Академический Документы

Профессиональный Документы

Культура Документы

Knauf D131 System

Загружено:

Amin ChhipaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Knauf D131 System

Загружено:

Amin ChhipaАвторское право:

Доступные форматы

D131

Drywall and Floor Systems

2007-04

D131 Knauf Free-spanning Ceilings

D131 Knauf Free-spanning Ceilings with metal substructure CW/UW

New

Free-spanning Ceiling with T connection and L connection

D131 Knauf Free-spanning Ceilings

Knauf Boards / Fastening of Cladding / Multi-layer Cladding

Knauf Premium Drywalling

Installation cavity Free available installation cavity without interfering suspenders Optimum sound protection through total decoupling from basic ceiling or existing ceiling

Comparison of Knauf Boards

Board type General properties

Easy installation Few control joints

Building physics

Fire protection Sound insulation Stability / strength

Sophisticated application

Surface quality

Diamant (Hard gypsum board) Solid Board Knauf Fire-resistant Board Knauf Wallboard

GKFI *) GKF / GKFI *) GKF / GKFI *) GKB / GKBI *)

*) Impregnated boards GKBI and GKFI are suitable for humid rooms suitable more suitable most suitable All dimensions in mm Centers of fasteners max. 170 mm Cut edge joint 170

Fastening of cladding / covering strips on substructure with Knauf Screws

Knauf Boards

Thickness in mm 12.5

Metal substructure

(Penetration � 10 mm; metal thickness s � 0.7 mm) Diamant Screws Drywall Screws TN 3.5 x 25 mm HGP 3.9 x 23 mm

Alternating fastening

18 to 25

TN 3.5 x 35 mm

2x 12.5

TN 3.5 x 25 mm + TN 3.5 x 35 mm

HGP 3.9 x 23 mm + HGP 3.9 x 35 mm

170 340

Knauf CW double profile

Covering strip

w � 120 mm Thickness in mm 25

Metal substructure

(Penetration � 10 mm; metal thickness s � 0.7 mm) Drywall Screws TN 3.5 x 35 mm

Alternating fastening

250

Centers of fasteners max. 250 mm

500

Knauf Drywall Screw TN 3.5x35 All dimensions in mm

Multi-layer cladding

In case of multi layer cladding, apply layers with staggered joints according to application scheme. Press boards of each layer firmly on to the substructure and screw attach each layer separately. For fastening of first layer, spacing of screws can be increased up to max. 500 mm if second layer is applied immediately afterwards (within one working day). In case of multi-layer cladding, a filling of joints of first layer without further finishing is sufficient.

Board width 1250 1250

1st board layer 1250 1250 2nd board layer

2 2

Copyright by Knauf Gips KG D131-S02 Stand 04.07

Board width

D131 Knauf Free-spanning Ceilings

Fire Protection from Below / from Below and from Above

Subceilings that are fire protection rated independently

Requirement to the basic ceiling for fire protection: From below

No fire protection requirements to basic ceiling / roof construction

Fire resistance class for fire exposure from below from above

Knauf Boards

Ceiling Insulation layer profile required for

fire protection

Knauf Premium Drywalling

Min.

thickness Soild Board Knauf GKF Diamant

Max. axial spacing

Min. Min. thickness density

From above (plenum)

The basic ceiling should have the same fire protection rate as the subceiling

b

mm mm mm kg/m

D131 Knauf Free-spanning Ceiling

Independently from below

18 2x 12.5

625

System "Multi-level Ceiling" is possible (see page 16) Mineral wool G 40 -

500

without

or

F30 25 2x 12.5

625

insulation min. B2

500

System "Multi-level Ceiling" is possible (see page 16)

D131 Knauf Free-spanning Ceiling

Type A

with insulation layer

Independently from below and from above

F30

F30

18

625

Mineral wool S 40 40 oder 60 30

Covering strip: GKF 25 mm

Type B

with upper board layer GKF 12.5 mm without

F30

F30

18

625

or

insulation min. B2

Covering strip: GKF 25 mm Flanking components should have a fire resistance class of � F30. Easy handling The handy dimensions of the Solid Board makes transport and installation easy. Sound insulation: Particularly good sound insulation with Diamant Boards.

Mineral wool insulation layer acc. to DIN EN 13162, section 3.1.1 G Building material class A S Building material class A

e.g. Knauf Insulation Melting point � 1000 C acc. to DIN 4102-17

Proof

ABP P-3964/2172

Note:

Free-spanning Fireboard Ceilings F90 Independently from below F90 Independently from below and from above Knauf Technical Data Sheet K219

D131 Knauf Free-spanning Ceilings

Anchoring

Anchoring of the supporting UW perimeter runners

Anchoring on Anchor 2x Knauf All Purpose Screw FN 4.3x35

Metal stud partitions (Anchoring in metal studs) for cladding thickness up to 20 mm

Maximum spacing of anchors

2x Knauf All Purpose Screw FN 4.3x65 Knauf Ceiling Steel Dowel

625 mm

Reinforced concrete walls

acc. to permission ETA - 07/0049

Knauf Nailable Plug L 8/80

Substantial masonry without cavities or light concrete (density � 1000 kg/m) Other materials

Knauf Nailable Plug L 8/80 Suitable anchors

minumum shear load capacity 0.35 kN per anchor

300 mm

For room widths � 2.25 m the number of anchors can be reduced by 50 %, i.e. the spacing of the anchors can be doubled.

Connections to partitions

Knauf single or double CW profiles Screw connection of Knauf CW double profiles � 750 mm

m 5m 2 6

30 mm

Knauf UW runner Connect Knauf CW profiles as single or double profiles (per flange) with UW runner by riveting, crimping or screwing with Knauf Metal Screws LB 3.5x9.5 mm.

Screw Knauf CW profiles at web with Metal Screw LB 3.5x9.5 mm at a spacing of � 750 mm

Knauf CW double profiles with covering strip

Covering strip GKF 25 mm 120 mm wide

m 5m 62

30 mm

Knauf UW runner Knauf CW double profile

D131 Knauf Free-spanning Ceilings

Without Fire Protection

Cladding Knauf GKB

12.5 mm

or

2x 12.5 mm

or

A A

18 mm

No jointing is allowed for free-spanning ceiling profiles Higher room widths with mid-span support are available on request

b C

Max. room width 5.5 m

Max. room width (m)

Knauf CW Profile

Knauf CW single profile

as ceiling profile

Knauf CW double profile

as ceiling profile

UW perimeter runner as wall connection

Maximum room width

with max. axial spacing of ceiling profiles

Maximum room width

with max. axial spacing of ceiling profiles b

b 500 mm

Metal thickness 0.6 mm Cladding thickness in mm + extra 12.5 2x 12.5 load 1)

+ extra load 1)

500 mm

Cladding thickness in mm + extra 12.5 2x 12.5 load 1)

+ extra load 1)

625 mm

18

+ extra load 1)

Metal thickness 0.6 mm

CW 50 CW 75 CW 100 CW 125 CW 150

2.5 3.25 3.75 4.25 4.75

2.5 3 3.5 4 4.5

2.25 2.75 3.25 3.75 4.25

2 2.5 3 3.5 4

3 3.75 4.25 5 5.5

2.75 3.5 4 4.5 5

2.5 3.25 3.75 4.25 4.75

2.25 3 3.5 4 4.5

2.75 3.25 4 4.5 5

2.25 3 3.5 4 4.5

UW 50 UW 75 UW 100 UW 125 UW 150

1) Including extra loads ( 0.05 kN/m = 5 kg/m ) for insulation layers required for sound protection

Details, scale 1:5 D131-A1 Construct. connection to partition D131-C1 Cut edge joint single profile

All dimensions in mm

D131-C2 Cut edge joint double profile

Knauf CW double profile, as ceiling profile Metal Screw LB 3.5x9.5 centers � 750 mm

Knauf CW profile UW runner Fastening acc. to page 4

Free-spanning Knauf CW single profile, connect with UW runner by riveting, crimping or e. g. with Metal Screws LB 3.5x9.5

Free-spanning Knauf CW Knauf CW double profile, connect each flange single profile as ceiling profile with UW runner by riveting, crimping or UW runner e. g. with Metal Screws LB 3.5x9.5

� 62,5

Knauf GKB 2x 12.5 mm

� 75

Knauf GKB 12.5 mm

Knauf GKB 18 mm

b � 500

b � 500

b � 500

b � 625

b � 625

� 68

D131 Knauf Free-spanning Ceilings

Fire Resistance F30

Cladding Knauf GKF

18 mm

Mineral wool insulation layer acc. to DIN EN 13162, section 3.1.1 Building material class A Thickness � 40 mm

Independently from Below

25 / 2x 12.5 mm

No insulation layer required. Insulation of minimum building material class B2 is allowed.

