Академический Документы

Профессиональный Документы

Культура Документы

Preparation of Biodegradable Crosslinking Agents and Application in PVP Hydrogel

Загружено:

Deva RajИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Preparation of Biodegradable Crosslinking Agents and Application in PVP Hydrogel

Загружено:

Deva RajАвторское право:

Доступные форматы

Preparation of Biodegradable Crosslinking Agents and

Application in PVP Hydrogel

Yanpeng Jiao, Zonghua Liu, Shan Ding, Lihua Li, Changren Zhou

Department of Material Science and Engineering, Jinan University, Guangzhou, Peoples Republic of China 510632

Received 11 April 2005; accepted 21 May 2005

DOI 10.1002/app.22291

Published online in Wiley InterScience (www.interscience.wiley.com).

ABSTRACT: Firstly, biodegradable crosslinking agents

(BCA) were synthesized by ring-opening polymerization

reaction of lactide, four kinds of which with different mo-

lecular weights were got by means of changing the ratio of

dl-lactide(LA) and glycerol(GL). Then a series of poly(N-

vinyl pyrrolidone) (PVP) hydrogels were prepared success-

fully by radical polymerization of BCA and N-vinyl pyrro-

lidone(NVP). Both the ratio of NVP/BCA and the molecular

weight of BCA were used to control the performance of PVP

hydrogels, which were measured in terms of the ratio of

swelling, contact angle, mechanical properties, and biode-

gradability in vitro. This study showed that increasing both

the ratio of NVP/BCA and the molecular weight of BCA

resulted in a low crosslinking density of the hydrogels. The

crosslinking density played an important role in determin-

ing the properties of biodegradable PVP hydrogels. Both the

ratio of NVP/BCA and the molecular weight of BCA con-

tributed to high ratio of swelling. A smaller amount of

crosslinking agent caused a lower contact angle, while the

molecular weight of BCA had little effect on it. In terms of

mechanics of hydrogels on both dry and wet conditions,

tensile modulus decreased along with decreasing BCA,

while the extension at break increased at the beginning and

decreased at the end. In the end, measured by mass loss,

biodegradability in vitro of hydrogels had two stages: an

initial stage with approximately constant loss of mass (stage

1) followed by a stage with rapid mass loss (stage 2). Both

increased content and molecular weight of BCA improved

the degradation rate of the hydrogels. 2006 Wiley Periodicals,

Inc. J Appl Polym Sci 101: 15151521, 2006

Key words: biomaterials; biodegradable crosslinking agent;

PVP hydrogel; swelling; mechanical properties

INTRODUCTION

Hydrogel is a polymeric network which can absorb

and retain large amounts of water. In a polymeric

network, hydrophilic groups or domains are hydrated

to create a hydrogel structure in an aqueous environ-

ment. Crosslinking agents have to be introduced to

avoid dissolution of the hydrophilic polymeric chains

or segments into the aqueous phase. A great variety of

methods of crosslinking have already been used to

prepare hydrogels.

1

Because of its excellent performance, hydrogel has

been applied in many elds, including biosensors,

bioreactors, bioseparators, tissue engineering, and

drug delivery.

27

Among them, hydrogel has shown

great promise as a scaffold material for tissue engi-

neering.

811

Hydrogel, with a high water content and

tissue-like elasticity, is easily formed in situ during

implantation and is then encapsulated by cells as it is

crosslinked with tissue surfaces. Furthermore, its rel-

ative biocompatibility makes it a prime candidate for

tissue engineering applications.

Currently, many synthetic biocompatible polymers,

such as poly(vinyl alcohol) (PVA),

12,13

poly (dl-lac-

tide) (PLA),

14

and poly(2-hydroxyethyl methacrylate)

(pHAMA),

15

as well as natural polymers such as gel-

atin, alginate, and peptide,

16

have been introduced

into hydrogel. As a hydrosoluble polymer, PVP has

already been used for the synthesis of hydrogel for

many years.

For its well-known biocompatibility, PVP has many

biomedical applications such as a blood plasma ex-

tender, and a carrier for drug delivery.

1721

Because of

its special molecular structure, PVP has many out-

standing properties. First of all, it is soluble in water

and also in most organic solvents. Second, the struc-

ture of pyrrolidone provides it with similar properties

to those of a protein. For example, it can be precipi-

tated by most protein precipitators. Third, it has little

immunogenicity and antigenicity, which is the foun-

dation of its wide application in elds related to hu-

man health.

22

In addition to these, it has a favorable

chelating ability and is used in the drug and food eld

as a chelating agent. Finally, PVP has positive biocom-

Correspondence to: C. Zhou (tcrz9@jnu.edu.cn).

Contract grant sponsor: National High Technology Re-

search and Development Program of China (863 Program);

contract grant number: 2001AA625050.

Contract grant sponsor: National Natural Science Foun-

dation of China; contract grant number: 30170272.

Contract grant sponsor: Major Programs of Guangdong Sci-

ence and Technology; contract grant number: A302020104.

Journal of Applied Polymer Science, Vol. 101, 15151521 (2006)

2006 Wiley Periodicals, Inc.

http://www.paper.edu.cn

patibility and hydrophilic properties, which have been

proposed as an effective and interesting tissue engi-

neering matrix. However, high water-solubility pre-

vents PVP from being shaped in vivo, so that PVP is

used mainly in the form of a crosslinked network. On

the other hand, hydrogel, after it is crosslinked, be-

comes nonbiodegradable, which limits its application

in the eld of tissue engineering.

Since it is advantageous in many biomedical appli-

cations for hydrogel to be biodegradable under phys-

iological conditions, labile bonds are frequently intro-

duced into gels. Two typical approaches are used to

obtain degradable hydrogels.

23

First, the backbone of

the gelling polymer is designed to be degradable by

hydrolysis and/or enzymatic action. For example,

many polymers, including aliphatic polyester and col-

lagen, can undergo main chain scission by hydrolysis

and enzymatic action respectively. A second attractive

approach is to introduce biodegradable crosslinking

agents into systems composed of nondegradable poly-

mer.

