Академический Документы

Профессиональный Документы

Культура Документы

21010-BAE-70000-In-SP-0030 Tech Spec For Inst. and Controls For Packaged Equipment

Загружено:

Jignesh BanavaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

21010-BAE-70000-In-SP-0030 Tech Spec For Inst. and Controls For Packaged Equipment

Загружено:

Jignesh BanavaАвторское право:

Доступные форматы

Doc.

No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 1 of 36

CHARTER HIRE OF FPSO FOR D1 FIELD SUPPLY OF LEASED FPSO TECHNICAL SPECIFICATION FOR INSTRUMENTS & CONTROLS FOR PACKAGED EQUIPMENT

C0 A0 Rev

1 Jul 11 28 Jun 11 Date

AFB Approved For Bid IFR Issued For Review Description

SVS SVS Prepared

RM RM Checked

RM RM Engr

HH HH Approved

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 2 of 36

REVISION HISTORY Rev

A0 C0 Issued For Review Approved for Bid

Description of Change

Number of Pages

52 52

Date

28 Jun 11 1 Jul 11

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 3 of 36

TABLE OF CONTENTS

1. INTRODUCTION ......................................................................................................................... 5 1.1 1.2 1.3 1.4 2. PROJECT BACKGROUND ......................................................................................... 5 OBJECTIVES ............................................................................................................... 5 DEFINITIONS ............................................................................................................... 5 ABBREVIATIONS ........................................................................................................ 5

SCOPE ........................................................................................................................................ 7 2.1 2.2 2.3 2.4 GENERAL .................................................................................................................... 7 SCOPE OF SUPPLY .................................................................................................... 7 TECHNICAL BID PROPOSAL SUBMISSION ............................................................ 8 CONFLICTING REQUIREMENTS ............................................................................... 8

3.

DESIGN FEATURES................................................................................................................... 9 3.1 3.2 3.3 3.4 GENERAL .................................................................................................................... 9 CLASS APPROVAL/CERTIFICATION ....................................................................... 9 CODES,STANDARDS AND FEDERAL REGULATIONS AND LAWS ...................... 9 DESIGN CRITERIA .................................................................................................... 10 3.4.1 Design Life, Availability/Reliability .................................................................. 10 3.4.2 Units of Measurement .................................................................................... 10 3.4.3 Operating Conditions ...................................................................................... 11 3.4.4 Hazardous Area and Ingress Protection ........................................................ 11 DESIGN FEATURES ................................................................................................. 12 3.5.1 General ........................................................................................................... 12 3.5.2 Field Instrumentations .................................................................................... 17 3.5.3 Fire and Gas System Devices ........................................................................ 24 3.5.4 Control, Shutdown and Safety System........................................................... 25 DESIGNATION AND NAME PLATES ....................................................................... 27 3.6.1 Designation ..................................................................................................... 27 3.6.2 Name Plates ................................................................................................... 27

3.5

3.6

4.

GUARANTEES .......................................................................................................................... 28 4.1 4.2 4.3 EQUIPMENT PERFORMANCE ................................................................................. 28 PERFORMANCE GUARANTEES ............................................................................. 28 WARRANTY ............................................................................................................... 28

5.

QUALITY AND ENVIRONMENTAL MANAGEMENT, INSPECTIONS AND TESTS .............. 30 5.1 QUALITY AND ENVIRONMENTAL MANAGEMENT REQUIREMENTS ................. 30 5.1.1 Responsibility for Quality, Environmental Compatibility and Their Management ............................................................................................................... 30 5.1.2 Conformance to ISO Standards ..................................................................... 30 INSPECTION AND TESTS ........................................................................................ 30 5.2.1 Extent of Testing and Inspection .................................................................... 31 5.2.2 Test Reports ................................................................................................... 32 5.2.3 "AS-BUILT" Drawings ..................................................................................... 32

5.2

6. 7.

PAINTING/COATING/PRESERVATION AND PROTECTION ................................................. 33 DOCUMENTATION AND PROGRESS REPORTING .............................................................. 34 7.1 7.2 GENERAL .................................................................................................................. 34 TRAINING DOCUMENTS .......................................................................................... 34

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 4 of 36

7.3 8.

PROGRESS REPORTING ......................................................................................... 34

SHIPMENT AND FIELD SERVICES......................................................................................... 35 8.1 8.2 8.3 PACKAGING .............................................................................................................. 35 STORAGE .................................................................................................................. 35 TRANSPORTATION AND HANDLING ..................................................................... 35

9.

APPENDICES ........................................................................................................................... 36 APPENDIX C3: APPENDIX C6: APPENDIX E1: APPENDIX E4: APPENDIX E4: SPECIFIC INSPECTION AND TEST REQUIREMENTS ............................ 37 APPLICABLE PROJECT REQUIREMENTS .............................................. 40 VENDOR DOCUMENT REGISTER LIST .................................................... 41 RECOMMENDED INSTRUMENT VENDOR LIST ...................................... 50 RECOMMENDED INSTRUMENT VENDOR LIST ...................................... 51

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 5 of 36

1.

1.1

INTRODUCTION

PROJECT BACKGROUND

Oil and Natural Gas Corporation (ONGC) are further developing the D1 Field located about 200 km to the west of Mumbai City, India in the Western Offshore area. This specification is applicable to the FPSO for the D1 Field Development Project.

1.2

OBJECTIVES

This specification defines the minimum requirements for the design, materials, fabrication / manufacturing, assembly, painting, inspection and testing, preparation for shipment and supply of the Instruments and Controls required for packaged units as per project requirements.

1.3

DEFINITIONS

The following words and expressions shall have the meanings hereby assigned to them except where the context otherwise requires. Company: PURCHASER: Bidder/VENDOR: Oil and Natural Gas Corporation (ONGC) Bumi Armada Berhad (BAB) Any potential VENDOR invited to submit technical and price proposals for the scope of work and services described in this specification.

1.4

ABBREVIATIONS

API ANSI ASME CCR ESD FAT FGS FRP HMI American Petroleum Institute American National Standards Institute American Society of Mechanical Engineers Central Control Room Emergency Shutdown System Factory Acceptance Test Fire and Gas System Fiberglass Reinforced Plastic Human Machine Interface

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 6 of 36

IP ICSS JB PCS PLC PSU RFI SAT SDV SIL UCP UPS USD UV /IR VHF VDU VFC VFD

Ingress Protection Integrated Control and Shutdown System Junction Box Process Control System Programmable Logic Controller

Power Supply Unit

Radio Frequency Interference Site Acceptance Test Shutdown Valve Safety Integrity Level Unit Control Panel Uninterruptible Power Supply Unit Shutdown Ultra Violet /Infra Red Very High Frequency Visual Display Unit Volt Free Contact Variable Frequency Drive

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 7 of 36

2.

2.1

SCOPE

GENERAL

The proposed Package shall fully comply with the applicable specifications, datasheets, drawings, national / international codes and standards. The VENDOR shall assume full responsibility for the performance of the Package. This shall include complete co-ordination between various sub-VENDORs responsible for design, fabrication, assembling, testing and shipping of the complete Package. All conflicts between the requirements of the relevant documents shall be referred to the PURCHASER for clarification. Any omissions from this specification of any item or items essential for the correct design and construction work shall be brought to the attention of the PURCHASER. All substitutions and deviations from this specification shall be highlighted by the VENDOR who shall notify the PURCHASER in writing of requested substitutions or deviations. VENDOR shall not proceed with any such substitution/deviation, installation or purchasing prior to receiving the PURCHASER's written approval. The VENDOR shall ensure that all design and construction work offered shall be acceptable to ABS and applicable codes and standards listed in this specification. VENDOR shall provide all drawings, certificates etc., necessary to obtain the above said certification as highlighted in the VDRL. VENDORs shall comply with the requirements of the relevant Standards and Codes.

