Академический Документы

Профессиональный Документы

Культура Документы

Calculo de Lavador de Gases 10.000m Por Hora

Загружено:

hilcerИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Calculo de Lavador de Gases 10.000m Por Hora

Загружено:

hilcerАвторское право:

Доступные форматы

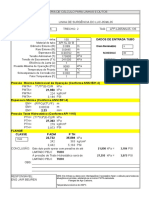

SCRUBBER DESIGN (Coluna de enchimento)

Elaborado por: Verificado por: Data:

Column Tag No. Job No. Client Project Stream = Anel Pall = = = = =

: : : : :

CL2 Scrubber

Entrada de dados Tipo de embalagem Tamanho da embalagem Packing MOC Gas pr. Drop / m bed Altura total de embalagens Altura Coluna Propriedade do Gas Vazo

50 mm PP 30 mmWC / m packing height 3.54 m (including all packed beds) 6.04

2 294.2 (N/m )/m

= =

8964.59 kg/h 2.4902 kg/s 1.00 atm o 30.00 C 70

OR =

3 10000.00 m /h 3 2.77778 m /s

Presso de entrada do Gas = Temperatura de entrada Gas = Taxa fluxo ar / gs = Componente a ser lavado Nome = Taxa de fluxo do compente = % comp. ar/gas = Peso molecular do componente =

303.00 K

Cl2 1038.16 Kg/h 8.64 % (v/v) 70.906

(presumed) / (given by client) / (by process cal.)

Propriedades da Soluo de lavagem Soluo mdia = 20% NaOH Taxa de fluxo de liquido = 15600 kg/h = 4.3333 kg/s 3 Densidade do liquido = 1200 kg/m 2 Viscosidade do liquido = 0.1 Ns/m Fator de empacotamento, Fp =

-1 203 m

= Conversion : 80 Cp

13.00 m/h

Ns/m2

Caracteristicas do fator de empacotamento,C = Ref. Table 6.3, Characterstics of Random packings f 102 Fator de converso, J = 0.92 factor for adequate liquid distribution & irrigation across the bed

Sheet 1 of 12 www.union.ind.br

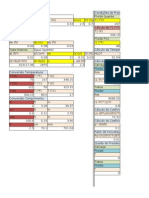

Para calcular dimetro da coluna Uma vez que grandes quantidades de fluxo esto no fundo de um amortecedor, o dimetro sero escolhidos para acomodar as condies de fundo Para calcular a densidade do gas Avg. Peso molecular = Se a taxa de fluxo de gs de dado por kg/h Gas in = 0.035122199 Kmol/s kmol = mass / mol wt = (kmol/s) x T in kelvin x 1.0 atm x 22.4 273 pr. In atm 1 3 = 0.873192 m /s

70.9 Kg / Kmol Se a taxa de fluxo dado em m3/h Gas in = (m /s) x

3

273 x pr. in atm x T in kelvin 1.0 atm

1 22.4

= =

0.11173 Kmol/s 7.92165 Kg/s mass = mol wt x kmol

Selecione vol. de taxa de fluxo e taxa de fluxo de massa por cima Selecionados taxa de fluxo de = massa 2.4902 Kg/s 3 Selecionados taxa de fluxo de = volume 0.873192 m /s Selecionados Vazo molar = 0.035122199 Kmol/s Portanto densidade do gas = 2.8518 Kg/m

3

(mass flow rate / vol. Flow rate)

Para encontrar L', G' e rea da Torre c/s Assumindo a absorso completa Componente removido = 0.2150 Kg/s Liquido deixando = 4.5484 Kg/s L' G'

G L 0.5

(molar flow rate x % comp. x mol. Wt.) (Inlet liquid flow rate + comp. Removed)

0.08904

Utilizao

0.08904

as ordinate, =

(N/m2)/m Refer fig.6.34 usando uma queda de presso 294.2 de gas de 0.039 (from graph)

