Академический Документы

Профессиональный Документы

Культура Документы

Astm A529 1975

Загружено:

dharlanuctcom0 оценок0% нашли этот документ полезным (0 голосов)

144 просмотров4 страницыASTM Specification

Оригинальное название

astm.a529.1975

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документASTM Specification

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

144 просмотров4 страницыAstm A529 1975

Загружено:

dharlanuctcomASTM Specification

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

By Authority Of

THE UNITED STATES OF AMERICA

Legally Binding Document

By the Authority Vested By Part 5 of the United States Code 552(a) and

Part 1 of the Code of Regulations 51 the attached document has been duly

INCORPORATED BY REFERENCE and shall be considered legally

binding upon all citizens and residents of the United States of America.

HEED THIS NOTICE: Criminal penalties may apply for noncompliance.

Official Incorporator:

THE EXECUTIVE DIRECTOR

OFFICE OF THE FEDERAL REGISTER

WASHINGTON, D.C.

Document Name:

CFR Section(s):

Standards Body:

e

American Society for Testing and Materials

ASTM A529: Structural Steel with 42,000PSI (290 Mpa)

Minimum Yield Point (1/2 in (12.7 mm) Maximum

Thickness

24 CFR 200, Subpart S

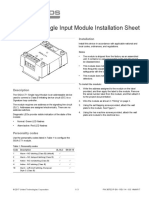

AMERICAN NATIONAL ANSI! ASTM A 529 - 75

STANDARD

Standard Specification for

STRUCTURAL STEEL WITH 42 000 psi (290 MPa)

MINIMUM YIELD POINT (Yz in. (12.7 mm)

MAXIMUM THICKNESSP

This is issued under the fixed designation A 529; the number immediately following the designation indicates the

year of onglOal adoptIOn or, in the case of revision, the year of last revision. A number in parentheses indicates the year of

last reapproval.

1. Scope

1.1 This specification covers carbon steel

plates and bars 1/2 in. (12.7 mm) and under in

thickness or diameter and Group I shapes

shown in Table A of ASTM Specification A

6, General Requirements for Rolled Steel

Plates, Shapes, Sheet Piling, and Bars for

Structural Use,2 of structural quality for use

in buildings and similar riveted, bolted, or

welded construction. When used in welded

construction, welding procedures shall be

suitable for the steel and the intended service.

NOTE-The values stated in inch-pound units are

to be regarded as the standard.

2. General Requirements for Delivery

2.1 Material furnished to this specification

shall conform to the applicable requirements

of the current edition of Specification A 6.

3. Process

3.1 The steel shall be made by any of the

following processes: open-hearth, basic-oxy-

gen, or electric-furnace.

4. Chemical Requirements

4.1 Heat Analysis:

4.1.1 The heat analysis shall conform to

the requirements prescribed in Table l.

4.1.2 When tension tests are not required

in accordance with 5.1.2, chemistry consistent

with requirements in Table I and with the

mechanical properties desired shall be ap-

plied.

487

4.2 Product Analysis:

4.2.1 The steel shall conform on product

analysis to the requirements prescribed in

Table I, subject to the product analysis toler-

ances in Specification A 6, except as specified

in 4.2.2.

4.2.2 Product analysis is not required for

bar-size shapes or flat bars 1/2 in. (12.7 mm)

and under in thickness.

5. Mechanical Requirements

5.1 Tensile Properties:

5.1.1 The material as represented by the

test specimen, except as specified in 5.1.2,

shall conform to the requirements as to the

tensile properties prescribed in Table 2.

5.1.2 Shapes less than I in.

2

(6.45 cm 2) in

. cross section and bars other than flats, less

than V2 in. (12.7 mm) in thickness or diam-

eter need not be subjected to tension tests.

5.1.3 For material under 1'16 in. (7.94 mm)

in thickness or diameter, a deduction of 1.25

percent from the percentage of elongation in 8

in. or 200 mm as specified in Table 2, shall

be made for each decrease of VJ2 in. (0.79

mm) of the specified thickness or diameter

below 1'16 in. (7.94 mm).

