Академический Документы

Профессиональный Документы

Культура Документы

Sec 4B

Загружено:

hatakerobotИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sec 4B

Загружено:

hatakerobotАвторское право:

Доступные форматы

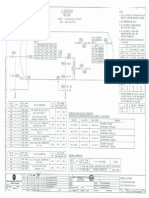

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 1 OF 1

4B

SECTION 4 B SUBMARINE PIPELINES AND RISERS (FLEXIBLE PIPELINE OPTION)

A.K.M. PREPARED BY

A.K.S REVIEWED BY

V.K.K APPROVED BY

ISSUED FOR BID REMARKS

19 NO. OF PAGES

26.8.03 DATE

0 REV.

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 2 OF 2

4B

CONTENTS

4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11

General Scope Design Criteria Design Review Pipeline Installation Tie-in Operation Testing of Pipeline System Post Test Procedure Post Construction Survey Clean-up As-built Pipeline System Report

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 3 OF 3

4B

TABLES & APPENDICES (PLACED AT ANNEXURE TO SECTION 4B)

TABLE 4.1B TABLE 4.2B APPENDIX A APPENDIX B APPENDIX C APPENDIX D APPENDIX E ENVIRONMENTAL PARAMETERS SUBMARINE PIPELINE DESIGNATION LIST OF DRAWINGS LIST OF SPECIFICAITONS JACKET DEFLECTIONS WAVE EXCEEDANCE TABLE PROCESS PARAMETERS

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 4 OF 4

4B

4.1

4.1.1

GENERAL

Oil and Natural Gas Corporation Limited (ONGC) is planning for installation of a number of submarine pipelines. The details/data of pipeline and riser system to be installed under flexible pipeline and platforms connected by these pipelines are given in field layout, Table 4.2B (placed at Annexure to Section 4B) & other drawings including specifications. This section includes the minimum requirements for survey, design, engineering, material procurement, fabrication, transportation, installation, hook-up and testing/pre-commissioning of the submarine flexible pipelines & flexible riser system along with associated I-tube/J-tube assembly etc. covered within this Bid Package. The final design of the pipeline system is the ultimate responsibility of the Contractor. The Contractor shall ensure that the final design of the flexible pipeline system complies fully with the design criteria and operating philosophy as presented in this Bid Package. The Contractor shall also be responsible for the supply of material, fabrication, transportation, installation, hook-up, testing/pre-commissioning and making the entire flexible pipeline system as described herein operational to the extent that they fulfill the intent of the system.

4.1.2

As used in this specification, the following definitions shall apply : Company Contractor : : Oil and Natural Gas Corporation Ltd Turnkey Contractor for the project

4.1.3

Contractor shall obtain Companys written approval for any deviations from the requirement of the bid specifications. This document is not intended to be all inclusive and the use of the guidelines set forth does not relieve the Contractor of his responsibility in performing the work for its intended service. Design/installation requirements shall be in accordance with Table 4.1B and 4.2B, drawings and specifications listed at Appendix A & B (placed at Annexure to Section 4B).

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 5 OF 5

4B

4.2 4.2.1

SCOPE

Requirements This section includes the minimum indicative requirements for the design, detailed engineering, material supply, inspection, expediting and transportation to site, fabrication, installation as per approved drawings / procedures and testing / pre-commissioning of the flexible submarine pipeline & riser system covered within this bid package.

4.2.2

Scope of Work The scope of work to be performed by the Contractor shall be but not limited to the following: a) Pre-engineering and Pre-construction surveys : Carrying out seabed survey along the proposed routes, collection / interpretation of survey results/data, selection and recommendation of final route (keeping the pipeline length and crossing as minimum and clearance with respect to jacket legs of existing well platform as shown in the relevant drawing of bid package) after finalizing departure and approach angles of flexible pipelines at various platforms based on the survey carried out within the corridor or within additional corridor/area duly surveyed/investigated by Contractor and approved by the Company. Pre-installation survey shall be carried out to ensure the installation in the designated slot/route with control during installation supervision. The scope of work shall also include survey and inspection of jacket face to check the adequacy and sizes of members and space available for installation of flexible risers along with I-tube/J-tube assembly and clamps etc. Interference or obstruction, if any, shall be identified by the Contractor.The survey shall be carried out as per Spec. 2011, Rev. 1. b) Finalisation of design data/basis for Companys approval for carrying out design, detailed engineering, procurement, preparation of construction drawings and documents, installation and testing of flexible pipelines & flexible riser system and other associated works. Finalization of design basis shall be done in accordance with Table 4.1B & 4.2B (placed at Annexure to Section 4B ) and design criteria, codes, standards and specifications contained in the bid package. Design, detailed engineering of all submarine flexible pipeline & flexible riser system along with fixing/protection arrangement (viz. I-tube/J-tube assembly, clamps, etc.), CP System, fittings, all tie-ins, pipeline

c)