A A

b C D D

No jointing is allowed for free-spanning ceiling profiles Higher room widths with mid-span support are available on request

Max. room width 4.5 m

Max. room width (m)

Knauf CW double profile as ceiling profile Metal thickness 0.6 mm Max. axial spacing ceiling profile Cladding

Max. room width

with additional ceiling level acc. to page 16 (max. 0.15 kN/m)

UW perimeter runner as wall connection Metal thickness 0.6 mm

Min. thickness

2x CW 50 2x CW 75 2x CW 100 2x CW 125 2x CW 150

625 mm 500 mm

18 / 25 mm 2x 12.5 mm

2.25 3 3.5 4 4.5

2 2.75 3.25 3.5 4

UW 50 UW 75 UW 100 UW 125 UW 150

Including extra loads ( 0.05 kN/m = 5 kg/m ) for insulation layers required for fire protection and/or sound insulation.

Details, scale 1:5 D131vu-D1 Supporting connection to partition

Fix UW perimeter runner to metal studs of partition with 2 Knauf All Purpose Screws FN 4.3x35, acc. to page 4

All dimensions in mm

D131vu-B1 Longitudinal edge joint

Metal Screw LB 3.5x9,5 Knauf CW double profile as ceiling profile

Knauf CW double profile as ceiling profile

Solid Board 25 mm Max. room width

Solid Board 25 mm

D131vu-A1 Constructional connection to partition

Knauf CW Profile UW perimeter runner, anchoring acc. to page 4

D131vu-C1 Cut edge joint

Free-spanning Knauf CW single profile, connect with UW runner by riveting, crimping or e. g. with Metals Screws LB 3.5x9.5 UW perimeter runner Knauf CW double profile as ceiling profile

� 75

Knauf GKF 2x 12.5 mm b � 500

Mineral wool, building material class A, min. thickness 40 mm, (required for fire protection)

Knauf GKF 18 mm

� 625

� 625

� 68

� 75

D131 Knauf Free-spanning Ceilings

Fire Resistance F30

Cladding Knauf GKF

18 mm 25 mm (covering strip � 120 mm wide)

Mineral wool insulation layer acc. to DIN EN 13162, section 3.1.1

Independently from Below and from Above - Type A

Type A

A A

S Building material class A,

melting point � 1000 C, acc. to DIN 4102-17

b C D D

Thickness: � 60 mm; density: � 30 kg/m or Thickness: � 40 mm; density: � 40 kg/m No jointing is allowed for free-spanning ceiling profiles Higher room widths with mid-span support are available on request

Max. room width 4 m

Max. room width (m)

Knauf CW double profile as ceiling profile Metal thickness 0.6 mm Max. axial spacing ceiling profile Cladding

Max. room width

with additional ceiling level acc. to page 16 (max. 0.15 kN/m)

UW perimeter runner as wall connection Metal thickness 0.6 mm

Min. thickness

2x CW 50 2x CW 75 2x CW 100 2x CW 125

625 mm

18 mm

2.25 3 3.5 4

2 2.75 3.25 3.5

UW 75 UW 100 UW 125 UW 150

Including extra loads ( 0.05 kN/m = 5 kg/m ) for insulation layers required for fire protection and/or sound insulation.

Details, scale 1:5 D131vuvo-D1 Supporting connection to partition

Fix UW perimeter runner to metal studs of partition with 2 Knauf All Purpose Screws FN 4.3x35, acc. to page 4

All dimensions in mm

D131vuvo-B1 Longitudinal edge joint

Covering strip GKF 25 mm 120 mm wide Knauf CW double profile as ceiling profile

Knauf CW double profile as ceiling profile

Knauf GKF 18 mm Max. room width

D131vuvo-A1 Constructional connection to partition

Covering strip GKF 25 mm 60 mm wide Knauf CW Profile

D131vuvo-C1 Cut edge joint

Covering strip GKF 25 mm 120 mm wide 10 120 100 10 UW perimeter runner

Mineral wool, S 60 mm; 30 kg/m

or

40 mm; 40 kg/m

Knauf GKF 18 mm

� 625

� 625

� 625

� 93

� 93

D131 Knauf Free-spanning Ceilings

Fire Resistance F30

Cladding Knauf GKF

18 mm 25 mm (covering strip � 120 mm wide)

Covering upper board layer Knauf GKF 12.5 mm applied loose with tight joints Covering of Knauf CW double profiles incl. covering strips on the entire ceiling area

Independently from Below and from Above - Type A

Type B

A A

b C

No jointing is allowed for free-spanning ceiling profiles Higher room widths with mid-span support are available on request

Max. room width 4 m

Max. room width (m)

Knauf CW double profile as ceiling profile Max. axial spacing ceiling profile Cladding

Max. room width

with additional ceiling level acc. to page 16 (max. 0.15 kN/m)

UW perimeter runner as wall connection

b

Metal thickness 0.6 mm Min. thickness

+ extra load 1)

+ extra load 1) Metal thickness 0.6 mm

2x CW 50 2x CW 75 2x CW 100 2x CW 125

625 mm

18 mm

2.25 3 3.5 4

2.25 2.75 3.25 3.75

2 2.75 3.25 3.5

2 2.5 3 3.25

UW 75 UW 100 UW 125 UW 150

1) Including extra loads ( 0.05 kN/m = 5 kg/m ) for insulation layers required for fire protection and/or sound insulation.

Details, scale 1:5 D131vuvo-D2 Supporting connection to partition

Fix UW perimeter runner to metal studs of partition with 2 Knauf All Purpose Screws FN 4.3x35, acc. to page 4

All dimensions in mm

D131vuvo-B2 Longitudinal edge joint

Covering strip GKF 25 mm 120 mm wide Covering upper board layer with Knauf GKF 12.5 mm, applied loose with tight joints, on entire area

Knauf CW double profile as ceiling profile

Knauf GKF 18 mm Max. room width

Knauf CW double profile as ceiling profile

D131vuvo-A2 Constructional connection to partition

Covering strip GKF 25 mm 60 mm wide Knauf CW Profile

D131vuvo-C2 Cut edge joint

10 120 100 10 Knauf CW double profile as ceiling profile

Covering upper board layer with Knauf GKF 12.5 mm, applied loose with tight joints, on entire area Covering strip GKF 25 mm 120 mm wide UW perimeter runner

Knauf GKF 18 mm

� 625

� 625

� 625

� 105.5

� 105,5

D131 Knauf Free-spanning Ceilings

Profile Dimensions - Supporting Profiles for T and L Connections

Adjacent room Room width

* Use the respective table of the construction to

2 1 See pages 5 to 8

determine the maximum permissible room width

Without weight determination - Required profile dimensions of supporting Knauf UA Profiles 1

Ceiling of continuous room Max. Room width (m) * 2 2.5 3 3.5

Multi-level ceiling is not considered

Continuous room Room width

+ 2

for room widths up to 3.5 m

Adjacent room Max. Room width (m) * 2 2.5 3 3.5

Profile dimensions

2x UA 75 2x UA 100 2x UA 125 2x UA 150

Dead weight of ceiling

Weight of Knauf Boards (kg/m) Type Thickness

mm

The determination of the dead weight is the basis for the determination of the profile dimension of the supporting UA Profile

Weight

11.3 16.2 22.5 4.5 13 26

+ Weight of substructure (kg/m)

Knauf Profile

Knauf GKB / GKF

12.5 18

CW CW single profile double profile axial spacing axial spacing

500 mm 500 mm 625 mm

+ Possible extra load (kg/m)

e.g. insulation ....

