Академический Документы

Профессиональный Документы

Культура Документы

Journal of the American Oil Chemists' Society Volume 29 Issue 12 1952 [Doi 10.1007%2Fbf02631723] Daniel Swern; Winfred E. Parker -- Application of Urea Complexes in the Purification of Fatty Acids, Esters, And Alc

Загружено:

bexigaobrotherИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Journal of the American Oil Chemists' Society Volume 29 Issue 12 1952 [Doi 10.1007%2Fbf02631723] Daniel Swern; Winfred E. Parker -- Application of Urea Complexes in the Purification of Fatty Acids, Esters, And Alc

Загружено:

bexigaobrotherАвторское право:

Доступные форматы

Application of Urea Complexes in the Purification of Fatty Acids, Esters, and Alcohols? II.

Oleic Acid and Methyl Oleate From Olive Oil

DANIEL SWERN and WINFRED E. PARKER, Eastern Regional Research Laboratory, 3 Philadelphia, Pennsylvania

H E use of urea complexes in the preparation of oleic acid of 80-95% purity in good yield from various commercially available inedible animal fat sources was recently reported by us (4). In this paper we are describing the use of urea complexes in the isolation of oleic acid and methyl oleate from olive oil, employing the "single dose of u r e a " technique first described in our previous paper (4). Schlenk and Holman (2) were apparently the first workers to employ urea complexes in the preparation of purified methyl oleate (purity, 97-98%) from olive oil. These investigators employed a stepwise addition of urea which was designed to remove first two successive 10% portions of the olive oil methyl esters as urea complexes (to eliminate saturated methyl esters), followed by a precipitation of the bulk of the remaining esters (mostly methyl oleate) as urea complexes, leaving most of the methyl linoleate in the final filtrate (non-complex fraction). Fractional distillation of the methyl oleate was again followed by urea treatment. For reasons given in our previous paper (4), with olive oil acids or methyl esters, we prefer to use a single dose of urea to precipitate both saturated and monounsaturated materials as urea complexes in one step, leaving the polyunsaturated materials in the filtrate, and, if necessary, separate saturates from the oleic acid or methyl oleate by solvent crystallization and/or fractional distillation.

Experimental

Materials Used. Urea and methanol were the purest

available reagent grades. California olive oil (iodine number, 78.0) was employed and had the following fatty acid composition (1): oleic acid, 80.2%; linoleie acid, 3.7%; linolenic acid, 1.0%; saturated acids, 15.1%. The fatty acids (iodine number, 81.3) were prepared in quantitative yield by the rapid saponification technique previously reported (3).

less oleic acid, b.p. 205-206~ (iodine number, 82.8; composition: oleie acid, 90.4%; linoleic acid, 0.9%; saturated acids, 8.7%). The overall yield of oleic acid recovered was 43%. To obtain a higher purity and polyunsaturate-free oleic acid, as well as a better overall yield, the acids isolated from the complex were fractionally crystallized from acetone (12 ml./g.) prior to distillation. From 840 g. of these (iodine number, 77), 140 g. of saturated acids (iodine number, 16) were obtained as a precipitate at --20 ~ ; 620 g. of an oleie acid fraction (iodine number, 85; composition: oleie acid, 94.4%; linoleic acid, 0.1%; saturated acids, 5.5%) were obtained as a precipitate at --50 ~ The yield of oleic acid recovered to this point was 72%. Fractional distillation of the precipitate obtained at --50 ~ yielded 500 g. of colorless, odorless liquid (iodine number, 88.0; composition: oleic acid, 97.7%; linoleic acid, 0.1% ; saturated acids, 2.2%). The final yield of oleic acid was 60%. Purification of Oleic Acid (Slurry Method). In the slurry method the volume of methanol is reduced to one-half that used in the Solution Method and the time is shorter. In a stainless steel kettle a slurry was prepared consisting of 3,600 g. of urea and 4,500 ml. of methanol. To the well-stirred slurry 1,000 g. of olive oil acids were added at such a rate that the temperature did not exceed 35 ~. The slurry was stirred until the internal temperature had fallen approximately to room temperature (this required about 8 hours), and the mixture was filtered. The urea complexes weighed 3,680 g. from which 900 g. of almost colorless oil was obtained (iodine number, 78; composition : oleic acid, 85% ; linoleic acid, 1% ; saturated acids, 14%). Subsequent processing and results were approximately the same as just described under Solution Method except that yields of oleic acid recovered at each step were about 5% higher.

