Академический Документы

Профессиональный Документы

Культура Документы

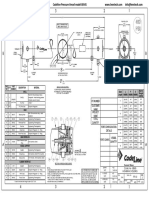

DWG REF QTY Number Description Material Shell: Order Section

Загружено:

RamanNegiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DWG REF QTY Number Description Material Shell: Order Section

Загружено:

RamanNegiАвторское право:

Доступные форматы

DWG PART QTY REF NUMBER

DESCRIPTION SHELL

MATERIAL

Dash Length -1

L IN(MM) 59.15 (1502) 79.15 (2010) 99.15 (2518) 139.15 (3534) 179.15 (4550) 199.15 (5058) 219.15 (5566) 259.15 (6582) 299.15 (7598) 319.15 (8106) 339.15 (8614)

P S IN(MM) IN(MM) 47 (1194) 67 (1702) 87 (2210) 127 (3226) 167 (4242) 187 (4750) 207 (5258) 247 (6274) 287 (7290) 307 (7798) 327 (8306) 23X1 (588) 40.5X1 (1028) 56X1 (1422) 80X1 (2032) 64X2 (1626) 71X2 (1803) 78X2 (1981) 92X2 (2337) 106X2 (2692) 113X2 (2870) 120X2 (3048)

Approx Weight LB(KG) 82 (37) 90.5 (41) 99 (45) 117 (53) 135 (61) 143.5 (65) 152 (69) 170 (77) 187 (85) 195.5 (87) 204 (93)

1 2 3

1 ORDER A/R SECTION A/R

SHELL F/C Port F/C Port Seal

Filament Wound Epoxy/Glass composites - Head locking grooves integrally wound in place. CF3M * Ethylene Propylene .

-1.5 -2 -3 -4 -4.5 -5 -6 -7 -7.5

HEAD - NON CODED 4 5 2 2 96243 96000 Elliptical Head Assy. Engineering Thermoplastic. Head Seal Ethylene Propylene - O - Ring

HEAD INTERLOCK 6 2 47336 Quick Release Spiral 316 Stainless Steel. Ring VESSEL SUPPORT 7 8 9 *2 *2 4 52169 45042 46265 Saddle Strap Assy. Strap screw. Engineering Thermoplastic. 304 Stainless Steel-PVC Cushion. 5/16-18 UNC, 18-8 Stainless Steel.

-8

ELEMENT INTERFACE 10 11 12 13 2 2 4 1 A/R 52245 A/R 97014 Adapter Adapter seal PWT Seal Thrust Cone Engineering Thermoplastic. Ethylene Propylene - O - Ring Ethylene Propylene - O - Ring Engineering Thermoplastic.

* 3 each furnished with length code 4,5,6,7 & 8.

RATING: DESIGN PRESSURE...300 PSIG at 190F (2.1 MPa at 88C) MIN. OPERATING TEMP....20F (-7C) FACTORY TEST PRESSURE...450 PSIG (3.1 MPa) QUALIFICATION PRESSURE ....1800 PSI (12.4 MPa) INTENDED USE: The CodeLine 80S30 Non Coded Fiberglass RO Pressure Vessel is designed for continuous, long term use as a housing for reverse osmosis membrane elements to desalt typical brackish waters at pressures up to 300 psi. Any make of eight-inch nominal diameter spiral-wound element is easily accommodated; the appropriate interfacing hardware for the element specified is furnished with the vessel. The Shell of CodeLine 80S30 Non Coded is designed in accordance with the engineering standards of the Boiler and Pressure Vessel Code of the American Society of Mechanical Engineers (ASME) Code. The CodeLine 80S30 Non Coded must be installed operated and maintained in accordance with the listed precautions and good industrial practice to assure safe operation over a long service life. The high performance Filament wound FRP shell must be allowed to expand under pressure; undue restraint at support points or piping connections can cause leaks to develop in the shell. This side-ported vessel requires special precautions in mounting and connection to piping so that the vessel will not be subjected to excessive stress due to bending moments acting at the side openings in the fiberglass shell. The end closure, incorporating close fitting, interlocking metal components, must be kept dry and free of corrosion; deterioration can lead to catastrophic mechanical failure of the head. Pentair Water will assist the purchaser in determining the suitability of this standard vessel for their specific operating conditions. The final determination however, including evaluation of the standard material of construction for compatibility with the specific corrosive environment, shall be the responsibility of the purchaser. Alternate materials with enhanced corrosion resistance are available on special order. Specifications are subject to change without notice.

