Академический Документы

Профессиональный Документы

Культура Документы

ITP 63113 XX Stockpile ITP (Working)

Загружено:

soni10483Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ITP 63113 XX Stockpile ITP (Working)

Загружено:

soni10483Авторское право:

Доступные форматы

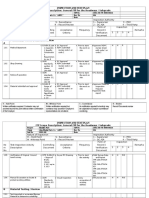

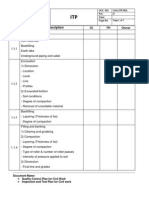

STOCKPILE INSPECTION AND TEST PLAN

ITP--XX

REV DATE DESCRIPTION PREPARED CHECKED APPROVED

Ref : ITP--XX Rev : 1 Page : 2 of 6

STOCKPILE INSPECTION & TEST PLAN

Item

1.00

1.01

Process Description & Activity

Preliminaries

Review Contract & Scope of Works, confirm against tender Review Specification

Document

Acceptance Criteria

Verifying Document

Contract Review Checklist Signed ITP

Inspection CS KT KJV

Remarks

1.02

Client Contract & SOW Central Systems tender submission Client Specifications G1-TE-S-0000-SPC5004 G1-TE-S-0000-SPC5007 Client supplied drawings G1-TD-C-1900: PAS1001 Rev 1 PAS1002 Rev 1 GRD1000 Rev 1 GRD1001 Rev 1 GRD1002 Rev 1 Central Systems IMS

Tender & Contract Document

Client Specifications G1-TE-S-0000-SPC5004 G1-TE-S-0000-SPC5007 Approved for Construction Drawings (AFC)

1.03

Review Drawings

Approved for Construction Drawings (AFC)

2.00

2.01

Approvals

Quality Management Plan Client Approval Approved Management Plan 004257-QMP Approved Management Plan 004257-HSEMP

2.02

Health, Safety, Environment Management Interface Plan

Central Systems IMS

Client Approval

2.03 2.04

Construction Method Statement Inspection Test Plan

Central Systems Method of Statement ITP Embankment / Structural Fill Client HSS & Environmental R S ITR

Client Approval Client Approval

Approved Method Statement (SWMS) Approved ITP

Excavation / Clearance Approval M W H Monitor Witness Hold Point

Land Clearance Permit Approved Land Tenure Boundary Verified Review Submit Documentation Inspection & Test Report

Approved Permits KT KJV VB KT Pty Ltd Kellogg Joint Venture Verifying Body

Once printed this document becomes uncontrolled.

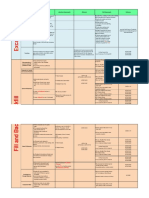

Ref : ITP--XX Rev : 1 Page : 3 of 6

STOCKPILE INSPECTION & TEST PLAN

2.05 Verifying Checklists / Registers Procedures QA/QC Registers: Compaction Lot Subgrade etc Excavation & Penetration Permit Approved Client Approval Approved documents

3.00

3.01

Materials Note: Due to the minimal depth of fill / cut (<1.5m) & quantity, all suitable excavated materials shall be transported to crusher for processing to Class S-B for all general structural fill requirements (subject to client approval)

Class 500 Rock Fill Client Specifications G1-TE-S-0000-SPC5004 Client Specifications G1-TE-S-0000-SPC5004 100% <500mm 55-100% <300mm 40-80% <200mm 25-60% <100mm Class S-B below <100mm Particle Size Distribution Test / 20,000m3 Client Specifications G1-TE-S-0000-SPC5004 100% <300mm 80-100% <200mm 60-100% <200mm Class S-B below <100mm Particle Size Distribution Test / 20,000m3 Client Specifications G1-TE-S-0000-SPC5004 Class S-B - AP 100mm Particle Size Distribution 1 Test / 2,000m3 (SP) Atterberg Limit 1 Test / 2,000m3 (SP) PI Max 20, LL Max 30 Modified Compaction Curve 1 Test / 1,000m3 (SP) Client Specifications G1-TE-S-0000-SPC5004 - Sea water may be used within 50m of Land Tenure Boundary at discretion of Company. - Sea water can be used in embankment construction but R S ITR Review Submit Documentation Inspection & Test Report Material Test Certificates