Purification of Oleic Acid (Solution Method). One

thousand grams of olive oil fatty acids were dissolved in a boiling solution of 3,600 g. of urea in 9,000 ml. of methanol. Crystals of urea complexes formed as soon as the container was removed from the steam bath. The mixture was cooled to 0 ~ overnight and filtered, yielding 3,870 g. of urea complexes. These were stirred with a large volume of hot water to dissolve the urea, yielding 840 g. of almost colorless oil as an upper layer (iodine number, 77; composition: oleie acid, 83.9%; linoleic acid, 0.9% ; saturated acids, 15.2%). The yield of oleic acid recovered to this point was 88%. Fractional distillation through a 10-plate column yielded 432 g. of a lower, semi-solid fraction, b.p. 192-205~ (iodine number, 64.9), and 380 g. of colorless, odor1The first paper in this series is reference 4. 2Presented at the Fall meeting of the American Oil Chemists' Society, Cincinnati, Ohio, Oct. 20-22, 1952. SOne of the laboratories of the Bureau of Agricultural and Industrial Chemistry, Agricultural Research Administration, U. S. Department of Agriculture. 614

Purification of Methyl Oleate (Solution Method).

Three grams of freshly cut metallic sodium was dissolved in 5,000 ml. of anhydrous methanol. One thousand grams of olive oil were added and the solution was refluxed for 30 minutes. An additional 5,000 ml. of methanol and 3,600 g. of urea were then added, and the mixture was boiled until the urea dissolved. The reaction mixture was cooled to 20 ~ and filtered, yielding 3,400 g. of urea complexes. These were stirred with hot water to dissolve the urea yielding 790 g. of a methyl oleate fraction (iodine number, 71.4; composition: methyl oleate, 81.5%; methyl linoleate, 0.9%; saturates, 17.6%), as an almost colorless upper layer. The methyl oleate recovered to this point was 80%. Fractional distillation yielded 170 g. of lower fraction, b.p. 164-179~ (iodine number, 50.2), and 550 g. of colorless, odorless methyl oleate fraction, b.p. 180-1~ (iodine number, 78.0; composition: methyl oleate, 89%; methyl linoleate, 1%; saturates, 10%). The overall yield of methyl oleate recovered was 61%.

T H E JOURNAL OF THE AMERICAN O I L C H E M I S T S ' SOCIETY, DECEMBER, 1 9 5 2

615

Fractional crystallization from acetone (10 ml./g.) of 790 g. of methyl oleate (iodine number, 71.4), recovered from the urea complexes, yielded 140 g. of saturated methyl esters (iodine number, 15) at --35~ 580 g. of methyl oleate (iodine number, 83.5; composition: methyl oleate, 97.2%; methyl linoleate, 0.2%; saturates, 2.6%) was obtained as a precipitate at --60 ~ The yield of methyl oleate recovered to this point was 70%. Fractional distillation of the methyl oleate fraction yielded 540 g. of methyl oleate, b.p. 184~ (iodine number, 84.9; composition: methyl oleate, 98.9%; methyl linoleate, 0.2%; saturates, 0.9%). The final yield of methyl oleate recovered was 66%. Purification of Methyl Oleate (Slurry Method). The methanolysis of olive oil was carried out as described earlier, but at its completion no additional methanol was added. The reaction mixture was cooled to room temperature and 3,600 g. of urea were then added. The slurry was stirred until the reaction temperature had again reached room temperature (about 8 hours were required). The mixture was filtered, yielding 3,870 g. of complexes from which 812 g. of methyl oleate (iodine number, 73.4; composition: methyl oleate, 83.8% ; methyl linoleate, 1.0%; saturates, 15.2%) was obtained. Subsequent processing and results were approximately the same as just described under Solution Method except that yields of methyl oleate recovered at each step were about 5% higher.

urea complexes, to precipitate the saturated fatty acids, particularly palmitic acid, which are still present. For each gram of palmitic acid which must be separated by distillation, as much as two grams of oleic acid will be distilled along with it even when efficient fractionating columns are used. This undesirable phenomenon, which does not occur with methyl esters, is probably caused by azeotrope formation. Thus fractional distillation of the fatty acids obtained from the urea complexes (palmitic acid present) gives an overall yield of recovered oleic acid of 43-48%, fractional distillation after separation of saturated acids by solvent crystallization (palmitic acid substantially absent) gives 60-65% yields, and distillation of methyl esters (methyl palmitate present or absent) also gives 60-65% yields.