1 This specification is under the jurisdiction of ASTM

Committee A-Ion Steel, Stainless Steel and Related Alloys,

and is the direct responsibility of Subcommittee AOl.02 on

Structural Steel for Bridges, Buildings, Rolling Stock, and

Ships.

Current edition approved July 25, 1975. Published

October 1975. Originally published as A 529 - 64. Last

previous edition A 529 - 72.

'Annual Book of ASTM Standards, Part 4.

A 529

SUPPLEMENTARY R'EQUlREMENtS

1 j:

Standardized supplementary requirements for use at the option of the purchaser are

listed in Specification A 6. Those which are considered suitable for use with this specifi-

cation are listed below by title.

S14. Bend Test.

'TABLE 1 Chemical (Heat Analysis)

Element

Carbon, max

Manganese, "max:

PhosphOrus, max :

Sulfur, max

Copper, min, when copper

is specified

, Composition,

percent

0.27

1.20

0.04

0.05

0.20

TABLE 2 Tensile Requirements

Tensile strength '

Yield min

Elongation in 8 in. or 200

mm, min, percent

60 000 to'

85 000

42 000 '

MPa

, '" 414 to

586

290

19'

a For plates wider than 24 in. (610 mm), the test

speCimen is :faken iii the transverse' direction. See 11.2 of

Specification A 6. "."

'See5.1.3. "",'

, C For plates wiaer than 2,\ in. '(610' mm), the elongation

requirement is reduced two percentage points. '

, The'American SOCiety, fl, or, Te, Stin,'g ,a, tid, Mater,ials tak,es no pOS,ition eCtiilg;,!he .va!i"',i,t

y

of a, ny patent rights asser,ted, in

cOl!nection wi(h any.item mentione,a in, this standard. User,s oJ this standard ,are advised that determination of

validity of any such pateni ifghts, and the rifk of infringement of is elitirelj their ' i;

This standard is subject to revision at any time by the responsible technical: comflJille,e-:'ahd mUS( beJe'viewed everyjJve

years and if not revised; either ,reapprQved oi'.withdra.wn. Your comm,en(s are invited either for revision of this standanf 'ir

for additional standards and should be t;lddressed (0 ASTM Headquarters. Your comments will receive careful consideraiion

at a meeting of the responsible 'technical 'committee, which you may attend. it you feel that your comments 'have not received

a fair hearing you sh.ould. make yow views known (0 ihe ASTM Committee, 011 Slal!da,r,d!,,; .Race St.,. Philadelphia; Pa.

19103,. which. will sch.edule ,a further. hearil:lg regarding yqur comments. Failing' ,there, you may appeal to

ASTM Board of Direciors.

488

Вам также может понравиться

- Astm A285 1978Документ5 страницAstm A285 1978Juan Manuel Cruz MárquezОценок пока нет

- Astm A242 1979Документ4 страницыAstm A242 1979bkprodhОценок пока нет

- Anclajes Red HeadДокумент8 страницAnclajes Red HeadLeonardo AvilaОценок пока нет

- Astm A82 1979Документ6 страницAstm A82 1979yoki_triwahyudiОценок пока нет

- Astm A325 1979Документ11 страницAstm A325 1979Deana WhiteОценок пока нет

- Ansi c80-6 2005Документ22 страницыAnsi c80-6 2005supervisor.electricistaОценок пока нет

- A126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsДокумент3 страницыA126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsJosh HansenОценок пока нет

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessДокумент9 страницGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarОценок пока нет

- Astm b85 1984Документ7 страницAstm b85 1984Siddhi Sharma100% (1)

- Astm A 143M-03Документ3 страницыAstm A 143M-03MritunjayОценок пока нет

- Enovia VPLM VPM NavigatorДокумент11 страницEnovia VPLM VPM NavigatorAsker Ali TPОценок пока нет

- Abs - Approved Steel Mills and Pipe MillsДокумент60 страницAbs - Approved Steel Mills and Pipe Millsgeorgekc77Оценок пока нет