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 6 OF 6

4B

crossings and free span corrections if any etc., all complete in accordance with approved design basis and requirements of this bid package. Contractors scope shall also include furnishing of design reports, calculations and drawings etc. as per the requirement of bid package. d) Preparation of material requisition, purchase and supply of all materials i.e. flexible pipe with sacrificial anodes, end fittings, connectors, Itube/J-tube etc. including expediting, inspection, fabrication, testing and transportation to intermediate storage/plant locations and job site(s) including sea fastening, for successful execution of works at site. Supply of Flexible Pipes shall conform to enclosed Spec. No 2020E Rev.2 . Design, engineering, supply, installation & testing of cathodic protection system for all flexible pipeline & flexible riser system including I-tube/Jtube assembly etc. The cathodic protection system shall be as per scope of work, design criteria and specification No. FS 4002 Rev. 1 enclosed and applicable codes and standards. Removal and cleaning of marine growth/fouling from jacket braces/members to facilitate installation and proper fit-up of new clamps for I-tube/J-tube assembly/brace clamps of additional members. Flexible riser system along with fixing/protection arrangement (viz. clamps, I-tubes/J-tubes assembly etc.) contemplated by the Contractor shall be clearly indicated and supported by necessary design calculations, sketches, references etc. for Companys review. Such facilities approved by the Company, shall be designed, supplied, fabricated and installed by the Contractor. The assembly of I-tube/J-tube shall include bellmouth / seals etc. The I-tube/J-tube assembly shall be designed as per structural design criteria enclosed in the bid package. Fixing/protection arrangement (i.e. I-tube/J-tube assembly, clamps etc.) and new structural members (wherever required) to support I-tube/J-tube assembly shall be designed, supplied, fabricated and installed by the Contractor. Riser clamps, wherever existing in the same location where the new flexible risers & fixing/protection arrangement i.e. I-tube/J-tube are to be installed, shall be removed by the Contractor. Procedure for the same shall be approved by the Company.

e) f)

g)

h)

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 7 OF 7

4B

The indicative location of flexible risers along with I-tube/J-tube assembly are given in the drawings enclosed in the bid package and the same shall be finalized during survey/detailed engineering. All works incidental to installation of flexible risers along with I-tube/Jtube assembly such as design and provision of additional/new members/braces wherever necessitated by detailed engineering, removal of interfering structures/members, boat landing, riser protector, barge bumper, anodes etc., and modifications thereof, if any and reinstallation of the same as per original design conditions shall form part of Contractors scope of work and cost of such works shall be deemed to be included in the price quoted by the Contractor. The removal/reinstallation procedures to facilitate installation of flexible risers along with I-tube/J-tube assembly shall be approved by the Company. i) Finalization and submission of installation procedures including analysis/ calculations for safe installation of flexible pipelines & flexible riser system for Companys approval, as per the bid package requirements. Installation of all flexible pipelines & flexible riser system as per Companys approved procedure including rectification of all unsupported spans (if any) to design permissible limit, pipeline crossing etc. Checking of flexible pipelines & risers for through bore after installation by passing a gauging pig through the entire pipeline & riser system. This must be done for each pipeline segment as per the requirements of the bid package. Cleaning and hydrostatic pressure testing of all installed submarine flexible pipeline & flexible riser system in accordance with the specification enclosed with the bid package. All flexible pipelines including associated flexible risers after hydrostatic testing shall be left with treated sea water till the commissioning activities commence. Contractor shall supply 4 nos. of pigs of appropriate size and compatible to the flexible pipeline for each pipeline segment to Company after hydrostatic testing. Commissioning shall be done by the Company for which necessary assistance required shall be provided by the Contractor.

j)

k)

l)

m) Carrying out post installation survey including C.P. survey, all clean-up operations and preparation of as built drawings and documents as per bid package requirement.

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 8 OF 8

4B

4.2.3

Contractors Responsibility a) Entire work(s) defined above shall be carried out by Contractor in accordance with the specifications, drawings and other requirements of the bid package and instructions/directions of the Company. Quality control shall be carried out as per the governing code(s) and Companys specification. Review and approval of Contractors entire work(s) by Company shall in no way, relieve the Contractor of his sole responsibility for safe and efficient design, engineering, supply, installation and subsequent operation of all the pipeline(s)/risers(s) by Company in accordance with applicable codes and standards and intended use of the pipeline(s) system. The Contractor is deemed to have recognized any restrictive features of the site(s) and/or specific requirements of the work and made due allowances for it in the work to be performed by him. The Contractor is cautioned to exercise extreme care and take necessary precautions to prevent damage to the existing offshore pipeline(s), riser(s), electrical and other cables, marine structures and/or jackets during execution of the entire works. The Company gives no guarantee or warranty as to the accuracy or completeness of the information provided on these existing facilities in enclosed drawings and it is Contractors sole responsibility to obtain sufficient information on these existing facilities for safe and sound execution of the work. Entire cost of repair or replacement of these facilities damaged due to Contractors negligence shall be to Contractors account including any production loss to the Owner/Company thereof. Company shall be the sole judge for deciding the same.

b)

c)

d)

4.2.4

Companys Responsibilities Company has provided available information on the existing pipelines and other facilities, however, Company gives no guarantee or warranty as to the accuracy or completeness of the information on these existing facilities. It is the Contractors sole responsibility to obtain sufficient information on these existing facilities to allow safe and sound design and installation of the new pipeline(s) and riser(s).

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 9 OF 9

4B

4.3 4.3.1

DESIGN CRITERIA Design Parameters The design of flexible pipelines and riser system, pipeline crossing, and tie-ins shall follow the guidelines of API RP 17B Recommended practice for Flexible Pipe and following documents enclosed with the bid package. 1. 2. 3. Specification for flexible pipe material as per Spec. 2020E Rev. 2. Environmental Parameters: The Table 4.1B represents environmental parameters and minimum stability requirements. Details of flexible pipeline system are presented in Table 4.2B (placed at Annexure to Section 4B). However, the pipe internal shall be suitable for intended services.