2427

In this study, a series of biodegradable crosslinking

agents were synthesized, in which glycerol provided

multi-arm initiating sites, and the segments of lactide

copolymer offered labile hydrolysable bonds, and vi-

nyl acted as functional groups for crosslinking. Then

PVP hydrogels were prepared by radical polymeriza-

tion of BCA and NVP. Finally, the effect of crosslink-

ing agents on the performance of hydrogels was in-

vestigated.

EXPERIMENTAL

Materials

LA was synthesized and recrystallized twice with

dried acetic ether and then dried for 24 h in vacuum at

60C before use. GL was obtained from Guangdong

Reagent Inc. (China), puried by reduced pressure

distillation and dried by molecule sieve to remove any

residual moisture. Triethylamine, acryloyl chloride,

NVP, and stannous octoate (ACROS, USA) were all

puried by reduced pressure distillation. Azoisobuty-

ronitrile (AIBN), purchased from Tianjin Reagent Inc.

(China), was puried by recrystallization with dried

ethanol and then dried for 24 h in vacuum at room

temperature before used. Other chemicals such as di-

chloromethane and acetone were purchased from do-

mestic chemical distributors, and were of analytical

grade.

Synthesis of biodegradable crosslinking agents

A series of biodegradable triacrylate crosslinking

agents were synthesized as described previously by

Sawhney et al.

24,28

Briey, different ratios of LA to GL

were put into the ampoules that were treated by sili-

cation before used, and then stannous octoate was

added. After purging three times with dried nitrogen,

the ampoules were sealed in vacuum. The ampoules

were heated up to 140C for 24 h. Then the ampoules

were broken and the products were dissolved in di-

chloromethane, followed by microltering. The solu-

tion was precipitated out of cooled hexane and the

precipitate was dried for 24 h in vacuum at 50C to get

the copolymer of LA and GL, the molecular weight of

which was measured by GPC (WATERS). A certain

amount of copolymer and triethylamine was dis-

solved in dichloromethane and stirred, and then acry-

loyl chloride was added slowly. The reaction contin-

ued about 6 h in an icewater bath and 24 h at the

room temperature. After removal of the precipitate of

triethylamine hydrochloric acid by microltering, the

solution was precipitated by cooled diethyl ether and

ltered. The precipitate was dried for 24 h in vacuum

at room temperature to obtain the biodegradable

crosslinking agents.

Preparation of crosslinked PVP hydrogels

Different ratios of biodegradable crosslinking agents

to NVP were dissolved in dichloromethane and 0.5%

(w/w) AIBN was added, followed by thorough stir-

ring. The solution was cast onto a mold and after the

reaction of heating up with infrared lamp the hydro-

gel lms were obtained. The lms were extracted with

acetone in Suos distiller for 3 h to remove NVP mono-

mers and PVP homopolymers, then dried for 24 h in

vacuum at room temperature for further measure-

ments.

Testing of swelling

The measurement of swelling was carried out in a PBS

at a pH 7.4. The hydrogel lms, categorized by weight,

were cut into round shapes with a diameter of 1 cm

and a thickness of 1 mm, and then equilibrated in 15

mL of PBS at 37C for 24 h. The sample was weighed

after removal of excessive surface liquid using an ab-

sorbant paper. Swelling ratio Q was calculated as fol-

lowed:

Q% W

S

W

0

/W

0

100

where W

S

is the weight of swollen lms and W

0

is the

weight of dry lms. For each sample, measuring the

swelling involved three trials and the average of three

values was reported.

Testing of contact angle

The static contact angle of water was used to monitor

the change of wettability of the surface of hydrogel

lms. Briey, a 5-L drop of distilled H

2

O was placed

1516 JIAO ET AL.

http://www.paper.edu.cn

on the surface and static contact angle was measured

using a CAM-PLUS goniometer (TANTEC, Germany)

at 25C with 60% relative humidity. For each reported

contact angle value, ve measurements on different

areas of the surface were obtained and the average

taken.

Testing of mechanical properties

The tensile test has been widely accepted and used

successfully for characterization of hydrogel lms. For

testing, the hydrogel lms were cut into strips with

dimensions of 5 cm in length, 1 cm in width and 0.1

cm in thickness. Before mechanical testing, some of the

lms were hydrated in 0.1M phosphate buffered sa-

line (PBS; pH 7.4), while others were tested directly.

An Instron machine (AG-5000G, Shimadzu, Japan)

with a 1-kN load cell was used for tensile mechanical

test. The crosshead speed was set at 1 mm/min and

the load was run until the lm was broken. Tensile

modulus was calculated with the slope of the initial

linear portion of the stressstrain curve. The extension

at break was determined as followed:

Extension at break% (L L

0

)/L

0

100

where L is the length of the hydrogel lms at break

and L

0

is the length of original lms. For each test, ve

times of measurements were obtained on different

hydrogel lms and the average taken.

Biodegradation in vitro

Two series of PVP hydrogels were used for the de-

gradability research. One series was made from the

different ratios of NVP to BCA with one xed

crosslinking agent BCA-6. The other series were made

from different kinds of crosslinking agents with a

xed ratio of NVP to BCA of 3. The initial dry PVP

hydrogel lms were placed in weighing bottles, each

containing 20 mL of 0.2M PBS. The samples were

shaken at 37C up to 8 weeks. PBS was changed every

week. At the end of each week, the samples were

taken from PBS and air-dried overnight and further

vacuum-dried for 24 h at room temperature till they

attain constant weight. The weights of these samples

were then recorded respectively. After weighing, the

dry hydrogel lms were placed into PBS again as

before for further mass loss measurement. The follow-

ing equation was used to determine the mass loss

ratio:

Mass loss ratio % (W

0

W)/W

0

100

where W and W

0

are the weights of the samples after

degradation and the initial weights of the samples,

respectively. The effect of the amount and the molec-

ular weight of crosslinking agents on mass loss was

determined using the same procedure. In each situa-

tion, measurements of samples were performed, and

the average of the ve values was reported.