2.2

SCOPE OF SUPPLY

The VENDOR shall supply the Instrumentation and Control System required for packaged units as per the datasheets supplied, complete with accessories to satisfy operational requirements under the conditions described in this specification. The VENDOR scope of supply shall also include the followings: Supply all special tools required for operation, configuration, commissioning, removal, installation and maintenance purposes. Commissioning and start-up spare parts. 2-years operation spare part list. Documentation in accordance with VDRL. Surface preparation and painting for offshore environment. Inspection and testing. Certification.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 8 of 36

Packing, preservation, preparation for shipment and shipment to the nominated fabrication yard.

2.3

TECHNICAL BID PROPOSAL SUBMISSION

Refer to requirements as specified in main equipment specification.

2.4

CONFLICTING REQUIREMENTS

In case of any inconsistencies or conflicting requirements between this specification and any other document forming part of subject Purchase order, the VENDOR shall indicate such to PURCHASER and shall obtain PURCHASER's written directive. VENDOR shall refer to main equipment specification document for details on order of precedence to be used.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 9 of 36

3.

3.1

DESIGN FEATURES

GENERAL

If the VENDOR considers any technical requirements stated in this specification to be detrimental to the performance or quality of the equipment specified he shall indicate this to PURCHASER's engineer and shall obtain written directive on how to proceed. Otherwise, he will be held fully liable for any consequence of not following such procedure.

3.2

CLASS APPROVAL/CERTIFICATION

It is VENDORs responsibility to submit the required design document to the CLASSIFICATION SOCIETY (in this case ABS) to obtain class approval/certification. The required design document which needs submission shall be in accordance to ABS Guidelines. VENDOR is also responsible to include all necessary Class Surveys and Inspections for their supplied equipment, including the Class certification.

3.3

CODES,STANDARDS AND FEDERAL REGULATIONS AND LAWS

It shall be VENDORs responsibility to become knowledgeable of the requirements of these Standards and Codes. Any changes or alterations to the equipment, to make the system to meet the requirements mentioned shall be at the expense of the VENDOR. The specified equipment shall fulfill the requirements of local and national regulations and codes applicable at the facility location. Furthermore, latest edition and all current amendments and addenda shall be used for all applicable Codes and Standards: Code/Standard

ABS

Title Guide for Building and Classing Floating Production Installations July 2009 Guide for Building and Classing Facilities on Offshore Installations January 2009

ASME B16.5 CENELEC / ATEX IEC 60079 IEC 60092 IEC 60331 IEC 60332

Pipe Flanges and Flanged Fittings EEx Certification for Electrical Protection Electrical Apparatus for Explosive Gas Atmospheres Electrical Installations on Ships Fire Resistant Characteristic of Electric Cable Test of Electric Cables under Fire Condition

IEC 61331-2 Controllers: Part-2: Equipment Requirements and Tests Programmable IEC 61000 Electromagnetic Compatibility (EMC)

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 10 of 36

Code/Standard IEC 61508 IEC 60529 IEC 60534-2 IEC 60536

Title Functional Safety Degrees of protection provided by enclosures (IP Code) Industry process control valves Classification of electrical and electronic equipment with regard to protection against electric shock Surge Protection Emergency and Standard Power Systems for Industrial and Commercial Application Guide for Surge Withstand Capability Tests Standard Digital Interface for Programmable Instrumentation Standard Codes, Formats, Protocols and Common Commands for Use with IEEEE std. 488.1-1987 Software Quality Assurance Plans Interface Between Data Communication Equipment Terminal Equipment and Data

IEEE-712 IEEE Std 446 IEEE Std 472 IEEE-488.1 IEEE-488.2 IEEE Std 730.1 RS-232C & RS-485

NACE MR0175 / ISO 15156 ISO 5167 ANSI / ISA S84.00.01.3

Material for use in H2S Containing Environments in Oil and Gas Production Measurement of Fluid Flow Functional Safety Safety Instrumented Systems for the Process Industry Sector

3.4

3.4.1

DESIGN CRITERIA

Design Life, Availability/Reliability

All equipment must be of proven design and suitable for operation in a marine environment and subject to the motion of the FPSO with a required design life of 15 years. In making the assessment of availability/reliability, the VENDOR shall submit the required spares holding in order to comply with the availability/reliability requirements specified.

3.4.2

Units of Measurement

Unless otherwise defined by the project requirements the following SI units of measurement shall be used: FLOW RATE Mass Liquid (Volume) Gas (Volume) LEVEL kg/h Bpd, m /h MMscfd 0 - 100 %, mm

3

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 11 of 36

PRESSURE

Normal

barg (gauge pressures) bara (absolute pressures)

Low, Differential VACUUM TEMPERATURE LENGTH VOLUME WEIGHT DENSITY HEAT / POWER VISCOSITY CONTENT COMBUSTION GAS DETECTION H2S GAS DETECTION CONDUCTIVITY

mbar bara (absolute pressures)

o

mm or m m

3

kg kg/m kW cP % Vol, % WT, % Mol, ppm % LEL ppm S/cm

3

3.4.3

Operating Conditions

All instrumentation and control systems, devices, sensors, valves, components, accessories, etc shall be designed for the site conditions defined in the Utility, Environmental and Metocean Data (refer document 21010-BAE-70000-PR-SP-0001).

3.4.4

Hazardous Area and Ingress Protection

Equipment, components, panels and enclosures will be selected to suit the hazardous area classification in which they are to be installed in accordance with the relevant IEC 60079 Standards. The process areas on the FPSO will be classified as Zone 2, Gas Group IIA, Temperature Class T3, unless specified otherwise. Hazardous area conformance certificates for electrical equipment will be produced from one of the following statutory bodies: ATEX BASEEFA KEMA, PTB etc conforming to CENELEC Standards

The equipment is to be installed in a harsh marine environment and shall have a minimum ingress protection rating of IP56.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 12 of 36

3.5

3.5.1

3.5.1.1

DESIGN FEATURES

General

Enclosure Generally all field instrumentation including solenoid valves installed in areas designated as hazardous shall be intrinsically safe (EExi) and be certified by a nationally recognized certification authority (e.g. ATEX). For special cases, as lack of availability, EExd Explosion-Proof type instrumentation can be considered. All external surfaces shall be suitably treated to provide anti-corrosion protection in a saline marine environment. All field instrument used for the ESD and FGS shall be minimum SIL-2 certified suitable for area classification. All equipment mounted in the field shall have an ingress protection rating of IP56 as a minimum. Additionally, all electronic equipment exposed to direct sunlight shall have protective sun shields / canopy. Where the design, enclosure, installation or protection of instruments in the package cannot meet stated site conditions, this shall be identified in the proposal to PURCHASER for review. In general, Control Panels/PLCs and programmable electronics shall be installed in a safe area, such as PURCHASERs instrument equipment room. The instrument equipment room is temperature and humidity controlled to ensure the equipment is operating well below its design temperature and humidity. Where VENDOR recommends these electronic systems and equipment to be installed at a suitable location on the package equipment skid, these electronic systems shall meet the hazardous area requirements as specified for the particular location. Alternatively, VENDOR may consider providing an enclosure/room that is certified as a safe area on the package equipment skid for these electronic systems. In addition, all equipment shall be marked legibly and indelibly with the following minimum particulars: Name and address of the manufacturer Designation of Series or Type Tag number Serial number Year of construction The specific marking of explosion (e.g. EExi, EExd) followed by the symbol of the Instrument and category The letter G (denoting explosive atmosphere caused by gases, vapours or mists) All information essential to their safe use.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 13 of 36

3.5.1.2

ATEX certificate identification

Connections Cable connections for locally mounted instruments, devices and Junction Boxes shall be with metric threads. Flange size, rating and facing shall be specified. Flange shall be in accordance with ASME B16.5 steel pipe flanges and flanged fittings standard. Pneumatic tubes for valve actuators shall be imperial (minimum 3/8 O.D., 0.049 inch thickness) 316L stainless steel tubes, and fittings shall be 316L stainless steel double compression type. VENDOR shall provide diaphragm seals for all process condition with waxy, dirty or high temperature service to ensure his supplied equipment/instruments/devices/valves etc meet the performance requirements specified for his package and guaranteed by him. However, where VENDOR deems that diaphragm seals are not required and standard process connections can be used, these process connections for instruments shall be O.D, 0.065 inch thickness tube. Tubing selection will be based on the process conditions (i.e. type of fluid, temperature and pressure). Generally, 316L SS (molybdenum content minimum 2.5%) to ASTM A268 will be used. Fittings and tubing used shall be Swagelok. VENDOR shall indicate in his bid the proposed make (manufacturer) he intends to use. Instruments used for process control shall not share the same tapping point as that used for shutdown purposes. This is to ensure that independent and discrete tapping points shall be used for instruments used in process control and those used for shutdown circuits.