Geotechnical data shall be collected by the Contractor during survey as per bid package requirements. Soil data collected should be enough to determine strength and index properties required for detailed engineering areas prone to scour and instability. The pipeline routes are approximate only. Final route selection and design and installation engineering of submarine pipeline, crossings and tie-ins shall be based on the results and interpretation of surveys carried out by the Contractor in accordance with Spec.No. 2011 Rev. 1 of the bid package. 4.3.2 All calculation methods which bidder proposes to use in detail design, the installation procedures, testing procedures and marine equipment etc. proposed to be used shall be in sufficient detail to allow the Company to verify the design basis and technical suitability of bidders proposal. If computer output is proposed, bidder shall furnish a brief description of the analytical methods employed in the program and identify the basis and theory used. The bidder should submit list of the softwares proposed to be used for this project, their proven capability, reference and track record. Codes and Standards The design, fabrication and installation of all pipelines shall meet the requirements of the latest editions of the various Codes and Standards as referred in clause 1.2 of Specification of flexible pipe material, engineering and design, storage, transportation and installation enclosed as Spec. 2020E, in addition to following codes and standards wherever applicable.

4.3.3

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 10 OF 10

4B

ANSI B 31.4 IP6 API STD 1104 API RP 1110 API RP 1111

Liquid Petroleum Transportation Pipeline System Institute of Petroleum Model Code of Safe Practice. Standard for welding pipelines and related facilities. Recommended Practice for the pressure Testing of Liquid Petroleum Lines. Recommended Practice for design, construction, operation and maintenance of offshore hydrocarbon pipeline. Recommended Practice for Flexible Pipe Design and Operation of subsea production system. Minimum Federal Safety Standards for Liquid pipelines. Swedish Standards Institution for Surface preparation. Technical notes for flexible pipes and hoses for submarine pipelines system. Cathodic Protection System. Recommended practice : Control of Corrosion on Offshore Steel Pipelines.

API RP 17B API RP 7A U.S. Part 195 SIS 055900 DNV TNA 503 DNV RPB 401 NACE Std. RP 06 75

ASTM standards whenever applicable and all relevant Specifications in the Bid Package. Where conflicting statements exist between the different Codes and standards, the most stringent one shall apply unless directed or agreed otherwise by the Company. 4.3.4 4.3.4.1 Pipeline Design Method Pipeline and related facilities shall be designed by taking into consideration all the analysis as specified in Specification No. 2015A & 2020E and requirements indicated in Table 4.1B, Table 4.2B ( placed at Annexure to Section 4B), drawings ( enclosed elsewhere in the bid document) and specifications listed in Appendix A & B (( placed at Annexure to Section 4B). Flexible pipeline shall be designed for hydrostatic collapse for a breached outer sheath with the

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 11 OF 11

4B

pipeline in empty condition. The different layers & sub layers in each layer and thickness of layers required in the structure shall be finalized during detailed engineering. The Contractor shall design the entire pipeline system in such away to ensure the piggability of pipelines from pig barrel to pig barrel. 4.3.4.2 Route and Profile Utilizing the Pre-engineering survey information, the Contractor shall finalize the pipeline alignment. The pipeline route shall be selected such that the pipeline follows a smooth seabed profile and avoid, wherever possible, coral reefs and soft or liquified soils keeping the length and number of crossings to minimum. The detailed seabed survey shall be carried out near the platform to find out termination point coordinates of each end of the pipeline segment along with approach / departure angles.

4.3.4.3

Offshore Pipeline Crossing The crossings shall be designed such that the existing or proposed pipeline shall not be over stressed, either during installation or operation as per governing stress criteria and the resulting spans, if any shall not exceed their allowable limits. The minimum clearance shall be subject to the Companys approval and shall be based on the predicted settlement of pipes, size & type of supports, allowable span length, if any etc. Contractor shall design the crossing configuration/arrangement considering the parameters given in Table 4.1B (placed at Annexure to Section 4B) and submit to company for review and approval. The crossing configuration/arrangement shall be designed so as to maintain physical separation of 200 mm or more between the existing pipeline and the proposed pipeline for the life span of proposed pipeline. In the event, the proposed pipeline is crossing two or more existing pipelines without any touch down point in between existing pipelines, then the crossing configuration shall be considered as one crossing.

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 12 OF 12

4B

4.3.4.4

Cathodic Protection The cathodic protection for entire pipeline and riser system alongwith I-tube/Jtube assembly, end fittings etc. shall be provided by the Contractor in accordance with Electrical Design Criteria given and Functional Specification 4002 Rev.1.

4.3.4.5

Stability analysis The stability requirements shall be evaluated by lateral and vertical stability analysis of the pipeline during installation, testing and operation. The lateral stability analysis, shall include all environmental forces such as drag, inertia and lift as well as frictional resistance. The vertical stability analysis shall include pipe buoyancy, an assessment of soil liquefaction potential, trenching depth and backfilling requirements. The following design cases shall be considered: Pipe resting on the seabed Pipe resting on seabed and stabilized by other means such as placing additional restraints e.g. grout bags etc. Pipe crossing with pipe resting on supports (if applicable)

The required submerged weight of the pipe for the stability analysis shall be determined for the following design conditions: 4.3.4.6 Pipe empty during installation Pipe filled with product during operation

Pipelay Analysis The pipelay analysis shall be performed using details of proposed barge/laying method to confirm that flexible pipelines can be laid with proposed barge satisfying requirements given in relevant Code(s) and Standards & Specification.