RESULTS AND DISCUSSION

Synthesis of biodegradable crosslinking agents

The biodegradable crosslinking agents were synthe-

sized by a ring-opening polymerization reaction of

lactide using glycerol as an initiator and stannous

octoate as a catalyst, followed by functionalization of

the hydroxyl end group with acryloyl chloride in the

presence of triethylamine. Generally, in the ring-open-

ing polymerization with stannous octoate as catalyst,

the polymerization mechanism was neither a cationic,

nor anionic, nor pseudoanionic mechanism. It is the-

orized that it is a complexation mechanism or co-

ordinate-insertion mechanism.

29

It is at the hydroxy

site where species are combined with the catalyst and

polymerization initiated. In this research, it is glycer-

ols three hydroxyl groups, which can be called coini-

tiators, that offered three polymerizing sites and -

nally formed a three-arm polymer. Many hydrogels

have been synthesized using di-, tri-, and multi-arm

copolymers obtained from copolymerization of lactide

in the presence of polybasic alcohol.

24,28

They show a

wide range of interesting properties depending on the

relative chain length of PLA segments. Usually, mo-

lecular weight of the copolymer can be adjusted by

changing the ratio of lactide to OOH groups. In this

research, four ratios of LA to GL were studied, (12, 15,

18, and 21) to get three-arm copolymers with different

molecular weights. As shown in Table I, molecular

mass increased with the increasing LA/GL ratio.

Compared with the theoretic molecular weight, the

results from GPC suggested that initiation of polymer-

ization of lactide occurred via OOH group of glycerol.

The copolymers could easily be functionalized by ac-

ryloyl chloride by esterication. This reaction was an

exothermic reaction and must be carried out in ice

TABLE I

Molecular Weights of Biodegradable Crosslinking

Agents

Types

(BCA-m)

a

LA/GL

b

M

n

(calc)

c

M

n

(GPC)

M

w

/M

n

(GPC)

BCA-4 12 1769 1375 1.3083

BCA-5 15 2222 1808 1.3618

BCA-6 18 2648 2116 1.3467

BCA-7 21 3074 2494 1.3768

a

m is the number of repeating units of lactide on each arm

of glycerol.

b

LA/GL stands for the molar ratio of LA to GL.

c

M

n

(calc) is calculated from 144 LA/GL MW (glyc-

erol).

BIODEGRADABLE CROSSLINKING AGENTS AND APPLICATION IN PVP HYDROGEL 1517

http://www.paper.edu.cn

water bath. Acryloyl chloride rapidly reacts with even

a small amount of water, so the reaction system must

be anhydrous. This was a useful method to introduce

terminal double bonds and ester groups in each arm of

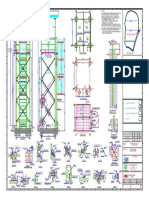

the triarm BCA macromolecule, the structure of which

was shown in Figure 1.

Testing of swelling

In this study, a series of PVP hydrogels were prepared

successfully by radical polymerization of BCA and

NVP with AIBN as an initiator. The swelling behavior

of crosslinked hydrogel depended on the nature of

both the polymer and the solvent. Mass swelling of the

crosslinked polymer in solvent is the most important

parameter normally examined in swelling studies. As

we know, there are many factors concerning solvent,

which can affect the swelling behavior of hydrogel,

including pH,

30

temperature,

31

ionic strength,

32

and

others.

33

In this study, the equilibrium swelling behav-

ior of PVP hydrogel was investigated using water as a

solvent with the pH and temperature xed. In addi-

tion, the effect of the types of BCA and various mass

ratios of BCA to NVP on swelling behavior was the

point of interest in this study. Equilibrium swelling

curves of PVP hydrogels were shown in Figure 2. It

can be seen that the swelling capability of PVP hydro-

gels increased with the increasing mass ratios of

NVP/BCA after a certain period of time. Another

phenomenon was that the swelling of PVP hydrogels

depended on the type of BCA. The condition of xed

mass ratio of NVP/BCA, increased the molecular

weight of BCA and decreased crosslinking density,

which resulted in a higher equilibrium swelling ratio.

Testing of contact angle

Contact angle, formed on the three-phase line of sol-

id/liquid/gas system, provides a simple and inexpen-

sive technique in a laboratory situation for describing

the wetting behavior of biomaterials. The measuring

condition of biomaterials is usually xed with pure

water or PBS as liquid phase and air as gaseous phase.

Besides the nature of biomaterials and liquid, there are

several factors affecting the value of contact angle,

such as contact time, drop size, and surrounding hu-

midity. Figure 3 shows that the values of contact angle

of PVP hydrogels decreased with the increasing mass

ratios of NVP/BCA. Namely, with the increasing con-

tent of NVP, the wettability of hydrogels increased.

Another phenomenon observed from Figure 3 was

that the molecular weight of BCA had little effect on

contact angle of PVP hydrogel, unlike the observation

with swelling. Swelling is a bulk property of hydrogel

and depends on not only the component of hydrogel

but also the structure, in particular, the crosslinking

density. However, contact angle was a measurement

of the surface properties. It strongly relied on the

composition of the surface. Though molecular weight

of BCA could affect crosslinking density, it had little

effect on the composition once the mass ratio of BCA

to NVP was xed.

Testing of mechanics

The tensile test was adopted to examine mechanical

property of hydrogels prepared using BCA-4. The ten-

sile modulus and the extension at break were showed

in Figure 4 and Figure 5. In crosslinked materials, such

as hygrogels, crosslinking density plays a key role in

affecting not only the swelling of materials but also

their mechanical performance. Figure 4 shows that the

Figure 1. The structure of biodegradable crosslinking

agents.

Figure 2. The effect of the ratio of NVP/BCA (g/g) on

swelling ratio

Figure 3. The effect of the ratio of NVP/BCA (g/g) on

contact angle.

1518 JIAO ET AL.

http://www.paper.edu.cn

tensile modulus decreases with the increasing ratio of

NVP to BCA, namely with the decreasing of the

crosslinking density. The curves of the extension at

break are plotted in Figure 5. A maximum tensile

strength was observed with respect to the ratio of NVP

to BCA within the range of ratios that were studied.