G' 2 Cf L0.1 J

G( L

--

G)

gc = 0.039

G( L

Portanto, G'

--

G)

gc

0.5

Cf L0.1 J = rea de torre c/s Dimetro da Torre = = =

2 1.3515 Kg / m .s 2 1.8425 m

( c/s area = mass flow rate / G' ) = 1531.7 mm

1.5317 m 2000 mm

2 3.1416 m

Area correspondente c/s =

Sheet 2 of 12 www.union.ind.br

REQUISITO PARA ESTIMAR PERDA DE POTNCIA eficincia do ventilador = 60 % assumed / given

Para calcular a queda de presso Queda de presso de irrigao = embalagem Para embalagens local seco O/L Gas flow rate, G' = O/L Gas pressure = Densidade do Gas, = G 1040.52 N/m

2

(pressure drop per m packing x total ht. of packing)

0.7242 Kg / m .s (Gas inlet flow rate - Component removed) / c/s area 2 100284.4821 N/m (subtracting pressure drop across packing) gas mol wt. x 273 x gas o/l pr. 22.41m3/Kmol T in kelvin 101330 3 = 2.7853 Kg/m = = CD = G'

2 G

CD Delta P Z

47.5

Ref. Table 6.3, Characterstics of Random packings

8.94 N/m

Perda de pressao por enchimento = Perda de pressao por internos = = Velocidade do Gas Inlet expansion & outlet contraction losses

2 1049.46 N/m

(irrigated packing + dry packing) (packing supports and liquid distributors)

30 mmWC 2 294.20 N/m

= 0.884194 m/s = 1.5 x Velocity heads = 0.59 N m / Kg 2 = 1.67 N/m =

2 1345.33 N/m

1.5 x (V / 2g) (divide by density)

Perda total de presso

(packing + internals + losses)

Perda total de presso

137.28 Kgf/m

0.01

atm

Fan power output

2 = pressure drop,N/m x (gas in - component removed) Kg/s O/L gas density, Kg/m3 = 1098.91 N .m / s = 1.10 kW

Power for fan motor

= =

1.83 kW 2.46 hp

(fan power output / motor efficiency)

Sheet 3 of 12 www.union.ind.br

COLUMN DIAMETER / HYDRAULIC CHECK Liq.-Vap. Flow factor, FLV = (L / V) x ( =

V

L)

0.0848 35 7.00 0.85 mm H2O /m packing

Design for an initial pressure drop of From K4 v/s FLV, K4 K4 at flooding Trial % flooding = = = ( = =

(K4 / K4 at flooding) 286.9720 K4 .

V( L

) x 100

Gas mass flow rate, Vm

-L)

13.1 Fp (L / = Trial column c/s area (Trial As) = = Trial column dia., D =

V) 0.1

(1/2)

2 4.8485 kg/m .s

V / Vm

2 0.5136 m

0.8087 m

D = (4/pi) x Trial As

Round off 'D' to nearest standard size Therefore, D =

1.8 m

2 2.5447 m 2 As = (pi/4) x D

Column C/S area, As

% flooding

57.9201

% flooding = Trial % flooding x (Trial As / As)

Conclusion Generally packed towers are designed for 50% -- 85% flooding. If flooding is to be reduced, (i) Select larger packing size and repeat the above steps. OR (ii) Increase the column diameter and repeat the above steps.