- ASTM A656 Grade 50: General Product DescriptionДокумент1 страницаASTM A656 Grade 50: General Product DescriptionHarsh ChopraОценок пока нет

- HILTI HSA Anchor DesignДокумент6 страницHILTI HSA Anchor DesignJay PОценок пока нет

- Asme B18.2.6 2003Документ11 страницAsme B18.2.6 2003Jesse ChenОценок пока нет

- A270 PDFДокумент5 страницA270 PDFHansSarmientoОценок пока нет

- NEMA Product ScopesДокумент39 страницNEMA Product ScopesPaul AlvaradoОценок пока нет

- Mech Malleable Iron Fittings Catalogue PDFДокумент12 страницMech Malleable Iron Fittings Catalogue PDFics companyОценок пока нет

- Astm F1200-1988Документ4 страницыAstm F1200-1988Abhijit TumbreОценок пока нет

- Asme Section II A-2 Sa-688 Sa-688mДокумент10 страницAsme Section II A-2 Sa-688 Sa-688mAnonymous GhPzn1xОценок пока нет

- Aa 60005Документ30 страницAa 60005ashishkesharwaniОценок пока нет

- SIGA CT1 Est Manual Instalacion SH IngenieriaДокумент3 страницыSIGA CT1 Est Manual Instalacion SH IngenieriaedgarОценок пока нет

- Hilti North American Product Technical Guide 813255 PDFДокумент147 страницHilti North American Product Technical Guide 813255 PDFMUHAMMAD UMAR RIAZОценок пока нет

- A 872 - 91 R02 Qtg3mi05mviwmgДокумент3 страницыA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdОценок пока нет

- Astm A216Документ8 страницAstm A216Hamdan AtaminiОценок пока нет

- Astm B575Документ5 страницAstm B575Jota JacquesОценок пока нет

- Steelwise: Are You Properly Specifying Materials?Документ9 страницSteelwise: Are You Properly Specifying Materials?Muhammad AhsunОценок пока нет

- Al Busbar 6060 DatasheetДокумент1 страницаAl Busbar 6060 DatasheetpiirsaluОценок пока нет

- 2062Документ17 страниц2062hswed91100% (1)

- Asme B107.3-1978Документ21 страницаAsme B107.3-1978noahb110Оценок пока нет

- Astm A756 PDFДокумент3 страницыAstm A756 PDFCristian OtivoОценок пока нет

- Electricity Board DocsДокумент41 страницаElectricity Board DocsM_D_MendisОценок пока нет

- Cispi Designation 301-09 PDFДокумент80 страницCispi Designation 301-09 PDFsina_84Оценок пока нет

- NADCA Tolerances 2009Документ44 страницыNADCA Tolerances 2009Tom HagertyОценок пока нет

- 1 Edition, Rev. 8Документ54 страницы1 Edition, Rev. 8alexayala5151Оценок пока нет

- Designation B 828 - 002Документ11 страницDesignation B 828 - 002Raron1Оценок пока нет

- Analizador XRF PDFДокумент212 страницAnalizador XRF PDFMaritza EstefesОценок пока нет

- B729Документ3 страницыB729LambertWayneОценок пока нет

- North American Standard For Cold-Formed Steel Framing - GeneralДокумент49 страницNorth American Standard For Cold-Formed Steel Framing - GeneralNishan GajurelОценок пока нет

- Dual Phase SteelsДокумент22 страницыDual Phase SteelsAngele IvanovskiОценок пока нет

- Astm A216-A216m 2008Документ4 страницыAstm A216-A216m 2008Guilherme de BarrosОценок пока нет

- Astm F3125 F3125M 18Документ6 страницAstm F3125 F3125M 18Amine ait talebОценок пока нет

- Seamless and Welded Ferritic Stainless Steel Feedwater Heater TubesДокумент7 страницSeamless and Welded Ferritic Stainless Steel Feedwater Heater TubesMina RemonОценок пока нет