Summary

Oleic acid and methyl oleate of high purity (97-99%) and substantially free (0.2% or less) of polyunsaturated contaminants have been isolated in 60-70% yield from the fatty acids or methyl esters of olive oil by procedures which require only one precipitation of urea complexes (single dose of urea technique) one low-temperature crystallization, and one fractional distillation. The best yields of the highest purity acids are obtained when saturates are removed by fractional crystallization prior to a final distillation. The urea complex separation technique can be applied directly to olive oil methanolysis reaction mixtures without prior isolation of the mixed methyl esters. Oleie acid or methyl oleate obtained by decomposition of urea complexes contains approximately 1% of polyunsaturated contaminants. After fractional distillation or crystallization to separate saturated acids the oleic content is about 90-97%. Such products are satisfactory for many uses and in their preparation low-temperature (--50 ~ or lower) crystallizations are not required. Solution and slurry techniques have been studied for the preparation of urea complexes from olive oil acids or esters. The former technique is preferred when a maximum of about 1,000 grams of acids or esters are to be processed. The latter is preferred for larger size experiments mainly because the volume of methanol employed is cut in half, the time is shorter, and also because yields are about 5% higher.

REFERENCES 1. Brice, B. A., and Swain, M. L., J. Opt. Soc. Am., 35, 532-544 (1945). 2. Schlenk, H., and Holman, P~. T., J. Am. Chem. Soc., 72, 50015 0 0 4 (1950). 3. Swern, Daniel, Knight, H. B., Scanlan, J. T., and Ault, W. C., Oil & Soala, 22, 302-304 (1945). 4. Swern, Daniel, and Parker, W. E., J. Am. Oil Chem. Soc. (in press). [Received April 16, 1952]

Discussion

Oleic acid and methyl oleate of high purity (9799%) and substantially free (0.2% or less) of polyunsaturated contaminants can be obtained in good yield (60-70%) from the fatty acids or methyl esters of olive oil by procedures which require only one precipitation of urea complexes, one low-temperature crystallization, and one fractional distillation. In the purification of methyl oleate it is not necessary to isolate the mixed methyl esters of olive oil because the urea complex precipitation technique can be applied directly to the methanolysis reaction mixture. "Reerystallization" of urea complexes from methanol does not separate the polyunsaturated contaminants completely and merely reduces the overall yield of oleic acid recovered. If a polyunsaturate-free oleic acid or methyl oleate is not required, the low temperature crystallizations can be eliminated entirely. If low temperature facilities are not available or are inconvenient to set up, the urea complex technique permits the preparation of oleic acid or methyl oleate sufficiently low in polyunsaturated contaminants for many chemical investigations. To obtain the best yields of fractionally-distilled oleic acid it is necessary, after decomposition of the

CORRECTION Corrections for the paper entitled " T h e Aliphatic Alcohols of Wool Wax. V. Studies in Waxes," by K. E. Murray and R. Schoenfeld, published in the October 1952 issue of the Journal (29, 416-420) are as follows :

Reference 3 should read:

Darmst~dter, L., and Lifschiitz, J., Bet. 29, 2890 (1896). Reference 10 should read: Knol, H. W., Dutch Pat. 65,260 (1950). U. S. Pat. 2,536,753 (1951). :Br. Pat. 626,299 (1950).

