Академический Документы

Профессиональный Документы

Культура Документы

En 88

Загружено:

Ana-Maria DincaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

En 88

Загружено:

Ana-Maria DincaАвторское право:

Доступные форматы

88

EN

E u r o p e a n

ISSN 1681-2123

A g e n c y

f o r

S a f e t y

a n d

H e a l t h

a t

W o r k

Safe maintenance Safe workers

Definition

Maintenance of equipment, plant, buildings or means of transport includes technical, administrative and managerial actions intended to keep it in, or restore it to, a state in which it can perform the required function1, protecting it from failure or decline. Maintenance activities include: inspection testing measurement replacement adjustment repair fault detection replacement of parts servicing

OSH outcomes of maintenance

Whether the task is small or big, it can have a serious impact on the safety and health, not only of the workers performing it, but also on others, as shown in the following examples: An accident/injury may occur during the maintenance process workers performing maintenance on a machine can be injured if the machine is accidentally switched on, they may be exposed to radiation or dangerous substances, be hit by a moving part of the machine or be at risk of developing an MSD. Poor quality maintenance can cause safety problems using the wrong parts for replacement or repair may result in serious accidents and injuries to workers as well as damage the equipment. Lack of maintenance may not only shorten the lifespan of equipment or buildings, but also cause accidents for example, unrepaired damage to the oor of a warehouse may cause a forklift accident, injuring the driver, those around and also damaging the goods being moved.

A very common activity exposing workers to various hazards

Maintenance is carried out in every workplace and in all industry sectors. It is included in the everyday duties of most workers, not just maintenance technicians and engineers. Workers involved in maintenance activities may be at risk of developing: musculoskeletal disorders (MSDs), when performing tasks involving bending and awkward postures, occasionally in dicult environmental conditions (e.g. cold); respiratory problems related to exposure to asbestos while maintaining old buildings or industrial installations; skin and respiratory diseases due to contact with dangerous substances greases, solvents, corrosives and dusts, including carcinogenic wood dusts; asphyxiation in conned spaces; diseases resulting from exposure to biological hazards hepatitis A, legionella. They also face accident risks of many types, including falls and being hit by a piece of machinery. Maintenance activities range from very minor, such as replacement of a light bulb or the toner in a printer, to major, such as periodic inspection of a power plant.

(1) Association Franaise de Normalisation. Terminologie de la maintenance. Norme NF-EN 13306. X 60-319, AFNOR, Saint-Denis La Plaine, Juin 2001.

Five basic rules for safe maintenance

Maintenance is a process that starts before the task itself begins, and nishes when the work has been checked, signed o and the task documentation has been completed. Participation of workers and/or their representatives in all stages and aspects of this process increases not only the safety of the process, but also the quality of work. The ve steps to safe maintenance are further explained hereunder.

HEALTHY WORKPLACES

GOOD FOR YOU. GOOD FOR BUSINESS.

http://hw.osha.europa.eu

FACTS 88 E u r o p e a n

Planning of maintenance The employer must conduct a risk assessment for the activity, and involve workers in this process. The following points have to be considered: The scope of the task: what needs to be done, how much time is needed for the task, how other workers and activities will be aected at the workplace; The identication of the hazards: for example electricity, exposure to dangerous substances, presence of dust/ asbestos in the air, conned space, moving parts of machinery, falling from or through something, heavy objects to be moved, parts dicult to reach or to access; What is needed for the activity: skills and number of workers doing the job, who will be involved, what the roles of individual persons are (responsibilities for contacts with the workers of the contractor or host employer, managing the tasks, who to report possible problems to), tools that have to be used, personal protective equipment (PPE) and other measures to protect workers (e.g. scaolding, monitoring equipment) that may be needed; Safe access to the work zone, and means of (quick) escape; The training/information that has to be provided for workers involved in the task, as well as those working around them, about the task (to ensure competence of workers and their safety), the chain of command and any procedures that will be used during the activity, including the reporting of problems. This is especially important if the maintenance is done by subcontractors. Workers should be involved in the planning stage they can identify hazards and the most ecient ways of dealing with them. The risk assessment ndings and outcomes of the planning stage should be communicated to the workers participating in the maintenance task and also to others who may be aected. Involving the workers, including subcontractors, in the training and familiarising them with the established procedures are very important elements in ensuring their safety. Working in a safe environment The procedures developed at the planning stage in risk assessment have to be put into action. For example, the power supply to the equipment worked on should be switched o and the agreed on lock-o system used. The warning card with the date and time of lock-o as well as the name of the person authorised to remove the lock should be attached. This way, the safety of the worker performing maintenance on the machine will not be jeopardised by anyone inadvertently starting up the machine, who could also be aected, if, for instance, the machine is not in safe operating condition (e.g. if the safeguards have been removed). Workers should check that there is a safe way to enter and leave the work zone, in accordance with the work plan.