Calculation example:

acc. to DIN 1055-1:2002-06 25 / 2x 12.5 900 kg/m *) 25 Covering strip

CW 50 CW 75 CW 100 CW 125 CW 150

1.5 1.75 2 2.25 2.5

3 3.5 4 4.5 5

2.4 2.8 3.2 3.6 4

Diamant

1040 kg/m *)

12.5 2x 12.5

*) Load assumption for dimensioning

Indep. from below and from above (Type A) Knauf GKF 18 mm 16.2 kg/m CW double profile 125 Axial spacing 625 mm 3.6 kg/m Covering strip 4.5 kg/m Insulation layer 60 mm, 30 kg/m 1.8 kg/m

Dead weight

26.1 kg/m

0.261 kN/m

The continouos room is decisive for weight determination

Load class

+ 2

� 0.30 kN/m

With weight determination - Required profile dimensions of supporting Knauf UA Profiles 1

Ceiling of continuous room Load class Max. room kN/m width (m) *

2.5

Adjacent room Max. room width (m) * 2.5 2

2x UA 50 2x UA 75 2x UA 75 2x UA 75 2x UA 75

3

2x UA 75

3.5

4

2x UA 100

4.5

2x UA 100 2x UA 125

5

2x UA 125 2x UA 150 2x UA 150 -

5.5

2x UA 125 2x UA 150 -

� 0.15

3.5 4.5 5.5 2.5 3.5 4.5 5.5 2.5

2x UA 100 2x UA 100 2x UA 125 2x UA 125 2x UA 100 2x UA 125 2x UA 150 2x UA 125 2x UA 150 2x UA 150 2x UA 125 2x UA 150 -

2x UA 150 2x UA 150 -

� 0.30

2x UA 100

2x UA 75 2x UA 100 2x UA 100 D131-S09

� 0.50 � 0.65

3.5 4.5 2.5 3.5

2x UA 100 2x UA 125 2x UA 125

Multi-level ceiling

2x UA 125

2x UA 150

9

9

Copyright by Knauf Gips KG

Stand 04.07

D131 Knauf Free-spanning Ceilings

Supporting Profiles for T Connection and L Connection

T connection

Adjacent room Room width

L connection

Top view - scheme drawings Adjacent room Room width

"Detail A"

Continuous room Room width

E E

Continuous room Room width

"Detail A"

E E

"Detail A" - direct anchoring of supporting Knauf UA Profiles 1 on wall

Top view Adjacent room Room periphery UW perimeter profile Metal stud partition Metal Traverse Knauf All Purpose Screw FN with washer Continuous room

Example: Metal stud partition

Connection Angle as installation aid, to be used for UA 100 and bigger, fastened on metal stud of partition Supporting profiles: Knauf UA Profile 2 Knauf UA Profile 1

UW-Randprofil Extension length of Knauf UA profile 1 ca. 650 mm *)

*) Extension length in case of reinforced concrete wall: UA 50: � 200 mm, UA 75-150: � 400 mm (with Knauf Ceiling Steel Dowel acc. to approval ETA - 07/0049) View Supporting Knauf UA Profile 1 , anchored on Metal Traverse with Knauf All Purpose Screws FN (see also table below) Metal Traverse Room periphery Supporting Knauf UA Profiles 1 + 2 , connected with attachment screws M8 at perimeter connection (UA 50: 2x M8, UA 75 to 150: 4x M8)

ca. 70

Room periphery Supporting Knauf UA Profiles 1 + 2 , connected alternating in slot rows with attachment screws M8 � 750 mm

Direct anchoring of supporting Knauf UA Profile 1

Anchoring substrate Anchor Knauf UA Profiles 50

Knauf UA Profiles 75-150 alternating in slot rows

Spacing of anchors

Distance to room periphery

First anchor

Thickness of

Metal stud partition with Metal Traverse Reinforced concrete wall Other substrate

4x Knauf All Purpose Screw 8x Knauf All Purpose Screw FN 4.3 x 35 (cladding thickness � 20 mm) / FN 4.3 x 65 with suitable washer, t = 2 mm, 30 mm 3x Knauf Ceiling Steel Dowel 6x Knauf Ceiling Steel Dowel with suitable washer, t = 2 mm, 30 mm

Suitable anchor, min. load capacity: � 1 kN � 2 kN

approx. 70 mm

50 mm + cladding of partition

of the adjacent room

50 to 80 mm

50 to 80 mm

Refer to instructions of anchor manufacturer

10

Note

For configuration / anchoring of UW Profiles and CW Profiles (ceiling profiles) see pages 12 and 13

D131 Knauf Free-spanning Ceilings

Supporting profile for L Connection

L Connection

Top view - scheme drawings Connection Angle Adjacent room Room width Connection angle, before bending 82.5 29.5 34 29.5 93 100 200 100

Example: Metal stud partition

All dimensions in mm

E

Continuous room Room width

"Detail B"

"Detail B" - Anchoring of supporting Knauf UA Profiles 1

Top view

+ 2

with 2x Connection Angles on wall

Room periphery

Supporting profiles: Knauf UA Profile 2 Knauf UA Profile 1

Supporting Knauf UA Profiles 1 + 2 , and Connection Angle, connected with attachment screws M8 (UA 50: 2x M8, UA 75 to 150: 4x M8) UW perimeter profile Metal Traverse

Room periphery

2x Connection Angle, anchored on Metal Traverse with Knauf All Purpose Screws FN (see also table below) Metal stud partition

Anchoring of supporting Knauf UA Profiles 1

Substrate / anchors / spacings

Metal stud partition with Metal Traverse

+ 2

with 2x Connection Angles on wall

Reinforced concrete wall

All dimensions in mm

UA 50: UA 75 to 150:

4x Knauf All Purpose Screw 8x Knauf All Purpose Screw FN 4.3 x 35 (cladding thickness � 20 mm) / FN 4.3 x 65

with suitable washer, t = 2 mm, 30 mm � 70 � 70

UA 50: UA 75 to 150:

4x Knauf Ceiling Steel Dowel 6x Knauf Ceiling Steel Dowel (acc. to approval ETA - 07/0049)

with suitable washer, t = 2 mm, 30 mm � 50 � 50 � 50

2x Connection Angle, bended

2x Connection Angle, bended

� 50 Other substrate Suitable anchor (Refer to instructions of manufacturer for spacings of anchors) Total min. load capacity � 1 kN UA 50: Total min. load capacity � 2 kN UA 75 to 150:

50

Note

For configuration / anchoring of UW Profiles and CW Profiles (ceiling profiles) see pages 12 and 13

11

D131 Knauf Free-spanning Ceilings

Supporting Profiles for T Connection and L Connection

"Detail A" - construction

Example: Metal stud partition - scheme drawings

"Detail B" - construction

Example: Metal stud partition - scheme drawings

Metal Traverse

Installation of Metal Traverse*) in metal stud partition for anchoring of supporting Knauf UA Profile 1

Metal Traverse

Installation of Metal Traverse*) in metal stud partition for anchoring of Connection Angle

Room periphery

Supporting profiles

2 Anchoring supporting Knauf UA Profile 1 on Metal Traverse with Knauf All Purpose Screws FN (see page 10) 1 Connect supporting Knauf UA Profiles 1 + 2 with attachment screws M8 alternating in slot rows at a spacing � 750 mm Additionally connect supporting profiles at perimeter connection with M8 screws (UA 50: 2x M8, UA 75 to 150: 4x M8)

Connection Angle

Anchor both bended Connection Angles on Metal Traverse with Knauf All Purpose Screws FN (see page 11) Place angle in UW perimeter runner of the adjacent room (Cut out upper flange in the area where the angle will be placed, if necessary)

Room periphery

UW Profiles

Interleave UW-Profil 3 with supporting Knauf UA Profile 1 , and connect them with Metal Screws LB 3.5x9.5 mm on the upper flange at a spacing of � 250 mm Connect UW perimeter runner 4 with UW Profile 3 with 2x Knauf All Purpose Screws FN 4.3x35 mm at web, at a Room periphery spacing of � 500 mm 3 2 4

Supporting profiles

Connect supporting Knauf UA Profiles 1 + 2 and Connection Angles with attachment screws M8 (UA 50: 2x M8, UA 75-150: 4x M8)

Knauf CW Profiles

Insert ceiling profiles of the continuous rooms into the UW perimeter runner (see page 4)

UW Profiles

For installation and anchoring of UW Profiles 3 + 4 see "Detail A"

Knauf CW Profiles

Room periphery

For installation of the ceiling profiles of the continuous room see "Detail A"

*) For installation of Metal Traverse see Technical Data Sheet W21 Knauf Sanitary Built-Ins

Fire protection: Notes

For configuration with fire protection see details on page 13.

