Академический Документы

Профессиональный Документы

Культура Документы

Customer Complaints Register

Загружено:

danielsasikumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

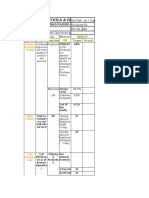

Customer Complaints Register

Загружено:

danielsasikumarАвторское право:

Доступные форматы

Customer Complaints Register

Sl.No. Description of Complaint Damage of thread in M12x115 Cut Length Bolt and M12x90 Hex head bolt. The cut length bolt and Hex head bolt are assembled instead of stud. (Qty : 25 nos) Complaint Issued by Maruthi Sharma, WIPRO Mode of Complaint Complaint Received on Qty Rejected Root Cause Corrective Action

Phone & Email

25.08.09

Studs and bolts should not machined or reworked.

Standard studs to be only used

Ring Gear ID found over size upto 225 +0.05 +0.2 against 225 +0.046

Dantal

Phone & Email

12.12.09

Inner dia oversized during Heat treatment.

1. The bends / ovaulty after Teeth cutting / Tuffriding to be measured and removed.2. Plug gauge / Snap gauge to be introduced to measure the ID

In G 600 V2 PTO, mounting of pump is difficult. Before mounting filing is being done

Hyva, Bangaluru

Direct

12.12.09

This is due to fouling of Bearing cover with pump

Bearing cover CD 41 +0.1 was modified as 39 +0.1

Drive Gear Damage at edge in GBS 40 PA PTO (2 nos)

WIPRO

Phone

10.01.10

This is because of PTO is engaged before the gear box stops. This is operator's mistake.

PTO operating instruction leaflet to be prepared and supplied along with every PTO

MLK V1 shifting shoe worn out in 45 days (qty:2 nos)

Mahindra

Phone

12.01.10

Shifting shoe material is Brass which not a good wear resistance material

Shifting shoe material changed to Phospher bronze, because it has higher wear resistance

Leakage of oil in GBS 40 PA PTO

WIPRO

Phone

20.01.10

Redesigning of U cup and O ring to be done.

Breakage of Bearings and Gears in G 600 V2 PTO

Hyva

E mail

04.03.10

This is because of PTO is engaged before the gear box stops. This is operators mistake.

We sent our service person to Delhi to attend this problem. PTO operating instruction leaflet to be prepared and supplied along with every PTO

Oil leakage from input shaft in MLK V1 PTO

Mahindra

E mail

05.06.10

This is due to damage of O Ring in the input shaft. When the input shaft along with O ring is inserted into housing hole during assembling, the sharp edge in the hole damages the O ring.

To avoid this,O Ring groove to be made and O Ring to be fitted in

ZF Alpha drive gear breakage (3 nos)

WIPRO

E mail

14.06.10

Microstructure is tested and found OK.The Hardness of the drive gear is tested and found OK. The case depth is checked and found 2.5 instead of 0.6 - 0.8. This is the reason for the breakage.

This is discussed with M/s Sri Heat treatment and M/s Best heat Treatment. 1 sample tested in ASTER from Sri Heat treatment and found 0.8. SOP for Heat treatment process to be made. Supplieaudit to be conducted.

10

Pump cannot be fitted into G 750 V2 PTO

Hyva

17.11.2010

Sliding Gear internal spline depth under size.

Sliding Gear to be tested 100 % using plug gauge before assembly.

11

ZF Alpha PTO oil leakage

Palfinger

27.11.2010

This is due to Hardening of U cup where the PTO was operated without oil.

The PTO is designed to use only in tipping purpose and the failure is happened in crane application which is not suitable for our PTO

12

G600 MPH leakage due to O Ring Worn out

Hyva

25.11.2010

This is due to O ring damage. Damage may happened because of sharp corners.

1. Before assembling it is to be ensured no sharp edges.2. Damaged O rings are to be replaced by VITON O ring. 1. In future VITON O rings only to be used 2. Piston O Ring subassembly is to be redesigned.

13

ZF 9S 1C oil leakage

WIPRO

E mail

07.12.2010

Nitrile O rings fitted on PTOs were replaced with Viton O rings. The O Failure of O Ring caused by hardening of rubber leading to ring material to be changed to a compound which is resistant to water, premature wear. heat and air.

14

G 600 V2 Nylon Dummy breakage

Hyva

E mail

20.12.2010

This is due to Blow holes in the nylon dummy. During inward inspection 10 nos of dummy to be broken to find any blow holes present.