Use the appropriate equipment Workers performing maintenance tasks should have the appropriate tools and equipment, which may be dierent from those normally used. They may be working in areas that are not normal workstations and be exposed to many hazards. Therefore, they must also have appropriate PPE. For example, workers cleaning or replacing lters on extraction ventilation may be exposed to concentrations of dust much higher than normal for that workplace. Access to these lters, frequently located in the roof area, has to be made safe as well. The tools needed for the job and PPE identied in the planning and in risk assessment have to be available (together with instructions on how to use them, if required) and used. Safe work practices developed in the planning stage have to be followed The work plan should be followed even when there is time pressure: shortcuts could be very costly and may lead to accidents, injuries, or damage to property. It may be necessary to notify supervisors and/or consult with other specialists should anything unexpected happen. It is very important to remember that exceeding the scope of ones own skills and competence may result in a very serious accident. The work has to be checked To ensure that the task has been completed, the item maintained is in a safe condition, and all waste material generated has been cleaned away. When all is checked and declared safe, then the task can be signed o, the locks can be removed, supervisors and other workers notied. The nal step is to complete a report for the management, describing the work done, including comments on diculties encountered and recommendations for improvement. Ideally, this should also be discussed at a sta meeting where the workers involved in the process, as well as those working around them, can comment on the activity and come up with suitable suggestions to improve the process. Maintenance activities can put workers at risk, but not carrying out maintenance may put more workers at risk. Please remember: when you are performing maintenance your health and safety as well as your colleagues depend on the quality of your work.

A g e n c y f o r S a f e t y a n d H e a l t h a t W o r k

Further information

This factsheet has been produced to support the European 2010/11 Campaign on Safe Maintenance. Other factsheets in the series and further information on this topic is available at http://osha.europa.eu/en/topics/maintenance This resource is being continually developed and updated.

TE-AE-09-088-EN-C

European Agency for Safety and Health at Work Gran Va, 33, E-48009 Bilbao, SPAIN Tel. +34 944794360 Fax +34 944794383 E-mail: information@osha.europa.eu

European Agency for Safety and Health at Work. Reproduction is authorised provided the source is acknowledged. Printed in Belgium, 2009

http://osha.europa.eu

Вам также может понравиться

- Safe Maintenance OperationsДокумент61 страницаSafe Maintenance OperationsMohamed Fathy Tash100% (1)

- Safety in MaintenanceДокумент5 страницSafety in MaintenanceKavindra MishraОценок пока нет

- Orientation Maintenance EnglishДокумент4 страницыOrientation Maintenance Englishanaghp123456780Оценок пока нет

- Safety in Chemical Process PlantsДокумент5 страницSafety in Chemical Process PlantsSrinivasan .MОценок пока нет

- Maintenance Safety L3 Pre Ori 1.2Документ14 страницMaintenance Safety L3 Pre Ori 1.2PROMISE JULIUSОценок пока нет

- Machine Safety GuidelinesДокумент21 страницаMachine Safety GuidelinesPampanagouda YadavОценок пока нет

- Porter Abs PDFДокумент6 страницPorter Abs PDFSANJEEV KUMARОценок пока нет

- IntroductionДокумент8 страницIntroductionArokiaraj AmalrajОценок пока нет

- PSM (Assignment 3)Документ6 страницPSM (Assignment 3)Glacier RamkissoonОценок пока нет

- English EseiДокумент12 страницEnglish EseiAndrae TurnerОценок пока нет

- Plumbing BookДокумент24 страницыPlumbing BookbendeniОценок пока нет

- MT QB Unit 6Документ7 страницMT QB Unit 6Aditya BishtОценок пока нет

- Safety Related QuestionsДокумент5 страницSafety Related QuestionsShivaniОценок пока нет

- Safety Assignment Ver.2Документ18 страницSafety Assignment Ver.2Lik ChanОценок пока нет