Вам также может понравиться

- D Limonene UsesДокумент7 страницD Limonene Usesbexigaobrother100% (1)

- ASTM 6365 - 99 - Spark TestДокумент4 страницыASTM 6365 - 99 - Spark Testjudith_ayala_10Оценок пока нет

- Asades: Crude Oil Treatment For Cotton Transesterification AlkalineДокумент4 страницыAsades: Crude Oil Treatment For Cotton Transesterification AlkalineJavier AlbaОценок пока нет

- Basic OleoДокумент42 страницыBasic OleoellysОценок пока нет

- Biodiesel Production From Waste Coconut Oil in Coconut Milk ManufacturingДокумент9 страницBiodiesel Production From Waste Coconut Oil in Coconut Milk ManufacturingTristan Tabago ConsolacionОценок пока нет

- April - Petrochemical - Analysis and Identification of Fatty Acid Methyl Ester Composition in Different Vegetable Oil (Biodiesel) Source Using GCMSДокумент2 страницыApril - Petrochemical - Analysis and Identification of Fatty Acid Methyl Ester Composition in Different Vegetable Oil (Biodiesel) Source Using GCMSAlex's SustaitaОценок пока нет

- Research Paper: Extraction of Ambrette Seed Oil and Isolation of Ambrettolide With Its Characterization by H NMRДокумент6 страницResearch Paper: Extraction of Ambrette Seed Oil and Isolation of Ambrettolide With Its Characterization by H NMRMimbel WimbelОценок пока нет

- OutДокумент7 страницOutIzzatisaharОценок пока нет

- CarnaubaДокумент2 страницыCarnaubaVishal GuptaОценок пока нет

- Tuk - Návody - AnglickyДокумент7 страницTuk - Návody - AnglickyBlessing HarvestОценок пока нет

- COI T.20 Doc. No 29 Rev 1 2017 BiophénolДокумент8 страницCOI T.20 Doc. No 29 Rev 1 2017 BiophénolSlaw Ben AissaОценок пока нет

- COI-T.20-Doc.-No-33-Rev.-1-2017 (Fatty Acid MOA)Документ16 страницCOI-T.20-Doc.-No-33-Rev.-1-2017 (Fatty Acid MOA)KhalidОценок пока нет

- Fatliqur Jajoba OilДокумент8 страницFatliqur Jajoba OilAnbarasu ArasuОценок пока нет

- Fatty Acid EthanolamideДокумент9 страницFatty Acid Ethanolamidegaurav chauhanОценок пока нет

- 1084 2283 1 SMДокумент6 страниц1084 2283 1 SMruliОценок пока нет

- Acidic Number of Fatty AcidДокумент8 страницAcidic Number of Fatty AcidKy ChangОценок пока нет

- Acid Value Phase 2Документ7 страницAcid Value Phase 2Emmanuel AkolyОценок пока нет

- Synthesis of DHA Rich PUFA From Cod Liver Fish OilДокумент7 страницSynthesis of DHA Rich PUFA From Cod Liver Fish OilS Bharadwaj ReddyОценок пока нет

- CIE MechanismДокумент6 страницCIE MechanismEvan KeeОценок пока нет

- Groundnut Oil Fatty Acid CompositionДокумент5 страницGroundnut Oil Fatty Acid CompositionAtul MittalОценок пока нет

- Glycerol Residue-A Rich Source Glycerol and Medium Chain Fatty AcidДокумент5 страницGlycerol Residue-A Rich Source Glycerol and Medium Chain Fatty AcidRikardo LumbantoruanОценок пока нет

- 3 Preparation and CharactersationДокумент26 страниц3 Preparation and Charactersationsindhnayak48Оценок пока нет

- EXTRACTION OF NEEM OIL (Azadirachta Indica A. Juss) USING N-HEXANE AND ETHANOL: STUDIES OF OIL QUALITY, KINETIC AND THERMODYNAMICДокумент6 страницEXTRACTION OF NEEM OIL (Azadirachta Indica A. Juss) USING N-HEXANE AND ETHANOL: STUDIES OF OIL QUALITY, KINETIC AND THERMODYNAMICNikhil MohananОценок пока нет

- Soap and Related Products Palm and Lauric OilДокумент5 страницSoap and Related Products Palm and Lauric OilscornelioОценок пока нет

- Polycyclic Aromatic Hydrocarbon Determination by Reversed-Phase High-Performance Liquid Chromatography in Olive Oils On The Iranian MarketДокумент3 страницыPolycyclic Aromatic Hydrocarbon Determination by Reversed-Phase High-Performance Liquid Chromatography in Olive Oils On The Iranian Marketkurleigh17Оценок пока нет