The crosslinking density had two kinds of effects on

the extension at break. That is to say, low crosslinking

density meant weak tension of hydrogel. However,

when it was too high, the hydrogel proved to be rigid

and brittle. The extension at break was lower with low

or extremely high crosslinking density.

Biodegradation in vitro

With mass loss as function of degradation time, the

biodegradation in vitro of PVP hydrogels was shown

in Figure 6 and Figure 7. In both gures, a two-stage

mass loss curve was observed: an initial approximate

constant mass loss (stage 1) followed by a rapid mass

loss (stage 2). After stage 2, the integrity of the hydro-

gels was so greatly diminished, that the degradation

could not be measured any further. Figure 6 is the

prole of the mass loss ratio of the hydrogels with

different ratios of NVP to BCA-6. Although the initial

approximately constant mass losses were observed for

all PVP hydrogels irrespective of ratios of NVP to

BCA-6, the degradation rates of different hydrogels

were different. For example, when the ratio of NVP to

BCA-6 was 5, the degradation rate was the highest.

When the ratio was 1, the degradation rate was the

lowest. Another result observed from Figure 6 was

that the beginning time of the stage 2 was different.

For instance, when the ratio was 5, the beginning time

of the stage 2 was in the fth week. However, when

the ratio was 1, the constant mass loss was kept for 7

weeks. It was easy to explain the phenomena. With the

ratio of NVP to BCA-6 decreased, hydrophobic/bio-

degradable PLA chains in crosslinked hydrogel in-

creased. More importantly, the crosslinking density

became bigger. Both factors made the degradation rate

lower and the collapse time of hydrogels longer.

The prole of the degradation of hydrogels with

different molecular weights of BCA but xed ratio of

NVP to BCA is shown in Figure 7. The tendency of the

four curves is the same as that shown in Figure 6. The

duration of stage 1 became shorter as the molecular

weight of BCA increased, e.g., 7, 6, 6, and 5 weeks for

BCA-4, BCA-5, BCA-6, and BCA-7, respectively. At

the same time, the degradation rate became higher

Figure 4. The effect of the ratio of NVP/BCA (g/g) on

tensile modulus.

Figure 5. The effect of the ratio of NVP/BCA (g/g) on the

extension at break.

Figure 6. The effect of the content of crosslinking agent on

mass loss ratio.

Figure 7. The effect of the molecular weight of the

crosslinking agent on mass loss ratio.

BIODEGRADABLE CROSSLINKING AGENTS AND APPLICATION IN PVP HYDROGEL 1519

http://www.paper.edu.cn

along with the increasing molecular weight of BCA. In

these four types of hydrogels, the mass ratio of NVP to

BCA was the same, and the content of hydrophobic

PLA chains was the same as well. The crosslinking

density became lower as the molecular weight of BCA

increased, which resulted in the same change as that in

Figure 7.

Many researchers have proven that crosslinking

structure plays an important role in determining the

macroscopical properties of hydrogel during degrada-

tion.

26

The hydrolysis of crosslinked PVP hydrogel

was based on the ester groups, the hydrolysis dynam-

ics of which was similar to that of linear polymer

molecules, such as PLA. However, because of the

crosslinking structure of the PVP hydrogel, its macro-

scopical degradation was different to that of linear

polymer molecules.

34

Figures 6 and 7 could easily be

explained in view of the crosslinking structure of PVP

hydrogel. PVP chains were crosslinked into a poly-

meric network by means of connecting the hydrolyz-

able and degradable PLA segments on their both

sides. Along with the degradation of PLA segment on

both sides of PVP chains, these PVP chains would be

released at a relatively constant rate by rst order

kinetic ways. From the aspect of hydrolysis dynamics,

the concentration of ester groups and further the deg-

radation rate of hydrogel decreased along with time.

And the net structure began to be destroyed along

with the degradation process, so the PVP chains could

be released even by the breaking of PLA on only one

side of each PVP chain, which counteracted the de-

crease of the degradation rate. Macroscopically, an

overall constant mass loss ratio was kept as illustrated

by stage 1 of the mass loss curves. Later, further deg-

radation of PLA segments destroyed the crosslinking

structure completely and tridimensional net structure

was unbound into linear polymer chains that soon

dissolved into the surrounding solvent, which led to

the rapid collapse of the whole polymeric network as

shown in stage 2 of the mass loss curves.

From above results, the degradation rate and deg-

radation time of hydrogels can easily be adjusted by

controlling the content and molecular weight of de-

gradable crosslinking agents.

CONCLUSIONS

In this study, the molecular weight of crosslinking

agent was controlled successfully by changing the

ratio of LA to GL. Further, PVP hydrogels were pre-

pared by radical polymerization of above biodegrad-

able crosslinking agents and NVP using AIBN as ini-

tiator. The crosslinking density, which was adapted by

both the ratio of NVP to BCA and the molecular

weight of the crosslinking agent, played an important

role in determining the properties of PVP hydrogel.

Along with the increasing ratio of NVP to BCA, the

ratio of swelling increased and the value of contact

angle decreased. In addition, the molecular weight of

BCA had a signicant effect on the former but little on

the latter. The test of mechanics on dry and wet con-

ditions showed that the tensile modulus of hydrogels

decreased along with the increasing ratio of NVP to

BCA, while the extension at break increased rst and

decreased in the end. In conclusion, biodegradability

in vitro included two stages: the rst with constant

mass loss ratio and the second with rapid one. The

content and molecular weight of degradable crosslink-

ing agents could adjust the degradation rate and time

of hydrogels.

In short, by changing the content and molecular

weight of crosslinking agent, various ideal perfor-

mances of hydrogel can be gained. In view of its

biodegradability and swelling ability, biodegradable

PVP hydrogel has a great potential utility in the eld

of tissue engineering and drug delivery carrier. More

importantly, the synthesis of biodegradable crosslink-

ing agents provides a new means to obtain the biode-

gradable hydrogel.

References

1. Hennink, W. E.; van Nostrum, C. F. Adv Drug Delivery Rev

2002, 54, 13.

