdОценок пока нет

- Specialist Diploma in M&E Coordination: Cable Television (CATV) Lesson By: Lim Ee Kiong RCDD / NTS SpecialistДокумент63 страницыSpecialist Diploma in M&E Coordination: Cable Television (CATV) Lesson By: Lim Ee Kiong RCDD / NTS SpecialistSuthaОценок пока нет

- Bca Seminar OnДокумент15 страницBca Seminar Onwafa_salsabilaОценок пока нет

- CFD Assessment of Railway Tunnel Train FireДокумент16 страницCFD Assessment of Railway Tunnel Train FireodmanОценок пока нет

- SCADA Notes by Vijay Kumar Dubey (UNIT 1, 2 & 3)Документ42 страницыSCADA Notes by Vijay Kumar Dubey (UNIT 1, 2 & 3)Muzammil KhanОценок пока нет

- E&MДокумент37 страницE&Mrishabhbhagat100% (1)

- General Fire Safety ReportДокумент48 страницGeneral Fire Safety ReportBalgo BalgobinОценок пока нет

- Subway ReportДокумент89 страницSubway ReportMelijruth Valentino100% (1)

- Fire Safety Requirements For Persons With Disabilities Ms Goh Sia ImmДокумент39 страницFire Safety Requirements For Persons With Disabilities Ms Goh Sia ImmhutuguoОценок пока нет

- Approved Final Draft Spec TI SPC RCC SCADA 0134Документ101 страницаApproved Final Draft Spec TI SPC RCC SCADA 0134Anurag SanodiaОценок пока нет

- Measurement of High VoltageДокумент2 страницыMeasurement of High VoltageShahzaid AhmadОценок пока нет

- Tunnel Emer Egress & Mid-Train Fire - R3Документ15 страницTunnel Emer Egress & Mid-Train Fire - R3corson42100% (2)

- ADB AFG Tunnel Short TORДокумент12 страницADB AFG Tunnel Short TORSujatОценок пока нет

- Fire Sprinkler Design-Part2Документ2 страницыFire Sprinkler Design-Part2Henry SuarezОценок пока нет

- Fire Protection Overview2008Документ66 страницFire Protection Overview2008undertaker55100% (1)

- Tunnel Ventilation System OHДокумент44 страницыTunnel Ventilation System OHSonu RdОценок пока нет

- Is 13039 External Fire HydrantДокумент10 страницIs 13039 External Fire HydrantNanu PatelОценок пока нет

- Aironn English CatalogДокумент180 страницAironn English Catalogsloba68Оценок пока нет

- Comparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13Документ16 страницComparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13coolth2Оценок пока нет

- Deluge Valve SprinklerДокумент9 страницDeluge Valve SprinklerBrijesh SharmaОценок пока нет

- Cold Water Plumbing DesignДокумент17 страницCold Water Plumbing DesignKHA120096 StudentОценок пока нет

- FP Planning Requirements & Design GuidelineДокумент19 страницFP Planning Requirements & Design GuidelinelkakeanОценок пока нет

- Working Together: To Prevent Cable DamageДокумент16 страницWorking Together: To Prevent Cable DamageinnОценок пока нет

- Topic 3 ACMV (2012) StudentДокумент64 страницыTopic 3 ACMV (2012) StudentLuisLoОценок пока нет

- Fs2011 FullДокумент242 страницыFs2011 FullryankckoОценок пока нет

- Hose Stream Demands Part-1 PDFДокумент4 страницыHose Stream Demands Part-1 PDFHugo Mario Ariza PalacioОценок пока нет

- Keo ReportДокумент22 страницыKeo ReportJoshua EvansОценок пока нет

- BAFSA Technical Guidance No 1, November 2012Документ30 страницBAFSA Technical Guidance No 1, November 2012flegheton100% (1)

- Acmv Technical SpecificationДокумент40 страницAcmv Technical SpecificationRamakrishnanОценок пока нет

- BCA Green Mark For New Non-Residential Buildings Ver NRB.4.1Документ20 страницBCA Green Mark For New Non-Residential Buildings Ver NRB.4.1Nay Soe NaingОценок пока нет

- Acmv DesignДокумент10 страницAcmv DesignLuís AbreuОценок пока нет

- Water Based Suppression SystemsДокумент2 страницыWater Based Suppression SystemsdebasisdgОценок пока нет

- Duct Leakage TesterДокумент8 страницDuct Leakage TesterJay PresleyОценок пока нет

- Unit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Документ21 страницаUnit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Navya chowdaryОценок пока нет

- Tunnel Luminaires: Public Shopping Traffic Sports Industry OfficeДокумент20 страницTunnel Luminaires: Public Shopping Traffic Sports Industry Officeiai77Оценок пока нет

- ADC Section 4 - Commuter Facilities Design RequirementsДокумент127 страницADC Section 4 - Commuter Facilities Design Requirementsusernaga84Оценок пока нет

