Академический Документы

Профессиональный Документы

Культура Документы

Ignition System

Загружено:

Joel DsouzaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ignition System

Загружено:

Joel DsouzaАвторское право:

Доступные форматы

Study of ignition Systems

Experiment No. AIM: To study Spark Ignition System of S.I.Engine Specimens:- Battery ignition system and Magneto ignition system

Date:- ..

T E!"# :- The ignition system should provide sufficiently large voltage across the spark plug electrodes to effect the spark discharge. Further, it should supply the required energy for the spark to ignite the combustible mixture adjacent to the plug electrodes under all operating conditions. For given engine design, the optimum spark timing varies ith engine speed, manifold pressure and mixture composition. The ignition system should take into account these factors to provide the spark of proper energy and duration at the appropriate time. FUNCTIONAL REQUIREMENTS OF AN INJECTION SYSTEM For a smooth and reliable functioning of an engine the ignition system must satisfy follo ing requirement. ! # $ & ' ( "t should provide a good spark bet een electrodes at correct timing "t should function effectively over entire range of engine speed "t should should be light, effective % reliable in service "t should be compact and easy to maintain "t should be cheap and convenient to handle The radio interference from high voltage source should not affect the functioning of radio and other equipment inside the vehicle.

COMPONENTS OF A BATTERY IGNITION SYSTEM ) ) ) ) ) ) ) ) Battery "gnition s itch Ballast *esistor +ontact breaker "gnition +oil +apacitor ,istributor -park .lug

/0*1"23 0F B4TT5*6 "32"T"02 -6-T5M

Dashed line indicates common cam shaft for contact Breaker & Distributor

,iagram of a typical battery ignition system is sho n in fig. .o er for such a circuit is often supplied from a (7 or !# 7 battery. There are t o circuits, the primary circuit and the secondary circuit. The primary circuit consists of a battery, one end of hich is connected to earth. The earth is usually the engine body itself. 0ther side of battery 89ve terminal: is connected to the primary inding of a coil via an ammeter and "gnition s itch. Ballast resistor is provided to regulate primary current. The objective is to prevent overheating % damage to spark plug. The contact breaker is, a spring;closed s itch, and is operated by means of a cam. The other side of the contact breaker is connected to earth. 4 capacitor is connected across the contact breaker points to earth. The points, as they are called, are the contact breaker contact surfaces. This completes the primary circuit. The secondary circuit is as follo s. The bottom end of the secondary inding of the coil is connected to the bottom end of the primary inding. The top end of the secondary inding is connected to the centre of the distributor rotor. The distributor rotor is a rotating contact hich s eeps past, and makes contact ith fixed contacts hich in turn are connected to the sparking plugs in the engine. The other side of the sparking plugs gaps is connected to the engine earth. This completes the secondary circuit.

!peration:- The operation of the complete circuit is as follo s. /ith the ignition s itch closed and the engine running, a current ill flo in the primary circuit as soon as the contact breaker closes. The build;up of current in the primary inding of the coil is relatively slo , since it must overcome the counter emf of its o n magnetic field. The contact breaker cam, hich is continuously revolving, no opens the contact breaker. "mmediately, the magnetic field in the coil begins to collapse. This collapse of the magnetic field tends to keep the current flo ing in the primary inding, ith the result that the capacitor is rapidly charged. 4s soon as it is fully charged, the capacitor ill begin to discharge through the primary inding and hence increases the rate of collapse of the magnetic field. This rapidly collapsing magnetic field ill induce a current flo in the secondary inding of the coil hich, because of its high turn<s ratio, ill produce a very high voltage in the secondary circuit. 4t the same time that the contact breaker in the primary circuit opens, the distributor rotor connects ith a contact to a sparking plug and hence a high voltage ill be set up across the sparking plug gap. This ill cause a high;intensity arc to spread across this gap, thus igniting the cylinder charge. The capacitor across the contact breaker points not only helps to collapse the magnetic field, but also prevents excessive arcing across the contact breaker. This is because the major proportion of the current flo in the primary circuit is discharged into the condenser instead of producing an arc across the points as they open. "n the diagram sho n the circuit for a four;cylinder engine is illustrated. "t ill be noted that the contact breaker cam is square having four lobes= thus effecting four openings of the contact breaker per revolution of the cam. The distributor has four contacts. >sually the number of cam lobes and the number of distributor contacts is the same as the number of engine cylinders. Both the cam % distributor rotor are motored in phase and mounted on the same shaft.