2. Sean, B.; Dyer, N.; Anthony, G. Biosens Bioelectron 2002, 17, 973.

3. Sean, B.; Dyer, N.; Anthony, G. Biosens Bioelectron 2002, 18, 60.

4. Miyata, T.; Uragami, T.; Katsuhiko, N. Adv Drug Delivery Rev

2002, 54, 79.

5. Behravesh, E.; Jo, S.; Zygourakis, K.; Mikos, A. G. Biomacromol-

ecules 2002, 3, 374.

6. Lee, K. Y.; Alsberg, E.; Mooney, D. J. J Biomed Mater Res 2001,

56, 228.

7. Kikuchi, A.; Okano, T. Adv Drug Delivery Rev 2002, 54, 53.

8. Drury, J. L.; Mooney, D. J. Biomaterials 2003, 24, 4337.

9. Lee, K. Y.; Mooney, D. J. Chem Rev 2001, 101, 1869.

10. Song, J.; Saiz, E.; Carolyn, R. B. J Am Chem Soc 2003, 125, 123.

11. Lim, D. W.; Choi, S. H.; Park, T. G. Macromol Rapid Commun

2000, 21, 464.

12. Xiao, C.; Zhou, G. Polym Degrad Stabil 2003, 81, 297.

13. Nuttelman, C. R.; Henry, S. M.; Anseth, K. S. Biomaterials 2002,

23, 3617.

14. Zhang, Y. L.; Chu, C. C. J Mater Sci Mater Med 2003, 13, 667.

15. Kim, S. H.; Opdahl, A.; Marmo, C.; Somorjai, G. A. Biomaterials

2002, 23, 1657.

16. Pakstis, L. M.; Ozbas, B.; Hales, K. D.; Nowak, A. P.; Deming

T. J.; Pochan, D. Biomacromolecules 2004, 5, 312.

17. Blanco, M. D.; Trigo, R. M.; Garcia, O.; Teijo n, J. M. J Biomater

Sci Polym Edn 1997, 8, 709.

18. Risbud, M. V.; Bhat, S. V. J Mater Sci Mater Med 2001, 12, 75.

19. Tunney, M. M.; Gorman, S. P. Biomaterials 2002, 23, 4601.

20. Kamada, H.; Tsutsumi, Y.; Sato-Kamada, K.; Yamamoto, Y.;

Yoshioka, Y.; Okamoto, T.; Nakagawa, S.; Nagata, S.; Mayumi,

T. Natl Biotechnol 2003, 21, 399.

21. Kodaira, H.; Tsutsumi, Y.; Yoshioka, Y.; Kamada, H.; Kaneda,

Y.; Yamamoto, Y.; Tsunoda, S.; Okamoto, T.; Mukai, Y.; Shibata,

H.; Nakagawa, S.; Mayumi, T. Biomaterials 2004, 25, 309.

22. Robinson, B. V.; Sullivan, F. M.; Borzelleca, J. F.; Schwartz, S. A

Critical Review of the Kinetics and Toxicology of polyvinylpyr-

rolidone. Lewis Publishers: Chelsea, MI, 1990.

1520 JIAO ET AL.

http://www.paper.edu.cn

23. Lee KY; Bouhadir KH; Mooney DJ. Biomaterials 2004, 25,

2461.

24. Sawhney, A. S.; Pathak, C. P.; Hubbell, J. A. Macromolecules

1993, 26, 581.

25. Hubbell, J. A. J Controlled Release 1996, 39, 305.

26. Metters, A. T.; Anseth, K. S.; Bowman, C. N. Polymer 2000, 41,

3993.

27. Lu, S.; Anseth, K. S. Macromolecules 2000, 33, 2509.

28. Arvanitoyannis, I.; Nakayama, A.; Kawasaki, N.; Yamamoto, N.

Polymer 1995, 36, 2947.

29. Kricheldorf, I.; Kreiser-Saunders, I.; Boettcher, C. Polymer 1995,

36, 1253.

30. Richter, A.; Bund, A.; Keller, M.; Arndt, K. F. Sensor Actuat B

Chem 2004, 99, 579.

31. Zhang, X. Z.; Wang, F. J.; Chu, C. C. J Mater Sci Mater Med 2003,

14, 451.

32. Saraydin, D.; C aldiran, Y. Polym Bull 2001, 46, 91.

33. Miyata, T.; Uragami, T.; Nakamae, K. Adv Drug Delivery Rev

2002, 54, 79.

34. Burkersroda, F.; Gref, R.; Gopferich, A. Biomaterials 1997, 24, 1599.

BIODEGRADABLE CROSSLINKING AGENTS AND APPLICATION IN PVP HYDROGEL 1521

http://www.paper.edu.cn

Вам также может понравиться

- Biotransfrmtns Prepartv Organic Chemistry: The Use of Isolated Enzymes and Whole Cell Systems in SynthesisОт EverandBiotransfrmtns Prepartv Organic Chemistry: The Use of Isolated Enzymes and Whole Cell Systems in SynthesisОценок пока нет

- PVA Chitosane SelДокумент21 страницаPVA Chitosane SelpowerkimyОценок пока нет

- Bercea 2016Документ9 страницBercea 2016sjonathanpastorОценок пока нет

- Pullalan DerrivativesДокумент9 страницPullalan DerrivativesMehul KhimaniОценок пока нет

- Structure and ApplicationsДокумент29 страницStructure and ApplicationsIk MikОценок пока нет

- AdvPolySci 153 37-652000 PDFДокумент29 страницAdvPolySci 153 37-652000 PDFJuan Carlos BeltranОценок пока нет

- Efficient 2019 Construction and Enriched Selective Adsorption-PhotocatalyticДокумент16 страницEfficient 2019 Construction and Enriched Selective Adsorption-PhotocatalyticA V SUDHAMSHU 2047301Оценок пока нет

- Novel Nanocomposite Hydrogel For Wound Dressing and Other Medical ApplicationsДокумент12 страницNovel Nanocomposite Hydrogel For Wound Dressing and Other Medical ApplicationsSantiagoSossaUОценок пока нет