3.5.1.3

Material of Construction Material of construction for instruments including all minor devices such as pneumatic filter/ regulators shall be consistent with temperature, pressure, corrosion conditions and suitable for installation ina salt laden marine environment. All instruments / components and tubing for process connections wetted by sour hydrocarbon liquid / gas shall conform to NACE MR-0175 latest edition. No asbestos products shall be used as material of construction for any parts or components. 316 SS (or higher grade SS) shall be used for components. If use of Aluminium is unavoidable, copper free, marine grade Aluminium with Epoxy coating may be acceptable. This will however require PURCHASERs written consent during pre-order phase.

3.5.1.4

Accessories An air filter/regulator with supply air gauge shall be provided for each locally mounted pneumatic actuated control valves. Instrument air manifold shall be tagged and installed in the skid as per VENDOR grouping with the isolation and drain valves.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 14 of 36

All differential pressure transmitters that do not utilize diaphragm seals shall be provided with integral five-valve manifolds with vent valves and drain valves. Pressure transmitters without diaphragm seals shall be provided with two-valve manifolds. According to process conditions, pulsation dampers may be required and if so, these shall be provided, made of 316 SS (unless specified otherwise) and having adjustable damping effect. 3.5.1.5 Instrument Utility PURCHASER will provide the instrument utilities as follows: Instrument power supply shall be Instrument Air supply (min/normal/max) 3.5.1.6 Instrument Cable and Cable Gland All cables supplied and used shall be suitable for installation in the environmental conditions as specified and referenced to herein, with ABS Class certification. All the instrumentation cables for monitoring and control and power cables shall be flame retardant and comply with IEC 60332-1. All the instrumentation cables used for critical services, including ESD and Fire & Gas applications shall be fire resistant and comply with IEC 60331. All multipair/ multicore / triad cables shall have minimum spare of 20%. Armored / braided cable shall be used in all external areas and unarmoured cables may be used within instrument equipment room and control room. All cable entries / exits to the control room shall be via Multi Cable Transit (MCT) blocks, suitably rated for the fire rating of the control room. Any cable with its origin and destination within the same area and which is run wholly within that area is to be installed and terminated. No cables are to be partly installed and coiled for completion at the PURCHASERs yard unless by prior agreement with the PURCHASER. As far as practical, all cables shall be installed on cable trays/ladders. All the cables shall be properly secured with PVC-coated stainless steel cable ties. All installed cables shall be protected from damage from moving or falling objects during package load out. External sheath of intrinsically-safe (IS) cables shall be light-blue in color and non-IS shall be grey. All the cable glands shall be dual certified, EExe and EExdand shall be weather proof to IP56. All the cable glands shall be nickel plated brass type and thread shall be as per ISO (metric threads). All the terminations shall be made with compression (crimped) type cable lugs. All cables shall be clearly tagged at both ends as per PURCHASERs tagging philosophy using stainless steel tags. All transit frames shall be completely blocked prior to transport to PURCHASERs yard even if there is a requirement to add further cables offshore. Cables shall be marked either side of each transit as defined in the relevant clause of this specification. : 220 VAC, 50 Hz : 5 barg/ 7 barg/ 10 barg

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 15 of 36

3.5.1.7

Junction Boxes All instruments shall be cabled to junction boxes located on the module skid edge. Segregation shall be provided for PCS, ESD and F&G. Further, these shall be segregated between Analog and Digital signals as well as IS and non-IS signals. All junction boxes shall be suitably rated for the circuits they contain. Cable Junction boxes shall primarily be via the bottom gland plate. Side entry considered for single pair/triad cable. However, cables shall not enter the through the top. Blanking Plugs shall be fitted in all unused entries as well gland. entry into the may also be Junction Box as a breather

Junction boxes shall be designed with sufficient space for installation and termination of all expected cables and allotted future spares for ease of maintenance. All junction boxes shall be clearly labelled and tagged. Each box shall be certified according to the hazardous area requirements and achieve a minimum Ingress Protection of IP56 in accordance with IEC 60529 as stated below. Hazardous areas Safe areas 3.5.1.8 EEx e or EExd EEx e

Cable / Ladder Trays All cable ladders and trays shall be made of 316L SS / FRP type. Cable trays shall be of perforated type. The trays and ladders shall be routed such that they are accessible for easy removal/replacement/re-routing of cables. All the cable trays and ladders shall have 20% spare capacity for future cables and shall be provided with top ventilated cover for the mechanical protection.

3.5.1.9

Instrument Earthing The general principles applying to system bonding/earthing are as follows: Metallic enclosures, gland plates and cable glands shall have earth continuity by physical connection to the local structure to ensure a common potential. Cable screens shall be continuous from the field device to the panel/cabinet terminations and earthed at one point only, within the relevant panel/cabinet. Screens shall be pin crimped prior to termination. For safety earthing requirements the cable armour or braid will be bonded to the platform Protective Earth (PE) system at both ends via the cable glands. Instrument Earth and Intrinsically Safe Earth busbars in panels/cabinets shall be copper, minimum 6mm thick, 50mm wide and length to suit requirements. The busbars shall be insulated from metal by 25mm minimum. Metal cases of field devices shall be connected to Protective Earth (PE) via the device cable gland, cable armour and cable gland at intermediate field junction box, or remote I/O cabinet

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 16 of 36

or outstation as applicable, to a welded earth boss located near the field junction box (or remote I/O cabinet or outstation). Protective Earth (PE) A 12mm stud bolt shall be provided in each panel, cubicle and intermediate junction box or remote I/O cabinet or outstation. These stud bolts shall be employed to earth bond each of the above equipment to the nearest steel structure using cable of a minimum size of 10 mm2 cross-sectional area. Multiple use of stud bolts for earth bonding shall be minimised. The protective earth point ensures reliable earthing independent from the effects of corrosion and contamination likely to be experienced if reliance were to be placed upon enclosure fittings, supports and holding bolts. All earth bosses shall be welded to the structure, as close to the equipment as practical, during fabrication and not offshore. Where practicable, internal mounted equipment shall be bolted connections with lock nuts. In the case of hinged doors, chassis holding power supplies and other non-bolted connections earth straps of minimum 2.5mm2 cross-sectional area shall be connected from the equipment to the cabinet PE. All external earth bolts, nuts and washers shall be manufactured from 316 Stainless Steel or Marine Quality Brass. Protective earth cables shall have an outer sheath colored green with a yellow stripe. Instrument Earth (IE) The Instrument Earth (Clean) provides a separate means of earthing all non-intrinsically safe instrumentation system cable screens ensuring a common potential reference point earth bonded at a single location. At intermediate junction boxes overall cable screens shall be isolated from earth and connected through, the intention being that the screens shall be electrically continuous from the field device to the Instrument Earth terminal of destination equipment such as System Cabinets and telecom termination facilities. This shall be achieved by use of separate terminals or isolated earth bars for screens that will facilitate grouping of device cable field screens onto the outgoing multicore screen. The overall screen of field device signal cables (multicore or single) for non-IS signals shall be individually terminated at the System Cabinet and taken to its Instrument Earth busbar. For field devices associated with local panels the overall screen of cables shall be terminated at the IE bar of the associated local panel. Intrinsically Safe Earth (ISE) As mentioned in section 5.2, the preferred method of protection for all instrumentation including field devices shall be intrinsically safe IS (EEx-i) type devices. However, Eex-d type devices may be used subject to Company approval. The Intrinsically Safe Earth provides a separate means of earthing shunt diode safety barriers, which require high integrity earth connections to divert fault currents. Shunt diode

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 17 of 36

safety barriers will be used in Instrument Systems only where use of galvanic isolator type of safety barriers, which do not require high integrity earth for operation, is not feasible. The IS earth system ensures that the integrity of the IS earth is maintained in the event of a power supply fault. Isolation and termination of IS field cable screens at field devices, junction boxes and cabinets shall be done in the same manner as for the Instrument Earth explained above. However the overall screen of field device signal cables for IS signals shall be terminated individually at the System Cabinet and taken to its IS Earth bar. For field devices associated with local panels the overall screen of cables shall be terminated at the IS Earth bar of the associated local panel.