4.3.5

Riser Design Method Riser shall be designed taking into consideration all the applicable analysis as specified in Spec. No. 2015A & 2020E and requirements indicated in Table 4.1B, Table 4.2B (( placed at Annexure to Section 4B), drawings (enclosed elsewhere in the bid) and specifications listed in Appendix-A & B ( placed at Annexure to Section 4B).

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 13 OF 13

4B

4.3.5.1

Riser Location Indicative locations for each flexible riser along with I-tube/J-tube assembly is given in riser drawings enclosed in bid document . This shall be finalized during pre-engineering survey/detailed engineering. For new platform to be installed , the jacket face on which I-tube/J-tube is to be installed, has been indicated in Table 4.2B (placed at Annexure to Section 4B) and the location on the jacket face shall be finalized during detailed engineering.

4.3.5.2

Clamps/Alternative Fixture Normally, risers shall be supported from top by hanger flange and guided by suitable fixing arrangement like I-tube/J-tube along with bell mouths/seals, clamps, etc. attached to the jacket members. Contractor shall accordingly propose fixing arrangement suitable for flexible riser along with supporting documents for Companys review and approval. Such fixing arrangement shall be designed, fabricated and installed by the Contractor. No. of clamps/fixtures and their spacing/location shall be decided based on analysis during detailed engineering.

4.3.5.3

Hanger Flanges All flexible risers shall be provided with suitable hanger flanges to support the risers form the top. The riser hanger flanges shall be designed, manufactured and installed by Contractor as per relevant codes and standards. The complete details, design, fabrication and installation of riser hanger flanges shall be approved by the Company.

4.3.5.4

I-Tubes/J-Tubes Based on fixing arrangement, Contractor shall design, fabricate and install all necessary I-Tubes/J-Tube along with other related appurtenances like bell mouth/seals, clamp etc. for all flexible risers. In case of alternative arrangement also, the same shall be applicable. The I-tube/J-tube assembly shall be designed as per structural design criteria enclosed in Section-3 and shall be provided with external monel sheathing in the splash zone portion i.e. between elevation 2.0 m and upto the bottom of hanger clamp or +5.5 m elevation, whichever is higher. Monel sheathing shall be provided as per Spec. No. 2015, Rev. 1.

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 14 OF 14

4B

4.3.6

In addition to the technical requirements and conditions stated herein, drawings and specifications enclosed as Appendix A & B (placed at Annexure to Section 4B)shall be complied with to the extent applicable for the various works to be performed by the Contractor. DESIGN REVIEW Requirements Contractor shall be required to present written substantiation of all proposed designs, installation and testing procedures for the approval of the Company. This shall be done thirty (30) days prior to the commencement of any phase of fabrication or installation activity. The work shall begin only after Companys approval has been obtained. The presentation may be in the form of one or more reports and shall contain the design calculations to substantiate Contractors proposed materials and construction techniques. The report shall also contain the design assumptions, design calculations, material specifications and details of construction. Data included in the report shall be sufficient to shown that all factors listed in Section 4.3 have been considered Calculations shall also be submitted for any other factors not listed in Section 4.3 but which are necessary to prove the validity of Contractors design or proposed construction methods. Contractor shall furnish his document schedule including their submission sequence clearly. The following paragraphs cover the minimum requirements for the design documents which includes. i) ii) Reports Drawings

4.4 4.4.1

iii) Calculation Books The above mentioned items shall be a part of design documentation by the Contractor and shall be the property of the Company. 4.4.1.1 Reports The Contractor shall prepare the following reports, as applicable. a) b) c) d) e) f) Pipeline Design Criteria Report Pipeline Design Reports Riser Design Reports Installation/Testing Methods Report Specifications Additional Report

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 15 OF 15

4B

a)

PIPELINE DESIGN CRITERIA REPORTS Pipeline Design Criteria Report shall include the following items. Appraisal of data (environmental, bathymetry, soils etc.) provided by company and data collected by Contractor after survey. Selection of the Pipeline Route and Pipeline length Pre-engineering, Pre-construction and post installation survey reports.

b)

PIPELINE DESIGN REPORTS The Pipeline Design Reports shall include: Pipeline & riser Internal Diameter design and flexible pipe composition / construction. End Fitting design System Static Analysis System Dynamic Analysis Local Stress Analysis Component Analysis Flow Induced Motion Cathodic Protection Analysis Service Life Analysis Pipeline Crossing Stability Analysis Free Span Correction Analysis (if any) Flexible Pipeline In-place Analysis

(c)

INSTALLALTION/TESTING METHOD REPORT The Installation Methods Report shall include:

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 16 OF 16

4B

Offshore Pipeline & Riser Hydrotesting & Hook-up Pull-in Analysis (d) SPECIFICATIONS Flexible pipe End Connectors/Fittings Corrosion Protection Coating for I-tube/J-tube assembly, end connector/ fittings Cathodic Protection of flexible pipe, I-tube/J-tube assembly, end connectors/fittings. Pipeline Crossings Tie-ins fittings and valves, if any Splash zone materials 4.4.1.2 Drawings The Contractor shall prepare all drawings required to complete the design. The drawings shall include pipeline alignment drawings, schematics, layouts, tie-ins, pipe end details etc. The drawing index shall be divided into the following major categories: Field Maps Pipeline Alignment Drawings Pipeline Approach to and Departure from platforms Pipeline Crossings Sketches and Illustrations A scale 1:5000 for the pipeline alignment sheet and a scale of 1:250 for the platform approach covering a distance of minimum 200 meters shall be used unless otherwise specified by the Company.