PRECAUTIONS: DOread, understand and follow all instructions; failure to take every precaution will void warranty and may result in vessel failure DOmount the shell on horizontal members at span S using compliant vessel supports furnished; Shim saddles if required. Tighten hold down straps just snug DOalign and center side ports with the manifold header. Correct, causes of misalignment in a row of vessels connected to the same header DOuse flexible type IPS grooved-end pipe couplings, at side ports; allow full, 0.125 inch gap between port and piping, and position piping to maximize flexibility of connection. DOprovide flexibility in, and support for piping manifolds so that vessel can grow in length under pressure without undue restraint; provide additional flexible joints in large pipes leading to manifold header. DOprovide overpressure protection for vessel set at not more than 105% of design pressure DOinspect end closures regularly; replace components that have deteriorated and correct causes of corrosion DO Lubricate seals sparingly, using nonpetroleum Based lubricants, i.e. Parker Super O-lube, Glycerin or suitable silicone based lubricants. DO NOTwork on any component until first verifying that pressure is relieved from vessel DO NOTmake rigid piping connections to ports or clamp vessel in any way that resists growth of fiberglass shell under pressure; *** DIA = 0.015 in. (0.4mm) and *** L = 0.2 in. (6mm) for a length code 8 vessel DO NOT hang piping manifolds from ports or use vessel in any way to support other components DO NOTtighten Permeate Port connection more than one turn past hand tight DO NOT operate vessel without connecting both Permeate Ports internally to complete set of elements or otherwise plug ports internally so that external piping connection is not subjected to feed pressure DO NOTinstall Spacer on downstream end of vessel DO NOToperate vessel without Thrust Cone installed downstream DO NOTpressurize vessel until double-checking to verify that the Locking Ring is in place and fully seated. DO NOToperate vessel at pressure and temperature in excess of its rating. DO NOToperate vessel with permeate pressure in excess of 125 psi at 190F (0.86 Mpa at 880 C). DO NOTtolerate leaks or allow end closures to be routinely wetted in any way DO NOToperate outside the pH range 3-10.

PP

ORDERING: Using the chart below, please check the features you require and fax them with your purchase order to our customer service department for further processing. For optional materials and / or feature not listed below, please consult the factory for pricing and availability VESSEL LENGTH CODE please check one MODEL 80S30 Non Coded -1 -1.5 -2 -3 -4 -4.5 -5 -6 -7 -7.5 -8

MEMBRANE BRAND AND MODEL please check one and fill in information Please supply adapters for the following membrane brand and specific model Brand_________________________ Model_______________________ Membrane brand and model information is not currently available, but will be supplied to Pentair Water on or before the following date. ___ / ___ / ___

CERTIFICATION REQUIRED CE Marked Standard, Certified by Pentair water. MATERIAL OPTIONS please check one Standard: all materials as per drawing 99172 on the previous page NOTE: The options listed below will increase the vessel price. Call factory for pricing details. Option: Customer specified port configuration. (Please consult factory as these options will affect pricing and

vessel lead time)

PORT SIZE CODE FEED/CONCENTRATE PORT CONFIGURATION Standard 1 IPS pipe, grooved ends, with ports in-line Optional Multi-Ports

TM

D E F

1 GROOVED END 2 GROOVED END 2 GROOVED END

Using the instructions in Order Specification Sheet #99007 please fill out your feed port configuration in the space below. List port location first, followed by port size for each choice.

Serial number end Opposite end

PERMEATE PORT CONFIGURATION: Standard. 1 FNPT & 1.5 VICTUALIC. Optional. 1 BIS F/JIS F-Parallel Thread &1.5VIC.