Washers: (t = 2 mm, 30 mm)

12

Apply attachment screws M8 that are included in the Connection Angle kit with one washer on the side of the nut. Apply customary attachments screws M8 (strength class 8.8) with two washers (one on each side).

D131 Knauf Free-spanning Ceilings

Supporting Profiles for T Connection and L Connection

Details, scale 1:5 D131-E1

Supporting profile for T connection and L connection

Without fire protection � 250 mm

D131vu-E1

Supporting profile for T and L connection

F30 Independently from below � 250 mm

UW Profile 3 Metal Screw LB 3.5x9.5, spacing � 250 mm 2x FN 4.3x35, spacing � 500 mm UW perimeter runner 4

Supporting profiles Knauf UA Profile 1 Knauf UA Profile 2 Attachment screw M8,

UW Profile 3 Metal Screw LB 3.5x9.5, spacing � 250 mm 2x FN 4.3x35, spacing � 500 mm UW perimeter runner 4

Supporting profiles Knauf UA Profile 1 Knauf UA Profile 2

Cut out upper flange if necessary

Knauf CW double profile as ceiling profile Room periphery

Knauf CW double profile as ceiling profile Connection Angle, as installation aid, for UA 100 and bigger

Knauf CW double profile as ceiling profile

� 20 mm � 25 mm � 25 mm

Knauf CW double profile as ceiling profile

Continuous room Adjacent room

D131vuvo-E1 Supporting profile for T connection and L connection

� 250 mm

D131vuvo-E2 Supporting profile for T and L connection

F30 Independently from below and from above - Type 2 � 250 mm

� 10 mm

Supporting profiles Knauf UA Profile 1 Knauf UA Profile 2 Mineral wool S in supporting profiles

Supporting profiles Knauf UA Profile 1 Knauf UA Profile 2 Mineral wool S in supporting profiles 3 runner 4

� 20 mm � 25 mm � 25 mm Room periphery

Knauf CW double profiles as ceiling profiles

spacing � 500 mm

� 20 mm � 25 mm � 25 mm

Knauf CW double profiles as ceiling profiles Mineral wool S up to CW double profiles

Room periphery Continuous room Adjacent room

Mineral wool insulation layer

acc. to DIN EN 13162, section 3.1.1

Note:

Refer to respective configuration of the Free-spanning Ceiling: (see pages 5 to 8)

S Building material class A,

melting point � 1000 C, density � 30 kg/m acc. to DIN 4102-17

13

D131 Knauf Free-spanning Ceilings

Ceiling Plan - Shadow Gap, Movement Joint, Ceiling Bulkhead

Ceiling plan

D1 D1

B2 / B4 Knauf CW double profile

B1 B1 B2 / B4

For details of lighting and access panel see page 15

Details, scale 1:5 Examples: Fire resistance F30

Lighting

A1

A1

C3

C3

C1

C1

C2 / C4

Access panel

C2 / C4

A2

A2

Independently from below and from above

Type A

All dimensions in mm

D131-SO-A1 Connection to wall with shadow gap

Board strip GKF 25 mm Drywall Screw TN 3.5x35

D131-SO-D1 Connection to wall with shadow gap

Board strip GKF 25 mm Knauf Nailable Plug L8/80

� 20

�5

Knauf CW Profile UW perimeter profile Edge Trim, if necessary

e. g. Knauf Fugenfller Leicht �5 � 20

D131-SO-C3 Movement joint

D131-SO-A2 Ceiling bulkhead

Knauf All Purpose Screw FN 4.3x35, fastened to metal stud of ceiling bulkhead Knauf CW Profile Covering strip GKF 25 mm

Glued with Knauf Fugenfller Leicht on one side

Board strip GKF 18 mm

Ceiling bulkhead

Edge Trim, if necessary � 25 a � 25 a � 100 � 100

Knauf GKF 18 mm

Ceiling bulkhead

Fire resistance � F30 a � 20 mm

Application acc. to Technical Data Sheet D16 Knauf Ceiling Built-Ins

14

D131 Knauf Free-spanning Ceilings

Lighting, Access Panel

Fire protection encasement for built-in lighting D131-SO-C1 Lateral section of built-in lighting

Axial spacing of ceiling profiles � 625 mm 25 Encasement � 400 x 1000 mm made of Knauf GKF 25 mm Steel staples acc. to DIN 18182 Steel staples acc. to DIN 18182 25 Example: Fire resistance F30 Independently from below Details, sclae 1:5

D131-SO-B1 Longitudinal section of built-in lighting

� 400 mm

25

� 1000 mm

Encasement � 400 x 1000 mm made of Knauf GKF 25 mm

Built-in lighting, fastening acc. to providers spec.

� Hhe Lighting box

Built-in lighting, fastening acc. to providers spec.

Additional profile (for openings up to 200 x 200 mm not required)

Access panel

Example: Fire resistance F30

Independently from below and from above

D131-SO-C4 Lateral section of access panel

Type A

D131-SO-C2 Lateral section of access panel

Type B Axial spacing of ceiling profiles � 625 mm Board srips GKF, fastened on UW Profile with Drywall Screws TN UW Profile

�5

Drywall Screw TB 3.5x35, spacing 170 mm

Knauf Alutop Access Panel 6

450 mm

Clearance

D131-SO-B4 Longitudinal section of access panel

Type A

D131-SO-B2 Longitudinal section of access panel

Type B Board strip GKF fastened on CW Profile with Drywall Screws TN �5 CW Profile

Drywall Screw TB 3.5x35, spacing 170 mm

Knauf Alutop Access Panel 6

� 1500 mm

Clearance

Knauf Alutop Access Panel

Standard sizes: (clearance) 450 mm x 450 mm 450 mm x 1500 mm

Intermediate sizes on request The Knauf Alutop Access Panel can be fully dismounted

15

D131 Knauf Free-spanning Ceilings

Multi-level Ceiling

Exposed ceiling below free-spanning ceiling Example: Fire resistance F30

Spacing of suspenders

exposed ceiling Independently from below and from above Type A

1

F30

Fire protection level

Independently from below Independently from below and from above

Knauf Free-spanning Ceiling D131

Proof: ABP P-3964/2172

2 2

Exposed ceiling � 0.15 kN/m

b

exposed ceiling

E. g. Cleaneo Acoustic Design Ceiling (Application acc. to Technical Data Sheet D12) For exposed ceilings made of metal: Min. suspension height 150 mm Apply suspended channels of exposed ceiling always lateral to ceiling profiles of fire protection level Anchoring of suspenders in ceiling channels of the fire protection level with Knauf All Purpose Screws FN 4.3x35 / FN 4.3x65 (acc. to ABP P-VHT-1802/05-FN) Max. load of exposed ceiling: 100 N per suspender

Axial spacing of furring channel

1 Free-spanning ceiling as fire protection level

The additional dead load of the exposed ceiling (� 0.15 kN/m) has to be considered for the maximum ceiling span (room width) of the Free-Spanning Ceiling. Maximum room widths can be taken from the tables on pages 6 to 8.