3.5.2

Field Instrumentations

VENDOR shall refer to Appendix E4 for list of recommended instrument make/manufacturers.

3.5.2.1

Pressure Instrumentation Pressure Gauge Pressure gauges sensing element shall be generally bourdon type. Diaphragm seal type pressure gauges shall be used, where the process services requires. Pressure gauges shall be weather resistant to IP56 (minimum) with minimum dial size of 100 mm. Accuracy of the offered Pressure and differential pressure gauges shall be +/-0.5% of full scale for gauges without diaphragm seals. For gauges with diaphragm seals, accuracy shall be +/-1% of full scale. The process connection for the pressure gauge shall be NPT (M) located at bottom. Pressure gauges shall have over range and blow out protection where required. Gauges shall be of the solid front design furnished with blowout back or blowout disc protection and shatter-proof front glass. The measuring range of pressure gauges shall be selected so that the operating pressure shall be between 33% and 66% of the full scale. Pressure gauges sensing element and movement shall be as specified in data sheet suitable for process conditions and minimum of SS 316 (NACE MR-0175 compliant). The case shall be minimum of stainless steel. In the selection of material for wetted parts, compatibility with process fluids shall be the primary selection criteria. Pressure / Differential Pressure Transmitter Transmitters shall be SMART type with two wires, 4-20mA output with HART protocol facility. Accuracy shall be equal to or better than 0.1% of span.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 18 of 36

Transmitters wetted part shall be as specified in data sheet and shall be suitable for process conditions and minimum of SS 316 (NACE MR-0175 compliant). Diaphragm seals shall be used where required by the process service conditions. Instruments cable entry shall be M20. All electric connections shall be carried out through certified terminal blocks within a certified terminal box furnished as part of the transmitter. The process connections for pressure transmitters shall be NPT, with five-valve or twovalve manifold as required. In the case of diaphragm seal type pressure transmitter, the process connection shall be 2 flange. All the field-mounted transmitters shall be furnished with a mounting bracket for a 2 pipe yoke. VENDOR shall supply canopy / Sunshade for all the field transmitters.

3.5.2.2

Level Instruments Level Gauge Level gauges shall in general be of the magnetic float type. Where VENDOR is able to recommend a gauge which is better suited to the process conditions as specified, he shall notify PURCHASER in writing. Gauge assemblies shall have minimum design pressure and temperature equal to the design pressure of the corresponding Vessel. Process connection between vessel and level gauge chamber shall be 2 inch flange. Heat tracing shall be provided on the chamber of level gauges where required by the the process service conditions. All the gauges shall be supplied with the inch NPT vent and drain connection with SS 316 ball valve and plug. Level Transmitter Level transmitters used for remote monitoring and control applications shall be based on process applications. Level transmitters may be of the ultrasonic, guided wave radar, magnetostrictive or differential pressure type. All the transmitters shall be SMART type with two wires, 4-20mA output with HART protocol facility. Accuracy shall be equal to or better than 0.2% of span. DP type level transmitter shall have accuracy equal to or better than 0.1% span. If top mount level instrumentation is to be used then the flange size shall be 4 inch flange minimum. The correct selection of the level instruments is essential to ensure control of levels within the vessels, operating under severe motion characteristics. A selection process as to the most suitable level instrument will be completed by the Packaged Equipment VENDOR during design stage.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 19 of 36

3.5.2.3

Flow Instruments Flow Element (Orifice plate) Primary element for flow measurement shall normally be done with square edged concentric orifice plate mounted between a pair of weld neck flanges with flange taps. The orifice flanges shall be as per the Piping Class Specification and in accordance with ANSI/ASME B 16.36. Two pairs of diametrically opposite inch flange taps shall be provided. Turbine Type Turbine type meters shall be either flow meters forming part of the process pipe flanged (pipe spool) for apparatus sized up to 4" or Insertion type flow meters for pipe size larger than 4". Meters should be hydro-dynamically balanced so that the rotor rotates freely on its bearings during operation. Electrical pick-up coils shall be fully encapsulated. Electrical connection entry shall be M20 thread. Accuracy shall be 0.5 % of maximum flow. Meters shall be provided with a two wire SMART transmitter with a 4-20mA output and HART protocol facility. Heat tracing shall be provided as required by the the process service conditions. Ultrasonic Flow Meters Ultrasonic flow meters based on the time-of-flight or transit-time method shall be used. Meters based on the Doppler principle shall not be used. Transit-time ultrasonic flow meters are designed to be used for clean liquids or gases and steam. They should not be used for fluids containing solid particles in liquid or gas measurements or gas entrainment in liquid measurements. Dual beam meters with symmetrical parallel beams, located at a distance of radius from the centre line, are less sensitive to velocity profile variations and should be used by preference. Meters shall be provided with a two wire SMART transmitter with a 4-20mA output and HART protocol facility. Heat tracing shall be provided as required by the the process service conditions. Electromagnetic Flow Meters Electromagnetic flow meters require a process liquid with a minimum conductivity. Neither graphite nor spiral wound metal gaskets shall be allowed for magnetic flow meters. Short spool pieces may be installed upstream and downstream of the meter to protect the liner during removal from the pipe (the meter and the spool pieces can then be removed together).

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 20 of 36

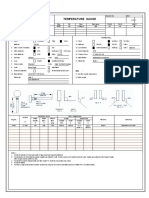

Meters shall be provided with a two wire SMART transmitter with a 4-20mA output with HART protocol facility. Heat tracing shall be provided as required by the the process service conditions. 3.5.2.4 Temperature Instruments Thermowell All the temperature instruments shall be installed with thermowells. All the thermowells shall be 2 flanged connection. Wake frequency/vibration calculation as per ASME PTC 19.3 shall be carried out for all thermowells. Thermowell material shall be 316 SS unless specified otherwise. Temperature Gauge Temperature gauges shall be Bimetallic type and be of any angle type with a view to rotate the gauge to facilitate viewing from the desired angle. Temperature gauges shall be weather proof with minimum dial size of 100mm and shall have features like screwed bezels. Temperature gauges shall be constructed with SS 316 casing. Temperature Element RTD shall be as per DIN 43760 and shall be PT-100 three wires type.

Temperature Transmitter Temperature transmitters shall be used for all remote monitoring and control. The transmitters shall be either remote or head mounted type (where the location of temperature sensor is in approachable and is in a safe location). Temperature transmitters shall be SMART type with two wire, 4-20mA output and HART protocol facility. Accuracy shall be equal to better than 0.1% of span. Cable entry shall be M20. All the remote mounted transmitters shall be furnished with a mounting bracket for a 2 pipe yoke and sunshade. 3.5.2.5 Control Valves Control valves for throttling service shall be normally Globe type. Other types like butterfly, ball valves etc. shall be selected as per service and as indicated in the P&ID. Control valve sizing documentation, face to face dimensions, Inherent Flow characteristics, rangeability, Noise calculations etc. shall be generally as per ISA S 75. All the valves shall be flanged end type. Minimum body and flange rating, body material of control valves etc. shall be as per piping class.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 21 of 36