3.02

Class 300 Rock Fill

Client Specifications G1-TE-S-0000-SPC5004

Material Test Certificates

3.03

Class S-B Sub-base Undercut / unsuitable reconstruction Embankment Construction Subgrade Construction

Client Specifications G1-TE-S-0000-SPC5004

Material Test Certificates

3.04

Water - Construction

Client Specifications G1-TE-S-0000-SPC5004

Site Inspection

M W H

Monitor Witness Hold Point

KT KJV VB

KT Pty Ltd Kellogg Joint Venture Verifying Body

Once printed this document becomes uncontrolled.

Ref : ITP--XX Rev : 1 Page : 4 of 6

STOCKPILE INSPECTION & TEST PLAN

not with 300mm of surface or final pavement layers.

4.0

4.01

Foundation Preparation for Embankments

Embankment Foundation (Rock Material) - Surface Preparation Note: All Stripping & Grubbing Completed Prior Client Specifications G1-TE-S-0000-SPC5004 Client Specification - All high spots removed to satisfaction of Company - Surface to be evenly graded to promote compaction - Joint Inspection surface for cracking - Attain approval prior to placing fill layers - Fill lows with Class S-B - Wet surface prior to placement of fill layers Client Specification - Rip & Remake 150mm top layer - Sloping surfaces may need to be benched to ensure tie in - Surface condition with water Field Inspection Record

4.02

Embankment Foundation (General) Preparation

Client Specifications G1-TE-S-0000-SPC5004

Field Inspection Record

4.03

Embankment Foundation (General) Compaction

Client Specifications G1-TE-S-0000-SPC5004

4.04

Embankment Foundation (General) Unsuitable Material

Client Specifications G1-TE-S-0000-SPC5004

Client Specification - Poof Roll / Compact using 12t roller (min) with 6 passes in LF/HA then 6 passes in HF/LA - Joint Inspection for surface deformation - Attain approval prior to placing fill layers Client Specification - For any unsuitable areas where excessive deformation is noted, remove / reconstruct failed areas using 300mm Class S-B as directed by company. - Further proof rolling (2 passes) required on completion of dynamic compaction

Field Inspection Record

Field Inspection Record Site Instruction Survey Record

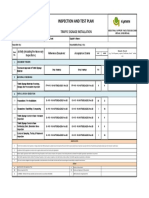

5.0

5.01

Embankment Construction: Class 500 / 300 Rock Fill Material

Line & Level Client Specifications G1-TE-S-0000-SPC5004 Client Specifications AFC Drawings -- Class 500 not to be used with 1000mm of - Class 300 not to be used within 250mm of pavement layer, allowing for at least one layer of Class S-B -/+ 200mm FL Client Specifications R S ITR Review Submit Documentation Inspection & Test Report Survey Log Books

5.02

Layer Thickness M W H Monitor Witness Hold Point

Client Specifications

Visual Inspection KT KJV VB KT Pty Ltd Kellogg Joint Venture Verifying Body

Once printed this document becomes uncontrolled.

Ref : ITP--XX Rev : 1 Page : 5 of 6

STOCKPILE INSPECTION & TEST PLAN

G1-TE-S-0000-SPC5004 5.03 Compaction Client Specifications G1-TE-S-0000-SPC5004 - Class 500 placed in 800-1000mm layers - Class 300 placed in 500-700mm layers Client Specifications G1-TE-S-0000-SPC5004 - Compaction trials to be developed to attain a plate load test if 30MPa/m2 - Class 300/500 to be conditioned (wetted) and pushed into place by Dozer / Grader - Padfoot roller compaction method with - Smooth drum proof roll prior to successive layers Field Test Sheet Nata Test Reports Trial Compaction Method