For complete information on proper use of the vessel Please refer to the 80S Series USERS GUIDE 94182. DWG. NO. 99172-M, Pentair Water PAGE 2 OF 2.

Вам также может понравиться

- Drawing 80H30Документ3 страницыDrawing 80H30kpranjal15Оценок пока нет

- Codeline, 150 PSI, Drawing - 80S15Документ3 страницыCodeline, 150 PSI, Drawing - 80S15RamanNegiОценок пока нет

- Codeline Drawing 80S45 Non CodedДокумент2 страницыCodeline Drawing 80S45 Non CodedoctavioОценок пока нет

- Codeline Drawing 80S30 Non CodedДокумент2 страницыCodeline Drawing 80S30 Non CodedDarren PonichaiОценок пока нет

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Документ3 страницыDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiОценок пока нет

- (2012) Complete IELTS Bands 5-6.5 Student's BookДокумент3 страницы(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Codeline 80S45Документ3 страницыCodeline 80S45Julian Bocanegra ReyesОценок пока нет

- Datasheet Codeline OCTA 80S SeriesДокумент4 страницыDatasheet Codeline OCTA 80S SeriesJulian Bocanegra ReyesОценок пока нет

- Codeline Drawing 80E30Документ2 страницыCodeline Drawing 80E30hargote_2Оценок пока нет

- DWG REF QTY Number Description Material ShellДокумент2 страницыDWG REF QTY Number Description Material ShellimtiyazОценок пока нет

- SAIC-D-2009 Rev 2Документ6 страницSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுОценок пока нет

- YM Specs and Dimensions L - Certainteed PDFДокумент12 страницYM Specs and Dimensions L - Certainteed PDFedumaster1891Оценок пока нет

- 2010B 2020B VB15 PDFДокумент5 страниц2010B 2020B VB15 PDFbnjaimahОценок пока нет

- Trampa Socket WeldДокумент2 страницыTrampa Socket WeldOscar Nieves ZamoraОценок пока нет

- Codeline Drawing 80H60Документ3 страницыCodeline Drawing 80H60octavioОценок пока нет

- Europa Valve Non Slam Check ValvesДокумент16 страницEuropa Valve Non Slam Check ValvesBryan KellyОценок пока нет

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Документ5 страницVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardОценок пока нет

- Erection and Commissioning Procedure PDFДокумент94 страницыErection and Commissioning Procedure PDFShankar JhaОценок пока нет

- 08 6.H Pressure VesselДокумент32 страницы08 6.H Pressure VesselstargaxxxxОценок пока нет

- A1200 Red Thread II PipingДокумент0 страницA1200 Red Thread II PipingjimmycabreraОценок пока нет

- Water Cooled Fcu Piping DetailsДокумент14 страницWater Cooled Fcu Piping Detailsfernandoreyes893Оценок пока нет

- Super Duplex Stainless Steel Vic-Ball ValveДокумент4 страницыSuper Duplex Stainless Steel Vic-Ball Valvemayukhguha88Оценок пока нет

- Topworx Position SwitchДокумент60 страницTopworx Position SwitchsarkaftОценок пока нет

- Valves & Controls: Crosby Safety Valves Style HSLДокумент12 страницValves & Controls: Crosby Safety Valves Style HSLeborresonОценок пока нет

- D 100394 X 012Документ52 страницыD 100394 X 012Preyas SuvarnaОценок пока нет

- Formed-Cylinders 2007-04 LoДокумент14 страницFormed-Cylinders 2007-04 LomartinvandoornОценок пока нет

- 2010 KMT Waterjet PSC Catalog - LДокумент39 страниц2010 KMT Waterjet PSC Catalog - LaeradriОценок пока нет

- Drainage Handbook SpecificationsДокумент57 страницDrainage Handbook Specificationshussainelarabi100% (1)

- CV For Pressure Up To 50bДокумент4 страницыCV For Pressure Up To 50bmattuiffОценок пока нет