Sheet 4 of 12 www.union.ind.br

Table 6.2 Constant for HETP Correlation

Ref.:: Random Packings and Packed Towers ---- Strigle

Ref. : : Chemical Engineering, Volume-6 , COULSON & RICHARDSON'S

Ref. : : Mass Transfer Operation : : Treybal

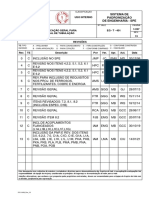

Massa em gramas / metro cubico * 24.45 / peso molecular 183.662 mg/M = PPM * PESO MOLECULAR / 24.45 533.3333 m/h L/mol composio ar m 10000 24.4 L Mol g mg/m g/4100m oxigenio nitrogenio% 0.21 28 2100000 86065.57 2409836 240.98 2409800 nitrogenio% 0.78 16 7800000 319672.1 5114754 511.47 5114700 Total 0.99 Cloro 24kg 71 494873.2 20281.69 1440000 533.33 5333300 Vazao massica Total kg 8964.59 12857.8 kg/10000m 1 35286.89 x 114 Taxa Ar/Gas20.20719 Torre Fabricada vazio 0.15 camada elimiunador 0.15 bico ate eliminador otas 0.3 bico ate encimento 0.3 entrada ar+ recheio 1.7 total 2.45 m m m m m m 28 V/V: 0.000645 4.99872

ppm=

so molecular

/10000m

Вам также может понравиться

- Planilha de Trocador de CalorДокумент265 страницPlanilha de Trocador de CalorRafael Guglielmi Daros100% (3)

- Dimensionamiento de TubosДокумент5 страницDimensionamiento de TubosFernandoОценок пока нет

- Projeto de Ventilação IndustrialДокумент13 страницProjeto de Ventilação IndustrialNosgam SilvaОценок пока нет

- Cálculo da chaminé com dados de entrada e saída de vapor, água, gases e combustívelДокумент5 страницCálculo da chaminé com dados de entrada e saída de vapor, água, gases e combustívelJoão AugustoОценок пока нет

- Pressão Máxima Admissível para TubosДокумент5 страницPressão Máxima Admissível para TubosAlexandre FreitasОценок пока нет

- Dimensionamento de BombasДокумент1 страницаDimensionamento de BombasPauloVictorg19Оценок пока нет

- Os SonhosДокумент58 страницOs SonhosAPPARATOR100% (4)

- Memória de cálculo para linha de surgênciaДокумент9 страницMemória de cálculo para linha de surgênciaorea1Оценок пока нет

- Funcionamento e dimensionamento de ciclonesДокумент7 страницFuncionamento e dimensionamento de ciclonesPaulo Roberto de Carvalho100% (2)

- Projeto de tanque de armazenamento API 650Документ15 страницProjeto de tanque de armazenamento API 650FredFredericoОценок пока нет

- 6 Ano LivroДокумент384 страницы6 Ano LivroJoão CarlosОценок пока нет

- Medidor de Vazao - Venturi Ou Placa de OrificioДокумент4 страницыMedidor de Vazao - Venturi Ou Placa de Orificiomichel macedoОценок пока нет

- Cálculo de volume e dimensões de elementos hidráulicosДокумент29 страницCálculo de volume e dimensões de elementos hidráulicosthiagorep17Оценок пока нет

- Tabela para Calculo Direto de Estacao de Tratamento de EsgotoДокумент28 страницTabela para Calculo Direto de Estacao de Tratamento de EsgotoLuiz Henrique100% (1)

- Tampos abaulados e rebordados para indústriaДокумент38 страницTampos abaulados e rebordados para indústriavigobboОценок пока нет

- Cálculo vão tubulaçãoДокумент4 страницыCálculo vão tubulaçãoAline Pires Dias RibeiroОценок пока нет

- Calcular Tubulação de Ar ComprimidoДокумент1 страницаCalcular Tubulação de Ar ComprimidoCleberson PereiraОценок пока нет

- Tabela Calc. TubulaçãoДокумент22 страницыTabela Calc. TubulaçãoVinicius Renard100% (2)

- Scrubber design para remoção de Cl2Документ12 страницScrubber design para remoção de Cl2Maiara Lima Pereira100% (2)

- Serpentina para Tanque Memorial de CalculoДокумент20 страницSerpentina para Tanque Memorial de CalculoInspetor Soldagem67% (3)

- Dados de Projeto de AgitadorДокумент29 страницDados de Projeto de Agitadorjbrferracin782100% (1)