- Report On NeemДокумент16 страницReport On Neemadityaksrivastava100% (1)

- Determinarea Proteinelor La UleiuriДокумент8 страницDeterminarea Proteinelor La UleiuriVoicu ValeriuОценок пока нет

- Pengaruh Komposisi Katalis H Zeolit DanДокумент6 страницPengaruh Komposisi Katalis H Zeolit DanZia NajlaОценок пока нет

- Ester Extraction From The Chicken Fat: Wladimir Rubio, Pamela Avilés and Gaira MolinaДокумент5 страницEster Extraction From The Chicken Fat: Wladimir Rubio, Pamela Avilés and Gaira MolinaWladimir RubioОценок пока нет

- Biodiesel Extraction From Cotton Seed OilДокумент12 страницBiodiesel Extraction From Cotton Seed OilShashank PathakОценок пока нет

- Biodiesel Feed Stock, Production TechnologyДокумент27 страницBiodiesel Feed Stock, Production TechnologySaswata PradhanОценок пока нет

- Investigation On The Performance and Emission Characterstics by Using Bio Diesel From Leucaena Leucocephala SeedДокумент33 страницыInvestigation On The Performance and Emission Characterstics by Using Bio Diesel From Leucaena Leucocephala SeedArun prakashОценок пока нет

- Transesterification For The Preparation of Biodiesel From Crude Oil of Milk BushДокумент6 страницTransesterification For The Preparation of Biodiesel From Crude Oil of Milk Busha_minisoft2005Оценок пока нет

- A PhenylacetoacetonitrileДокумент4 страницыA PhenylacetoacetonitrileNik OthmanОценок пока нет

- RRLДокумент9 страницRRLLourdes CagungunОценок пока нет

- Manuscript AguacateДокумент27 страницManuscript AguacateLoredana Veronica ZalischiОценок пока нет

- Renewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixДокумент7 страницRenewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixIka SulistyaningtiyasОценок пока нет

- Acido OleicoДокумент7 страницAcido OleicoDanii ValenciaОценок пока нет

- Biodiesel, Mono-Alkyl Ester: Biorefining Application Note 9.02.00 Biodiesel ProcessДокумент2 страницыBiodiesel, Mono-Alkyl Ester: Biorefining Application Note 9.02.00 Biodiesel ProcessEdward ChanОценок пока нет

- Phenolic Compounds and Some Quality Parameters of Pumpkin Seed OilДокумент10 страницPhenolic Compounds and Some Quality Parameters of Pumpkin Seed OilLarisa CatautaОценок пока нет

- Production of Monoacylglycerols (MAG) Via Lipase Catalyzed Esterification of Glycerol With Fatty Acids of Skipjack TunaДокумент3 страницыProduction of Monoacylglycerols (MAG) Via Lipase Catalyzed Esterification of Glycerol With Fatty Acids of Skipjack Tunaijat_Оценок пока нет

- Chen 2008Документ8 страницChen 2008Yunita PujiastutiОценок пока нет

- Refinacao Oleo CruДокумент7 страницRefinacao Oleo CruCésar AlbuquerqueОценок пока нет

- Semi-Continuous Producing Process For Ethyl FormateДокумент4 страницыSemi-Continuous Producing Process For Ethyl FormateKiran KumarОценок пока нет

- Opi LipiДокумент1 страницаOpi Lipinoel.manroeОценок пока нет

- Fractionation of Medium Chain Fatty Acid Ethyl Esters From Virgin Coconut Oil Via Transesterification and Distillation Under Reduced PressureДокумент5 страницFractionation of Medium Chain Fatty Acid Ethyl Esters From Virgin Coconut Oil Via Transesterification and Distillation Under Reduced Pressurei love chubzОценок пока нет

- Transesterification of Neat and Used Frying Oil: Optimization For Biodiesel ProductionДокумент8 страницTransesterification of Neat and Used Frying Oil: Optimization For Biodiesel ProductionCristiОценок пока нет

- Analysis of Edible Oils: Apostolos Kiritsakis and William W. ChristieДокумент30 страницAnalysis of Edible Oils: Apostolos Kiritsakis and William W. ChristieBianca AndreeaОценок пока нет