- Process Plant Safety Unit IiДокумент13 страницProcess Plant Safety Unit IiShivaniОценок пока нет

- Principles of Prevention and ControlДокумент6 страницPrinciples of Prevention and ControlArcher ArtilleryОценок пока нет

- Puwer 1998Документ9 страницPuwer 1998Jogi Oscar SinagaОценок пока нет

- Safe Design and Operation of PlantsДокумент7 страницSafe Design and Operation of PlantsAlfie Delos Reyes100% (1)

- JOB CERT 2 Information Sheet Plumbing 2024Документ66 страницJOB CERT 2 Information Sheet Plumbing 2024wallendelroyОценок пока нет

- ECR IncДокумент2 страницыECR IncecrincorporatedОценок пока нет

- Why Machinery Safety ImportantДокумент3 страницыWhy Machinery Safety ImportantmechjogeswardasОценок пока нет

- EVT (Sop)Документ21 страницаEVT (Sop)Farvin FleetОценок пока нет

- NVQ-3-Beauty-Helath-and-Safety 3Документ6 страницNVQ-3-Beauty-Helath-and-Safety 3Mehnaz Babar100% (1)

- Eal Qpeo2001 AДокумент5 страницEal Qpeo2001 A4612011Оценок пока нет

- Chapter 6 - Housekeeping in PetrochemicalДокумент25 страницChapter 6 - Housekeeping in Petrochemicalchristina jeitolОценок пока нет

- Risks To Maintenance During Plant ShutdownДокумент23 страницыRisks To Maintenance During Plant ShutdownpiolinwallsОценок пока нет

- Inspecting Technical Quality of WorkДокумент3 страницыInspecting Technical Quality of Workkhurvy keishaОценок пока нет

- 20220426+Romann+Logistics+Hazard Observation Procedure-V1Документ14 страниц20220426+Romann+Logistics+Hazard Observation Procedure-V1ArunОценок пока нет

- Construction Safety: Working at HeightsДокумент6 страницConstruction Safety: Working at Heightsakb2853Оценок пока нет

- Tahmina-Zebin-General Risk Assessment FormДокумент6 страницTahmina-Zebin-General Risk Assessment FormTahmina L. ZebinОценок пока нет

- Wind Energy ChecklistДокумент23 страницыWind Energy ChecklistBalaji_Rajaman_2280Оценок пока нет

- Lecture 3 - The Building EnvironmentДокумент41 страницаLecture 3 - The Building EnvironmentYounq KemoОценок пока нет

- Cep Industrial ZohaibДокумент3 страницыCep Industrial ZohaibQamar zmanОценок пока нет

- Emergency Plans Fact SheetДокумент6 страницEmergency Plans Fact SheetLalit TomarОценок пока нет

- 2850 L2u201 Handout 11Документ3 страницы2850 L2u201 Handout 11OwenОценок пока нет

- Permit To WorkДокумент11 страницPermit To WorkJagan RjОценок пока нет

- Nebosh Questions & Answers-GC2 New New NewДокумент94 страницыNebosh Questions & Answers-GC2 New New NewMohsin Nisar80% (15)

- Control Measures For OSH Hazards-Labordo, M.E.-4GNДокумент13 страницControl Measures For OSH Hazards-Labordo, M.E.-4GNeric labordoОценок пока нет

- Hazards, Risk and Risk Control in Tractor OperationsДокумент61 страницаHazards, Risk and Risk Control in Tractor OperationsJeline LunaОценок пока нет

- Employee Welfare ServiceДокумент6 страницEmployee Welfare ServicekrishnaОценок пока нет

- Emergency Plans Fact SheetДокумент6 страницEmergency Plans Fact SheetJack fearnleyОценок пока нет

- 1 - Dis Short NoteДокумент26 страниц1 - Dis Short NoteUseless MeОценок пока нет

- Mis 022Документ36 страницMis 022Shahab AlamОценок пока нет

- Information Sheet 4.1-3 Maintain Safe Personal Presentation StandardsДокумент6 страницInformation Sheet 4.1-3 Maintain Safe Personal Presentation StandardsMyrene Sarmiento100% (1)

- Employee HealthДокумент22 страницыEmployee HealthLogaNathanОценок пока нет

- Preventative-Maintenance Final PDFДокумент4 страницыPreventative-Maintenance Final PDFikyusan86Оценок пока нет

- Chapter Nine: Environment, Health and Safety (Ehs)Документ5 страницChapter Nine: Environment, Health and Safety (Ehs)Ejay AbanteОценок пока нет