- Preparation of CMC/HEC Crosslinked Hydrogels For Drug DeliveryДокумент14 страницPreparation of CMC/HEC Crosslinked Hydrogels For Drug DeliverySantiagoSossaUОценок пока нет

- State of Water in Chitosan-PVA Hydrogel: Tao Wang, Sundaram GunasekaranДокумент6 страницState of Water in Chitosan-PVA Hydrogel: Tao Wang, Sundaram GunasekaranDgek LondonОценок пока нет

- PAN Chitosan HydrogelsДокумент5 страницPAN Chitosan HydrogelsZakiah PriskaОценок пока нет

- Effect of Hydraulic Retention Time On Biohydrogen Production and Anaerobic Microbial CommunityДокумент6 страницEffect of Hydraulic Retention Time On Biohydrogen Production and Anaerobic Microbial CommunityAlejandro Duvan Lopez RojasОценок пока нет

- Superabsorbent Hydrogels Based On Cellulose For Smart Swelling and Controllable DeliveryДокумент9 страницSuperabsorbent Hydrogels Based On Cellulose For Smart Swelling and Controllable DeliveryDaniel MuñozОценок пока нет

- A New Approach For The Immobilization of Permeabilized Brewer's Yeast CellsДокумент5 страницA New Approach For The Immobilization of Permeabilized Brewer's Yeast CellsKevin Jagler Retuerto GamboaОценок пока нет

- Omidian 12 Book ChapterДокумент31 страницаOmidian 12 Book ChapterAlina DОценок пока нет

- Weng2013 PDFДокумент36 страницWeng2013 PDFadilОценок пока нет

- Hydrogels Based On Chemically Modified Poly (Vinyl Alcohol) (PVA-GMA) and PVA-GMA/chondroitin Sulfate: Preparation and CharacterizationДокумент13 страницHydrogels Based On Chemically Modified Poly (Vinyl Alcohol) (PVA-GMA) and PVA-GMA/chondroitin Sulfate: Preparation and CharacterizationDgek LondonОценок пока нет

- Hemodialysis Biocompatibility in HemodialysisДокумент14 страницHemodialysis Biocompatibility in HemodialysisspallocОценок пока нет

- 1 s2.0 S0141813021018432 MainДокумент10 страниц1 s2.0 S0141813021018432 MainAnisa RatnasariОценок пока нет

- Genipin Crosslinked Chitosan Hydrogels Preliminary Evaluation of The in VitroДокумент11 страницGenipin Crosslinked Chitosan Hydrogels Preliminary Evaluation of The in VitroASHISH PANDITОценок пока нет

- Physically Crosslinked HydrogeДокумент14 страницPhysically Crosslinked HydrogeSarah Ariefah SantriОценок пока нет

- Duhok Polytechnic University Faculty of Petrochemical Engineering School of PolymerДокумент6 страницDuhok Polytechnic University Faculty of Petrochemical Engineering School of Polymerkamyar farsОценок пока нет

- The Effect of Lignin Removal by Alkaline Peroxide Pretreatment On The Susceptibility of Corn Stover To Purified Cellulolytic and Xylanolytic EnzymesДокумент11 страницThe Effect of Lignin Removal by Alkaline Peroxide Pretreatment On The Susceptibility of Corn Stover To Purified Cellulolytic and Xylanolytic EnzymesAhmad Rama RamadhanОценок пока нет

- 1 s2.0 S1381514813000047 MainДокумент6 страниц1 s2.0 S1381514813000047 Main도경민Оценок пока нет

- Innovative Complex Coacervates of Gelatin and Sodium Carboxymethyl Cellulose For Cinnamaldehyde Delivery: Impact of Processing Conditions On Characteristics and BioactivityДокумент10 страницInnovative Complex Coacervates of Gelatin and Sodium Carboxymethyl Cellulose For Cinnamaldehyde Delivery: Impact of Processing Conditions On Characteristics and BioactivityMamta AgarwalОценок пока нет

- International Journal of Biological MacromoleculesДокумент9 страницInternational Journal of Biological MacromoleculesFaizhal Dimas LeksonoОценок пока нет

- Stimuli Responsive HydrogelsДокумент10 страницStimuli Responsive HydrogelsAnujОценок пока нет

- Sjoqvist 2010Документ21 страницаSjoqvist 2010Wayan ArnataОценок пока нет

- Cho Et Al 2018 Glycol ChitosanДокумент10 страницCho Et Al 2018 Glycol ChitosanIsa AguirreОценок пока нет

- Biomaterials ReviewДокумент8 страницBiomaterials ReviewJosevi Jiménez MerinoОценок пока нет

- A Multifunctional Hydrogel With High Conductivity, Ph-Responsive, Thermo-Responsive and Release Properties From Polyacrylate/polyaniline HybridДокумент7 страницA Multifunctional Hydrogel With High Conductivity, Ph-Responsive, Thermo-Responsive and Release Properties From Polyacrylate/polyaniline HybridPpa Gpat AmitОценок пока нет

- Preparation and Characterization of Melittin-Loaded Poly (Dl-Lactic Acid) or Poly (Dl-Lactic-Co-Glycolic Acid) Microspheres Made by The Double Emulsion MethodДокумент10 страницPreparation and Characterization of Melittin-Loaded Poly (Dl-Lactic Acid) or Poly (Dl-Lactic-Co-Glycolic Acid) Microspheres Made by The Double Emulsion MethoddetesОценок пока нет

- Pretratamiento de Autohidrolisis y AlcalinoДокумент5 страницPretratamiento de Autohidrolisis y AlcalinoElena FloresОценок пока нет

- Loading Quantum Dots Into Thermo-Responsive Microgels by Reversible Transfer From Organic Solvents To WaterДокумент8 страницLoading Quantum Dots Into Thermo-Responsive Microgels by Reversible Transfer From Organic Solvents To Waterprakush01975225403Оценок пока нет

- Characterization of Nata de Coco Produced by Fermentation of Immobilized Acetobacter XylinumДокумент8 страницCharacterization of Nata de Coco Produced by Fermentation of Immobilized Acetobacter XylinumJay MeeОценок пока нет