Equal percentage or linear trim characteristics shall be used normally and the individual valve characteristics shall be decided based on Process requirements. Material used for trim shall be as specified in the data sheet and shall be suitable for process conditions and minimum of SS 316. Valve seat leakage shall be as per ANSI / FCI 70-2 and the leak tightness requirements for each valve shall be considered on a case by case basis as per the process requirements subject to a minimum leakage classification of Class IV. Control valves for each process case, control shall be performed between 10% and 90% of valve opening. Control Valve noise level shall be limited to 85 dBA at 1 meter distance from the valve. Vibration, hydrodynamic and aerodynamic Noise calculations shall be carried out for each valve and suitable measures like noise-reducing trims shall be selected if found required. Control valve shall be designed for expected turndown condition. Where this is not practicable with single valve, an additional small bypass control valve sized for turndown volume shall be supplied. Also all control valves shall be supplied with the isolation valves for maintenance purpose. Control valve actuators shall be pneumatic operated diaphragm type or pneumatic double acting piston type and shall be factory assembled and tested with valve positioner, and air set (filter regulator and pressure gauge). Actuator sizing shall be carried out to ensure that the actuator / positioner combination can open as well as close and reseat the valve with adequate speed of response and repeatability and without sacrificing control loop performance. Air failure position (open/close/stay-put) shall be as indicated in the P&ID and datasheets. Control valves shall be provided complete with electro-pneumatic positioners, air sets and mechanical valve positioner indicators. Mechanical positioner indicators shall be directly connected to stem or shaft. Valve position shall be indicated on a reversible scale with clearly graduated markings at 25% valve opening position intervals. The electro-pneumatic positioners shall be certified for the hazardous area as applicable. The control valves shall be completed with handwheel, when no by-pass group is provided. The handwheel shall be preferably of the lateral permanently installed type, with the control independent from the spring of the actuator. 3.5.2.6 Regulators Special consideration shall be given to the ratings of the downstream section of regulators with respect to the maximum upstream shut in pressure based on the assumption that the regulators may leak. Self-actuating regulators shall be considered for services such as starting gas or air, blanket gas, individual engine fuel-gas and other applications with the following characteristics: The set point is changed infrequently Proportional only control is not an impediment to effective process control

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 22 of 36

The application is at a remote location where air is not available for control valve operation.

3.5.2.7

Shutdown/Blowdown Valves Ball valves shall be used for SDV/BDV application. Valves installed in lines subject to scrapping / pigging operations shall be Full Bore type. Valves shall be in accordance with the relevant piping specification and shall be fire rated as per API STD 6FA. Leakage class of all shut down and blow down valves shall be tight shut off Class V1. Spring return actuator shall be used to actuate the SDV valves and shall be designed for the fail-safe operation. Valve failure position shall be as per the P&ID. The valve stroking speed of 1 second per inch of NPS shall be considered. The valves shall be furnished with a local mechanical position indicator and open / close limit switches for remote indication. Actuator shall be suitable for quick closing / opening of SDV valves as per shutdown philosophy and specifically, as defined in the valve datasheets. Actuator sizing shall be based on the minimum available air supply pressure as indicated in the data sheets. Actuator sizing shall take into consideration the valve torque at maximum differential pressure across a fully closed valve, with a safety margin of 1.5 times the required torque. All control circuitry associated with the operation of the SDV (Operating elements for Opening and closing the Valve, Solenoid valve, Quick Exhaust valve if required for faster closing time, air supply regulator, air supply to the pneumatic actuator etc.), shall be mounted on the valve actuator. Air filter regulator shall be provided for all shutdown valves with pressure gauge to indicate output.

3.5.2.8

Solenoid Valves SDV solenoid valves shall be interfaced with the ESD system. The SDV solenoid valves shall be EExi certified and minimum ingress protection of IP56 suitable for the Hazardous area classification of the intended location. Solenoid valve coil shall be rated 24 VDC for continuous operation under the site condition as specified. Coils shall be capable of permanent energisation at the maximum specified solar radiation temperature, unless specified with permanent attached sunscreen. Solenoid valve body and trim material shall be of 316L stainless steel. Solenoid valve coils shall be fitted with a suppression diode by the VENDOR. The polarity of connection terminals shall be indelibly marked inside the termination enclosure. Solenoid valve coils shall be low powered type. Solenoid valve shall be Automatic reset, 3/2-way universal type. The pneumatic ports of solenoid valves shall automatically change over when the solenoid valve coil is de-energised. The pneumatic ports shall return to their normal position only on coincident presence of rated supply voltage at the coil.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 23 of 36

Solenoid valves shall be designed for direct operation of their pneumatic ports in response to their coil voltage. Use of pneumatic pilot assistance for main port operation is not permitted. 3.5.2.9 Limit Switches Limit switches shall be suitable for mounting on the valve actuator and must not be affected mechanically or functionally by any vibration. Limit switches shall be non-mechanical, magnetic proximity type hermetically sealed, single pole double throw (SPDT) changeover switches, preferably certified intrinsically safe. Switches to operate within the first 4% of valve travel. The number of limit switches required per valve is as specified on individual valve data sheets. The open/close limit switches shall be enclosed in a switch box with a minimum ingress protection of IP 56, EExi certified for use in Zone 2, Gas Group IIA/B, Temperature Class T3.The switch box shall suitable for the hazardous area it is to be installed in and provided with ISO M20 cable entries. 3.5.2.10 Safety Relief Valve The Safety Relief Valve type shall be either Conventional (Constant backpressure, Built up backpressure less than or equal 10% of set pressure @ 10% overpressure). Balanced Bellows (if total backpressure (superimposed + builtup) is more than 10% of set pressure and does not exceed approx 50% of set pressure), Pilot Operated shall be used for vapour and gas service applications where the margin between the maximum operating pressure and the set pressure is less than 10% of the set pressure. Accessories like back- flow preventer (for high back pressure, vacuum service), field test connection and filter shall be considered as per project specifications. The safety relief valve body material shall be as per piping material specification. The Safety Relief Valve shall be designed as per Design Standard: API RP 520, API Std 521,526,527,ASME SEC VIII (Vessels), SEC I (Boilers).Seat leakage testing shall be in accordance with API Std 527.Noise calculation shall be as per API Std 521. The Safety Relief Valve sizing Basis shall be either of as below: Blocked Outlet / Control Valve failure/ Power failure: ASME SEC VIII Fire Case: As per API Std 521 Thermal Expansion as per ASME SEC VIII.

Sizing basis for two phase applications API 520 Appendix D, OMEGA METHOD. Two phases density shall be specified in the datasheet. Safety Relief Valve shall be sized in accordance with API RP 520. The standard effective orifice size shall be selected in accordance with API Std 526.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 24 of 36

Bonnet shall be Open Bonnet type for steam service applications. Environmental conditions (corrosive) shall be considered while selecting open bonnet. Close Bonnet shall be selected for all applications except for Steam. Lifting Levers and Test gag shall be according to ASME requirements and per application requirements. All Safety Relief Valves shall be flanged connection as per Piping Material Specification. The design of the pressure-relieving device shall be such that no liquid can collect on the discharge side of the device. If the design of pressure relieving device is such that liquid can collect on the discharge side of the relief valve, the valve must be fitted with a drain where liquid can collect and be self-draining. Safety Relief Valve intended for hydrocarbon (liquid/gas) service shall have wetted parts conforming to NACE MR-0175. Full nozzles shall be provided for valve of sizes 1 and larger. For ASME coded safety valves Stamping shall be done by National board UV stamp identifies ASME VIII Valve for pressure vessel applications

3.5.3

3.5.3.1

Fire and Gas System Devices

Gas Detectors The gas detection shall provide early warning of an outbreak of gas release in an area, and the indication of the status and control actions to confine the gas release and reduce the probability of escalation of the hazard. Point Type

On the facility, IR point type gas detector are utilised in enclosed area to detect potential ingress of gas and to protect non-certified electrical equipment by isolating it electrically. The set points for point detectors (for hydrocarbon gas) are as follows: HIGH at 20% LEL, HIGH HIGH at 60% LEL. Gas detectors shall be certified flameproof for use in classified areas as specified in the datasheets and the area class where these detectors are to be installed. Beam Type

Beam type IR gas detector shall be used in open area where possible leakage of gas exists. For open path sensors, particular care must be given to minimising contamination of the optics. Sensors are to be a type that immune to the effects of welding arcs and sunlight. The affect of sea mist, fog, rain and radiation from the flares need to be considered during installation. 3.5.3.2 Flame Detectors Infra Red (IR) Triple spectra band type flame detectors shall be used for the facility.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 25 of 36

Flame detectors are located at the corners of the process area so that most equipment shall be within their 'sight'. Additional flame detectors are provided, if there is an obstruction that conceals other equipment from the flame detectors' vision range.