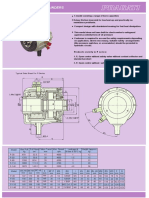

M4325T0 "32"T"02 -6-T5M

The high tension magneto incorporates in itself indings to generate as ell as to step up voltage and thus does not require a separate coil to boost up the voltage required to operate the spark plug. Magnet can be either rotating armature type or rotating magneto type. "n the first type armature consisting of the primary and secondary indings and condenser all rotate bet een plates of a stationary magneto. /hile in the second type magnet revolves and indings are kept stationery. *est of the operation is similar to battery ignition

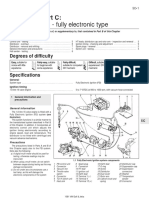

-.4*1 4,742+5 M5+?42"-M The point in the cycle here the spark occurs must be regulated to ensure maximum po er and economy at different speeds and loads % this must be done automatically. By means of spark advance mechanisms the advance angle is accurately set so that ignition occurs before the T,+ point of the piston. The t o mechanisms used for spark advance are !. +entrifugal advance mechanism #. 7acuum advance mechanism

$. %entrigua& Ad'ance Mec(anism: 4 typical sliding contact type centrifugal advance mechanism is sho n in the figure. +entrifugal advance mechanism controls the ignition timing for full load operation. The cam is mounted movable on distributor shaft so that as the speed increases, the fly eights hich are s ung farther % farther out ard shift the same cam in the direction of cam rotation. 4s a result, the cam balls make contact ith the breaker lever rubbing back some hat earlier, thus shifting the ignition point in the advance direction. ,epending on the speed of engine, the eights are s ung out ard a greater or lesser distance from the centre. They are held in the extended position, in the state of equilibrium corresponding to the shifted timing angle, by a retaining spring hich exactly balances the centrifugal force. ). *acuum Ad'ance Mec(anism: This mechanism shifts the ignition point under partial load conditions. "n this mechanism the adjustment control quantity is the static vacuum prevailing in the carburetor, a pressure hich depends on the position of throttle valve at any given time and hich is at a maximum hen this valve is about half open. The diaphragm of a vacuum advance unit is moved by changes in the gas pressure. The position of this diaphragm is determined by pressure differential at any given moment bet een prevailing vacuum and atmospheric pressure. The diaphragm movement is transmitted through a vacuum advance arm connected to a movable breaker plate, and this movement shifts the breaker plate an additional amount under part load condition in a direction opposite to the direction of rotation of the distributor shaft.

Вам также может понравиться

- Electronic Ignition 2Документ11 страницElectronic Ignition 2Kelvin WairiОценок пока нет

- Defination of Ignition SystemДокумент28 страницDefination of Ignition SystemDawood KhanОценок пока нет

- 3.study of Ignition SystemДокумент10 страниц3.study of Ignition SystemShridhar RaskarОценок пока нет

- Chapter 9Документ89 страницChapter 9Si Thu AungОценок пока нет

- Chapter 6 NotesДокумент13 страницChapter 6 NotesPankaj Gaurav100% (1)

- Starter MotorДокумент15 страницStarter MotorfieraminaОценок пока нет

- Secondary Coil, and This Induces Within It An EHT VoltageДокумент3 страницыSecondary Coil, and This Induces Within It An EHT VoltagePrerak Kumar SharmaОценок пока нет

- Thermal Power Plant Simulator TPP 200 Laboratory Exercise Tutorial N1: Rolling Up of Turbine Train and Connection of Generator To The GridДокумент13 страницThermal Power Plant Simulator TPP 200 Laboratory Exercise Tutorial N1: Rolling Up of Turbine Train and Connection of Generator To The GridPriyajit SahooОценок пока нет

- Mce 115Документ14 страницMce 115Kolawole folorunsho johnОценок пока нет

- Engine Systems (p1)Документ27 страницEngine Systems (p1)dfgОценок пока нет

- Vorm GierДокумент16 страницVorm GierStefan GabrielОценок пока нет

- Ignition SystemsДокумент19 страницIgnition Systemshotbuddy723100% (1)