- Alocação de Fluidos em Trocador de CalorДокумент3 страницыAlocação de Fluidos em Trocador de CalorjonjonAF50% (2)

- Calculo - Rosca TransportadoraДокумент4 страницыCalculo - Rosca TransportadoraEder MendesОценок пока нет

- Fundamentos de Eletrotécnica para Técnicos em EletrônicaДокумент221 страницаFundamentos de Eletrotécnica para Técnicos em EletrônicaVilson Pimmel100% (1)

- Cálculos Roscas 2Документ2 страницыCálculos Roscas 2Michael SanchezОценок пока нет

- FormulasДокумент19 страницFormulaspaulo zanettiОценок пока нет

- Projeto de dimensionamento de máquina operatriz com arranque de cavacoДокумент32 страницыProjeto de dimensionamento de máquina operatriz com arranque de cavacoMarcos C. MirandaОценок пока нет

- Cálculo de Tubulação para VaporДокумент4 страницыCálculo de Tubulação para VaporfrobertocardosoОценок пока нет

- Ciclones e Hidrociclones: princípios e equaçõesДокумент30 страницCiclones e Hidrociclones: princípios e equaçõesJuan Castro Centeno100% (1)

- Calc API 650 01Документ4 страницыCalc API 650 01Engenheiro AmauriОценок пока нет

- Cores guiaДокумент16 страницCores guiaEduardo0% (1)

- Teste avalia leitura 1o-2o ciclosДокумент25 страницTeste avalia leitura 1o-2o ciclosPaula Maciel100% (5)

- Especificação TubulaçãoДокумент237 страницEspecificação TubulaçãoKauê Velho100% (1)

- Projeto lavador gases chaminéДокумент13 страницProjeto lavador gases chaminéRicardo Pereira100% (1)

- Dados técnicos secadorДокумент1 страницаDados técnicos secadorVinicius Galvão0% (1)

- Calculo de Pressão para TubosДокумент10 страницCalculo de Pressão para TubosWellington Brito0% (1)

- Tanque de EscorvaДокумент70 страницTanque de EscorvaDj-Leandro Gomes100% (2)

- Dimensionamento de tanque de armazenamentoДокумент14 страницDimensionamento de tanque de armazenamentoJoão Vitor ConteОценок пока нет

- Trocador Casco Tubo 2Документ10 страницTrocador Casco Tubo 2vazzoleralex6884Оценок пока нет

- Cópia de MEMORIAL DE CÁLCULO - TROCADOR DE CALORДокумент5 страницCópia de MEMORIAL DE CÁLCULO - TROCADOR DE CALORJoseОценок пока нет

- Dimensões parafusos flangesДокумент8 страницDimensões parafusos flangesPercu100% (1)

- Trocador de calor contra fluxo com dados técnicosДокумент4 страницыTrocador de calor contra fluxo com dados técnicosAdriano Perez da SilvaОценок пока нет

- Dimensionador de trocadores de calorДокумент32 страницыDimensionador de trocadores de calorTiago MeloОценок пока нет

- FAET DESA Controle e Poluição do ArДокумент7 страницFAET DESA Controle e Poluição do ArIzabella Vieira100% (1)

- Viga MetalicaДокумент14 страницViga MetalicaDr ObraОценок пока нет

- Calculo Fundo ConicoДокумент30 страницCalculo Fundo Conicocavalc105292Оценок пока нет

- Cálculo de Sistema de VaporДокумент3 страницыCálculo de Sistema de Vaporjulio_cesar_wОценок пока нет

- Golpe de aríete em conduto forçadoДокумент6 страницGolpe de aríete em conduto forçadoLucas GasperinОценок пока нет

- Cálculo de Vazão Exaustão em Francisco de CastroДокумент4 страницыCálculo de Vazão Exaustão em Francisco de CastroJose GomesОценок пока нет