3.5.4

3.5.4.1

Control, Shutdown and Safety System

Control System Requirement General The VENDOR shall supply Unit Control System Panel (UCP) with Programmable Logic Controller (PLC) complete with HMI for operation maintenance and trouble shooting of the package as specified in the technical specification. VENDOR shall utilize either Allen-Bradley or Siemens make of PLCs. The UCP shall generally be located in the instrument equipment room, which is a designated Safe Area. The UCP shall provide stand-alone equipment monitoring and controls. The UCP shall provide stand-alone equipment monitoring and control Additionally, the UCP is responsible for the control of ancillaries common to the package (e.g. lube oil systems, seal gas systems, etc.). In the case where the control panel is located on the skid, these Local Control Panels shall be certified and be suitable for installation in the designated hazardous area. The UCP shall interface with the topsides ICSS system and the signals and controls required to be interface to the ICSS will be defined during detail design. The control systems provided shall be for optimum control and provide safe equipment operation and shutdown. The VENDOR shall also supply all instruments in the package, the hook-up materials, and all the other interconnection materials up to and including the junction boxes on the skid edge. All equipment supplied shall be to recognised international standards and is subject to classification and certification by ABS. The VENDOR shall ensure all requirements for Controls and Instrumentation as per outlined in API Standard 612 are adhered to. All materials and labour necessary as a minimum to furnish a complete and operational UCP as described as follows shall be provided. Enclosure The UCP enclosure shall contain all terminals necessary to terminate all field devices, interconnect cabling and power receptacle. As a minimum, at least 20 % terminals are required for spares. Field mounted UCP enclosure shall be suitable for installation in Zone 2, Gas Group IIA/B, Temperature Class T3 in accordance with IEC 60079 and shall be weather proof to IP 56 as a minimum. Equipment shall be provided with supports of sufficient strength to permit safe hoisting, location of lifting points shall be clearly shown on the VENDORs drawings. Equipment

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 26 of 36

The Human Machine Interface (HMI) is to be used for local start-up, monitoring and control on the package equipment as well as for maintenance and trouble shooting of the package. VENDOR is to propose suitable HMI for the UCP. It is preferred that the HMI is a touchscreen type, mounted on the UCP cabinet door with a sunshade for outdoor installation. Where the UCP is not installed on-skid and is instead mounted in theinstrument equipment room, it shall be supplied as a free-issue to the PURCHASER for installation in the instrument equipment room. All the cabling in the skid limit shall be completed fully and loop tested (Cold / Hot loop) before delivery by VENDOR. Programmable Logic Controller (PLC) The VENDOR shall be responsible to integrate all control, sequencing and protection with a single open architecture platform PLC. The PLC shall, as a minimum, be SIL-2 certified for the ESD functionality, including occurrence of a confirmed fire. Separate dedicated controllers are not preferable. The preferred platform shall be an advanced programmable logic controller capable of executing ladder logic for sequencing and protection and capable of handling a high level programming language such as C for the implementation of the control algorithms. The PLC shall provide control/data link communications/interface with the ICSS which is the main control system on the facility. Data transfer between the ICSS and UCP shall be achieved via serial link RS-485 MODBUS RTU protocol. The UCP will have a facility for automatic synchronization to the ICSS master clock. The ICSS is located in the instrument equipment room while the ICSS Operator Work Station (OWS) are located in the Central Control Room (CCR), situated within the accommodation block. The ICSS will be configured to enable full remote control and monitoring of the system by interfacing with the package UCP. Power supply shall be powered from single phase 220VAC, 60 Hz UPS. VENDOR to state power consumption requirements with the bid. The control system shall undergo an FAT (witnessed by PURCHASER) prior to acceptance. VENDOR shall conduct training for the PURCHASERs team members at site/ office. Software The operating system software shall be Microsoft Windows based. PLC software to permit review and editing of the PLC programming is to be provided by the VENDOR. This is to incorporate a password protection system to limit access to users. VENDOR is to supply all software and licenses as required. 3.5.4.2 Shutdown and Safety System Requirements Each package shall have Emergency Shutdown Valves (SDVs) for emergency shutdown. Remote Start/Stop of the package is via ICSS to the UCP.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 27 of 36

Emergency shutdown signals from ESD shall be hard-wired to the UCP.

3.6

3.6.1

DESIGNATION AND NAME PLATES

Designation

The equipment and components are designated according to the PURCHASERs systems and equipment numbering and tagging. VENDOR shall follow PURCHASERs Guidelines for Equipment Numbering.

3.6.2

Name Plates

All field mounted instruments shall have 316 stainless steel nameplates riveted to the instrument. All instruments shall be provided with manufacturers' standard corrosion resistant nameplate showing, Manufacturer Name, Tag No., Serial No., Model No. etc. In addition, all field mounted instruments / devices shall have white / black & white traffolyte label mounted visible adjacent to instrument or device stating tag no. and service. This label shall stay in place even when the instrument / device removed for maintenance. Nameplates for instruments used for ESD application shall be white letters on red background. Nameplates shall be installed on all instruments and their supports using stainless steel plates and screws. Where screws cannot be used, other suitable methods shall be used with prior approval of the PURCHASER representative. Panel mounted instruments and panels shall also have nameplates on the front of the panel with white labels and black text. The nameplates shall be fixed to the front and rear of the panel using stainless steel screws. They shall contain the tag number and the service written in English. Dymo tape or equivalent is not allowed. Terminations of electric conductors or pneumatic tubes (signals, power supply, etc.) shall be provided with appropriate numbered tags.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 28 of 36

4.

4.1

GUARANTEES

EQUIPMENT PERFORMANCE

VENDOR shall verify the performance of all supplied instrumentation systems, devices valves, accessories, etc that are provided as part of the package equipment. Individual performance test reports shall also be submitted for PURCHASERs approval. If the performance of the supplied instrumentation systems, devices valves, accessories, etc cannot meet the requirements of this specification, the VENDOR shall make good, repair or replace the defective items.

4.2

PERFORMANCE GUARANTEES

The VENDOR shall guarantee the performance of all the supplied instrumentation systems, devices valves, including all the accessories necessary to meet the requirements defined in this functional specification. The performance of all the supplied instrumentation systems, devices valves, accessories, etc under all operating conditions shall be the responsibility of the VENDOR. The VENDOR shall guarantee that the supplied instrumentation systems, devices, valves and accessories are designed to meet the performance as stipulated by the requirements in this functional specification. All items shall function safely at their design capacities.

4.3

WARRANTY

The warranty period for the equipment/instrument is to be 12 months from successful test run or 18 months from delivery, whichever is earlier. The VENDOR shall, with all possible speed and without cost to the PURCHASER, repair or replace the goods or any part thereof found to be defective due to faulty material, workmanship or design or due to any act or omission of the VENDOR and in these circumstances the VENDORs warranty shall apply to any goods which have been repaired or replaced. The VENDOR shall be responsible for the prepayment of all transportation and other costs incurred by the PURCHASER in effecting such repair or replacement at the point of use. If the good are subject to any other warranty or guarantee, the VENDOR shall extend the benefit of said warranty or guarantee to PURCHASER. The VENDOR warrants that the goods supplied shall hereunder be new, fit and sufficient for the purpose intended, and they will conform to the specifications, drawings or samples furnished or adopted by PURCHASER and will be of satisfactory quality and free from defects in design, material and workmanship. The VENDOR shall assume single point of responsibility for all aspect of the work. This shall include timely completion, liaison with PURCHASER, liaison with any VENDOR or sub-

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 29 of 36

VENDOR/manufacturer of specialised items, coordination of the work for the said equipment/ instrument. Where parts of the equipment/instrument are subcontracted and purchased by the VENDOR, these become part of the VENDOR package.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 30 of 36

5.