- Method based specification to be developed & approved

5.04 Moisture Content Client Specifications G1-TE-S-0000-SPC5004 Client Specifications G1-TE-S-0000-SPC5004 - Material to be conditioned prior to handling - Amount / application determined by Trial Compaction Method Trial Compaction Method

6.0

6.01

Embankment / Subgrade Construction using Class S-B Sub-base

Note: Due to the minimal depth of fill / cut (<1.5m) & quantity, all suitable excavated materials shall be transported to crusher for processing to Class S-B for all general structural fill requirements (subject to client approval)

Line & Level Client Specifications G1-TE-S-0000-SPC5004 Client Specifications AFC Drawings -- Class S-B to be used on Class 300 embankment fill for foundation layer (subject to depth of fill) - Class S-B to underside of pavement layer +10mm / - 25mm Client Specifications - Class S-B placed in 200 -250mm loose layers Client Specifications G1-TE-S-0000-SPC5004 - 98% MMDD - Minimum 150mm compacted layer thickness - 1 x MDD Field test / 500m2 Client Specifications G1-TE-S-0000-SPC5004 - Material to be conditioned prior to handling (stockpile) - MC to be within -/+ 2%m of OMC Survey Log Books

6.02 6.03

Layer Thickness Compaction

Client Specifications G1-TE-S-0000-SPC5004 Client Specifications G1-TE-S-0000-SPC5004

Visual Inspection Trial Compaction Method Compaction Test Reports Trial Compaction Method Compaction Test Reports KT KJV VB KT Pty Ltd Kellogg Joint Venture Verifying Body

6.04

Moisture Content

Client Specifications G1-TE-S-0000-SPC5004

M W H

Monitor Witness Hold Point

R S ITR

Review Submit Documentation Inspection & Test Report

Once printed this document becomes uncontrolled.

Ref : ITP--XX Rev : 1 Page : 6 of 6

STOCKPILE INSPECTION & TEST PLAN

9.0

5.01

Documentation

As-Built Drawings QA/QC Lot Registers QA/QC Verification Documents MDR to be complied progressively Client Specifications & Procedures Client / Drawings Specification / Tolerances Survey Record QA/QC Registers QA/QC Documents Field Inspection Records Approved MDR

5.02

Client Specifications & Contract Document MDR Index

Client Specifications & Contract Document All Records as per MDR Index

M W H

Monitor Witness Hold Point

R S ITR

Review Submit Documentation Inspection & Test Report

KT KJV VB

KT Pty Ltd Kellogg Joint Venture Verifying Body

Once printed this document becomes uncontrolled.

Вам также может понравиться

- 5.itp For Construction MaterialsДокумент8 страниц5.itp For Construction Materialsbinunalukandam100% (1)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkДокумент53 страницыA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacОценок пока нет

- ITP - General Fill For The Roads - SampleДокумент12 страницITP - General Fill For The Roads - SamplezubairОценок пока нет

- ENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Документ29 страницENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Sofia RegaladoОценок пока нет

- QCS 2010 Section 5 Part 2 AggregatesДокумент9 страницQCS 2010 Section 5 Part 2 Aggregatesbryanpastor106Оценок пока нет

- PROJECT QUALITY PLANДокумент69 страницPROJECT QUALITY PLANnatrix029Оценок пока нет

- QC Engr CV PDFДокумент5 страницQC Engr CV PDFMuthazhagan SaravananОценок пока нет

- Excavation and Fill Method Statement SummaryДокумент12 страницExcavation and Fill Method Statement Summary한상호Оценок пока нет

- Hydraulic crash barriers ITPДокумент4 страницыHydraulic crash barriers ITPmoytabura96Оценок пока нет

- PQP Vs ISO 9001 Clauses List PDFДокумент1 страницаPQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- How Are Cracked Sections Analyzed in SAFE. CSI SAFEДокумент3 страницыHow Are Cracked Sections Analyzed in SAFE. CSI SAFEJaime Manalili LandinginОценок пока нет