- Dados de Projeto de AgitadorДокумент29 страницDados de Projeto de AgitadorleslieОценок пока нет

- Dimensionamento da linha de ar comprimidoДокумент3 страницыDimensionamento da linha de ar comprimidoEllen Caroline Silvério VieiraОценок пока нет

- Resumo FQ - Teoria Ácido-BaseДокумент11 страницResumo FQ - Teoria Ácido-BasecarlaОценок пока нет

- Placa de Base Sandro AntigaДокумент8 страницPlaca de Base Sandro AntigaSandro ColoneseОценок пока нет

- Proposta de teste de avaliação de Matemática A para o 10o anoДокумент11 страницProposta de teste de avaliação de Matemática A para o 10o anoLiliana Silva100% (1)

- Cap 6 Ventilacao Industrial - ExaustoresДокумент63 страницыCap 6 Ventilacao Industrial - ExaustoresmgdornellesОценок пока нет

- CICLONEДокумент8 страницCICLONEJosé Carlos RepkaОценок пока нет

- Geometria Espacial - Cilindros - Exercicios PDFДокумент13 страницGeometria Espacial - Cilindros - Exercicios PDFLukasVictorОценок пока нет

- Ficha Matematica Trimestral FINALДокумент8 страницFicha Matematica Trimestral FINALDulce PintoОценок пока нет

- Hidrociclone: especificação e cálculosДокумент11 страницHidrociclone: especificação e cálculosIaraFerreiradeRezendeОценок пока нет

- AAP - Matemática - 1 Série Do Ensino MédioДокумент12 страницAAP - Matemática - 1 Série Do Ensino MédioWendler Santos100% (2)

- Dimensionamento Semi Dry ScrubberДокумент80 страницDimensionamento Semi Dry ScrubberAlan Castellani PimentelОценок пока нет

- OP2 - Absorção Gasosa e Design de Torres de RecheioДокумент20 страницOP2 - Absorção Gasosa e Design de Torres de RecheioMagno Felipe Teixeira100% (5)

- Dimensionamento de sistemas de lodos ativados convencional e com aeração prolongadaДокумент14 страницDimensionamento de sistemas de lodos ativados convencional e com aeração prolongadaEdinaldo Oliveira SantiagoОценок пока нет

- Cálculo Madeiramento de TelhadoДокумент17 страницCálculo Madeiramento de TelhadoPaola MarcondesОценок пока нет

- Lista 3 OP 1 JhessycaДокумент6 страницLista 3 OP 1 JhessycaJHESSYCA DANTAS MANARYОценок пока нет

- Tabela para Calculo Direto de Estacao de Tratamento de EsgotoДокумент5 страницTabela para Calculo Direto de Estacao de Tratamento de EsgotoMarcos C. MirandaОценок пока нет

- Trocadores Casco&Tubos (Exercicio Resolvido)Документ15 страницTrocadores Casco&Tubos (Exercicio Resolvido)Ubirajara GomesОценок пока нет

- Hojita MágicaДокумент3 страницыHojita MágicaIrxisОценок пока нет

- Atividade HidráulicaaaaaДокумент7 страницAtividade HidráulicaaaaaGABRIEL DE OLIVEIRAОценок пока нет

- Manual FossaДокумент8 страницManual FossahilcerОценок пока нет

- Modelo de CotaçõesДокумент1 страницаModelo de CotaçõeshilcerОценок пока нет

- Cotações Construção MuroДокумент3 страницыCotações Construção MurohilcerОценок пока нет

- Planilha de Dimensionamento de Moto BombasДокумент8 страницPlanilha de Dimensionamento de Moto BombashilcerОценок пока нет

- Cópia de Planejamento Geral de MetasДокумент29 страницCópia de Planejamento Geral de MetashilcerОценок пока нет

- 658 Quadro 04 Do Livro XXXДокумент2 страницы658 Quadro 04 Do Livro XXXhilcerОценок пока нет