- Document No. KE-2022-03: Operation ManualДокумент36 страницDocument No. KE-2022-03: Operation ManualGia Minh Tieu TuОценок пока нет

- Ib 10Документ2 страницыIb 10dchz_62Оценок пока нет

- Viega Profipress ManualДокумент16 страницViega Profipress Manualhasmit1Оценок пока нет

- Ti 2 516 UsДокумент2 страницыTi 2 516 Uswill_streetОценок пока нет

- General Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure TransmitterДокумент3 страницыGeneral Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure TransmitterJorge GuerreroОценок пока нет

- Allegheny Bradford Corporation: Craftsmen in StainlessДокумент11 страницAllegheny Bradford Corporation: Craftsmen in Stainlessアルビン ベネОценок пока нет

- Guth VSR Modulating ValvesДокумент8 страницGuth VSR Modulating ValvesRaul Guevara TorresОценок пока нет

- Oilfield Hoses Fittings AccembliesДокумент29 страницOilfield Hoses Fittings Accembliesthapa786mОценок пока нет

- Series 825YD Specification SheetДокумент2 страницыSeries 825YD Specification SheetFEBCOОценок пока нет

- ARI SpecДокумент4 страницыARI SpecLinggar Setiawan NОценок пока нет

- ASCO Miniature Valve Products (AV017R5)Документ96 страницASCO Miniature Valve Products (AV017R5)vasudeva yasasОценок пока нет

- Deluge ValveДокумент10 страницDeluge ValvevpnrrajaОценок пока нет

- FMC Weco Wing Union CatalogДокумент16 страницFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Double Block Bleed TOSVДокумент8 страницDouble Block Bleed TOSVplanet123Оценок пока нет

- Mangas PDFДокумент14 страницMangas PDFluisfer811Оценок пока нет

- 615499fb78247e6a4579d993 6202 Cosasco Disc Coupon HolderДокумент3 страницы615499fb78247e6a4579d993 6202 Cosasco Disc Coupon HolderPatricia RomeroОценок пока нет

- Pikotek Vcs Tech SpecsДокумент2 страницыPikotek Vcs Tech SpecsBaskar KannaiahОценок пока нет

- WATSON Separator 1Документ31 страницаWATSON Separator 1Apriliana DwijayantiОценок пока нет

- API 6A ValveДокумент12 страницAPI 6A Valveedo_tapia_ur100% (1)

- Steam TrapДокумент2 страницыSteam TrapAmpornchai PhupolОценок пока нет

- Ficha Tecnica PikotekДокумент2 страницыFicha Tecnica Pikoteking_arriagaОценок пока нет

- For Harsh and Hazardous Locations: Exe EnclosuresДокумент79 страницFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonОценок пока нет

- Manualn25 35 45 55 70 90 140 - GBДокумент24 страницыManualn25 35 45 55 70 90 140 - GBjonathan.gelli5153Оценок пока нет

- Flat Wall and Cylindrical Tanks - Design SummaryДокумент8 страницFlat Wall and Cylindrical Tanks - Design SummarychaitanyaОценок пока нет

- FreyssibarДокумент12 страницFreyssibarFelix Untalan Ebilane JrОценок пока нет

- GPT 1-3 PGE Tech SpecificationsДокумент4 страницыGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiОценок пока нет

- Ball Valve Seat Seal Injection SystemДокумент28 страницBall Valve Seat Seal Injection SystemmudrijasmОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- 3 Perform Industry CalculationsДокумент90 страниц3 Perform Industry CalculationsRobinson ConcordiaОценок пока нет

- Refining Corrosion Technologist NACE-RCT-001: NACE Cathodic Protection Technician (CP 2) Written ExamДокумент16 страницRefining Corrosion Technologist NACE-RCT-001: NACE Cathodic Protection Technician (CP 2) Written Examshoaib1985100% (1)