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsДокумент4 страницыA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterОценок пока нет

- Section 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Документ52 страницыSection 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Andy PhoenixОценок пока нет

- Steel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessДокумент9 страницSteel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessDarwin DarmawanОценок пока нет

- Astmf899 11Документ7 страницAstmf899 11Robert NatasorpОценок пока нет

- Astm A502 1976Документ6 страницAstm A502 1976dharlanuctcomОценок пока нет

- Astm A615 1979 PDFДокумент8 страницAstm A615 1979 PDFYassine ZamzamiОценок пока нет

- ASTM D 2000: Specification NumberДокумент3 страницыASTM D 2000: Specification NumberjanarthananОценок пока нет

- Aluminum Rectangular and Square Wire For Electrical PurposesДокумент7 страницAluminum Rectangular and Square Wire For Electrical Purposesvuqar0979Оценок пока нет

- B 824 PDFДокумент6 страницB 824 PDFKunal BhatiaОценок пока нет

- Astm A441 1979Документ4 страницыAstm A441 1979dharlanuctcomОценок пока нет

- Astm A572 1979 PDFДокумент5 страницAstm A572 1979 PDFzepol2000Оценок пока нет

- Astm A36 1977Документ6 страницAstm A36 1977Ben Yie Min100% (1)

- Astm A36 PDFДокумент5 страницAstm A36 PDFAnindya Aulia Pratiwi67% (3)

- Astm A992 PDFДокумент3 страницыAstm A992 PDFvasanthОценок пока нет

- A737Документ2 страницыA737doshi78Оценок пока нет

- Astm A611 1972Документ5 страницAstm A611 1972dharlanuctcomОценок пока нет

- Mil C 26074eДокумент11 страницMil C 26074edharlanuctcomОценок пока нет

- Nasa RP 1228Документ98 страницNasa RP 1228dharlanuctcomОценок пока нет

- Mechanical Properties and HardenabilityДокумент32 страницыMechanical Properties and Hardenabilitydharlanuctcom100% (1)

- Astm f1548 1994Документ6 страницAstm f1548 1994dharlanuctcomОценок пока нет

- Sequence Software 3.0 Object ChartДокумент1 страницаSequence Software 3.0 Object ChartdharlanuctcomОценок пока нет

- Astm f853 2005Документ10 страницAstm f853 2005dharlanuctcom100% (1)

- Astm f1155 1998Документ25 страницAstm f1155 1998ttplan800Оценок пока нет

- Astm f2291 2006Документ46 страницAstm f2291 2006dharlanuctcomОценок пока нет

- Astm f682 1982Документ7 страницAstm f682 1982dharlanuctcomОценок пока нет

- Astm f1193 2004Документ4 страницыAstm f1193 2004dharlanuctcomОценок пока нет

- Astm f2007 2006Документ7 страницAstm f2007 2006dharlanuctcomОценок пока нет

- Astm f478 1992Документ6 страницAstm f478 1992dharlanuctcomОценок пока нет

- Astm d3236 1988Документ10 страницAstm d3236 1988dharlanuctcomОценок пока нет

- Astm E29 1967Документ6 страницAstm E29 1967dharlanuctcomОценок пока нет

- Astm d1692 1968Документ6 страницAstm d1692 1968dharlanuctcomОценок пока нет

- Astm d413 1982Документ7 страницAstm d413 1982dharlanuctcomОценок пока нет

- Astm b227 1970Документ6 страницAstm b227 1970dharlanuctcomОценок пока нет

- Astm d1081 1960Документ5 страницAstm d1081 1960dharlanuctcomОценок пока нет

- Astm E1337 1990Документ7 страницAstm E1337 1990dharlanuctcomОценок пока нет

- Astm d4268 1993Документ9 страницAstm d4268 1993dharlanuctcomОценок пока нет

- Astm E23 1993Документ6 страницAstm E23 1993dharlanuctcomОценок пока нет

- Astm d1056 1973Документ13 страницAstm d1056 1973dharlanuctcomОценок пока нет

- Astm d750 1968Документ5 страницAstm d750 1968dharlanuctcomОценок пока нет

- Astm A514 1977Документ6 страницAstm A514 1977Elumalai Srinivasan100% (1)