Material to be changed

1.Studs to be fitted on the PTO instead of sending separately. 2.Mounting the PTO using M12x100 stud is difficult and instead of the stud Hexagonal head bolt to be used. 3.Pump cannot be fitted with the PTO because the length of the M12 x 115 stud is not sufficient. M12 x 130 mm stud to be used. AD Engineers visited WIPRO and found that this is due to burrs in pump shaft & the pump shaft is not made by Alpha Drives

15

AMW

E mail

10.02.2011

NA

16

Pump not entering into G600 MPH spline coupling

WIPRO

E mail

26.04.2011

NA

17

Bearing Damage in EATON 6306 PTO

MNAL

E mail

20.06.2011

This might happened while assembling the bearing in inclined position. This might also happened by improper method of disassembling of bearing. Rubbing mark is due to contact of face of grinding wheel during cylindrical grinding. This might happened by improper method of disassembling of adaptor. Bearing failure.

To avoid these 1.Bearings are fitted into the housing using hydraulic press to ensure proper alighnment. 2.Face out 0.05 max is permissible.3. Intially JSK Brand were used and now we are using INA Brand which is a higher quality.

17

PTO Pump Oil Leakage in ZF Alpha 6S PTO

AMW

E mail

29.07.2011

Thread length in M12 stud is less and so it could not be tightened enough to prevent oil leakage. This is because Thread length in M12 stud is less and so it could not be tightened enough to prevent oil leakage. To avoid this Instead of M12x115 mm stud M12 x 130 mm stud are supplied.BOM to be modified This may be due to mix up of pump gear which has been sent separately along with each PTO. This will be ensured only by verifying the defective PTO after receiving. The defective PTO is replaced as an interim action.

Instead of M12x115 mm stud M12 x 130 mm stud are supplied. BOM to be modified

18

PTO Pump Oil Leakage in ZF Alpha 6S PTO - Qty 2 nos

AMW

E mail

29.07.2011

Instead of M12x115 mm stud M12 x 130 mm stud are supplied. BOM to be modified

18A

Spline Wear out in GBS 40 PA PTO

WIPRO / KVUL

E mail

13.08.2011

28 teeth Drive Gear and 23 teeth Pump Gear sets to be stored in different place and clearly identified.

19

Noise while engaging in GBS 40 PA PTO

WIPRO / KVUL

E mail

13.08.2011

This may be due to mix up of 22 and 23 teeth pump gear which has been sent separately along with each PTO.

This will be ensured only verifying the defective PTO after receiving.

20

Mounting holes in GBS 40 PA Flange not matching.

WIPRO / KVUL

E mail

13.08.2011

The PTO and the flange are assembled together before despatch. During assembling the PTO is disassembled by the customer and again fitted in the vehicle gear box. During disassembling the holes may be shifted.

During assembly of PTO, customer should not dismantle the PTO.

21

PTO Pump fitment becoming hectic job and time consuming job

WIPRO / KVUL

E mail

13.08.2011

At body building stage before fitment they are Inserting one mounting bolt and washer before assembling the PTO dismantling the PTO to put one mounting bolt and fitment flange and PTO so that PTO can be directly fitted on the gear box. Time done on gear box in three separate parts. Which is killing and energy can be saved at Body builder and original fitment will not to min half hour time for every vehicle and it is hectic job. be disturbed.

22

Receiving two different PTO gear sets with different gear ratios. Gear mismatching and fitment problem

WIPRO / KVUL

E mail

13.08.2011

All the Drive Gears at customer end having 28 teeths to be replaced by This may be due to mix up of 28 teeth Drive Gear and 23 29 teeth Drive Gear and all the Pump Gears having 23 teeths to be teeth Pump Gear set, because earlier 28 teeth Drive Gear replaced by 22 teeth Pump Gear. 1. Only 29 teeth Drive Gear and 22 and 23 teeth Pump Gear set was used in GBS 40 PA PTO. Teeth Pump Gear Combination set to be used for WIPRO. 2. 28 teeth For the past 18 months 29 teeth Drive Gear and 22 Teeth Drive Gear and 23 teeth Pump Gear sets to be stored in different place Pump Gear Combination set is being used. and clearly identified.

23

GBS 40 PA Drive Gear not engaging with gear box shaft

WIPRO / KVUL

E mail

13.08.2011

1.New Counter shaft is bought from M/s ABT TATA Motors and the shaft smoothly enters into the spline of Drive Gear.2. Gauge used for inspection and the Counter Shaft dimensions are same. 3. Design and Manufacturer parameters are found OK.

24

Spline end bore depth is 16.5 instead of 14.5 in 6209 Quill Shaft

AMW

E mail

26.11.2011

1. Spacer thickness under size. (Measured 11.4 - 11.6 against 11.4 -0.05 in store stock). 2. Bore depth over size. (Measured 26.0 - 26.2 against 26.0 0.05 in store stock).3. Mix up of old model quill shafts. These quill shafts are having excessive step length. The bore is 2 mm deeper than current quill shafts.1.