- Ch. IIДокумент10 страницCh. IIhalloifОценок пока нет

- Studies On The Components of Essential Oil of Zanthoxylum: Armatum by GC-MSДокумент4 страницыStudies On The Components of Essential Oil of Zanthoxylum: Armatum by GC-MSsachin90ictОценок пока нет

- Characteristics Variation of Lavender Oil Produced by Different Hydrodistillation TechniquesДокумент15 страницCharacteristics Variation of Lavender Oil Produced by Different Hydrodistillation TechniquesRifa sabrina SalsabilaОценок пока нет

- Chem 213 FFR 4Документ10 страницChem 213 FFR 4bts176Оценок пока нет

- Determination of Biophenols in Olive Oils by HPLCДокумент8 страницDetermination of Biophenols in Olive Oils by HPLCghost2011Оценок пока нет

- Contaminantes AcroleinaДокумент4 страницыContaminantes AcroleinaOleggValVilОценок пока нет

- Optimization Carotenoids Isolation of The Waste Crude Palm Oil Using - Amylase, - Amylase, and CellulaseДокумент6 страницOptimization Carotenoids Isolation of The Waste Crude Palm Oil Using - Amylase, - Amylase, and CellulaseInternational Organization of Scientific Research (IOSR)Оценок пока нет

- A Comparison of The Steryl Esters of Coconut and Palm Kernel OilsДокумент4 страницыA Comparison of The Steryl Esters of Coconut and Palm Kernel OilsJuliette GaviriaОценок пока нет

- Patchouli OilsДокумент5 страницPatchouli OilsbudiliaОценок пока нет

- Biodiesel Production From Residual Oils Recovered From Spent Bleaching EarthДокумент6 страницBiodiesel Production From Residual Oils Recovered From Spent Bleaching EarthCamilo Andres Picon Prada100% (1)

- International Journal of Chemtech Research: Prajakt S Charhate, Madhura Bhalerao, Vijay Y KaradbhajneДокумент9 страницInternational Journal of Chemtech Research: Prajakt S Charhate, Madhura Bhalerao, Vijay Y KaradbhajneNo NameОценок пока нет

- Ester Extraction From The Chicken Fat: 1 AbstractДокумент5 страницEster Extraction From The Chicken Fat: 1 AbstractWladimir RubioОценок пока нет

- Palm Oil BiodieselДокумент5 страницPalm Oil BiodieselSudsiri HemsriОценок пока нет

- Soap-Making Manual: A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap PlantОт EverandSoap-Making Manual: A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap PlantОценок пока нет

- Product List Additives For Coatings - SynthronДокумент20 страницProduct List Additives For Coatings - SynthronbexigaobrotherОценок пока нет

- Corrosion Resistance of Chromium-Free Conversion Coatings Deposited OnДокумент10 страницCorrosion Resistance of Chromium-Free Conversion Coatings Deposited OnbexigaobrotherОценок пока нет

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingДокумент8 страницSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingbexigaobrotherОценок пока нет

- WeldingSpatterReductionandTimeStudy AReviewДокумент4 страницыWeldingSpatterReductionandTimeStudy AReviewbexigaobrotherОценок пока нет

- The Effect of Bicarbonate Additive On Corrosion ResistanceДокумент11 страницThe Effect of Bicarbonate Additive On Corrosion ResistancebexigaobrotherОценок пока нет

- Simple PresentДокумент8 страницSimple PresentbexigaobrotherОценок пока нет

- Chemistry and Life: Blood As A Buffered SolutionДокумент1 страницаChemistry and Life: Blood As A Buffered SolutionbexigaobrotherОценок пока нет

- E-T-5 Tech DataДокумент4 страницыE-T-5 Tech DatabexigaobrotherОценок пока нет

- Negations in The Simple Present, Don't or Doesn't - EnglishДокумент8 страницNegations in The Simple Present, Don't or Doesn't - EnglishbexigaobrotherОценок пока нет

- Present Natrosol PDFДокумент24 страницыPresent Natrosol PDFbexigaobrotherОценок пока нет

- Akypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40Документ3 страницыAkypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40bexigaobrotherОценок пока нет

- Catalogo Paints ING Out15Документ12 страницCatalogo Paints ING Out15bexigaobrotherОценок пока нет