QUALITY AND ENVIRONMENTAL MANAGEMENT, INSPECTIONS AND TESTS

QUALITY AND ENVIRONMENTAL MANAGEMENT REQUIREMENTS

Responsibility for Quality, Environmental Compatibility and Their Management

The VENDOR is held solely and fully responsible for the quality and the environmental compatibility of his supply and services.

5.1

5.1.1

5.1.2

Conformance to ISO Standards

As part of PURCHASER's Quality and Environmental Management programs, PURCHASER expects the VENDOR's Environmental Management System/Program as far as applicable for this supply to conform to the Standard ISO 14001 and his Quality System/Program to conform to the Standard ISO 9001

5.2

INSPECTION AND TESTS

The VENDOR shall prepare an Inspection and Testing Plan (ITP). The ITP shall be discussed and agreed before placement of any Purchase Order (PO). Inspection and Test Plan shall cover design, purchasing of materials, fabrication, inspection and testing of all instruments, devices, valves and accessories that form his scope of supply. All HOLD points during the manufacturing and fabrication program shall be agreed to, by mutual consent before placement of PO. Inspection by PURCHASER or his representatives shall in no way relieve the VENDOR of any of his responsibilities in ensuring that the equipment meets all the requirements and conforms in full, to the contents of this specification. The VENDOR shall advise the PURCHASER with at least fourteen (14) days notice of the date and location, for, as a minimum, the following points: Key production, inspection or testing activities (as identified in the ITP) will occur The equipment ready for final inspection

The VENDOR shall give the PURCHASER or his representatives, without charge, all facilities and access for satisfying himself that the equipment is being manufactured in accordance with the relevant data sheets, drawings, codes and standards. Any manufactured part which does not comply with the requirements or material which shows defects during inspection will be rejected. When a part of the unit is rejected, the VENDOR shall be notified in writing. If any rectification work is required to be done, it shall be carried out by the VENDOR at his own expense and without delay to the work. PURCHASERs

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 31 of 36

inspector shall have the right to request additional inspection or examinations, if required, to ensure that the equipment complies with the relevant codes and standards. These inspections will be to the PURCHASERs account, unless such examination reveals defects not previously detected, in which case the VENDOR shall bear the full cost of the inspection, repairs and subsequent examinations necessary to ensure the satisfactory manufacturing/installation of the equipment. The VENDOR shall submit a detailed ITP for PURCHASERs approval soon after the order placement. All testing procedures shall clearly specify method of testing and acceptance criteria. All testing shall be done using certified test equipment that has been approved by a recognised testing and certifying authority, and which has been calibrated / checked prior to the test. The calibration records shall be furnished to the PURCHASER for review/approval. Detailed testing procedure shall be submitted after order placement for PURCHASERs approval.

5.2.1

Extent of Testing and Inspection

After erection and completion of instrument and control system installation and connections, pre-delivery tests shall be made by the VENDOR and witnessed by PURCHASER to prove general conformity to applicable Regulations and Codes of Practice as defined in Section 3.0 of this specification. A comprehensive FAT procedure shall be provided for PURCHASERs approval and submitted as per the VENDOR Data Requirement List (VDRL) attached. All damage to the finish of steel work, including that caused by cutting or drilling is to be made good, prior to load out. VENDOR shall provide, at his expense, all appliances, instruments, labour and other facilities, required for pre-delivery and tests (this shall include supply of electrical isolation padlocks/keys and key safes) and shall perform the work as required by the PURCHASER. The following is a guide to inspection and testing required at the onshore location: Inspection of equipment and installation to check for mechanical integrity Inspection of equipment and installation to check for compliance with project documents, drawings, specifications, regulations and codes of practice UCP Control System and Logics Testing Verification of polarity and phase sequences Tests of continuity including point to point wiring checks( Hot & Cold Loop checking) Insulation resistance tests (Megger testing) Tests of effectiveness of earthing

The activities specified herein do not preclude the necessity for further inspection and testing to suit individual features or VENDOR's instructions and equipment.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 32 of 36

VENDOR shall be responsible for taking all necessary safety precautions, the replacing of all equipment and sundries (e.g. fuses damaged during testing) and the maintenance and preservation of the installation until taken over by PURCHASER. Upon delivery of equipment to the fabrication yard, a comprehensive Site Acceptance Test (SAT) will be performed for the integration of the supplied equipment with the ICSS system of the FPSO. A comprehensive SAT procedure shall be provided for PURCHASERs approval and submitted as per the VENDOR Data Requirement List (VDRL) as attached.

5.2.2

Test Reports

All tests made on instrumentation and control devices shall be entered on VENDOR furnished forms and shall show the following: Identity of instrument/device/system Date of test, time of test, for outdoor test indicate approximate ambient temperature and per cent relative humidity Test equipment utilised Basis/standard/specification used for the test Test results Any corrective action taken to make equipment pass test For faulty equipment, statement as to what is required, when and how it will be corrected or completed, shall be made before it is energised or placed in service Name of person or persons making test, approval signatures PURCHASERs approval

Test results shall be given to the PURCHASER immediately after completion. Test reports shall be in line with the PURCHASERs standards.

5.2.3

"AS-BUILT" Drawings

VENDOR shall update all drawings to "as built" status at completion of fabrication.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 33 of 36

6.

PAINTING/COATING/PRESERVATION AND PROTECTION

The surfaces of all supplied instruments, valves, devices accessories, etc shall be protected against internal and external corrosion and/or erosion throughout their design life. The chosen surface preparation and coating system shall be suitable for the medium and offshore environmental condition where these items will be located. The minimum requirement of the Painting and Coating System shall be as specified and referenced in the main specification of the equipment in this requisition. Non-coated and machined surfaces that will be exposed to the atmosphere in transit and subsequent storage shall be preserved with an easily removable rust preventative. Exposed flanged connections shall be protected by either rigid covers or molded plastic covers not smaller than flange outside diameter. Exposed gasket surfaces, couplings, bearings, shafts, male threads, etc. shall be protected by plastic or other suitable cover. Female threads shall be closed with forged steel plugs.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 34 of 36

7.

7.1

DOCUMENTATION AND PROGRESS REPORTING

GENERAL

The VENDOR shall provide all documents according to the required amount and schedule to PURCHASER's engineer (as specified in Appendix E1). All documents provided by the VENDOR shall be in English and shall be provided according to the Appendix E1 as a minimum. Text documents are to be generated with PC based 'MICROSOFT WORD'. Engineering data lists/calculations prepared and provided by VENDOR or sent to VENDOR for completion shall be PC based 'MICROSOFT EXCEL. All documents shall be prepared, provided and turned over to PURCHASER as hard copies, soft copies in native format and PDF, as well as on commercial readily available magnetic data carrier (CD or DVD). Drawings have to be provided as hard copies, soft copies in native format and PDF. For all stage of submission, one Auto CAD compatible file format (.dwg or .dxf formats) shall be provided via email or data carrier. The filed drawing shall identify the program type/version and be of scale 1:1 and have a structure of layers agreed with PURCHASER.

7.2

TRAINING DOCUMENTS

The VENDOR's documentation shall be sufficient to provide any necessary training covering his scope of supply. If not, the VENDOR shall provide a separate Training Documentation, sufficient to provide any necessary training covering his scope of supply.

7.3

PROGRESS REPORTING

The contents of Engineering and Fabrication Schedule as well as Progress Reports to be provided by the VENDOR shall be agreed with PURCHASERs Engineers. If not specified elsewhere, progress reporting shall be submitted bi-weekly after award.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 35 of 36

8.

8.1

SHIPMENT AND FIELD SERVICES

PACKAGING

All parts shall be marked for identification and suitably preserved and packed according to PURCHASER approved packing, marking and material handling instructions. The VENDOR shall provide detailed shipping and handling instructions for all shipping units (boxes, containers, etc.) requiring any special attention, as e.g. lifting restrictions and/or requirement for securing of parts inside the shipping unit after customs checks. Such instructions shall be submitted to PURCHASER as part of the installation documentation. One additional copy shall be given to the shipping PURCHASER. Key requirements shall be marked legibly and permanently on the outside of the shipping unit itself.