- Cronograma Financeiro Etapa 01Документ1 страницаCronograma Financeiro Etapa 01hilcerОценок пока нет

- Guiade Aula Op Uni Tec Amb 2006Документ197 страницGuiade Aula Op Uni Tec Amb 2006hilcerОценок пока нет

- Sistema de Meio Ambiente, Saúde e SegurançaДокумент19 страницSistema de Meio Ambiente, Saúde e SegurançahilcerОценок пока нет

- F228-ListaEx 1 GravitacaoДокумент3 страницыF228-ListaEx 1 GravitacaoJosé Carlos Salles JuniorОценок пока нет

- WEG Sca 05 Manual Da Comunicacao Profibus DP 0899.5818 Manual Portugues BRДокумент26 страницWEG Sca 05 Manual Da Comunicacao Profibus DP 0899.5818 Manual Portugues BRginaldo35Оценок пока нет

- Simulado 3a série 2019Документ2 страницыSimulado 3a série 2019JOSE AUGUSTO DA SILVAОценок пока нет

- Antissuborno PDFДокумент63 страницыAntissuborno PDFAna Cristina SouzaОценок пока нет

- Análise Funcional Curso Pós-GraduaçãoДокумент61 страницаAnálise Funcional Curso Pós-GraduaçãoMR100% (1)

- O realismo em Popper e Peirce: um contraponto filosóficoДокумент13 страницO realismo em Popper e Peirce: um contraponto filosóficoRaquel Rosalia AdamiОценок пока нет

- Matemática Financeira e Fluxo de CaixaДокумент38 страницMatemática Financeira e Fluxo de CaixaCP Santa MariaОценок пока нет

- Lotomática 2 - Valor PosicionalДокумент2 страницыLotomática 2 - Valor PosicionalGeraldo JuniorОценок пока нет

- 10 1 1 468 539 PDFДокумент295 страниц10 1 1 468 539 PDFVitor HugoОценок пока нет

- Lista de DeterminantesДокумент7 страницLista de DeterminantesJoão Pedro100% (1)

- Isoladas Matematica Do Zero Na FCC Dudan Aula 3 ResolvidoДокумент24 страницыIsoladas Matematica Do Zero Na FCC Dudan Aula 3 ResolvidoDavid XavierОценок пока нет

- Aplicação de Válvulas Redutoras de Pressão Na Redução de Perdas Reais em Redes de Distribuição de Água Na Unidade de Neócio Leste - SabespДокумент93 страницыAplicação de Válvulas Redutoras de Pressão Na Redução de Perdas Reais em Redes de Distribuição de Água Na Unidade de Neócio Leste - SabespRafael HoraОценок пока нет

- Apostila de Programação de Computadores 1Документ441 страницаApostila de Programação de Computadores 1anaccoОценок пока нет

- Funções Polinomiais do 2o Grau: Trajetórias e AplicaçõesДокумент28 страницFunções Polinomiais do 2o Grau: Trajetórias e AplicaçõesPapiro ReceitaОценок пока нет

- Questões Física II AДокумент2 страницыQuestões Física II AErikikoОценок пока нет

- DownloadДокумент7 страницDownloadJoão PortelaОценок пока нет

- Movimento em Duas e Três DimensõesДокумент41 страницаMovimento em Duas e Três DimensõesAndreas KneipОценок пока нет

- Verificação de Aprendizagem 3º Corte - Matemática - SilábicoДокумент6 страницVerificação de Aprendizagem 3º Corte - Matemática - Silábicogeisa lopesОценок пока нет

- Roteiro PIC2021 G2 Ciclo6Документ25 страницRoteiro PIC2021 G2 Ciclo6Nickerson OliveiraОценок пока нет

- DissertaçãoДокумент134 страницыDissertaçãofabioriemannОценок пока нет

- Exercícios de Fixação - TRANSCALДокумент14 страницExercícios de Fixação - TRANSCALGabriela OliverОценок пока нет