- JTAC Finale OnlineДокумент8 страницJTAC Finale OnlinednkОценок пока нет

- Influence of Seed Sludge and Pretreatment Method On Hydrogen ProductionДокумент9 страницInfluence of Seed Sludge and Pretreatment Method On Hydrogen ProductionProfessor Douglas TorresОценок пока нет

- Maktum - BioresTech - Reduced SizeДокумент8 страницMaktum - BioresTech - Reduced SizeArief WidjajaОценок пока нет

- Colloids and Surfaces B: BiointerfacesДокумент6 страницColloids and Surfaces B: BiointerfaceslgroscheОценок пока нет

- Molecular Origin of The Elastic State of Aqueous HA (G. Giubertoni - 2019)Документ7 страницMolecular Origin of The Elastic State of Aqueous HA (G. Giubertoni - 2019)lejartkОценок пока нет

- Jpin S 13 00029Документ40 страницJpin S 13 00029VinayОценок пока нет

- Acid-Induced Aggregation and Gelation of Natural Rubber Latex ParticlesДокумент10 страницAcid-Induced Aggregation and Gelation of Natural Rubber Latex Particlesmac_su038Оценок пока нет

- Bussemaker 2013Документ18 страницBussemaker 2013Wayan ArnataОценок пока нет

- REVISAR Colloids and Surfaces AДокумент6 страницREVISAR Colloids and Surfaces AJuan Sebastian Geraldo EscobarОценок пока нет

- Steinhilber 2013Документ6 страницSteinhilber 2013Lorenzo TellОценок пока нет

- Synthesis and Charn of in Situ Cross-Linked Hydrogel Based On Self-Assembly of Thiol-Modified Chitosan With PEG DiacrylateДокумент8 страницSynthesis and Charn of in Situ Cross-Linked Hydrogel Based On Self-Assembly of Thiol-Modified Chitosan With PEG Diacrylatealchemik1515Оценок пока нет

- Engineering Surface Adhered Poly (Vinyl Alcohol) Physical Hydrogels As Enzymatic MicroreactorsДокумент10 страницEngineering Surface Adhered Poly (Vinyl Alcohol) Physical Hydrogels As Enzymatic MicroreactorshusseinhshОценок пока нет

- Hydrogen Production by The Hyperthermophilic Eubacterium, Using Cellulose Pretreated by Ionic LiquidДокумент15 страницHydrogen Production by The Hyperthermophilic Eubacterium, Using Cellulose Pretreated by Ionic LiquidkimlinhОценок пока нет

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntДокумент23 страницыMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPОценок пока нет

- Cyclodextrins and Carrier SystemsДокумент6 страницCyclodextrins and Carrier SystemselcancerberoОценок пока нет

- Bai BaoДокумент8 страницBai BaoTran Xuan Mai B2014493Оценок пока нет

- Sub/Supercritical Carbon Dioxide Induced Phase Switching For The Reaction and Separation in Ils/MethanolДокумент5 страницSub/Supercritical Carbon Dioxide Induced Phase Switching For The Reaction and Separation in Ils/MethanolDoni RopawandiОценок пока нет

- Pharmaceuticals 13 00399Документ17 страницPharmaceuticals 13 00399Fibie LionaОценок пока нет

- 1 s2.0 S0360319922042458 MainДокумент11 страниц1 s2.0 S0360319922042458 Mainranjani093Оценок пока нет

- Jurnal Cangkang Kepiting BubukДокумент10 страницJurnal Cangkang Kepiting Bubukvixionmax24Оценок пока нет

- Preparation and Characterization of Cationic PLGA Nanospheres As DNA CarriersДокумент7 страницPreparation and Characterization of Cationic PLGA Nanospheres As DNA CarriersAna Maria PinillaОценок пока нет

- Japs PDFДокумент8 страницJaps PDFDrNiladri RoyОценок пока нет

- Controlled Cross-Linking Strategy For Formation of Hydrogels, Microgels and NanogelsДокумент10 страницControlled Cross-Linking Strategy For Formation of Hydrogels, Microgels and NanogelsFatma Nur ParınОценок пока нет

- Catalysts 12 01531 v2Документ25 страницCatalysts 12 01531 v2Adrian AntolinОценок пока нет

- Jun 2012Документ3 страницыJun 2012Deva RajОценок пока нет

- Dom Lesson PlanДокумент4 страницыDom Lesson PlanDeva RajОценок пока нет

- MechsyllДокумент33 страницыMechsyllrub786Оценок пока нет

- 6TH SEM MechsyllДокумент38 страниц6TH SEM MechsyllAnonymous SLKWYHBoОценок пока нет

- Polymer CompositeДокумент9 страницPolymer CompositeDeva RajОценок пока нет

- Physics March 2014 Kannada Version PDFДокумент8 страницPhysics March 2014 Kannada Version PDFPrasad C MОценок пока нет

- Chapter-16 Chemistry in Everyday LifeДокумент9 страницChapter-16 Chemistry in Everyday LifeDeva RajОценок пока нет

- UNIT 9 Topic: Coordination CompoundsДокумент9 страницUNIT 9 Topic: Coordination CompoundsDeva RajОценок пока нет

- Iodine RevisitedДокумент16 страницIodine RevisitedDeva RajОценок пока нет

- 34 ch15 PDFДокумент8 страниц34 ch15 PDFDeva RajОценок пока нет

- Between Aldehyde and Ketones Which One Is Confirmed Using Fehling's Solution.. 1Документ7 страницBetween Aldehyde and Ketones Which One Is Confirmed Using Fehling's Solution.. 1Deva RajОценок пока нет

- Unit 11. Alcohols, Phenols and Ethers One Mark Questions: Ans: EthanolДокумент10 страницUnit 11. Alcohols, Phenols and Ethers One Mark Questions: Ans: EthanolDeva RajОценок пока нет

- Unit 13-Nitrogen Containing Organic CompoundsДокумент5 страницUnit 13-Nitrogen Containing Organic CompoundsDeva RajОценок пока нет