Old model quill shafts in customer end to be replaced.

25

EATON 6209 Oil leakage from stud hole due to blow holes in the hole

AMW

E mail

30.11.2011

This is due to blow hole in 13 mm hole. This is due to slippage of spline shaft into the coupling. Slippage may be due to : 1. Spline shaft outer diameter under size.1. We have checked the spline shaft outer diameter in our stock and found OK.CAPA can be given only after inspecting the failed PTO

1.Vacum Impregnation to be done on all housings. 2. 100 % Visual Inspection to be done on all housings before assembly.

26

G750 MPH Spline Shaft teeth damage in the rear end

AMW

E mail

18.01.2012

Circlip to be provided in spline shaft to avoid slippage.

27

Instead of M10 x 1, 1/8 BSP tap is done in housing

TAL

Direct

28.03.2012

Ther is no clear drawing

28

Breakage of Bearings in G 750 V2 PTO

MGB Motors

E mail

20.04.2012

This is due to fitment of Pump in inclined position.

Francis visited MGB Motors. 1no replaced.

29

GBS 40 PA Drive Gear Damage

WIPRO

E mail

22.04.2012

This is due to improper clutching before engaging PTO.

30

Leakage between Oil seal bore and Adaptor shaft in MLK V1 PTO

Mahindra

E mail

22.04.2012

This is because 1. Oil seal bore over size. 2. Oil seal damage

Oil seals are checked for any damages in Alpha Drives Stock and no damaged oil seals. Assembling operators are instructed to sepatrate the damaged oil seals if any during assembling of PTOs.

31

Missing of Pump Gear, Circlip

WIPRO

Direct

01.06.2012

Packing is not verified before despatch

Francis visted WIPRO and segregated the lot and found Pump Gear missing in 6 PTOs. 6 nos of Pump Gear sent to WIPRO

32

Dummy Breakage in G 750 V2

WIPRO

Direct

14.06.2012

This is supplied on 8th month of 2011. This is due to blow holes in Nylon Dummy. The material is changed to HDPE(High Density Poyethelene).

33

Shifting Fork Breakage in MLK V1

Mahindra

Direct

20.06.2012

This is due to more gap between spacer and Drive Gear

While assembling the PTO the Gap to be maintained 0.2 max

34

Cannot assemble pump in G750 V2 PTO

WIPRO

E mail

12.08.2012

Pump Flange size variation. & Improper pump fitment

Pump drawing to be prepared and sent to HYVA,WIPRO

36

While operating GBS 40 PA PTO, it makes a improper meshing noise.

WIPRO

E mail

21.09.2012

Mr.Venakatesh of Alpha Drives visited PRERANA Motors on 24.09.2012 and replaced the damaged Drive Gear. Before engaging PTO, driver has This is because of Drive Gear damage. Damage occurred to press clutch pedal properly and wait for 5 seconds which failing will while PTO is continuously tried to engage before the gear finally damage the drive gear spline and counter shaft. The root cause box stops and preventive action is discussed with Mr.Jagadish of Prerana Motors by Mr.Venkatesh of Alpha Drives

37

GBS 40 PA PTO Housing fouling with Gear Box Flange

WIPRO

E mail

21.09.2012

Problem identified by Prerana Motors, Mysore. Outer milling operation is missed in this Housing

PTO replaced. An attachement is fitted on Test rig so that Housing that missed outer milling cannot be tested. Casting to be modified so that outer milling can be eliminated.

38

No PTO Name in Name Plate in GBS 40 PA PTO

WIPRO

E mail

20.10.2012

Not Rejected

No stock of name plate with printed PTO name. Stores issued empty name plate and assembly missed to punch PTO name

PTO name to be punched in name plate by assembly person

39

Packing Slip is not verified and signed for GBS 40 PA PTO

WIPRO

E mail

20.10.2012

Not Rejected

This is discussed with Francis. This is due to enough time is not given to him for assembling and packing.

100 % verification to be done by packing person and sampling inspection to be done by quality inspector.

40

G 750 PTO cannot be assembled with P408 pump using M12 x 50 mm stud because the non threaded portion length of the stud is high.

WIPRO

E mail

20.10.2012

Not Rejected

Same stud is used for all WIPRO PTOs for last two years and there is no such problem reported. The problem is only with G750 V2 PTO. Customer might have changed their pump's flange thickness.

Stud design to be modified to meet customer requirement and this modified stud can be used for all other PTOs

41

Blow hole in G750 MPH Housing

WIPRO

E mail

03.11.2012

1 no

1. Improper vent holes 2. Improper moulding 3. Presence of Humidity in moulding sand

100 % visual inspection to be carried out in inward inspection. Machining and assembly operators are instructed to separate and identify if defective castings found.