- Nawaz Khan - Civil InspectorДокумент4 страницыNawaz Khan - Civil InspectormlОценок пока нет

- Saes A 114Документ2 страницыSaes A 114Nino Celso AstilleroОценок пока нет

- Saudi Aramco Precast Concrete Installation PlanДокумент10 страницSaudi Aramco Precast Concrete Installation PlanNaushad AlamОценок пока нет

- RFI For 18.03.2014 Piping, Welding at SESA FabДокумент4 страницыRFI For 18.03.2014 Piping, Welding at SESA Fabmuhammedemraan100% (1)

- Quality InductionДокумент15 страницQuality InductionaleemmurtazaОценок пока нет

- 33 05 13 Manholes and Structures 10Документ4 страницы33 05 13 Manholes and Structures 10salamОценок пока нет

- Oman-India Fertilizer Project OIFДокумент24 страницыOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Punch List Civil Jan.13Документ10 страницPunch List Civil Jan.13Azam Islam KhanОценок пока нет

- Renovation Works at Al Forsan Sports ResortДокумент7 страницRenovation Works at Al Forsan Sports ResortAshimolowo BabatundeОценок пока нет

- Quality Assurance and ControlДокумент55 страницQuality Assurance and ControlACHESОценок пока нет

- Materials Acceptance by Certification and Laboratory StandardizationДокумент106 страницMaterials Acceptance by Certification and Laboratory StandardizationAyman KandeelОценок пока нет

- A Qac Pro 000 38951Документ30 страницA Qac Pro 000 38951Amin GОценок пока нет

- Project Quality RequirementsДокумент8 страницProject Quality RequirementsSIVAОценок пока нет

- ITP Heat ExchangerДокумент1 страницаITP Heat Exchangersarmad009Оценок пока нет

- MS Site and FenceДокумент11 страницMS Site and FenceSahabzada AamirОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistZia ur RehmanОценок пока нет

- QAQC Weekly Report (14072017)Документ15 страницQAQC Weekly Report (14072017)Namta GeorgeОценок пока нет

- ISO - Control of Inspection, Measuring & Test EquipmentДокумент4 страницыISO - Control of Inspection, Measuring & Test EquipmentAlmario SagunОценок пока нет

- Itp For U-G2Документ7 страницItp For U-G2Ramzi MusthafaОценок пока нет

- Sewerage and WWTP measures in the city of Korca“ project testing proceduresДокумент9 страницSewerage and WWTP measures in the city of Korca“ project testing proceduresJohnny RamboОценок пока нет

- Earth Moving EquipmentsДокумент2 страницыEarth Moving EquipmentsSHARAFUDHEEN TKОценок пока нет

- 02 Civil & Structure - Rev - 01Документ24 страницы02 Civil & Structure - Rev - 01Yasir MehmoodОценок пока нет

- 5.1.1. Construction of Access Road and Structure PadsДокумент7 страниц5.1.1. Construction of Access Road and Structure PadsALI ASGHARОценок пока нет

- Great Man-Made River Quality AuditingДокумент8 страницGreat Man-Made River Quality Auditingscriptd_ozd3nОценок пока нет

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFДокумент15 страницIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedОценок пока нет

- Internal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksДокумент3 страницыInternal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksBihanChathurangaОценок пока нет

- QAP FormatДокумент7 страницQAP FormatRajesh Kumar JhaОценок пока нет

- Asphalt Concrete PavingДокумент16 страницAsphalt Concrete Pavingprobook450_ehsanОценок пока нет

- ITP AllДокумент1 страницаITP AllMuhammadIqbalMughalОценок пока нет

- Method Statement of Mass Concrete Block Precast WorksДокумент41 страницаMethod Statement of Mass Concrete Block Precast WorksShams JogОценок пока нет

- Inspection and Test Plan-Structural Steel C011Документ2 страницыInspection and Test Plan-Structural Steel C011FurqanОценок пока нет