- 34 ch14 PDFДокумент9 страниц34 ch14 PDFDeva RajОценок пока нет

- 34 ch10 PDFДокумент13 страниц34 ch10 PDFDeva Raj100% (1)

- Finite Element Methods Jan 2014Документ2 страницыFinite Element Methods Jan 2014Prasad C MОценок пока нет

- Unit 8 The D-And F - Block Elements I. Answer The Following Questions. Each Question Carries One MarkДокумент9 страницUnit 8 The D-And F - Block Elements I. Answer The Following Questions. Each Question Carries One MarkDeva RajОценок пока нет

- Jobber JRДокумент2 страницыJobber JRDeva RajОценок пока нет

- Induction Sintering of %3 Cu Contented Iron Based Powder Metal PartsДокумент8 страницInduction Sintering of %3 Cu Contented Iron Based Powder Metal PartsDeva RajОценок пока нет

- 805836Документ7 страниц805836Deva RajОценок пока нет

- Jobber XLДокумент4 страницыJobber XLDeva RajОценок пока нет

- Mu TurnДокумент2 страницыMu TurnDeva RajОценок пока нет

- InTech-Interconnecting Carbon Nanotubes For A Sustainable EconomyДокумент20 страницInTech-Interconnecting Carbon Nanotubes For A Sustainable EconomyDeva RajОценок пока нет

- Formation of Zno Within Flexible Polymer FibersДокумент4 страницыFormation of Zno Within Flexible Polymer FibersDeva RajОценок пока нет

- 1 2Документ4 страницы1 2Deva RajОценок пока нет

- 641Документ5 страниц641aakriti_mathur_2Оценок пока нет

- 1656Документ5 страниц1656Deva RajОценок пока нет

- IndexДокумент5 страницIndexDeva RajОценок пока нет

- 3Документ6 страниц3Deva RajОценок пока нет

- Guess Who? The Periodic Table!Документ7 страницGuess Who? The Periodic Table!Natalie Gillis33% (3)

- Sheetmetal IntroductionДокумент9 страницSheetmetal IntroductionVinay BalineniОценок пока нет

- STPM Chemistry Practical Experiment 5 2012 Semester 1Документ4 страницыSTPM Chemistry Practical Experiment 5 2012 Semester 1Ning Jie Lee89% (54)

- 2CA S6 Mock Exam Paper 1 2020 EngДокумент33 страницы2CA S6 Mock Exam Paper 1 2020 Eng何卓函Оценок пока нет

- Oxetane PresentationДокумент60 страницOxetane PresentationEena BarmanОценок пока нет

- Prod. & Usages 2020-21Документ56 страницProd. & Usages 2020-21TOR PUBG KILLERSОценок пока нет

- ISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsДокумент10 страницISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsZahid Mahmood0% (1)

- Lab ReportДокумент8 страницLab ReportSean Regondola100% (1)

- Sodium YodideДокумент2 страницыSodium YodideBudi SusantoОценок пока нет

- HYdrocarbons PDFДокумент24 страницыHYdrocarbons PDFKumar PANKAJОценок пока нет

- Manav Sthali School, New Rajinder Nagar, New Delhi-110060 Chemistry Investigatory ProectДокумент13 страницManav Sthali School, New Rajinder Nagar, New Delhi-110060 Chemistry Investigatory ProectdevanshiОценок пока нет

- Prednisolone Acetate: Prednisoloni AcetasДокумент3 страницыPrednisolone Acetate: Prednisoloni AcetasMarcosОценок пока нет

- PVC WaterstopsДокумент6 страницPVC WaterstopsHiren DesaiОценок пока нет

- 6CH02 01R Que 20140603Документ24 страницы6CH02 01R Que 20140603Mathloob DexterОценок пока нет

- Activity 4 BiomoleculesДокумент3 страницыActivity 4 Biomoleculeseva palattaoОценок пока нет

- Sodium SilicateДокумент12 страницSodium Silicatemoses_cОценок пока нет

- Paper Sludge PDFДокумент13 страницPaper Sludge PDFDanie RoyОценок пока нет

- Process Validation Final ReportДокумент9 страницProcess Validation Final ReportShagorShagor75% (4)

- BioinorganicДокумент31 страницаBioinorganicNehaShailendraAgarwalОценок пока нет

- GCSE Comb Higher Chemistry 2023Документ57 страницGCSE Comb Higher Chemistry 2023Ramy MohamedОценок пока нет

- SCDPL - C - DWG - 087 - Detailed Drawing For Watchtower - R00 20200615Документ1 страницаSCDPL - C - DWG - 087 - Detailed Drawing For Watchtower - R00 20200615Raviraj Thorat100% (1)

- MaterialData AISI-SAE101Документ2 страницыMaterialData AISI-SAE101Ian KellyОценок пока нет

- TS22.C11.12.1 IUPAC Nomenclature of Organic Chemistry 22-10-2022Документ3 страницыTS22.C11.12.1 IUPAC Nomenclature of Organic Chemistry 22-10-2022ShОценок пока нет

- Astm D 1722 - 98Документ2 страницыAstm D 1722 - 98whutecompressor100% (1)

- Cp2377 Fluorglas Tape 2905-7 Pds1Документ2 страницыCp2377 Fluorglas Tape 2905-7 Pds1Panneer SelvamОценок пока нет

- Chlorination Mass Balance Calculation: Legend Overall Reactions (Mol/Hr)Документ2 страницыChlorination Mass Balance Calculation: Legend Overall Reactions (Mol/Hr)Husni RadiyanОценок пока нет

- Pre-Labs 2 Organic Compositions of The CellДокумент6 страницPre-Labs 2 Organic Compositions of The CellTrần Xuân QuỳnhОценок пока нет

- 01 History of PlasticsДокумент24 страницы01 History of PlasticsProf C.S.Purushothaman0% (1)

- Inorganic Report 4Документ5 страницInorganic Report 4wiqiОценок пока нет

- B) The Particles of A Suspension Will Sink Out If Left Over Time To RestДокумент5 страницB) The Particles of A Suspension Will Sink Out If Left Over Time To RestLunilyn OrtegaОценок пока нет