42

Drill holes found in flange aea of G750 MPH

WIPRO

E mail

03.11.2012

1 no

This is old design PTO. Design was changed 2 years ago and there is no drills on flange are in our existing design.

Any design changes to be communicated to customers and get their approval

43

Instead of 4 nos of M12 nut, only 3 nos are packed and sent to WIPRO in 2 nos G600 MPH

WIPRO

E mail

26.11.2012

Not Rejected

This is packed by new operator and he is not properly trained to do this job.

Packing instruction to be prepared and displayed. Understanding training to be given to ensure the operator is capable of packing . Effectivness to be monitored.

44

G 550 Not disengaging after engaging

Bafna

E mail

02.12.2012

1 no

44

Leakage in GBS 40 R2 PTO (X174190000)

WIPRO

E mail

14.12.2012

10 nos

These PTOs were supplied on Dec 2010 and kept ideal for 2 years before using. The rubber parts are damaged which leads to leakage

10 nos of Piston sub assy sent as free replacement.

45

G600 V2 PTO 20 nos despatched to TAL instead of G600 VO

TAL

E mail

28.12.2012

20 nos

This is due to Confusion and communication mistake.

46

ZF 9S 1110 PTO air leakage in Ashok Leyland which is supplied by WIPRO

WIPRO

E mail

29.12.2012

1 no

Pneumatic bore 40.1 is damaged

47

Excess noise and vibration in Schenck 1 Gear Box

Schenck

E mail

29.12.2012

1 no

48

Pump fouling in G750 V2 PTO

WIPRO

30.12.2012

1 no

This is due to pump flange size varition.

Need to request a pump from WIPRO. As per this pump we have to make a gauge.

49

MLK V1 Oil Leakage

MNAL

09.01.2013

1 no

50

G 550 Bearing Breakage and Transmission gear box damage

TATA

25.01.2013

1 no

Suspected due to non availability of circlip,shaft has continuously pressed bearing while working

51

Abnormal sound coming from Transmission gear box. PTO Name : G600 V2

Hyva

04.02.2013

1 no

This is due to mounitng G600 V2 PTO in GB 750 Gear Box instead of GB 600 Gear Box

52

Mounting Hole Under size in MLK V1 PTO

MNAL

14.02.2013

2 nos

Reaming not done.

53

G750 V2 Sliding Gear not entering into Pump Shaft

Hyva

11.03.2013

1 no

1. Internal spline damage. 2. Internal spline width o/s or u/s. 3. Major dia u/s. 4.Uneven Shrinkage during Heat treatment

After heat treatment 100% Inspection to be carried out

54

Drive Gear Damage & Leakage in GBS 40 PA PTO from Dummy side.

WIPRO

26.03.2013

In this PTO the flange is old type i.e without slot. During fitment of the PTO in vehicle Gear box the screw might be pressed the dummy into the bore

NA

55

Wrong supply of PT0190009 PTO- Eaton 6S ES9306A instead of PT0190005 ZF9S2W.

WIPRO

10.04.2013

30

PO not clear & No proper communication

Understanding PO requirement. Discuss with customers if PO is not clear

56

Pump Shaft not entering into G750 V2 Sliding Gear

Hyva

22.04.2013

Sliding Gear Internal spline width o/s

Sliding gear internal spline to be checked after Heat treatment 100 % using a gauge

57

M8 X 1.25 Thread damage in G550 Rear Housing

BAFNA

25.072013

Sticking of aluminium particles in M8 tap due to poor circulation or mixture of coolant. Missed to fit the part during assembly

Coolant to be checked periodically 1. PTO to be checked for engagement & disengagement before despatch. Test rig to be made. 2. Assembly instruction to be made.

58

Shifting Sleeve missing in G550 PTO

BAFNA

25.072013

59

Housing Breakage in G550

BAFNA

25.072013

1 This is due to bearing breakage. Damaged bearing is not received. During functioning any metal chips inside PTO might damaged bearing. It is not ZF Alpha PTO. It is ZF 9S 2W with quill shaft. It is not our regular supply to WIPRO, it was given for sample purpose. The quill shaft might not fitted properly in vehicle gear box. The PTO works properly. This is due to O ring damage in piston sub assy

60

G 750 V2 Input shaft 11 teeth breakage, housing damage

Hyva

E mail

03.08.2013

Replacement given.