Ax ial sp ac in ex g

2 Max. spacings of exposed ceiling

Max. axial spacing c carrying channels 1000 1200 Max. spacing of suspenders *), load class kN/m

up to 0.15

po of se ca d c rr eil yin ing g

ch

an

ne l

All dimensions in mm

Max. axial spacing b furring channels 500

(for Cleaneo Acoustic Ceilings see D12)

625 500

*) Suspension must be fastened to ceiling profiles of the fire protection level

Detail, scale 1:5 Example: Fire resistance F30 D131-D112

Independently from below

Knauf Exposed Ceiling below Free-spanning Ceiling

UW perimeter profile, anchoring on wall acc. to page 4 Knauf CW double profile

Alternative suspension:

Direct Bracket

(bend side tabs)

+ Knauf All Purpose Screw

FN 4.3x35 / FN 4.3x65

see Technical Data Sheet D12

Knauf All Purpose Screw FN Universal Bracket for CD 60x27 (apply alternating)

Knauf Board

16

Technical Data Sheet D11 Knauf Board Ceilings

Technical Data Sheet D12 Knauf Cleaneo Acoustic Ceilings

D131 Knauf Free-spanning Ceilings

Consumption of Material of selected examples

Consumption per m ceiling without allowance for loss and cut-off.

Description Italic= not provided by Knauf

Unit

Without fire resistance 12,5 mm 500 mm

Amounts refer to a ceiling area of: 2.5 m x 10 m = 25 m

Amount as average value

Fire resistance: Independently Fire resistance: Independently from below and from above from below

Type A Type B

2x 12,5 mm 500 mm

25 mm 625 mm

18 mm 625 mm

18 mm 625 mm

Profile spacing Profile spacing Profile spacing Profile spacing Profile spacing

Connection to wall

UW perimeter profile UW 50 / 75 / 100 / 125 / 150 x 40 x 0.6 fastener approved for substrate, e. g. Knauf All Purpose Screws 2x FN 4.3x35 for metal stud partitions or Knauf Ceiling Steel Dowels for reinforced concrete walls CW Profile - length acc. to span width (room width) Knauf CW 50 / 75 / 100 / 125 / 150 x 50 x 0.6 fastener approved for substrate, e. g. Knauf All Purpose Screws FN 4.3x35 for metal stud partitions bzw. Knauf Ceiling Steel Dowels for reinforced concrete walls m pcs pcs m pcs pcs 0.8 2.7 2.8 0.2

as required

0.8 2.7 2.8 0.2

as required

0.8 2.7 2.8 0.2

as required

0.8 *) 2.7 2.8 0.2 **)

as required

0.8 *) 2.7 2.8 0.2 **)

as required

Substructure

Single profile as ceiling profile - length acc. to span width (room width) Knauf CW 50 / 75 / 100 / 125 / 150 x 50 x 0.6 Connection of CW Profile with UW perimeter runner: e. g. metal rivet Double profile as ceiling profile - length acc. to span width (room width) Knauf CW 50 / 75 / 100 / 125 / 150 x 50 x 0.6 Metal Screw LB 3.5 x 9.5 mm (connection of CW Profiles at web) Connection of CW Profile with UW perimeter runner: e. g. 2x metal rivets Insulation layer (regard fire protection specifications, see page 3) m pcs m pcs pcs m 1.9 1.7 as required

3.8 3 3.2

as required

3 2.4 2.6

as required

3 **) 2.4 1

3 **) 2.4 as required

Knauf Boards

Knauf Wallboard GKB / GKBI; 12.5 mm alt. Knauf Fire-resistant Board GKF / GKFI or Diamant GKFI; 12.5 mm alt. Solid Board GKF / GKFI; 25 mm alt. Knauf Fire-resistant Board GKF / GKFI; 18 mm Covering strip 120 mm wide: Solid Board GKF / GKFI; 25 mm Covering upper board layer: Knauf Fire-resistant Board GKF / GKFI; 12.5 mm m 1 2 1 1 0.2 1 0.2 1

m m

Fastening of cladding

Fastening of Knauf Boards - Knauf Fasteners, see page 2 1st layer 2nd layer Fastening of covering strips - Knauf Drywall Screws TN 3.5 x 35 mm pcs 19 1 0.3 0.3 0.35 0.4 0.3 0.75

as required

14 19 1 0.5 0.5 0.35 0.6 0.5 0.75

as required

22 1 0.5 0.5 0.35 0.5 1.55

as required

17 8 1 0.4 0.4 0.35 0.4 0.75

as required

17 8 1 0.4 0.4 0.35 0.4 0.75

as required

pcs m kg m kg kg m m m St St

Filling

Trenn-Fix 65 alt. or bzw. Uniflott / Uniflott imgregnated; for hand filling TRIAS; for hand filling Joint Tape Kurt (for cut edge joints) Jointfiller Super; for machine filling Fugenfller Leicht; for hand filling Joint Tape Kurt (for cut edge and longitudinal edge joints)

Edge Trim 23/13; 2.75 m long

T connection / L connection (see pages 9 to 13)

Knauf UA Profiles / UW Profiles Metal traverse / Connection Angle Suitable anchor *) Not possible with UW 50 / **) not possible with CW 150

as required as required as required as required as required

17

D131 Knauf Free-spanning Ceilings

Specifications / Substructure

Item ......

Description Subceiling DIN 18168-1, installation height in m ...................., as free-spanning ceiling, ceiling span in m ............................. . Fire resistance class according to DIN 4102-2 F 30,* for the ceiling independently resistant to re from below to protect the basic ceiling and the plenum, */ for the ceiling independently resistant to re from the plenum and from below to protect the room below the ceiling, the basic ceiling and the plenum *. Anchored on reinforced concrete/ masonry/ metal stud partition/ wood frame partition/ ........................... *. Substructure made of galvanized metal channels acc. to DIN 18182-1, ceiling channels as single/ double * CW proles CW 50/ 75/ 100/ 125/ 150 *. Insulation layer made of mineral wool acc. to DIN EN 13162 thickness in mm ..............., min. density in kg/ m ..................., * building material class A, melting point 1000 C (1832 F). */ additional board layer on ceiling channels made of Knauf Boards GKF, thickness 12.5 mm *. Cladding made of gypsum boards acc. to DIN 18180: Knauf Diamant/ Knauf Solid Boards GKF/ GKFI */ Knauf Boards GKF/ GKFI/ GKB/ GKBI *, application acc. to DIN 18181, single/ double * layer, thickness 12.5/ 18/ 25/ 2x12.5 * mm. Joint lling in accordance with Code of Practice no. 2 (IGG, April 2003) quality standard Q1 basic lling to be coated with plaster/ ........... */ quality standard Q2 standard jointing *. Product/ System: Knauf Free-spanning Ceiling D131

No. of units

Unit price

Total price

.........

..........

..........

......

Subceiling DIN 18168-1 as described above, with additional exposed ceiling. Sound absorption coefcient according to DIN EN ISO 11654 W = .............*. Conguration of acoustical ceiling level with furring channels and carrying channels, suspend with Universal Bracket to ceiling proles of Free-spanning Ceiling D131, plenum damping with mineral wool, thickness min. 20 mm *. Cladding made of perforated/ slotted * gypsum boards DIN 18180, Knauf Cleaneo Acoustic with air-cleaning effect, board thickness 12.5 mm, application acc. to DIN 18181, single layer, perforation Standard Circular R: 6/18 R/ 8/18 R/ 10/23 R/ 12/25 R/ 15/30 R */ perforation Alternating Circular R: 8/12/50/ 12/20/66 * R/ perforation Random Plus R: 8/15/20 R/ 12/20/35 R */ perforation Standard Square Q: 8/18 Q, 12/25 Q *, lamination on rear side with sound absorbent Knauf Standard Fleece, color: white/ black/ ............ *. Joint treatment: lling/ with Knauf Joint Cover Prole, color ........../ .......... *. Product/ System: Knauf Cleaneo Acoustic Ceiling D127 below Free-Spanning Ceiling D131 ......... m .......... ..........

......