- Qip Ice 16 Ignition - SystemsДокумент60 страницQip Ice 16 Ignition - SystemsAjay KumarОценок пока нет

- Ignition SystemДокумент8 страницIgnition SystemAsraОценок пока нет

- Ignition SystemДокумент5 страницIgnition SystemPankaj GauravОценок пока нет

- Experiment No: 5: (A) Battery Ignition System Aim: Objective: TheoryДокумент4 страницыExperiment No: 5: (A) Battery Ignition System Aim: Objective: TheoryPrakash PrajapatiОценок пока нет

- Contact Breaker - WikipediaДокумент3 страницыContact Breaker - WikipediaSatya NarayanaОценок пока нет

- Start-Up of Large-Power Synchronous Motor With The 6 KV Voltage Source Inverter and Microprocessor-Controlled Unit For Excitation SupplyДокумент7 страницStart-Up of Large-Power Synchronous Motor With The 6 KV Voltage Source Inverter and Microprocessor-Controlled Unit For Excitation SupplyJono WangОценок пока нет

- IgnitionДокумент13 страницIgnitionडॉ. इन्द्रसेन सिंहОценок пока нет

- The Starting SystemДокумент20 страницThe Starting SystemRuth MwendaОценок пока нет

- Chapter-8 Inition SstemДокумент17 страницChapter-8 Inition SstemjeetОценок пока нет

- 17me655 Module 3.2Документ10 страниц17me655 Module 3.2VinayakОценок пока нет

- Governing, Ignition System, Fire OrderДокумент33 страницыGoverning, Ignition System, Fire OrderProf. Jignesh Sohaliya100% (1)

- Ata-80 Aircraft Engine Starting Systems: Electrical Starter MotorsДокумент5 страницAta-80 Aircraft Engine Starting Systems: Electrical Starter MotorsBharath Kumar GoudОценок пока нет

- Safari - 3 Nov 2022 at 9:47 AMДокумент1 страницаSafari - 3 Nov 2022 at 9:47 AMMohamed ArhamОценок пока нет

- Automatic Star Delta StaretrДокумент22 страницыAutomatic Star Delta StaretrRiya Priyadarshni80% (5)

- P - Automotive Ignition System Service RevisedДокумент29 страницP - Automotive Ignition System Service Reviseddmc constructionОценок пока нет

- ATTACHMENT REPORT For Simiyu.Документ15 страницATTACHMENT REPORT For Simiyu.Kevin ShiunduОценок пока нет

- Electronic IgnitionДокумент17 страницElectronic IgnitionMitsos TakisОценок пока нет

- Electronic Ignition1 Ed.15-06-18Документ27 страницElectronic Ignition1 Ed.15-06-18collins arogoОценок пока нет

- 22 Ignition System Unit IIДокумент69 страниц22 Ignition System Unit IIVignesh SenthilОценок пока нет

- Solution Manual For Electric Motor Control 10th EditionДокумент38 страницSolution Manual For Electric Motor Control 10th Editionperrierfoalvbi3hr100% (16)

- Parts of Ignition SystemДокумент16 страницParts of Ignition SystemAnthony ArgandaОценок пока нет

- Answers 4,5,6Документ8 страницAnswers 4,5,6Mohsin TariqОценок пока нет

- SChapter13 The Adams MotorGeneratorДокумент14 страницSChapter13 The Adams MotorGeneratorpranalar100% (1)

- The Magnetic Circuit of A Magneto Consists of A Permanent MultiДокумент13 страницThe Magnetic Circuit of A Magneto Consists of A Permanent MultiumeshОценок пока нет

- A Practical Guide To Free EnergyДокумент235 страницA Practical Guide To Free EnergyDorucreatoruОценок пока нет

- Voltage ControlДокумент49 страницVoltage ControlGraphic DesignerОценок пока нет

- Chapter 8 - Ignition System-1Документ23 страницыChapter 8 - Ignition System-1Yabtsega TadesseОценок пока нет

- Motor TypesДокумент10 страницMotor TypesRavi Anand PalОценок пока нет

- Ignition System: Internal Combustion Engines Boilers Electric SparkДокумент9 страницIgnition System: Internal Combustion Engines Boilers Electric SparkManu ChakkingalОценок пока нет