61

PTO continuously in engaged position even air not supplied in ZF Alpha PTO

WIPRO

E mail

14.08.2013

NA

62

Pneumatic Leakage in G600 MPH

WIPRO

E mail

14.08.2013

63

Iron cap found but abnormal noise reported in GBS 40 PA PTO

WIPRO

E mail

14.08.2013

Improper engagement of gear box counter shaft into PTO Drive Gear. After some time the drive gear will damage. Engaging Gear box counter shaft in rotating condtion into PTO Drive Gear

Before engaging the PTO, vehicle driver has to apply clutch fully and wait for 20 seconds to stop the Gear Box counter shaft and try to engage counter shaft into the PTO

64

Key Slipped off from pump shaft into pump shaft bore in Dantal 13 HP Gear box

Dantal

E mail

19.08.2013

Pump Shaft bore in Gear box is high

Pump shaft to be modified by reducing the bore depth

65

G 750 V2 PTO damage, Cylinder damage & scratches on PTO body Bearaing coming out & air leakage found in the piston in G 750 MPH (Sl.No.: 38263)

Hyva

E mail

10.10.2013

Due to improper handling the packing damaged and finally parts damaged Rejected PTO checked in Alpha Drives and the PTO is in good condition. No air leakage & no bearing loose & this is communicated to WIPRO Rejected PTO checked in Alpha Drives and the PTO is in good condition. No engagement / disengagement problem & this is communicated to WIPRO

Packing method to be improved by introducing special packing iside the cartoon box

66

WIPRO

E mail

10.10.2013

67

Eaton 6306 A PTO with quill shaft always in engaged postion even air not supplied

WIPRO

E mail

10.10.2013

Вам также может понравиться

- India MapДокумент2 страницыIndia MapdanielsasikumarОценок пока нет

- RouterTable Bob PlansДокумент24 страницыRouterTable Bob Plansiacob_gilberto6473100% (2)

- C MR 01 02 Ims Check ListДокумент16 страницC MR 01 02 Ims Check ListShaileshОценок пока нет

- Level - 01 IMS ManualДокумент54 страницыLevel - 01 IMS ManualAkd Deshmukh100% (1)

- FLVL-QHSE-SOP-F-006 Management Review MeetingДокумент7 страницFLVL-QHSE-SOP-F-006 Management Review MeetingmanjunathaОценок пока нет

- Outsourced Processes Procedure Full Client Name Reg Caps Rev Rev NumberДокумент1 страницаOutsourced Processes Procedure Full Client Name Reg Caps Rev Rev Numberdellanadia putriОценок пока нет

- Qa-R-07 Nonconformity and Corrective ActionДокумент2 страницыQa-R-07 Nonconformity and Corrective ActionvinothОценок пока нет

- Project Inspection Report Location Report NoДокумент2 страницыProject Inspection Report Location Report NoArturoОценок пока нет

- Vihtavuori Reloading Guide 2021 ENGДокумент59 страницVihtavuori Reloading Guide 2021 ENGFabien BonatoОценок пока нет

- A6. Control of Nonconforming ProductДокумент6 страницA6. Control of Nonconforming ProductStanley MtamboОценок пока нет

- Quality ObjectivesДокумент3 страницыQuality ObjectivesMuhammad ImranОценок пока нет

- Procedure for Purchase SOPДокумент6 страницProcedure for Purchase SOPShakti ShuklaОценок пока нет

- 05 Sop For Competence, Awareness & TrainingДокумент6 страниц05 Sop For Competence, Awareness & TrainingMusyoka UrbanusОценок пока нет

- Environment Aspect Impact Analysis (ISO 14001:2015) - GENERALДокумент1 страницаEnvironment Aspect Impact Analysis (ISO 14001:2015) - GENERALpramodcgnrОценок пока нет

- Quality ObjectivesДокумент1 страницаQuality ObjectivessimsonОценок пока нет

- Maruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingДокумент3 страницыMaruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingAnkush Chourasia100% (1)

- CAP PLANT VIETNAM GLASSДокумент6 страницCAP PLANT VIETNAM GLASSCuong PhanОценок пока нет

- IMS Procedures Table of ContentsДокумент2 страницыIMS Procedures Table of Contentsaadwitya0% (2)

- Fighting Knives ReviewedДокумент20 страницFighting Knives ReviewedTwobirds Flying Publications100% (3)

- NC Status Monitoring, Tracking SheetДокумент1 страницаNC Status Monitoring, Tracking SheetSachin RamdurgОценок пока нет

- Precast PCFQA AuditДокумент14 страницPrecast PCFQA AuditNguyễn Thanh Cường100% (2)

- R-11 Intrested PartiesДокумент5 страницR-11 Intrested PartiesSandeep PhatakОценок пока нет

- HC 109 Tools Ve Seal Kit Parça KataloğuДокумент13 страницHC 109 Tools Ve Seal Kit Parça KataloğuSales AydinkayaОценок пока нет

- Roles and Resposiblity-SampleДокумент7 страницRoles and Resposiblity-SampleELANTHENDRALОценок пока нет