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 17 OF 17

4B

4.4.1.3

Calculation Books The calculation books shall include all calculations and computer analysis for pipelines. The books shall have separate sections for pipeline.

4.5

PIPELINE INSTALLATION All works related to pipeline installation shall be performed in accordance with the specifications listed at Appendix-B (placed at Annexure to Section 4B), to the extent they are applicable. Detailed procedure shall be submitted for review & approval prior to start of installation.

4.6

TIE-IN OPERATIONS Contractor shall submit details for tie-ins between riser and deck piping to the Company for review and approval. Hook-up of flexible pipeline riser with topside piping end shall be done through flange connection or any suitable end connector arrangement which shall be approved by Company and these shall be located above the splash zone (at hanger flange). For such arrangement, three sets of seal/ring & bolting material shall be supplied to Company for each tie-in connection without any extra cost.

4.7

TESTING OF PIPELINE & RISER SYSTEM Testing of pipeline system shall be done as per the specification attached with bid package after completion of all installation works of pipelines, crossings, operations, and remedial works if any. Before hydrostatic testing, the pipeline shall be cleaned with a mechanical pig. Testing procedure and equipment shall be subject to Company approval and shall include cleaning, gauging and hydrotesting of the pipeline system. Companys Representative must be present to witness all pipeline tests conducted by the Contractor. Contractor shall hydrostatically test for a minimum continuous period of 24 hours after stabilization of pressure, all lines to a test pressure of 1.25 times the design pressure given in Table 4.2B (placed at Annexure to Section 4B).

4.8 4.8.1

POST TEST PROCEDURE Following completion of the hydrostatic tests, all completed pipelines shall be left full of inhibited test water by Contractor, unless cleaning and purging is required by the Company. Contractor will then make all above water tie-inconnections.

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 18 OF 18

4B

4.8.2 4.9 4.9.1

Contractor shall also remove all appurtenances that were installed to facilitate pigging and hydrotesting. POST CONSTRUCTION SURVEY The Contractor shall carry out a survey of the installed pipeline system, with all necessary equipment such as sub bottom profiler, side scan sonar, echo sounder etc. for determining the extent of unsupported spans, damage and preparation of as built documents etc. Testing of Cathodic Protection System Refer Section 3.5, enclosed. Details of all remedial subsea works, such as crossing, repair to pipeline system, supports to free spans etc. shall also be video recorded after carrying out the works and submitted to Company for record. CLEAN-UP Any stakes, buoys or temporary obstructions placed along the pipeline right of way in the water or on land shall be removed by Contractor or Company shall remove at contractors expense unless company specifically requests that they be left in place. Work spaces furnished to the Contractor by Company shall be cleaned of all scrap and debris and restored to their original conditions. Contractor shall remove all surplus material from the work site and shall deliver such material belonging to Company to the points designated by the Company.

4.9.2 4.9.3

4.10

. 4.11 4.11.1

AS-BUILT PIPELINE SYSTEM REPORT On completion of hydrostatic testing, the Contractor shall prepare As built Drawings/Reports for pipeline systems. The company will specify the Coordinate system and scale to be used. Alignment details shall be obtained from plotted data taken during construction and post construction surveys. All pertinent data such as pipeline appurtenances, end fittings, crossings, unsupported spans, burial details, location of anodes shall be accurately located on the As Built Drawings. The Contractor shall also prepare As Built Report which will include the following as minimum. a. b. Pipeline installation record showing pipeline material, diameter, reference to pipe tally Pipeline route/alignment maps at scale of 1:5000 and Approach to platform to a scale of 1:250 for 200M near the platform.

4.11.2

OFFSHORE DESIGN SECTION MUMBAI REGION

SUBMARINE PIPELINES AND RISERS

VOL-II

SECTION

REV. 0 SHEET 19 OF 19

4B

c. d.

Hydrostatic testing and pigging details Riser details showing approach angle of pipeline, riser location and orientation, details of I-tube/J-tube assembly, location/elevation of clamps. Details of Cathodic Protection Details of Field Joints Pipeline crossing details Other miscellaneous details such as diary of events, list of video tape recording, photographic records etc. Table 4.2B (placed at Annexure to Section 4B) shall be updated based on As Built data and co-ordinates of originating/terminating platforms/laterals shall also be indicated.

e. f. g. h. i.