Connection of free-spanning ceiling to free-spanning ceiling as T connection/ L connection *, Span width of continuous ceiling in m ........., Span width of adjacent ceiling in m .........., Anchored on: wall made of reinforced concrete/ masonry/ metal stud partition ........................... *. Conguration with supporting proles as double proles Knauf UA 50/ 75/ 100/ 125/ 150 * acc. to Knauf Technical Data Sheet D131, current edition. .......... m .......... ..........

* Cancel not applicable items

Sub-total ...............

Construction

Knauf Free-Spanning Ceilings are solely anchored on the walls at perimeter. Knauf Boards are fastened to a metal substructure made of Knauf CW proles as single or double proles. The application of additional loads like lighting xtures with max. 100 N (10 kg) per double prole and exposed ceilings such as D127 Knauf Acoustic Ceilings with load per unit area of 15 kg/m or max. single load of 100 N with suitable anchors directly to the metal substructure is permissible. Regard extra loads for dimensioning of T or L connections. Joints of free-spanning channels are not allowed. Movement joints have to be transferred into the construction of the free-spanning ceilings. Use control joints in the case of ceiling areas over approx. 15 m length, or for narrow ceiling spaces caused by a break of a wall. Separate connections of boards to components made of a different building material, especially columns, or

thermally highly stressed built-ins like lighting xtures, for instance with shadow gaps. Knauf proles are delivered galvanized. The corrosion protective coating is sufcient for indoor application, including bathrooms and kitchens in private housing. For other areas, e.g. under inuence of outdoor air, additional corrosion protection is necessary (see DIN 18168-1 table 2).

18

D131 Knauf Free-spanning Ceilings

Application / Filling / Coat and Linings

Application

Substructure Supporting perimeter connection made of UW Proles. Anchoring acc. to table on page 4. In case of sound protection requirements, seal up carefully with Acoustical Sealant according to DIN 4109, supplement 1, chapter 5.2; porous sealant strips like Sealing Tape are usually not suitable in this case. Ceiling proles made of Knauf CW Proles as single or double proles. In case of re protection requirements, apply only double proles. Connect CW Proles as double proles at web with metal screws acc. to page 4. Support length of CW Proles in UW perimeter runners has to be at least 30 mm. Connect upper anges of UW/CW Proles by riveting, screwing or crimping, if no covering strip is required. Cladding In case of re protection requirements, attach Knauf Board Strips GKF, 25 mm thick, 120 mm wide, as covering strips on upper anges of CW double proles alternating with Drywall Screws TN 3.5 x 35 mm at max. 250 mm centers. Apply Knauf Boards lateral to ceiling proles. Stagger cut edge joints by at least 400 mm while placing them on proles. If using 4AK Boards (4side tapered edges) cross joints are allowed in connection with lling with joint tape, preferably Knauf Joint Tape Kurt. Start fastening of Knauf boards either in the middle or at a corner in order to prevent upsetting deformation. Press boards rmly on to the grid and fasten with Drywall Screws acc. to page 2. Use separation strip Trenn-Fix and ller or acrylate for connections to other components. Multi-level Ceiling Application according to instructions on page 16.

Filling

Surface quality Filling of gypsum boards acc. to the required quality standard Q1 ro Q4 acc. to Code of Practice No. 2 Verspachtelung von Gipsplatten, Oberchengten o the IGG. Filling compounds Select suitable lling compound considering quality requiremens and board type: Uniflott: Hand filling without joint tape: HRAK, HRK / with joint tape: AK Uniflott impregnated: Hand filling of impregnated boards without joint tape: HRAK, HRK hydrophobic, green TRIAS: Hand filling without joint tape: HRAK, HRK / with joint tape: AK color adapted to paper color of gypsum boards, reduced absorption for surfaces with uniform appearance Fugenfller Leicht: Hand filling with joint tape: HRAK, AK Jointfiller Super: Machine filling with joint tape: HRAK, AK Readygips: Hand or machine filling with joint tape: AK Application For multi layer cladding, ll in joints of rst layers, smooth joints of top layer. Fill all visible screw heads as well. Recommendation: Fill cut edge joints of visible layers using Knauf Joint Tape Kurt, no matter which lling material is used. Slightly sand visible surface after drying of lling compound, if necessary. General note: Filling of all concealed board layers in case of multi-layer cladding is necessary to preserve the required properties for re protection, sound insulation and stability. Application temperature/ climate Filling of joints should only take place after the boards have been allowed to rest in the given humidity and temperature zones, and no more longitudinal changes can be expected, i.e. expansion or contraction. Joints should be filled at a minimum room and surface temperature of +10 C (50 F). In case of mastic asphalt screed, fill joints after screed has been applied. Refer to Code of Practice No. 1 Baustellenbedingungen of the IGG.

Coats an linings

Pre-treatment Before applying paints or coats the lled surface should be dust-free. Pre-treat and prime gypsum board surfaces before the application of coats and linings (wallpaper) according to Code of Practice No. 6 of the IGG Vorbehandlung von Trockenbauchen aus Gipsplatten zur weitergehenden Oberchenbeschichtung bzw. bekleidung. Ensure that the primer and the coat, paint or lining are compatible. To settle the different suction properties of the lled areas and the paper surface, primers such as Knauf Tiefengrund/ Spezialgrund/ Putzgrund are suitable. In case of wallpaper lining a primer that allows an easier removal of wallpaper for redecoration is recommended. Suitable coats and linings The following coats and linings can be used on Knauf Boards: Wallpapers: Paper, textile, and synthetic wallpapers. Use only adhesives made of cellulose according to Code of Practice no. 16 Technische Richtlinien fr Tapezier- und Klebearbeiten, released by Bundesausschuss Farbe und Sachwertschutz. Plasters: Knauf Structured Plasters, Knauf Skim Plasters, entire surface smoothing such as Knauf Readygips or Knauf Multi-Finish, up to 2 mm thickness. Regard extra load of plaster for the evaluation of permissible room width and when dimensioning L or T connections. Plaster coating only in connection with filling with joint tape. Coats: Resin dispersion paints, multicolored (rainbow) emulsion, oil paint, matte-nish lacquer, alkyd resin paint, polymer resin paint, PUR lacquer, or epoxy-based lacquer. Silicate-based emulsion paints may be used after application of a primer that is suitable for the respective surface acc. to the instructions of the provider. Unsuitable are: Alkaline coats such as lime, water glass paints and silicate-based paints After wallpapering or plastering ensure adequate ventilation for fast drying. Note: Gypsum plasterboard surfaces that have constantly been exposed to light without any protection can cause yellowing after coating. Therefore a trial coat is recommended that will extend across several boards including all joints. Yellowing can, however, be successfully avoided only by using a special primer.

19

D131 Knauf Free-spanning Ceilings

Declaration of Compliance A declaration of compliance specied for your project is available from Knauf Direkt Technical Advisory Service. Declaration of compliance by the installer of the building component

Installer: (name, address) ................................................................................................................................................................................................. ................................................. ................................................................................................................................................................................................. ......................................................................................... Site / building: Date of installation: Building Component / requirements: ................................................................................................................................................................................................. ...................................................................................... ................................................................................................................................................................................................. ................... ................................................................................................................................................................................................. ................... ................................................................................................................................................................................................. ............ It is certified herewith that the Knauf Free-spanning Ceiling system as stated above has as been built and installed in accordance with Knauf Technical Data Sheet D131 Knauf Free-spanning Ceilings, edition 2007-04 07-04

with the system components specified there, and has therefore been built regarding the declaration of compliance by the system manufacturer below n and fire protection. in accordance with the valid building supervisory proofs concerning statics, sound insulation

Declaration of compliance by the system em manufacturer

Knauf Gips KG Am Bahnhof 7 97346 Iphofen, Germany

It is certified herewith that the e construction variants, application details and an specified products included in Knauf Technical Data Sheet D131 Knauf Freespanning Ceilings, edition valid building supervisory proofs respectively. on 2007-04 are fully in accordance with the specified s As far as specified for the he respective system / detail, detail this applies particularly to the structural calculation tion acc. to DIN 18168 and/or DIN EN 13964 fire protection acc. to ABP P-3964/2172 In order to fulfill the building supervisory above in the installation of Knauf ceiling systems, building and application have to be done rvisory requirements specified sp according to the valid edition of Knauf nauf Technical Data Sheet D131 with system components specified there. This has to be certified by the installer of the component nent with the declaration of compliance (see above) towards the contractor. Iphofen, phofen, April 2007 2

sa

Prof. Dr. Hummel Knauf Direct Technical Advisory Service: Phone.: +49 9001 31-1000 * Fax: +49 1805 31-4000 ** www.knauf.de D131/engl./D/04.07/FB/D * **

0,14 /Min.

m

Dr. Ruf

.............................................................................................................. ......... Place, date

Knauf Drywall and Floor Systems Am Bahnhof 7, 97346 Iphofen, Germany

A rate of 0.39 per minute will be charged for calls from within the German landline network. Callers whose phone numbers are not registered in the address database of Knauf Gips KG, i.e. private builders or non-patrons, will be charged a rate of 1.69 per minute. Calls from mobile phones will be charged 1.48 per minute.