- Auto Transformer StarterДокумент9 страницAuto Transformer Starterdiana100% (2)

- Ignition SystemДокумент16 страницIgnition SystemShuguta LatiОценок пока нет

- DC StartersДокумент20 страницDC StartersGAURAV BHARADWAJОценок пока нет

- Lab 6 Kawalan MotorДокумент20 страницLab 6 Kawalan MotorMohd FiqrieОценок пока нет

- Electrical SystemДокумент5 страницElectrical SystemMoiz AamirОценок пока нет

- Recip Ignition StartingДокумент6 страницRecip Ignition Startingmellon3duwenОценок пока нет

- Story of Ignition System in AutomobilesДокумент56 страницStory of Ignition System in AutomobilesTejaОценок пока нет

- Ignition SystemДокумент23 страницыIgnition SystemGemedaОценок пока нет

- Elect III Sem NotesДокумент16 страницElect III Sem NotesVijayakumar ArunachalamОценок пока нет

- Theory Ignition SystemДокумент4 страницыTheory Ignition SystemJareewat Arnamnart100% (1)

- CBLM S Ignition SystemДокумент17 страницCBLM S Ignition Systemace ebradoОценок пока нет

- Motor StarterДокумент8 страницMotor StartercalecaleОценок пока нет

- Distributor BasicsДокумент3 страницыDistributor BasicsJasminder Singh DurejaОценок пока нет

- Unit 2 Single Phase Induction Motor - Watermark PDFДокумент21 страницаUnit 2 Single Phase Induction Motor - Watermark PDFPalak Jio100% (1)

- MEO Orals On Marine Electro Technology Function 5Документ2 страницыMEO Orals On Marine Electro Technology Function 5Salih Tuğrul SarıОценок пока нет

- 5.chapter Five - Ignition and Fuel Injection SystemsДокумент21 страница5.chapter Five - Ignition and Fuel Injection SystemsAhmed M MerzaОценок пока нет

- Capacitor MotorДокумент4 страницыCapacitor MotorianguiebОценок пока нет

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.От EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Рейтинг: 3 из 5 звезд3/5 (4)

- Study of a reluctance magnetic gearbox for energy storage system applicationОт EverandStudy of a reluctance magnetic gearbox for energy storage system applicationРейтинг: 1 из 5 звезд1/5 (1)

- Application VT1005 PW8001 Solar E1 220829Документ3 страницыApplication VT1005 PW8001 Solar E1 220829Joel DsouzaОценок пока нет

- C6 ProbeStation CatalogueДокумент5 страницC6 ProbeStation CatalogueJoel DsouzaОценок пока нет

- A Ta Pw0003e04Документ5 страницA Ta Pw0003e04Joel DsouzaОценок пока нет

- Semiprobe Analytical Probe System Checklist E - BookДокумент13 страницSemiprobe Analytical Probe System Checklist E - BookJoel DsouzaОценок пока нет

- Applied Sciences: Root Cause Analysis of A Printed Circuit Board (PCB) Failure in A Public Transport Communication SystemДокумент13 страницApplied Sciences: Root Cause Analysis of A Printed Circuit Board (PCB) Failure in A Public Transport Communication SystemJoel DsouzaОценок пока нет

- 1KW-60904-2 2450 Datasheet 082821Документ14 страниц1KW-60904-2 2450 Datasheet 082821Joel DsouzaОценок пока нет

- TMSJ 15 GДокумент10 страницTMSJ 15 GJoel DsouzaОценок пока нет

- Interview With Ravi Zacharias - Jesus Among Other GodsДокумент7 страницInterview With Ravi Zacharias - Jesus Among Other GodsJoel DsouzaОценок пока нет

- 6430 ManualДокумент558 страниц6430 ManualJoel DsouzaОценок пока нет

- Prologix: Gpib-Usb ControllerДокумент16 страницPrologix: Gpib-Usb ControllerJoel DsouzaОценок пока нет

- STUDYGUIDE TheHolinessofGodДокумент74 страницыSTUDYGUIDE TheHolinessofGodJoel DsouzaОценок пока нет

- Understanding The Trinity Arp13 2012 WSДокумент11 страницUnderstanding The Trinity Arp13 2012 WSJoel DsouzaОценок пока нет