4.11.3

Six copies of the As Built drawings and As Built report and three copies of all photographic records and video tape recordings (VHS-Pal system) for each pipeline system shall be submitted to the Company. Contractor shall also provide two copies on Compact Disc (CD) of all reports (in MS Office) and drawings (in AUTOCAD Release 2000 or latest version)

Вам также может понравиться

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОт EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОценок пока нет

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityОт EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityОценок пока нет

- Lazy AssignmentДокумент5 страницLazy Assignmentthefoot39Оценок пока нет

- Flexible Jumper Design PremiseДокумент12 страницFlexible Jumper Design PremiseAgus BudionoОценок пока нет

- Thesis Manuscript - Airindy Felisita - 11Документ232 страницыThesis Manuscript - Airindy Felisita - 11klop disposableОценок пока нет

- Static Analysis Report Rev-A PDFДокумент16 страницStatic Analysis Report Rev-A PDFbee4manuОценок пока нет

- Z-Subsea Free Span & VIVДокумент2 страницыZ-Subsea Free Span & VIVxiaoОценок пока нет

- Spool Lift and Loadout ProcedureДокумент75 страницSpool Lift and Loadout ProcedurePhani Kumar G SОценок пока нет

- LOTOS SIWZ A1-3 Z12 112996-EnG-RPT-00003 R02 IFC Pipeline Installation AnalysisДокумент33 страницыLOTOS SIWZ A1-3 Z12 112996-EnG-RPT-00003 R02 IFC Pipeline Installation AnalysisJP EDSОценок пока нет

- DNV Os C106Документ44 страницыDNV Os C106Wilson Barreta JuniorОценок пока нет

- Pipeline Protection and Stabilisation SLP The Submat Bitumen Mattress CanДокумент19 страницPipeline Protection and Stabilisation SLP The Submat Bitumen Mattress CanArianta RianОценок пока нет

- Moses Mooring Analysis - Introduction - 230903 - 101634Документ42 страницыMoses Mooring Analysis - Introduction - 230903 - 101634Hermawan Saini100% (1)

- D04 J-Tube Pull inДокумент4 страницыD04 J-Tube Pull inArie Indra MasudiОценок пока нет

- 109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InДокумент41 страница109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InMohd. Fadhil JamirinОценок пока нет

- BP Angelin Project: Jacket Loadout Analysis ReportДокумент48 страницBP Angelin Project: Jacket Loadout Analysis ReportDhanu PadhuОценок пока нет

- R3643 Flexible Pull-InДокумент9 страницR3643 Flexible Pull-IntungОценок пока нет

- Technical Specification: 0 OriginalДокумент22 страницыTechnical Specification: 0 OriginalGuilherme de BarrosОценок пока нет

- MWA ReportДокумент75 страницMWA ReportCyrus HongОценок пока нет

- Case Studies For Evaluating Hydrodynamic Motion Responses Using MOSESДокумент26 страницCase Studies For Evaluating Hydrodynamic Motion Responses Using MOSESATLURI SATYA SRINIVAS oe13m002Оценок пока нет

- Introduction FreeSpanningPipelinesDNV RP F105Документ13 страницIntroduction FreeSpanningPipelinesDNV RP F105Nabil37Оценок пока нет

- 2 不可靠 摩擦力参考文件 Expansion and Global Buckling Calculation ReportДокумент32 страницы2 不可靠 摩擦力参考文件 Expansion and Global Buckling Calculation ReportwangОценок пока нет

- Appendix e (Sacs Output)Документ6 страницAppendix e (Sacs Output)Tran Van DaiОценок пока нет

- Pre Trenching ProsedurДокумент19 страницPre Trenching Prosedurmaniacs14Оценок пока нет

- 0003 Mi20 00S1 0240 0Документ15 страниц0003 Mi20 00S1 0240 0Galih Suksmono AdiОценок пока нет

- Offshore Pipeline Design Course ChaptersДокумент6 страницOffshore Pipeline Design Course ChaptersDonald.K100% (1)

- OMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillДокумент8 страницOMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillLucas FladinirОценок пока нет

- Pull in AnalysisДокумент4 страницыPull in Analysisgvsha88Оценок пока нет

- Company Profile: IHC Engineering Business LTDДокумент35 страницCompany Profile: IHC Engineering Business LTDSatyavan L RoundhalОценок пока нет

- 14 - NRG - Pipe Installation - Davit LiftДокумент16 страниц14 - NRG - Pipe Installation - Davit LiftBalanОценок пока нет

- Section 4: Specifications Specifications For Quick Release HookДокумент17 страницSection 4: Specifications Specifications For Quick Release HookAnonymous iM2totBrОценок пока нет

- Thermal Buckling Comparative Analysis Using Different FE Tools 01Документ4 страницыThermal Buckling Comparative Analysis Using Different FE Tools 01Waldek BanasiakОценок пока нет

- Underwater Submarine Pipe LineДокумент30 страницUnderwater Submarine Pipe LinevillanuevamarkdОценок пока нет

- Microsoft Word - PRELIMINARY MOORING ANALISYS DSV TS504Документ48 страницMicrosoft Word - PRELIMINARY MOORING ANALISYS DSV TS504halimОценок пока нет

- Heerema Standard Criteria - Google 搜索Документ3 страницыHeerema Standard Criteria - Google 搜索jasonwu1115Оценок пока нет

- #How02 Z01apa01 Elh501 c01 Rcs Earthing Layout-001 CellarДокумент1 страница#How02 Z01apa01 Elh501 c01 Rcs Earthing Layout-001 CellarKonge ThethtunaungОценок пока нет

- UMF GN04 Issue 1 Free Span AnalysisДокумент5 страницUMF GN04 Issue 1 Free Span AnalysiszulikramОценок пока нет

- Quayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)Документ35 страницQuayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)cliff1234Оценок пока нет