All technical changes reserved. Only the current printed instructions are valid. Our warranty is expressly limited to our products in flawless condition. All application quantities and delivery amounts are based on empirical data that are not easily transferable to other deviating areas. The stated information represents current state-of-the-art Knauf technology. The entire state of approved engineering rules, appropriate standards, guidelines, and rules of craftsmanship are not included herewith. These and all application instructions have to be adhered to separately by the installer. All rights reserved. All amendments, reprints and photocopies, including those of excerpts, require the express permission of Knauf Gips KG, Am Bahnhof 7, 97346 Iphofen, Germany. Delivery via professional building material distributors only, in accordance with our current business, delivery and payment terms.

The constructional and structural properties, and characteristic building physics of Knauf systems can solely be ensured with the exclusive use of Knauf system components, or other products expressly recommended by Knauf.

pl

e

.......................................................................................................... ...... Stamp St Sta and signature

Вам также может понравиться

- Annex CHДокумент22 страницыAnnex CHMario1234Оценок пока нет

- I4.8 Information Sheet Glass in Stand Construction Inside Trade Fair Halls 2019 PDFДокумент12 страницI4.8 Information Sheet Glass in Stand Construction Inside Trade Fair Halls 2019 PDFatalayyОценок пока нет

- C 03 Detalii Atic-Racord VerticalДокумент24 страницыC 03 Detalii Atic-Racord VerticalStefana BernatОценок пока нет

- Izolatie AcoperisДокумент4 страницыIzolatie AcoperisAlexandru-SorinRizeaОценок пока нет

- AR 4.3a - ATELIERДокумент1 страницаAR 4.3a - ATELIERRobert KulcsárОценок пока нет

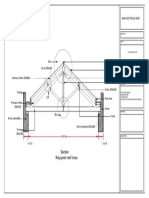

- King Post Truss Roof E1Документ1 страницаKing Post Truss Roof E1pankajОценок пока нет

- A Mechanics Based Approach For Determining Deflections of Stacked Multistorey Woodbased ShearwallsДокумент10 страницA Mechanics Based Approach For Determining Deflections of Stacked Multistorey Woodbased ShearwallsEtienneLampronОценок пока нет

- Detalii Constructive CorusДокумент24 страницыDetalii Constructive CoruskalinОценок пока нет

- Metal Deck and Cast in ChannelsДокумент8 страницMetal Deck and Cast in ChannelsrealdarossОценок пока нет

- Accidental Loading On BuildingsДокумент22 страницыAccidental Loading On Buildingssubin_mampallyОценок пока нет

- Referinte Turnuri de Racire Si Cosuri de FumДокумент75 страницReferinte Turnuri de Racire Si Cosuri de Fumpetronela.12Оценок пока нет

- Cable Tray PDFДокумент8 страницCable Tray PDFmaheshОценок пока нет

- Zero Footprint - ReSkinningAwards, 2010 PDFДокумент44 страницыZero Footprint - ReSkinningAwards, 2010 PDFfesterr100% (1)

- Building Economics (Group 4) FINAL PRINTДокумент34 страницыBuilding Economics (Group 4) FINAL PRINTJasbeer SharmaОценок пока нет

- Glulam Hand Volume-1Документ144 страницыGlulam Hand Volume-1Ion ClipaciОценок пока нет

- Technical Specification - JH ExoTec Facade PanelДокумент20 страницTechnical Specification - JH ExoTec Facade PanelSudhakar KrishnamurthyОценок пока нет

- Unistrut UKДокумент108 страницUnistrut UKPaul SinclairОценок пока нет

- WWW - Ubakus.de: Green RoofДокумент4 страницыWWW - Ubakus.de: Green Roofady adyОценок пока нет

- Energy and Buildings - Laboratory01 - Thermal Bridges - 2017 PDFДокумент55 страницEnergy and Buildings - Laboratory01 - Thermal Bridges - 2017 PDFSamantha GraciОценок пока нет

- Technical Brochure CLT enДокумент32 страницыTechnical Brochure CLT enFlaviu DobreanОценок пока нет

- Cembrit 41773 Cembrit Placi Din Fibrociment Pentru Placare Fatade VentilateДокумент13 страницCembrit 41773 Cembrit Placi Din Fibrociment Pentru Placare Fatade VentilateRatiuMonica100% (1)

- Latest Date For Receipt of Comments: 28 October 2023: Form 36Документ131 страницаLatest Date For Receipt of Comments: 28 October 2023: Form 36J MrОценок пока нет

- Cross Laminated Timber CLT Structural Design Basic Design and Engineering Principles According To EurocodeДокумент191 страницаCross Laminated Timber CLT Structural Design Basic Design and Engineering Principles According To EurocodeVladislavs PozņaksОценок пока нет

- BCT 122 Roof Framing 1Документ29 страницBCT 122 Roof Framing 1Ricardo NovondoОценок пока нет

- Tabla Cutata Cu Profil Inalt MBS 85 - Tabel IncarcariДокумент8 страницTabla Cutata Cu Profil Inalt MBS 85 - Tabel IncarcariionutzglimbeaОценок пока нет

- Lamella & Geodesic Dome ConstructionДокумент39 страницLamella & Geodesic Dome ConstructionFebie DОценок пока нет

- KVH TI Folder en Web3 02Документ19 страницKVH TI Folder en Web3 02mario_stefanecОценок пока нет

- Purmo Technical Catalogue Under Floor Heating Pipe System UFH HKS 08 2011 ANGДокумент36 страницPurmo Technical Catalogue Under Floor Heating Pipe System UFH HKS 08 2011 ANGanna_pomaranska0% (1)

- ECCS - 2005 - Charles de Gaulle Building in BucharesДокумент26 страницECCS - 2005 - Charles de Gaulle Building in BucharesmihaidelianОценок пока нет

- King SpanДокумент639 страницKing SpanS. MariusОценок пока нет

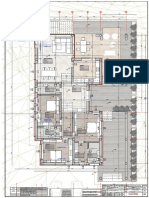

- A-03 Plan ParterДокумент1 страницаA-03 Plan ParterMirunaОценок пока нет

- Cofraplus77 enДокумент28 страницCofraplus77 enKristály AnikóОценок пока нет

- Brick Wall CalculationДокумент26 страницBrick Wall CalculationSaiful Hoque Sohel100% (1)

- Requirements Sauna wk2103.7Документ6 страницRequirements Sauna wk2103.7Anees Ahmad KhanОценок пока нет

- 08 Balint Karoly PrefbetonДокумент26 страниц08 Balint Karoly PrefbetonChinta IulianОценок пока нет

- Cavity Walls: Presented by - Aishwarya Deshmukh Aniket Late Tejas Joshi Dhananjay Marda Priti PawarДокумент30 страницCavity Walls: Presented by - Aishwarya Deshmukh Aniket Late Tejas Joshi Dhananjay Marda Priti PawarTejas JoshiОценок пока нет

- AntemasuratoareДокумент17 страницAntemasuratoareOlariu OvidiuОценок пока нет

- Detalii de Executie Porotherm 38Документ3 страницыDetalii de Executie Porotherm 38Alexandra StoicaОценок пока нет