- Process Safety ManagementДокумент19 страницProcess Safety ManagementKladees WorldОценок пока нет

- Lifting Equipment at Work: A Brief GuideДокумент36 страницLifting Equipment at Work: A Brief GuideDrishti MehtaОценок пока нет

- SUBTOPIC 1 Basic Safety Procedures in High Risk Activities and IndustriesДокумент54 страницыSUBTOPIC 1 Basic Safety Procedures in High Risk Activities and Industriesian jasper nathan100% (1)

- Engineering Health and SafetyДокумент24 страницыEngineering Health and SafetyKobby BrineОценок пока нет

- NASC - SG40 20 Scaffolding Yard OperationsДокумент20 страницNASC - SG40 20 Scaffolding Yard OperationsMIKE Harwood100% (2)

- 1510 1 - Job Safety Checklist For Field Operations r2Документ7 страниц1510 1 - Job Safety Checklist For Field Operations r2RodssRivsОценок пока нет

- Lifting Equipment at Work: A Brief GuideДокумент8 страницLifting Equipment at Work: A Brief GuideEka KurniawanОценок пока нет

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingДокумент29 страницDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- E4 Operation ProceduresДокумент14 страницE4 Operation ProceduresEl Sayed Saad ShehataОценок пока нет

- Guidelines For TheДокумент23 страницыGuidelines For TheArief FarhanОценок пока нет

- Project 1Документ3 страницыProject 1anthony_ragelОценок пока нет

- HIRAC Work at Height FedUniДокумент7 страницHIRAC Work at Height FedUnitemter100% (1)

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsОт EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsОценок пока нет

- Personal Protective EquipmentДокумент10 страницPersonal Protective EquipmentXozanОценок пока нет

- Electrical Safety AuditДокумент19 страницElectrical Safety AuditXozan100% (2)

- FIEF Recommended FA Kit Contents 162295Документ2 страницыFIEF Recommended FA Kit Contents 162295XozanОценок пока нет

- Siemens XДокумент13 страницSiemens XXozanОценок пока нет

- Title Carry Out In-Service Visual Inspections On Substation Equipment For Safe Operation Level 3 Credits 4Документ5 страницTitle Carry Out In-Service Visual Inspections On Substation Equipment For Safe Operation Level 3 Credits 4XozanОценок пока нет

- Lab Hazard Assessment Tool: Applicable PPE Specific Type (Example) Characteristics ApplicationsДокумент4 страницыLab Hazard Assessment Tool: Applicable PPE Specific Type (Example) Characteristics ApplicationsXozanОценок пока нет

- Project NavigatorДокумент9 страницProject NavigatorXozanОценок пока нет

- 2011 Dam Inspection ChecklistДокумент2 страницы2011 Dam Inspection ChecklistXozanОценок пока нет

- Step 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?Документ6 страницStep 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?XozanОценок пока нет

- OHS Plan 2012 University WideДокумент3 страницыOHS Plan 2012 University WideXozanОценок пока нет

- Deficiency Checklist: Is There Any Apparent... YES NO If Yes Then..Документ1 страницаDeficiency Checklist: Is There Any Apparent... YES NO If Yes Then..XozanОценок пока нет

- Personal Protective Equipment: For General IndustryДокумент28 страницPersonal Protective Equipment: For General IndustryXozanОценок пока нет

- Chemical Risk Assessment Worksheet: Printer Toner - MagentaДокумент3 страницыChemical Risk Assessment Worksheet: Printer Toner - MagentaXozanОценок пока нет

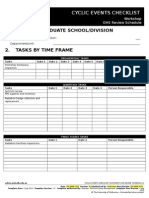

- Cyclic Events Biological Laboratory TemplateДокумент3 страницыCyclic Events Biological Laboratory TemplateXozanОценок пока нет

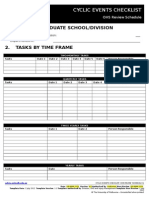

- Cyclic Events Checklist: 1. Faculty/Graduate School/DivisionДокумент3 страницыCyclic Events Checklist: 1. Faculty/Graduate School/DivisionXozanОценок пока нет

- Cyclic Events Checklist: 1. Faculty/Graduate School/DivisionДокумент2 страницыCyclic Events Checklist: 1. Faculty/Graduate School/DivisionXozanОценок пока нет