- Manual On Pavement Design PDFДокумент31 страницаManual On Pavement Design PDFAnil Kumsr T B100% (3)

- Part 7 StoichiometryДокумент59 страницPart 7 Stoichiometryjasumin91Оценок пока нет

- Cytech Products Data SheetsДокумент71 страницаCytech Products Data Sheetslinga2014Оценок пока нет

- Astm C 295-2019Документ9 страницAstm C 295-2019Mohammed Ali100% (1)

- Hot TappingДокумент21 страницаHot TappingnayakyaОценок пока нет

- Minimum VentilationДокумент4 страницыMinimum VentilationNathan Smith100% (1)

- Dielectric Strength of Transformer OilДокумент2 страницыDielectric Strength of Transformer OilAnil VarriОценок пока нет

- Component in Making Fiber Board As Substitute For HardiflexДокумент9 страницComponent in Making Fiber Board As Substitute For Hardiflexxiniac_1Оценок пока нет

- Hot Work PermitДокумент2 страницыHot Work PermitRex UrbiztondoОценок пока нет

- Folder GluingДокумент3 страницыFolder GluingSyed Mujtaba Ali Bukhari100% (1)

- Tyvek CodeДокумент1 страницаTyvek CodeDaveCindy ShaferОценок пока нет

- 3075-Article Text-9088-1-10-20201218Документ11 страниц3075-Article Text-9088-1-10-20201218Rasdawati RasulОценок пока нет

- Urea UV Freeze DriedДокумент1 страницаUrea UV Freeze DriedJanos ImreОценок пока нет

- List of Accredited List of Accredited EIA Consultant Organizations (As On March 05, 2015) Organizations - 170Документ135 страницList of Accredited List of Accredited EIA Consultant Organizations (As On March 05, 2015) Organizations - 170santhoshneo02@gmail.comОценок пока нет

- Procedures For Hvac System Design and InstallationДокумент5 страницProcedures For Hvac System Design and Installationrawadsultan100% (1)

- Database of Embodied Energy and Water Values For MaterialsДокумент3 страницыDatabase of Embodied Energy and Water Values For MaterialsMax Yanac TelleriaОценок пока нет

- Heat Transfer To Fluids With Phase ChangeДокумент9 страницHeat Transfer To Fluids With Phase Changepraveen4ubvsОценок пока нет

- Factors Affecting Drug Absorption PDFДокумент2 страницыFactors Affecting Drug Absorption PDFRobОценок пока нет

- Experiments 11 15 NotesДокумент16 страницExperiments 11 15 Notesforisko05Оценок пока нет

- Astm d1785Документ5 страницAstm d1785Kehinde AdebayoОценок пока нет

- Reading TOEFLДокумент13 страницReading TOEFLwelnitesiОценок пока нет

- En 10263-1Документ30 страницEn 10263-1Mogos PaulОценок пока нет

- A Clear & Present Danger 2 - The Use of QT or TMT Rebars in Seismic Zone 4Документ12 страницA Clear & Present Danger 2 - The Use of QT or TMT Rebars in Seismic Zone 4friends_y2k5Оценок пока нет

- HTT 45 CableДокумент1 страницаHTT 45 CableKoel DeyОценок пока нет

- 3G Metric A4 Overview PDFДокумент8 страниц3G Metric A4 Overview PDFDiadam SharmaОценок пока нет

- 70 Penetration Grade BitumenДокумент1 страница70 Penetration Grade BitumenJohn SnowОценок пока нет

- Bioprocess Engineering 2Документ1 страницаBioprocess Engineering 2asg rostОценок пока нет

- Co 2Документ6 страницCo 2Sitti Nur QomariahОценок пока нет

- Agave Biotechnology An OverviewДокумент15 страницAgave Biotechnology An Overviewadrian perezОценок пока нет