- Songs of BR AmitkДокумент17 страницSongs of BR AmitkJoel DsouzaОценок пока нет

- Industrial EngineeringДокумент24 страницыIndustrial EngineeringJoel DsouzaОценок пока нет

- Cylinder Head 3sfeДокумент27 страницCylinder Head 3sfePham Huy83% (18)

- Special Tools Wauke PDFДокумент102 страницыSpecial Tools Wauke PDFOscar Arciniegas Perez50% (2)

- Air HammersДокумент39 страницAir HammersJorge Rosero QuevedoОценок пока нет

- DBGVC 631-1lAF: ModelДокумент2 страницыDBGVC 631-1lAF: Modelmurillo_rodriguez8382Оценок пока нет

- Helvig Lifeboat Engine ManualДокумент20 страницHelvig Lifeboat Engine ManualjeyanthОценок пока нет

- P Data SheetДокумент1 страницаP Data SheetKalees WaranОценок пока нет

- Repair Manual For Iveco Nef Engines F4GE0484E - F4GE0684F - F4HE0684JДокумент258 страницRepair Manual For Iveco Nef Engines F4GE0484E - F4GE0684F - F4HE0684JbfscarreiraОценок пока нет

- Box Color Guide: Motorcycle Engine OilДокумент2 страницыBox Color Guide: Motorcycle Engine OilAndi Septian Eka SetiawanОценок пока нет

- 6.cylinder Head and ValvetrainДокумент14 страниц6.cylinder Head and ValvetrainKuba SwkОценок пока нет

- Q Inter Cooler DrawingsДокумент5 страницQ Inter Cooler DrawingsHri VitalionОценок пока нет

- Data Spare Part DatangДокумент7 страницData Spare Part DatangThaufan WijayaОценок пока нет

- Elixir European FormulaДокумент1 страницаElixir European FormulaJehuty88Оценок пока нет

- Construction of The Ai-9V EngineДокумент8 страницConstruction of The Ai-9V EngineYosif NorendoОценок пока нет

- Two Stroke EngineДокумент13 страницTwo Stroke EngineAaron PriceОценок пока нет

- Cc340 ManualДокумент242 страницыCc340 ManualOscar AraqueОценок пока нет

- TC BRG and LubДокумент3 страницыTC BRG and LubArun SОценок пока нет

- Thermal Module 3 - Part 1Документ31 страницаThermal Module 3 - Part 1Abubakkar SiddiqОценок пока нет

- Soalan LojiДокумент5 страницSoalan LojiSilver GrayОценок пока нет

- John Deere 1020 1520 1530 2020 2030Документ17 страницJohn Deere 1020 1520 1530 2020 2030Marius Gim0% (1)

- Golf2 1081-05c PDFДокумент4 страницыGolf2 1081-05c PDFmanoliroОценок пока нет

- C9 Service Letter Injector ReplaceДокумент6 страницC9 Service Letter Injector Replaceharikrishnanpd3327Оценок пока нет

- 2BMHДокумент21 страница2BMHEl Gitano XxxОценок пока нет

- Installation Check-Up and Commissioning Report: Large Diesel D25 D65Документ24 страницыInstallation Check-Up and Commissioning Report: Large Diesel D25 D65Naing Min HtunОценок пока нет

- Cub Cadet 2500 Parts ManualДокумент43 страницыCub Cadet 2500 Parts Manualafant70% (1)

- Provent FlyerДокумент7 страницProvent FlyerLAZOV workОценок пока нет

- D20Dtf Engine: 1. SpecificationДокумент26 страницD20Dtf Engine: 1. SpecificationLisetteGuzmánQuintupurraiОценок пока нет

- Orc: Hydraulic Pumps - Cylinders - Jacks - Pullers - ToolsДокумент32 страницыOrc: Hydraulic Pumps - Cylinders - Jacks - Pullers - ToolsTiffanoОценок пока нет

- Elementos de Desgaste 160hДокумент6 страницElementos de Desgaste 160hAnonymous F2Q7hAtscОценок пока нет

- 2007 Ford Ranger 2.3 PCMДокумент4 страницы2007 Ford Ranger 2.3 PCMpjmh.37Оценок пока нет

- Bosch M7.4.4 Me7.4.4 EobdДокумент66 страницBosch M7.4.4 Me7.4.4 EobdGustavo Burbano100% (2)