- Proper Engine Room VentilationДокумент2 страницыProper Engine Room VentilationAsok AyyappanОценок пока нет

- Technical Document On Smoke Extract & Car Park FansДокумент4 страницыTechnical Document On Smoke Extract & Car Park FansTanveer AzizОценок пока нет

- TCVN 7336-2003 Fire Protection Automatic Sprinkler System (En)Документ24 страницыTCVN 7336-2003 Fire Protection Automatic Sprinkler System (En)canniumОценок пока нет

- Fans For Metro Tunnel DesignДокумент34 страницыFans For Metro Tunnel Designkailasamvv100% (1)

- CO2 Sensor RoomДокумент8 страницCO2 Sensor RoomTrần Khắc ĐộОценок пока нет

- HVAC System OverviewДокумент150 страницHVAC System OverviewSeth Patrick ArceoОценок пока нет

- Designing A TunnelДокумент54 страницыDesigning A TunnelSumit RawatОценок пока нет

- Systemair CatalogueДокумент21 страницаSystemair CataloguePARVEZ AMEENОценок пока нет

- SES Presentation FinalДокумент65 страницSES Presentation FinalCurtis YehОценок пока нет

- Grease Interceptor Sizing Tool 22APR08Документ9 страницGrease Interceptor Sizing Tool 22APR08Aadii SoniОценок пока нет

- Vertical Openings Prevention: Means of EgressДокумент23 страницыVertical Openings Prevention: Means of EgressAhmed SowilemОценок пока нет

- Automatic Fire Extinguishing SystemДокумент33 страницыAutomatic Fire Extinguishing Systemlmt76Оценок пока нет

- Sizing An Exhaust FanДокумент1 страницаSizing An Exhaust Fanomar mohd zainiОценок пока нет

- Safety&Security RoadwayTunnelsДокумент102 страницыSafety&Security RoadwayTunnelsJjune96Оценок пока нет

- Jockey PumpДокумент1 страницаJockey PumpMajeed aliОценок пока нет

- Kidde AE Spec - ADS Using Novec 1230-01-2015Документ6 страницKidde AE Spec - ADS Using Novec 1230-01-2015kuraimundОценок пока нет

- Duct Design PDFДокумент3 страницыDuct Design PDFMassi MateenОценок пока нет

- Duct Design Myth BustersДокумент4 страницыDuct Design Myth BusterscphamfОценок пока нет

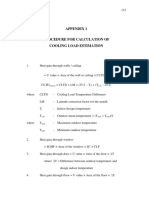

- 13 AppendixДокумент9 страниц13 AppendixFaquruddin AliОценок пока нет

- Ventilating Fan Specification Model FV-38CH8Документ3 страницыVentilating Fan Specification Model FV-38CH8Faquruddin AliОценок пока нет

- 12 Presentation SkalkoДокумент25 страниц12 Presentation SkalkoFaquruddin AliОценок пока нет

- Cooling and Dehumidifying AirДокумент5 страницCooling and Dehumidifying AirFaquruddin AliОценок пока нет

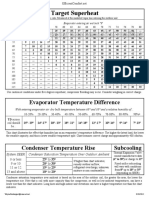

- Charging and TD Chart PlusДокумент1 страницаCharging and TD Chart PlusFaquruddin AliОценок пока нет

- Rules and Rules of Thumb For Duct SystemsДокумент1 страницаRules and Rules of Thumb For Duct SystemssauroОценок пока нет

- Mitsubishi Electric PURY-RP YJM-B Installation Manual EngДокумент20 страницMitsubishi Electric PURY-RP YJM-B Installation Manual EngFaquruddin AliОценок пока нет

- 5.6 Schedule of Electrical RequirementsДокумент7 страниц5.6 Schedule of Electrical RequirementsFaquruddin AliОценок пока нет

- Equipment and Systems - HVAC and Refrigeration PE Exam Tools - Mechanical PE Sample Exams, Technical Study Guides and ToolsДокумент35 страницEquipment and Systems - HVAC and Refrigeration PE Exam Tools - Mechanical PE Sample Exams, Technical Study Guides and ToolsFaquruddin AliОценок пока нет

- VRV SystemДокумент152 страницыVRV SystemKHA120096 StudentОценок пока нет

- Understanding Temperature and Altitude CorrectionsДокумент3 страницыUnderstanding Temperature and Altitude CorrectionsFaquruddin AliОценок пока нет

- Case Study Nicu PDFДокумент35 страницCase Study Nicu PDFFaquruddin AliОценок пока нет

- Microstrip Antennas: How Do They Work?Документ2 страницыMicrostrip Antennas: How Do They Work?Tebogo SekgwamaОценок пока нет

- Ruggedbackbone Rx1500 Rx1501Документ13 страницRuggedbackbone Rx1500 Rx1501esilva2021Оценок пока нет

- DS TEGO Polish Additiv WE 50 e 1112Документ3 страницыDS TEGO Polish Additiv WE 50 e 1112Noelia Gutiérrez CastroОценок пока нет