- OrcaFlex 9.2a ManualДокумент393 страницыOrcaFlex 9.2a ManualMyoung ChoiОценок пока нет

- Documents - Pub Case Study Sesamtm For Subsea Prepared by DNV GL Software TypicallyДокумент23 страницыDocuments - Pub Case Study Sesamtm For Subsea Prepared by DNV GL Software TypicallyMiguel PereiraОценок пока нет

- 23 Mooring Analysis During ShorepullДокумент53 страницы23 Mooring Analysis During ShorepullNoverdo Saputra100% (1)

- FEA Buckling AnalysisДокумент10 страницFEA Buckling AnalysisalexrodriguezabcОценок пока нет

- 2D Pipeline Bottom Roughness - Mochammad ImronДокумент6 страниц2D Pipeline Bottom Roughness - Mochammad ImronLK AnhDungОценок пока нет

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineДокумент1 страница4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaОценок пока нет

- MS002 ST Rep 076 00016Документ78 страницMS002 ST Rep 076 00016DavisTranОценок пока нет

- Catenary Cation of Cables PDFДокумент153 страницыCatenary Cation of Cables PDFPrashanth Talkad Rajagopal100% (1)

- Turret MooringsДокумент3 страницыTurret Mooringsjo0% (1)

- DNVGL Se 0080Документ27 страницDNVGL Se 0080Marco CordonОценок пока нет

- 0029 - ND Rev - 0 22-Jun-13 Guidelines For Submarine Pipeline InstallationДокумент54 страницы0029 - ND Rev - 0 22-Jun-13 Guidelines For Submarine Pipeline InstallationGiray Çıvak100% (1)

- Wall Thickness Calculation of Offshore PipelinesДокумент1 страницаWall Thickness Calculation of Offshore PipelinesAlvin Smith0% (1)

- Principia DeepLines PresentationДокумент45 страницPrincipia DeepLines Presentationbello imamОценок пока нет

- 8 - NRG - Pipeline Protection - AnchorДокумент38 страниц8 - NRG - Pipeline Protection - AnchorBalanОценок пока нет

- EGP3-01.22 Transportation of Cargo by Barge or ShipДокумент32 страницыEGP3-01.22 Transportation of Cargo by Barge or ShipMathias OnosemuodeОценок пока нет

- OMAE2012 84121 PresentationДокумент16 страницOMAE2012 84121 PresentationsojanvasudevanОценок пока нет

- On-Bottom Stability Check of Wellhead Jacket in Gulf of Thailand - Offshore Structural CornerДокумент17 страницOn-Bottom Stability Check of Wellhead Jacket in Gulf of Thailand - Offshore Structural Cornerthomas1313Оценок пока нет

- Collapse Analysis 1Документ13 страницCollapse Analysis 1samiransmitaОценок пока нет

- Jacket Installation FlowchartДокумент1 страницаJacket Installation FlowchartNath YauОценок пока нет

- 6 - NRG - Free SpanДокумент23 страницы6 - NRG - Free SpanBalanОценок пока нет

- Failure Modes, Inspection, Testing and Monitoring: Flexible PipesДокумент34 страницыFailure Modes, Inspection, Testing and Monitoring: Flexible PipesHamad HameedОценок пока нет

- PWCS Technical Specifications - PN C11 - C15Документ56 страницPWCS Technical Specifications - PN C11 - C15Bharat MaddulaОценок пока нет

- 33 05 23.13 - Horizontal Directional DrillingДокумент17 страниц33 05 23.13 - Horizontal Directional DrillingThomas Bennett100% (1)

- Pipeline Pressurisation & de Pressurisation CalculationДокумент4 страницыPipeline Pressurisation & de Pressurisation Calculationhatakerobot50% (2)

- CAN II 11.13 Vessel General Information - 01.06.2018Документ4 страницыCAN II 11.13 Vessel General Information - 01.06.2018hatakerobotОценок пока нет

- Highest Integrity Hand-Held Coiled Tubing Handling Tools: Features and Benefits of CoillokДокумент2 страницыHighest Integrity Hand-Held Coiled Tubing Handling Tools: Features and Benefits of CoillokhatakerobotОценок пока нет

- CC43 ACE-0395-11 Investigation Report - 2Документ3 страницыCC43 ACE-0395-11 Investigation Report - 2hatakerobotОценок пока нет

- PDM State Released: Item Qty Part Number Description MaterialДокумент1 страницаPDM State Released: Item Qty Part Number Description MaterialhatakerobotОценок пока нет

- IBCLiftersДокумент2 страницыIBCLiftershatakerobotОценок пока нет

- Hotstab Dummy Stab: PDM State ReleasedДокумент1 страницаHotstab Dummy Stab: PDM State ReleasedhatakerobotОценок пока нет

- Page 1 of 10Документ10 страницPage 1 of 10hatakerobotОценок пока нет

- Check Valves: P A G EДокумент3 страницыCheck Valves: P A G EhatakerobotОценок пока нет

- 3D Model 2 Configuration 3 Bill of Materials 4 Company Information 5Документ5 страниц3D Model 2 Configuration 3 Bill of Materials 4 Company Information 5hatakerobotОценок пока нет