- Addresses: Special Publication SP-528EДокумент30 страницAddresses: Special Publication SP-528ETiago MendesОценок пока нет

- Proiect LemnДокумент43 страницыProiect LemnVictor Rîndunica100% (1)

- AntemasuratoriДокумент58 страницAntemasuratoriLelea EmanuelaОценок пока нет

- KVH TI Folder2013Документ44 страницыKVH TI Folder2013johanОценок пока нет

- T12 - 03 Special Hybrid Moment Frames Composed of Discretely Jointed Precast and Post - Tensioned Concrete MembersДокумент15 страницT12 - 03 Special Hybrid Moment Frames Composed of Discretely Jointed Precast and Post - Tensioned Concrete MembersAndrew BlackОценок пока нет

- En Downloads Brochures TexlonHSP ETFE Brochure enДокумент4 страницыEn Downloads Brochures TexlonHSP ETFE Brochure ennubis_zionОценок пока нет

- Industrial Silos: Technical SheetДокумент31 страницаIndustrial Silos: Technical Sheetred patriotОценок пока нет

- Calcul ScaraДокумент6 страницCalcul ScaraGergo Juhasz50% (2)

- Rheinzink Roof Covering SystemsДокумент16 страницRheinzink Roof Covering Systemspablo_658Оценок пока нет

- Design in Brickwork Non Load BearingДокумент4 страницыDesign in Brickwork Non Load Bearingharicv019Оценок пока нет

- 1ALUCOBOND Product InformationДокумент97 страниц1ALUCOBOND Product InformationHangan Georgiana100% (1)

- Calculation of Thermal Bridges in Various European CountriesДокумент7 страницCalculation of Thermal Bridges in Various European CountriesbatteekhОценок пока нет

- American Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsДокумент32 страницыAmerican Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsMohammad Humayun KabirОценок пока нет

- Curtain Wall NoAnswersДокумент20 страницCurtain Wall NoAnswersLuiz CarlosОценок пока нет

- F3 Deviz ArhitecturaДокумент15 страницF3 Deviz ArhitecturaFlavia SimonaОценок пока нет

- Glulam SupplementДокумент24 страницыGlulam SupplementLee Ager100% (1)

- k219 2005-02 eДокумент12 страницk219 2005-02 eDoru HacaОценок пока нет

- W 13Документ12 страницW 13matsiasОценок пока нет

- Knauf D11 SystemsДокумент28 страницKnauf D11 SystemsAmin ChhipaОценок пока нет

- Knauf CeilingsДокумент32 страницыKnauf CeilingsSebastian BadilaОценок пока нет

- Cubo Room in Room k37!07!2012Документ40 страницCubo Room in Room k37!07!2012Dorin NicolaeОценок пока нет

- W 36Документ12 страницW 36matsiasОценок пока нет

- Zip Comfort, Quality Light For OutdoorДокумент24 страницыZip Comfort, Quality Light For OutdoorAmin ChhipaОценок пока нет

- Technical Features: 318 - Puk - ItДокумент1 страницаTechnical Features: 318 - Puk - ItAmin ChhipaОценок пока нет

- Way Medium 01 Round: Technical FeaturesДокумент1 страницаWay Medium 01 Round: Technical FeaturesAmin ChhipaОценок пока нет

- 10 LeanOhio Toolkit July2013Документ92 страницы10 LeanOhio Toolkit July2013Amin ChhipaОценок пока нет

- Method Statement PlumbingДокумент8 страницMethod Statement Plumbinggvs raoОценок пока нет

- Glass Company in DubaiДокумент5 страницGlass Company in DubaiMariyam KalsoomОценок пока нет

- Usg Boral Product Catalogue: Metal Framing Substrates Gypsum Boards Ceilings CompoundsДокумент9 страницUsg Boral Product Catalogue: Metal Framing Substrates Gypsum Boards Ceilings CompoundsJane RoОценок пока нет

- Cost Implication To DesignДокумент6 страницCost Implication To DesignShahrol Faizal AbdullahОценок пока нет

- Module-1 ECE403-CECS IntroductionДокумент21 страницаModule-1 ECE403-CECS Introduction121810201004 KURELLA SIDHARTHОценок пока нет

- IAY Vigyan Bhavan PPT 6052010Документ80 страницIAY Vigyan Bhavan PPT 6052010Vasudha GandhiОценок пока нет

- Cost and Quantity EstimationДокумент71 страницаCost and Quantity EstimationHarish4182100% (2)

- Trennwandkitt k433 de 0416 0 Eng ScreenДокумент2 страницыTrennwandkitt k433 de 0416 0 Eng ScreenAlexandru IonescuОценок пока нет

- Expansion Joint Treatment: Material & Techniques: March 2014Документ15 страницExpansion Joint Treatment: Material & Techniques: March 2014NIHAR SHAHОценок пока нет

- R 50Документ185 страницR 50Hari Nepalee BibashОценок пока нет

- Al Burraq Aluminium LLC, A UAE Based Aluminium-Glass CompanyДокумент46 страницAl Burraq Aluminium LLC, A UAE Based Aluminium-Glass CompanyShakeel Ahmad100% (1)

- Panel Systems: Joint LocationsДокумент1 страницаPanel Systems: Joint LocationsscribdztОценок пока нет

- HKSMM4 - Building Works (4th Edition-2005) RevДокумент221 страницаHKSMM4 - Building Works (4th Edition-2005) RevSiu Eric100% (4)

- 22m High Wall at Durga Temple With PECДокумент5 страниц22m High Wall at Durga Temple With PECGerald TanОценок пока нет

- Idesia Dasma Work ProgressДокумент1 страницаIdesia Dasma Work ProgressQueenie PerezОценок пока нет

- Section 09100 Metal Framing SystemДокумент5 страницSection 09100 Metal Framing Systemestimasi100% (1)

- Light Steel Framing Design: AgendaДокумент22 страницыLight Steel Framing Design: AgendaAmrar AbdelazizОценок пока нет

- Grand Designs Hse Berkshire A PR 2019Документ6 страницGrand Designs Hse Berkshire A PR 2019Juliet BenningОценок пока нет

- Kharadkar Wada PresentationДокумент15 страницKharadkar Wada Presentation19SA103. Ali100% (2)

- Modular CoordinationДокумент17 страницModular Coordinationkavya sundaramОценок пока нет

- Construction V2-0 Sept 10 - ACC - WE - DB1000Документ34 страницыConstruction V2-0 Sept 10 - ACC - WE - DB1000vin ssОценок пока нет

- SPECIFICATIONДокумент213 страницSPECIFICATIONnadeem UddinОценок пока нет

- B.o.Q of Baste Shelga BridgeДокумент12 страницB.o.Q of Baste Shelga BridgeAhmed BakrОценок пока нет

- Haima 7 Car Body Manual-ConstructionДокумент3 страницыHaima 7 Car Body Manual-ConstructionBenito CamelloОценок пока нет

- Cold Rolled Products Technical Manual: C1/SFB (27) Hh2 JANUARY 2018Документ28 страницCold Rolled Products Technical Manual: C1/SFB (27) Hh2 JANUARY 2018NickОценок пока нет

- Astm e 330Документ7 страницAstm e 330Zahoor Ahmed MohsanОценок пока нет

- M. C. Abdul Malick Chartered Valuer: 54/3C Prathibimbarama Road, DehiwelaДокумент3 страницыM. C. Abdul Malick Chartered Valuer: 54/3C Prathibimbarama Road, DehiwelaNaahidhОценок пока нет

- Aquapanel Cement Board Indoor Masonry Installation: Technical LeafletДокумент2 страницыAquapanel Cement Board Indoor Masonry Installation: Technical LeafletAttila SiklodiОценок пока нет

- EMI-Shield Installation InstructionsДокумент10 страницEMI-Shield Installation InstructionsSayedur RahmanОценок пока нет

- Pryda Steel Connectors Guide - June 2010Документ20 страницPryda Steel Connectors Guide - June 2010Pawel MilewskiОценок пока нет