- WCN SyllabusДокумент3 страницыWCN SyllabusSeshendra KumarОценок пока нет

- C.F.A.S. Hba1C: English System InformationДокумент2 страницыC.F.A.S. Hba1C: English System InformationtechlabОценок пока нет

- Wind Flow ProfileДокумент5 страницWind Flow ProfileAhamed HussanОценок пока нет

- A 150.xx Service Black/ITU Cartridge Motor Error On A Lexmark C54x and X54x Series PrinterДокумент4 страницыA 150.xx Service Black/ITU Cartridge Motor Error On A Lexmark C54x and X54x Series Printerahmed salemОценок пока нет

- Corr Shield NT 4292Документ9 страницCorr Shield NT 4292Donatas BertasiusОценок пока нет

- Marc-André Ter Stegen PES 2021 StatsДокумент1 страницаMarc-André Ter Stegen PES 2021 StatsSom VasnaОценок пока нет

- Method Statement For Backfilling WorksДокумент3 страницыMethod Statement For Backfilling WorksCrazyBookWorm86% (7)

- (English) 362L Stereoselective Wittig Reaction - Synthesis of Ethyl Trans-Cinnamate (#7) (DownSub - Com)Документ6 страниц(English) 362L Stereoselective Wittig Reaction - Synthesis of Ethyl Trans-Cinnamate (#7) (DownSub - Com)moОценок пока нет

- Midterm Quiz 1 March 9.2021 QДокумент5 страницMidterm Quiz 1 March 9.2021 QThalia RodriguezОценок пока нет

- Torque Converter Lock-Up FunctionДокумент2 страницыTorque Converter Lock-Up Functioncorie132100% (1)

- 09 20 17Документ26 страниц09 20 17WoodsОценок пока нет

- MVC Plus User Manual REV5Документ90 страницMVC Plus User Manual REV5Adalberto FentanezОценок пока нет

- Food Truck Ordinance LetterДокумент7 страницFood Truck Ordinance LetterThe Daily News JournalОценок пока нет

- MAYA1010 EnglishДокумент30 страницMAYA1010 EnglishjailsondelimaОценок пока нет

- Ferrovial / BAA - A Transforming Acquisition: 3rd July 2006Документ38 страницFerrovial / BAA - A Transforming Acquisition: 3rd July 2006Andrew YangОценок пока нет

- Válvula DireccionalДокумент30 страницVálvula DireccionalDiego DuranОценок пока нет

- DRPL Data Record Output SDP Version 4.17Документ143 страницыDRPL Data Record Output SDP Version 4.17rickebvОценок пока нет

- AWS Migrate Resources To New RegionДокумент23 страницыAWS Migrate Resources To New Regionsruthi raviОценок пока нет

- Anklet - Google SearchДокумент1 страницаAnklet - Google SearchManu KhannaОценок пока нет

- KR 10 Scara: The Compact Robot For Low PayloadsДокумент4 страницыKR 10 Scara: The Compact Robot For Low PayloadsBogdan123Оценок пока нет

- Iso 269-2022-014 Rotary Table NDT Cat IV - Rev1Документ1 страницаIso 269-2022-014 Rotary Table NDT Cat IV - Rev1Durgham Adel EscanderОценок пока нет

- Hey Can I Try ThatДокумент20 страницHey Can I Try Thatapi-273078602Оценок пока нет

- ScriptДокумент7 страницScriptAllen Delacruz100% (1)

- Frsky L9R ManualДокумент1 страницаFrsky L9R ManualAlicia GordonОценок пока нет

- Thematic CodingДокумент31 страницаThematic CodingLance Jazekmiel DOMINGOОценок пока нет

- Framework For Durable ConcreteДокумент8 страницFramework For Durable ConcreteDai ThanhОценок пока нет

- Big Data Hadoop Certification Training CourseДокумент12 страницBig Data Hadoop Certification Training Courseprema vОценок пока нет

- The Game: Penetrating the Secret Society of Pickup ArtistsОт EverandThe Game: Penetrating the Secret Society of Pickup ArtistsРейтинг: 4 из 5 звезд4/5 (131)

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthОт EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthРейтинг: 4.5 из 5 звезд4.5/5 (197)

- Proof of Heaven: A Neurosurgeon's Journey into the AfterlifeОт EverandProof of Heaven: A Neurosurgeon's Journey into the AfterlifeРейтинг: 3.5 из 5 звезд3.5/5 (165)

- Geneva, Lausanne, Fribourg & Western Switzerland Travel AdventuresОт EverandGeneva, Lausanne, Fribourg & Western Switzerland Travel AdventuresОценок пока нет

- Coastal Alaska & the Inside Passage Adventure Travel GuideОт EverandCoastal Alaska & the Inside Passage Adventure Travel GuideОценок пока нет

- Hollywood & the Best of Los Angeles Travel GuideОт EverandHollywood & the Best of Los Angeles Travel GuideРейтинг: 4.5 из 5 звезд4.5/5 (2)