- Customer Satisfaction Survey FormДокумент1 страницаCustomer Satisfaction Survey FormAnonymous qRbPsLpuNОценок пока нет

- Happy Forgings EMS PerformanceДокумент3 страницыHappy Forgings EMS Performancemool raj100% (1)

- 2017 ISO9001 External Audit ReportДокумент19 страниц2017 ISO9001 External Audit ReportTata OdoyОценок пока нет

- Strategic Direction ProcedureДокумент2 страницыStrategic Direction Procedurejaxf001Оценок пока нет

- 8.5.2 Identification and TraceabilityДокумент5 страниц8.5.2 Identification and Traceabilitymedtaher missaoui0% (1)

- BOQ LG Multi V VRF System (Bhilwara) PDFДокумент4 страницыBOQ LG Multi V VRF System (Bhilwara) PDFAjayОценок пока нет

- Minutes of Management Review MeetingДокумент5 страницMinutes of Management Review Meetingwinston11Оценок пока нет

- MTC-IMS-PR-15-Procedure For Externally Provided ProductsДокумент5 страницMTC-IMS-PR-15-Procedure For Externally Provided ProductssouravrobinОценок пока нет

- Edited EIM - Module Grade 11Документ7 страницEdited EIM - Module Grade 11Julius MendozaОценок пока нет

- SMCPGL Ims MRM - 2022Документ37 страницSMCPGL Ims MRM - 2022Smc PowerОценок пока нет

- MS-P01 Management Responsibility ProcedureДокумент8 страницMS-P01 Management Responsibility ProcedureMuhammad ZafarОценок пока нет

- Blow Packaging India LTD: List of Approved SuppliersДокумент3 страницыBlow Packaging India LTD: List of Approved Suppliersvishvendan100% (1)

- Control of Nonconforming Output ProcedureДокумент4 страницыControl of Nonconforming Output Procedureandi wahyudin50% (2)

- QF-822-01-Internal Quality Management Audit Report PDFДокумент5 страницQF-822-01-Internal Quality Management Audit Report PDFJAYFLOR PLANOSОценок пока нет

- Insert Your Company Logo/Name Here: InstructionsДокумент4 страницыInsert Your Company Logo/Name Here: InstructionsJamal BahriОценок пока нет

- Quality Assurance Manual Oct-18Документ176 страницQuality Assurance Manual Oct-18Ayush SharmaОценок пока нет

- QMS Audit ChecklistДокумент4 страницыQMS Audit ChecklistSyerifaizal Hj. MustaphaОценок пока нет

- Core ObjectiveДокумент1 страницаCore ObjectiveMatthew LeeОценок пока нет

- PDF Ims Manual 2019 FinalДокумент102 страницыPDF Ims Manual 2019 FinalThulasi RamОценок пока нет

- IT Sci Y6 Topical Test 7Документ4 страницыIT Sci Y6 Topical Test 7Adam DharmaОценок пока нет

- Swarda Tools & Dies: Company Wide Quality Objectives ApДокумент3 страницыSwarda Tools & Dies: Company Wide Quality Objectives ApSangram KandekarОценок пока нет

- ISO 9001-2015 Clause 10.2 Nonconformity and Corrective ActionДокумент4 страницыISO 9001-2015 Clause 10.2 Nonconformity and Corrective ActionOmnia ElshafieОценок пока нет

- Black Powder RifleДокумент20 страницBlack Powder RifleWilliam Doyle100% (3)

- QP-55-03 Customer Complaint Suggestion Comment & SurveyДокумент6 страницQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadОценок пока нет

- IMS APEX Manual Final LOCOДокумент64 страницыIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- Geometry of Plain Milling Cutter & Twist DrillДокумент30 страницGeometry of Plain Milling Cutter & Twist DrillTulsi ChouhanОценок пока нет

- Communication, Participation & ConsulatationДокумент7 страницCommunication, Participation & ConsulatationSuresh MuruganОценок пока нет

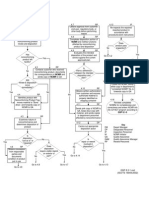

- NCR Flow ChartДокумент1 страницаNCR Flow ChartPramod AthiyarathuОценок пока нет

- Integrated Procedure 10 May 2018Документ36 страницIntegrated Procedure 10 May 2018Trivesh S100% (1)

- Health and Safety PolicyДокумент12 страницHealth and Safety PolicyVarsha RaneОценок пока нет

- CAR016 - Corrective Action Request Form - Doc (DECEMBER 2018)Документ2 страницыCAR016 - Corrective Action Request Form - Doc (DECEMBER 2018)Shalinur GonzalesОценок пока нет

- Internal Quality Audit ProcedureДокумент2 страницыInternal Quality Audit ProceduremahendraОценок пока нет