- Traffic Signage Installation ITPДокумент1 страницаTraffic Signage Installation ITPmoytabura96Оценок пока нет

- ItpДокумент7 страницItpJose Sherin100% (1)

- NCR Records FormДокумент10 страницNCR Records FormTariqMalik100% (1)

- UGFC-PQCP-49, Rev01 March 01Документ7 страницUGFC-PQCP-49, Rev01 March 01Mahaboob PashaОценок пока нет

- 1.request For Inspection (HEMT FO QC 01)Документ1 страница1.request For Inspection (HEMT FO QC 01)Balasai SabarinathОценок пока нет

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionДокумент2 страницыSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanОценок пока нет

- Top Quality Engineer Job Interview Questions That You Should KnowДокумент4 страницыTop Quality Engineer Job Interview Questions That You Should KnowUsman ShahidОценок пока нет

- Construction Method Statement PDFДокумент22 страницыConstruction Method Statement PDFFaruk AtalarОценок пока нет

- Presentation On QA QC Faisal Ali ShaikhДокумент14 страницPresentation On QA QC Faisal Ali ShaikhFaisal Ali ShaikhОценок пока нет

- QA Inspector Job DescriptionДокумент2 страницыQA Inspector Job DescriptionnorlieОценок пока нет

- QA/QC Guidelines Objectives & ScopeДокумент20 страницQA/QC Guidelines Objectives & ScopeFurqanam196100% (2)

- Transmittal SampleДокумент1 страницаTransmittal SamplekokocdfОценок пока нет

- Pqi Trend ChartДокумент4 страницыPqi Trend Chartmurtaza506Оценок пока нет

- Project Inspection and Test PlanДокумент9 страницProject Inspection and Test PlanjparsbОценок пока нет

- Saic N 2031Документ4 страницыSaic N 2031aamirapi100% (1)

- RTR Question and Answer For OWS and Utility LinesДокумент18 страницRTR Question and Answer For OWS and Utility Linesjana.alqimmaОценок пока нет

- HIC & SSC Test ProcedureДокумент32 страницыHIC & SSC Test ProcedureMohamed FarisОценок пока нет

- BS en 10113 2 PDFДокумент13 страницBS en 10113 2 PDFsoni10483Оценок пока нет

- Des FlexДокумент18 страницDes Flexsoni10483Оценок пока нет

- Victaulic Vic Press Fittings 18.12Документ21 страницаVictaulic Vic Press Fittings 18.12soni10483Оценок пока нет

- TM PFT510Документ25 страницTM PFT510soni10483Оценок пока нет

- Lincoln Weld Cost Analysis: CustomerДокумент2 страницыLincoln Weld Cost Analysis: Customersoni10483Оценок пока нет

- CogДокумент14 страницCogsoni10483Оценок пока нет

- Weldlock GratingДокумент16 страницWeldlock Gratingsoni10483Оценок пока нет

- Omega Amide Nylon Pa CatalogueДокумент5 страницOmega Amide Nylon Pa Cataloguesoni10483Оценок пока нет

- Maryland Metrics Thread Data ChartsДокумент4 страницыMaryland Metrics Thread Data Chartssoni10483Оценок пока нет

- Technical 133 PDFДокумент1 страницаTechnical 133 PDFSatheshkumar EagambaramОценок пока нет

- ITP 63113 XX Stockpile ITP (Working)Документ6 страницITP 63113 XX Stockpile ITP (Working)soni10483Оценок пока нет

- Material ComparasionДокумент1 страницаMaterial Comparasionsoni10483Оценок пока нет

- G1 VE V 1900 H08000500018Rev2290512Документ1 страницаG1 VE V 1900 H08000500018Rev2290512soni10483Оценок пока нет

- Pipeline Design and ConstructionДокумент47 страницPipeline Design and ConstructionSaber Abdel Moreid100% (5)

- Heavy Vehicle Driver HandbookДокумент136 страницHeavy Vehicle Driver Handbooksoni10483Оценок пока нет