- Test Bank For Chemistry An Atoms Focused Approach 3rd Edition Thomas R Gilbert Rein V Kirss Stacey Lowery Bretz Natalie FosterДокумент38 страницTest Bank For Chemistry An Atoms Focused Approach 3rd Edition Thomas R Gilbert Rein V Kirss Stacey Lowery Bretz Natalie Fosterauntyprosperim1ru100% (10)

- Vensim User ManualДокумент34 страницыVensim User ManualMahdan LondoОценок пока нет

- Backup Olt CodigoДокумент5 страницBackup Olt CodigoCarlos GomezОценок пока нет

- Lecture 2: Stacks and Queues: CSE 373: Data Structures and AlgorithmsДокумент31 страницаLecture 2: Stacks and Queues: CSE 373: Data Structures and AlgorithmsTawsifОценок пока нет

- A Practical Total Synthesis of CocaineДокумент13 страницA Practical Total Synthesis of CocaineRodrigo Fernanda100% (4)

- Integrals - Integral Calculus - Math - Khan Academy PDFДокумент7 страницIntegrals - Integral Calculus - Math - Khan Academy PDFroberteleeroyОценок пока нет

- RWC 123 Manoj Prabhakar KaiwartДокумент13 страницRWC 123 Manoj Prabhakar KaiwartManoj Prabhakar KaiwartОценок пока нет

- Machine Fault Detection Using Vibration Signal Peak DetectorДокумент31 страницаMachine Fault Detection Using Vibration Signal Peak Detectordavison coyОценок пока нет

- JPSP - 2022 - 698Документ10 страницJPSP - 2022 - 698hifeztobgglОценок пока нет

- Unit 6 - EarthingДокумент26 страницUnit 6 - Earthinggautam100% (1)

- Introducing Small Basic-1 PDFДокумент69 страницIntroducing Small Basic-1 PDFnilaОценок пока нет

- 7.GSM ChannelsДокумент24 страницы7.GSM Channelsmanthasaikarthik100% (1)

- RCC-DI-AC PipeДокумент10 страницRCC-DI-AC PipeNaveen NagisettiОценок пока нет

- Gas Welding Equipment PowerpointДокумент12 страницGas Welding Equipment PowerpointChristian RexОценок пока нет

- Analiza Procesa Ocenjivanja Na Časovima Matematike - BaucalДокумент22 страницыAnaliza Procesa Ocenjivanja Na Časovima Matematike - BaucalНевенка ЈовановићОценок пока нет

- Petrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01Документ61 страницаPetrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01luciandu100% (1)

- Glpi Developer DocumentationДокумент112 страницGlpi Developer Documentationvictorlage7Оценок пока нет

- EC205 Mathematics For Economics and Business: The Straight Line and Applications IIДокумент3 страницыEC205 Mathematics For Economics and Business: The Straight Line and Applications IIpereОценок пока нет

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersДокумент4 страницы144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarОценок пока нет

- Module 1 Engineering ScienceДокумент38 страницModule 1 Engineering ScienceLogan JesseОценок пока нет

- Soiling Rates of PV Modules vs. Thermopile PyranometersДокумент3 страницыSoiling Rates of PV Modules vs. Thermopile PyranometersAbdul Mohid SheikhОценок пока нет

- Betriebsanleitung SM-RI-X - Q-75 Rev2Документ65 страницBetriebsanleitung SM-RI-X - Q-75 Rev2ABDULSALAMОценок пока нет

- 6545 Us35000Документ4 страницы6545 Us35000Rafael BarrosОценок пока нет

- HST TrainingДокумент11 страницHST TrainingRamesh BabuОценок пока нет

- DLT Strand Jack Systems - 2.0 - 600 PDFДокумент24 страницыDLT Strand Jack Systems - 2.0 - 600 PDFganda liftindoОценок пока нет

- Day 3 Polygons Lesson PlanДокумент6 страницDay 3 Polygons Lesson PlanBA RTОценок пока нет

- AWK - WikipediaДокумент1 страницаAWK - WikipediachassisdОценок пока нет

- HV Filter Carts 1Документ2 страницыHV Filter Carts 1paulpopОценок пока нет