- QMS Record Control ProcedureДокумент2 страницыQMS Record Control ProcedureHammad GhauriОценок пока нет

- F02. Weekly Quality Observation Report - LTCDWSW&CWSBGQMQISF02 REV-0Документ4 страницыF02. Weekly Quality Observation Report - LTCDWSW&CWSBGQMQISF02 REV-0RamBinodSharmaОценок пока нет

- FT-SYS-11 Minutes of Management Review MeetingДокумент4 страницыFT-SYS-11 Minutes of Management Review Meetingjanak doshi100% (1)

- QHSE Induction KGA Employees NewДокумент30 страницQHSE Induction KGA Employees NewlavheОценок пока нет

- Management Review Meeting MinutesДокумент2 страницыManagement Review Meeting Minutesilayaraja MKОценок пока нет

- ISO 9001 Certified Precision MachiningДокумент21 страницаISO 9001 Certified Precision Machiningqmicertification100% (2)

- ASMI-OSHMS-PR-02 - Targets and Objectives ProcedureДокумент9 страницASMI-OSHMS-PR-02 - Targets and Objectives ProcedureJHUPEL ABARIALОценок пока нет

- QMS Audit Checklist On FFS Rev2 1Документ8 страницQMS Audit Checklist On FFS Rev2 1Xion100% (1)

- Standard Operating Procedures: Enquiry, Pricing & Payment Terms FinalizationДокумент5 страницStandard Operating Procedures: Enquiry, Pricing & Payment Terms FinalizationIan YongОценок пока нет

- QP7 Purchasing Control & Suppilers EvaluationДокумент4 страницыQP7 Purchasing Control & Suppilers EvaluationMuhammad Shiraz KhalidОценок пока нет

- 1S2S Audit ChecklisДокумент6 страниц1S2S Audit ChecklisArun Biswal100% (1)

- 1.J - Site Logistics PlanДокумент1 страница1.J - Site Logistics Planyusufu0% (2)

- Communications Plan Template: Project Name: Prepared By: DateДокумент1 страницаCommunications Plan Template: Project Name: Prepared By: DatevyerramallaОценок пока нет

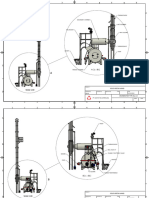

- Instruction Manual For Cylinder Set (124 CC) : Exclusively For Our Twin Spark Super Head +RДокумент5 страницInstruction Manual For Cylinder Set (124 CC) : Exclusively For Our Twin Spark Super Head +RMoto ExpertОценок пока нет

- Quotation Document Title GeneratorДокумент1 страницаQuotation Document Title GeneratordanielsasikumarОценок пока нет

- Weekly transaction report by module and personДокумент1 страницаWeekly transaction report by module and persondanielsasikumarОценок пока нет

- Money Doesn't Buy HappinessДокумент2 страницыMoney Doesn't Buy HappinessdanielsasikumarОценок пока нет

- Quality System Assessment Form Review and Improvement PlanДокумент1 страницаQuality System Assessment Form Review and Improvement PlandanielsasikumarОценок пока нет

- Bought Out ChecklistДокумент1 страницаBought Out ChecklistdanielsasikumarОценок пока нет

- JPДокумент5 страницJPdanielsasikumarОценок пока нет

- Po Numbepo Date (Dapo Status Po Type Vendor Covendor Naitem Code Item Descrpurchase QpurchaseДокумент14 страницPo Numbepo Date (Dapo Status Po Type Vendor Covendor Naitem Code Item Descrpurchase QpurchasedanielsasikumarОценок пока нет

- HEДокумент2 страницыHEdanielsasikumarОценок пока нет

- Perpetual calendar guide to find any date from 1901 to 2099Документ2 страницыPerpetual calendar guide to find any date from 1901 to 2099danielsasikumarОценок пока нет

- Case HardeningДокумент2 страницыCase HardeningdanielsasikumarОценок пока нет

- CCPДокумент6 страницCCPdanielsasikumarОценок пока нет

- BOДокумент2 страницыBOdanielsasikumarОценок пока нет

- IATF 16949 FAQs - Oct 2018 - 12nov2018Документ20 страницIATF 16949 FAQs - Oct 2018 - 12nov2018danielsasikumarОценок пока нет

- FunДокумент5 страницFundanielsasikumarОценок пока нет

- OKДокумент3 страницыOKdanielsasikumarОценок пока нет

- Weekly transaction report by module and personДокумент1 страницаWeekly transaction report by module and persondanielsasikumarОценок пока нет

- Final Inspection Report: Spline BДокумент4 страницыFinal Inspection Report: Spline BdanielsasikumarОценок пока нет