- IBC Lifting FrameДокумент1 страницаIBC Lifting FramehatakerobotОценок пока нет

- Test UploadДокумент15 страницTest UploadhatakerobotОценок пока нет

- Summary - Working On Weekend / Public Holidays Item Period Location Accrued Days Off in Lieu (TOIL) DaysДокумент1 страницаSummary - Working On Weekend / Public Holidays Item Period Location Accrued Days Off in Lieu (TOIL) DayshatakerobotОценок пока нет

- MEGlobal MEG PDFДокумент34 страницыMEGlobal MEG PDFYustinus Selis ToronОценок пока нет

- Darcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataДокумент1 страницаDarcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DatahatakerobotОценок пока нет

- Level SketchДокумент1 страницаLevel SketchhatakerobotОценок пока нет

- Subsea Temp Probe CW ReelДокумент1 страницаSubsea Temp Probe CW ReelhatakerobotОценок пока нет

- Api 17-H 10000psiДокумент4 страницыApi 17-H 10000psihatakerobotОценок пока нет

- OE CORP ENG TN 0002 Pre Commissioning Overview Umbilicals Rev C1Документ16 страницOE CORP ENG TN 0002 Pre Commissioning Overview Umbilicals Rev C1hatakerobot100% (1)

- TEJASWINIДокумент4 страницыTEJASWINIShìVâ KùMàrОценок пока нет

- Project Reoprt On JSW SteelsДокумент30 страницProject Reoprt On JSW SteelsSakthi Krishnan100% (1)

- Antony Kungu - Final Project AssignmentДокумент11 страницAntony Kungu - Final Project Assignmentapi-420816837Оценок пока нет

- CYMTCC For Windows: User's Guide and Reference ManualДокумент290 страницCYMTCC For Windows: User's Guide and Reference ManualJosselynGalloMuñozОценок пока нет

- Sa 449Документ8 страницSa 449Widya widya100% (1)

- 6CS6.2 Unit 5 LearningДокумент41 страница6CS6.2 Unit 5 LearningAayush AgarwalОценок пока нет

- List of The Registered UAE CompaniesДокумент3 страницыList of The Registered UAE Companiesirfan aminОценок пока нет

- Nyuszi SzabásmintaДокумент3 страницыNyuszi SzabásmintaKata Mihályfi100% (1)

- The 'X' Chronicles Newspaper - August 2010Документ50 страницThe 'X' Chronicles Newspaper - August 2010Rob McConnell100% (1)

- SV50SP2RevB Released User DocumentsДокумент8 страницSV50SP2RevB Released User DocumentsAhmed RamadanОценок пока нет

- Hydraulic Backhoe MachineДокумент57 страницHydraulic Backhoe MachineLokesh SrivastavaОценок пока нет

- Position PaperДокумент7 страницPosition PaperClem CollantesОценок пока нет

- HVPE Syllabus of Ist Year & IInd Year Degree StudentsДокумент5 страницHVPE Syllabus of Ist Year & IInd Year Degree StudentsReddyvari Venugopal0% (1)

- Goldwallet 2.1.1Документ16 страницGoldwallet 2.1.1yanuarОценок пока нет

- Model 7691Документ1 страницаModel 7691Khiết trầnОценок пока нет

- ASW Connection PDFДокумент7 страницASW Connection PDFWawan SatiawanОценок пока нет

- VFD Cable Selection Guide: NEC Allowable Conductor Ampacity Regulatory CodesДокумент1 страницаVFD Cable Selection Guide: NEC Allowable Conductor Ampacity Regulatory Codescarlos ortizОценок пока нет

- Waste To Wealth Green Potential From Palm Biomass in MalaysiaДокумент9 страницWaste To Wealth Green Potential From Palm Biomass in MalaysiaLai Mei EeОценок пока нет

- Fax 283Документ3 страницыFax 283gary476Оценок пока нет

- Thrust Bearing Design GuideДокумент56 страницThrust Bearing Design Guidebladimir moraОценок пока нет

- Sell Sheet Full - Size-FinalДокумент2 страницыSell Sheet Full - Size-FinalTito BustamanteОценок пока нет

- An Introduction To Coolants PDFДокумент57 страницAn Introduction To Coolants PDFPETER ADAMОценок пока нет

- Articles On Organic Agriculture Act of 2010Документ6 страницArticles On Organic Agriculture Act of 2010APRIL ROSE YOSORESОценок пока нет

- Ds Lm5006 en Co 79839 Float Level SwitchДокумент7 страницDs Lm5006 en Co 79839 Float Level SwitchRiski AdiОценок пока нет

- An 4160Документ8 страницAn 4160aurumstar2000Оценок пока нет

- Guideline G6 Certification Process v2 0Документ18 страницGuideline G6 Certification Process v2 0Wong Wong WLОценок пока нет

- Guidelines For Hall IC SubassemblyДокумент9 страницGuidelines For Hall IC SubassemblyvkmsОценок пока нет

- Module 3 Lesson 1 Edited For CBL Lesson ContentДокумент3 страницыModule 3 Lesson 1 Edited For CBL Lesson ContentMariecris BatasОценок пока нет

- Chapter 8 Designing and Developing Effective HRD ProgramsДокумент37 страницChapter 8 Designing and Developing Effective HRD ProgramsVincent Raj KumarОценок пока нет

- Buying Solutions' Total Cost of Ownership (TCO) CalculatorДокумент93 страницыBuying Solutions' Total Cost of Ownership (TCO) Calculatorankitch123Оценок пока нет