- Dissertation ErsatzteilmanagementДокумент7 страницDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- The hyperwall: A multiple display wall for visualizing high-dimensional dataДокумент4 страницыThe hyperwall: A multiple display wall for visualizing high-dimensional dataMahendra PututОценок пока нет

- Axial Shortening of Column in Tall Structure.Документ9 страницAxial Shortening of Column in Tall Structure.P.K.Mallick100% (1)

- Sample Cover Letter: No Work ExperienceДокумент4 страницыSample Cover Letter: No Work ExperienceMaya ElvisaОценок пока нет

- Chapter-Iv: Profile of The Hindu News PaperДокумент5 страницChapter-Iv: Profile of The Hindu News PaperMurugan SaravananОценок пока нет

- PJ1117CM-2 5VДокумент6 страницPJ1117CM-2 5VАлексей ГомоновОценок пока нет

- Sean Dickerson ResumeДокумент3 страницыSean Dickerson ResumeSeanОценок пока нет

- Transient and Random VibrationДокумент19 страницTransient and Random VibrationAman SharmaОценок пока нет

- ALTERNATOR - ST170741: Parts ListДокумент2 страницыALTERNATOR - ST170741: Parts Listkaswade BrianОценок пока нет

- Over View On 5 S TechnicДокумент14 страницOver View On 5 S TechnicSachleen Singh BajwaОценок пока нет

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Документ37 страницQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarОценок пока нет

- The Next 20 Billion Digital MarketДокумент4 страницыThe Next 20 Billion Digital MarketakuabataОценок пока нет

- Qcs 2010 Section 5 Part 8 Transportation and Placing of ConcreteДокумент7 страницQcs 2010 Section 5 Part 8 Transportation and Placing of Concretebryanpastor106Оценок пока нет

- Answers About HubSpotДокумент1 страницаAnswers About HubSpotPrasetyaОценок пока нет

- Unit V DSS Development: Arun Mishra 9893686820Документ17 страницUnit V DSS Development: Arun Mishra 9893686820Arun MishraОценок пока нет

- Surging & Blow Out of Loop Seals in A CFBC BoilerДокумент9 страницSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragОценок пока нет

- IEC Certificate 1000V Single Glass 202304Документ35 страницIEC Certificate 1000V Single Glass 202304Marian ProzorianuОценок пока нет

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFДокумент6 страницDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- Cybersecurity-Student-Book Res Eng 1014Документ38 страницCybersecurity-Student-Book Res Eng 1014Nistor Andreea Maria100% (1)

- Tugas 1Документ8 страницTugas 1Muhammad Robby Firmansyah Ar-RasyiedОценок пока нет

- General Purpose Relay SpecsДокумент2 страницыGeneral Purpose Relay SpecsAndres DiazОценок пока нет

- Learning Resource Management Made SimpleДокумент12 страницLearning Resource Management Made SimpleJosenia ConstantinoОценок пока нет

- System Engineering Management Plan (SEMPДокумент2 страницыSystem Engineering Management Plan (SEMPKatie WestОценок пока нет

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsДокумент9 страницArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelОценок пока нет

- E12817 GT AC5300 Manual EnglishДокумент152 страницыE12817 GT AC5300 Manual Englishlegato1984Оценок пока нет

- Siemens 1LE1 PDFДокумент308 страницSiemens 1LE1 PDFharold100% (1)

- Newsletter Template NewДокумент4 страницыNewsletter Template Newapi-458544253Оценок пока нет

- Safety Training Evaluation Form: Instructor RatingДокумент1 страницаSafety Training Evaluation Form: Instructor RatingNate JamesОценок пока нет

- Power Plant Engineering by G.R.nagpalДокумент729 страницPower Plant Engineering by G.R.nagpalGoutham Peri74% (23)

- Gillette and The Men's Wet Shaving Market: Group 8 Section BДокумент12 страницGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainОценок пока нет