- PTO Warranty DetailsДокумент3 страницыPTO Warranty DetailsdanielsasikumarОценок пока нет

- PSG GearsДокумент2 страницыPSG GearsdanielsasikumarОценок пока нет

- Managers Vs LeadersДокумент2 страницыManagers Vs LeadersdanielsasikumarОценок пока нет

- Daily weather report for June 10, 2018Документ1 страницаDaily weather report for June 10, 2018danielsasikumarОценок пока нет

- Interested Parties Needs & ExpectationsДокумент1 страницаInterested Parties Needs & ExpectationsdanielsasikumarОценок пока нет

- A.Personal Effectivenessdemonstrates Self-Awareness and Personal CapabilityДокумент5 страницA.Personal Effectivenessdemonstrates Self-Awareness and Personal CapabilitydanielsasikumarОценок пока нет

- ALPHA DRIVES PROFILE+LEAD TESTДокумент1 страницаALPHA DRIVES PROFILE+LEAD TESTdanielsasikumarОценок пока нет

- India Political Map - Regions & StatesДокумент2 страницыIndia Political Map - Regions & StatesdanielsasikumarОценок пока нет

- Cost of Conformance: Prevention CostsДокумент7 страницCost of Conformance: Prevention CostsdanielsasikumarОценок пока нет

- Tour Plan 2017Документ2 страницыTour Plan 2017danielsasikumarОценок пока нет

- Customer ComplaintsДокумент7 страницCustomer ComplaintsdanielsasikumarОценок пока нет

- Approved: Non ConformingДокумент1 страницаApproved: Non ConformingdanielsasikumarОценок пока нет

- Battlefield Bad Company 2 Weapon Stats Chart ExplainedДокумент12 страницBattlefield Bad Company 2 Weapon Stats Chart Explainedjumper456Оценок пока нет

- 7 4 Options Gauge Plates Sizing RingsДокумент1 страница7 4 Options Gauge Plates Sizing RingsGauravОценок пока нет

- Maintain Training Facilities TMIДокумент13 страницMaintain Training Facilities TMISam Louis LepitenОценок пока нет

- Qx189862 Lb185-275 - Lb185-275 Screw Air Compressor - Part Manual-EДокумент46 страницQx189862 Lb185-275 - Lb185-275 Screw Air Compressor - Part Manual-Eabdur rohmanОценок пока нет

- Preventive Maintenance - Clinical MicrosДокумент3 страницыPreventive Maintenance - Clinical MicrosBem GarciaОценок пока нет

- Machine Control Gage Selection GuideДокумент15 страницMachine Control Gage Selection GuideVikas ChoudharyОценок пока нет

- Kathrein 732317Документ1 страницаKathrein 732317Roy TanjungОценок пока нет

- Products Knowledge Training For: Service Admin & Non Technical StaffДокумент20 страницProducts Knowledge Training For: Service Admin & Non Technical StaffKhincho aye100% (1)

- Wusthof BrochureДокумент12 страницWusthof BrochureJames Steele100% (1)

- 30x113mm HEDP 1Документ2 страницы30x113mm HEDP 1Sulistyo SukarnoОценок пока нет

- Drilling MC ManualДокумент3 страницыDrilling MC ManualKS Rajawat100% (1)

- Sales Quote Acknowledgment 107216Документ3 страницыSales Quote Acknowledgment 107216AmirОценок пока нет

- Building a Home-Scale Vertical Axis Wind TurbineДокумент17 страницBuilding a Home-Scale Vertical Axis Wind TurbineYasser HassanОценок пока нет

- Luxurious Main Villa in Nasugbu from PHP 25KДокумент6 страницLuxurious Main Villa in Nasugbu from PHP 25KJazmene BasitОценок пока нет

- Pneumatic symbols overviewДокумент47 страницPneumatic symbols overviewVladan MilojevićОценок пока нет

- Boston Bay AirconДокумент3 страницыBoston Bay AirconMichael John PilotaОценок пока нет

- ADRIVE Compatible Absolute Encoders.V150.EnДокумент3 страницыADRIVE Compatible Absolute Encoders.V150.EnAtheer AmeerОценок пока нет

- LG Air Conditioner Service ManualДокумент63 страницыLG Air Conditioner Service ManualISMAEL ENRIQUE VALENCIA JURADOОценок пока нет

- DED Insinerator SLI PT CMCДокумент13 страницDED Insinerator SLI PT CMCFebri IdaОценок пока нет

- T03 Wunda Generic 16mm Nut and Insert Repair CouplingДокумент2 страницыT03 Wunda Generic 16mm Nut and Insert Repair CouplingPredescu GeorgeОценок пока нет

- MD Cabinet DoorsДокумент4 страницыMD Cabinet DoorsKamel NaitОценок пока нет