8.2

STORAGE

If required the VENDOR shall provide temporary storage of the specified items to comply with the required shipment schedule. In addition, the VENDOR shall inform on the required storage conditions to be provided by PURCHASER, should the delivered items, after take-over by PURCHASER, have to be stored before, or after dismantling of the packaging.

8.3

TRANSPORTATION AND HANDLING

Unless otherwise specified, in general, all items will be delivered as specified and referenced in the main specification of the equipment in this requisition.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Page 36 of 36

9.

APPENDICES

Design Criteria (C) Appendix C3 Appendix C6 : : Specific Inspection and Test Requirements Applicable Project Requirements

Documentation (E) Appendix E1 Appendix E4 : : VENDOR Document Register List Recommended Instrument VENDOR List

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Appendix C3

APPENDIX C3:

SPECIFIC INSPECTION AND TEST REQUIREMENTS

INSPECTION AND TESTING PLAN FOR PRESSURE GAUGES

LINE ACTIVITIES VENDOR INSPECTION REVIEW OF DOCUMENT BY CLIENT/PURCHASER 1. 2. 3. 4. 5. 6. 7. 8. 9. Pre-Manufacturing Meeting Review of Approved Documentation QC System Manual Inspection and Test Plan (ITP) Design Calculation Weld Procedures Qualification Welder / Welding Operator Qualification Welding Repair Procedures Welding Inspection Welding Material Verification Joint preparation / Fit Up Visual & Dimensional (Weldments) 10. 11. 12. 13. 14. 15. NDE Examinations NDE Procedures NDE Personnel Qualification Records Material Test Report and Certificates Material Verification Mechanical and Special Tests on Materials 16. Component/ Parts Inspection Dimensional Examination 17. Assembly Inspection Visual/ Dimensional 18. Testing: a. b. c. c. Functional Test Seat Leakage Test Hydrostatic Test Instrument Calibration X X X X R R R R W X X R X X X X R R R R X X X X X X X R R R R R R WITNESS BY CLIENT/ PURCHASER REMARKS

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Appendix C3

INSPECTION AND TESTING PLAN FOR PRESSURE GAUGES

LINE ACTIVITIES VENDOR INSPECTION REVIEW OF DOCUMENT BY CLIENT/PURCHASER d. e. f. g. h. 19. 20. Tubing Air Leakage Tubing Continuity Test Cables Inspection Test Inter-wiring test Test Report/Tests Certificates X X X X X X X R R R R R R R WITNESS BY CLIENT/ PURCHASER REMARKS

Coating Procedure Surface Preparation / Primer Coat Coating Application

21.

VENDOR Marking/Project Tagging/Nameplates

22. 23. 24. 25. 26. 27.

Weight Check Lifting Arrangement Final Inspection Documentation (per VDRL) Preparation for Shipment Release for Shipment

X X X X X

R R W H

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Appendix C3

INSPECTION AND TESTING PLAN FOR PRESSURE GAUGES

LINE ACTIVITIES VENDOR INSPECTION REVIEW OF DOCUMENT BY CLIENT/PURCHASER WITNESS BY CLIENT/ PURCHASER REMARKS

NOTES:

1.

These tests are applicable for package equipment instrumentation system. VENDOR shall perform the tests as applicable to the specific instruments/valves/devices/systems/accessories etc.

2. 3.

VENDOR shall advise PURCHASER the type of NDE required to be conducted. Relevant documentation and certification shall be provided if welding activities are required on valve construction.

LEGEND:

X -

Testing and inspection, document review and report by the VENDOR to the PURCHASER. All testing, inspection, document checks etc. shall be carried out by the VENDORs independent QA/QC Department unless stated otherwise.

H -

(Hold - Points) The VENDOR shall not carry out the specified controls and tests without PURCHASER attendance. Consequently, the attendance of PURCHASER and their representatives are mandatory. The VENDOR must notify PURCHASER of the dedicated inspection activity at least fourteen (14) days in advance.

W - (Witness) The VENDOR must notify PURCHASER of the indicated inspection activity at least fourteen (14) days in advance. PURCHASER witnessing is not mandatory, but at PURCHASERs option. If PURCHASER does not elect to be present, the VENDOR may proceed with their own inspection, provided controls and tests records are made available to PURCHASER for review.

R -

(Review) The VENDOR has to submit to PURCHASER for comments the documents required prior to the performance of the indicated activity (as per but not limited to Appendix E1, VDRL), transmit or make available for the review of PURCHASER the results of the controls and tests conducted, as applicable.

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Appendix C6

APPENDIX C6:

APPLICABLE PROJECT REQUIREMENTS

The following list of project specifications shall be applicable for the intended scope of work in this specification. No. 1. Document Description Utility, Environmental and Metocean Data Reference No. 21010-BAE-70000-PR-SP-0001

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Appendix E1

APPENDIX E1:

VENDOR DOCUMENT REGISTER LIST

VENDOR / sub-VENDOR shall provide the following documents as a minimum according to the submission schedule.

VDRL CODE DOCUMENT TITLE SUBMIT WITH TENDER NO. PRINTS REQD A.00 INTERFACE INFORMATION Drawings and documents within this class shall comprise all information which may interface with other facilities or PURCHASER, and are of major importance for platform/facilities design and project schedule. A.01 OUTLINE AND FOUNDATION LOADING DIAGRAMS A.02 A.03 GENERAL ARRANGEMENT DRAWINGS ELECTRICAL/INSTRUMENTATION LAYOUT DRAWINGS A.04 A.05 A.06 UTILITY FLOW DIAGRAMS PERFORMANCE CURVES PIPING AND INSTRUMENTATION DIAGRAMS (P&ID) A.07 A.08 A.09 A.10 A.11 A.12 A.13 A.14 A.15 A.16 A.17 P&ID INSTRUMENTATION LIST P&ID BILL OF MATERIAL JUNCTION BOX TERMINATION DRAWINGS CABLES SCHEDULE LOGIC DIAGRAMS FUNCTIONAL DESCRIPTION SINGLE LINE DIAGRAMS UTILITY CONSUMPTION LIST INSTRUMENT DATA SHEETS WEIGHT DATA SHEETS INSTRUMENT AND PROCESS DATA SHEETS 4 4 2WAFO 4 2 2 WPTD Note 5 4 4 4 4 2WAFO 2WAFO 2WAFO 2WAFO 4 4 4 4 2 2 2 2 2 WPTD 2 WPTD 2 WPTD 2 WPTD 4 2WAFO 4 2 2 WPTD 4 2WAFO 4 2 2 WPTD 4 2WAFO 4 2 2 WPTD NO. OF PRINTS REQD DATE REQD QUANTITY REQUIRED PRINTS ELECT DATE REQD SUBMIT FOR REVIEW FINAL DATA SUBMISSION NOTES

Doc. No Rev No Page

: : :

21010-BAE-70000-IN-SP-0030 C0 Appendix E1

VDRL CODE

DOCUMENT TITLE

SUBMIT WITH TENDER NO. PRINTS REQD

SUBMIT FOR REVIEW

FINAL DATA SUBMISSION

NOTES

NO. OF PRINTS REQD 4 4

DATE REQD

QUANTITY REQUIRED PRINTS ELECT 2 2

DATE REQD

A.18 A.20 A.21 A.22

CAUSE AND EFFECT CHARTS INTERFACE BLOCK DIAGRAM THERMAL DESIGN CALCULATION FIELD EQUIPMENT GENERAL ARRANGEMENT DRAWINGS

2WAFO 2WAFO

4 4

2 WPTD 2 WPTD

A.24 A.27

CONTROL PANEL LAYOUT INSTRUMENT/EQUIPMENT - SITE MOUNTED (LIST)

4 4

4 4

2WAFO 2WAFO

4 4

2 2

2 WPTD 2 WPTD

A.28 A.29 A.30 A.32 A.98 A.99 B.00