- Carbonato de Glicerina PDFДокумент29 страницCarbonato de Glicerina PDFbexigaobrotherОценок пока нет

- Review About MonoethanolamineДокумент59 страницReview About MonoethanolaminebexigaobrotherОценок пока нет

- Questions in The Simple Present - EnglishДокумент2 страницыQuestions in The Simple Present - EnglishbexigaobrotherОценок пока нет

- Paint DetackificationДокумент15 страницPaint DetackificationbexigaobrotherОценок пока нет

- TSCA Workplan Chemical Risk Assessment of NMPДокумент166 страницTSCA Workplan Chemical Risk Assessment of NMPbexigaobrotherОценок пока нет

- TrilonM Webinar Combined 04192016 v12-FINALДокумент39 страницTrilonM Webinar Combined 04192016 v12-FINALbexigaobrother100% (3)

- The Role of Surfactants in Phosphate Conversion Coatings - Book ChapterДокумент32 страницыThe Role of Surfactants in Phosphate Conversion Coatings - Book ChapterbexigaobrotherОценок пока нет

- Paint Coagulation enДокумент4 страницыPaint Coagulation enbexigaobrotherОценок пока нет

- Akypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40Документ3 страницыAkypo Lm-40 Leaflet Eng - KAO - AKYPO-LM-40bexigaobrotherОценок пока нет

- Rs7 Spray TdsДокумент2 страницыRs7 Spray TdsbexigaobrotherОценок пока нет

- MetamterialsДокумент3 страницыMetamterialsdhruba88Оценок пока нет

- Large Volume PoursДокумент7 страницLarge Volume PoursgordonОценок пока нет

- Lesson Plan - Revit Intro Lesson OverviewДокумент56 страницLesson Plan - Revit Intro Lesson Overviewlingga123Оценок пока нет

- UL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Документ7 страницUL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Juan Jose Teodoro AguilarОценок пока нет

- Implementation Steps For Oracle Alert ModuleДокумент12 страницImplementation Steps For Oracle Alert Modulemzee1981Оценок пока нет

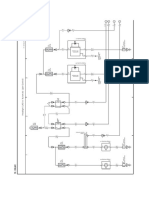

- Overall EWD Vehicle Exterior Rear Fog LightДокумент10 страницOverall EWD Vehicle Exterior Rear Fog Lightgabrielzinho43Оценок пока нет

- ADPlaylistEditor3 (Network Version)Документ42 страницыADPlaylistEditor3 (Network Version)Dramane BonkoungouОценок пока нет

- Quectel MC60 at Commands Manual V1.2Документ262 страницыQuectel MC60 at Commands Manual V1.2Adimaro MontoyaОценок пока нет

- EXCEL To Tally LeggerImport-ok - 2Документ7 страницEXCEL To Tally LeggerImport-ok - 2Mukesh MakadiaОценок пока нет

- Cp5151 Advanced Data Structures and AlgorithimsДокумент3 страницыCp5151 Advanced Data Structures and AlgorithimsPragaDarshОценок пока нет

- IBM Flex System p270 Compute Node Planning and Implementation GuideДокумент630 страницIBM Flex System p270 Compute Node Planning and Implementation GuideAnonymous Qvouxg2aОценок пока нет

- LAPORAN PRAKTIK KERJA LAPANGAN - Id.enДокумент25 страницLAPORAN PRAKTIK KERJA LAPANGAN - Id.enAhmad JupriОценок пока нет

- Certification - Speech Testing - Assistant PartnersДокумент2 страницыCertification - Speech Testing - Assistant PartnersRodrigo Freire BragaОценок пока нет

- Dominion EnergyShareДокумент2 страницыDominion EnergyShareMichelle HuynhОценок пока нет

- Spinner Array Tool (SAT) - GE EnergyДокумент2 страницыSpinner Array Tool (SAT) - GE Energygladwin CorreiaОценок пока нет

- Workshop Microproject ListДокумент2 страницыWorkshop Microproject ListABDUL KADIR MUZAMMIL HUSAIN KHANОценок пока нет

- Open Distance Education in MalaysiaДокумент35 страницOpen Distance Education in MalaysiaThong Boon LeongОценок пока нет

- Omfb MTC 11.12.23Документ2 страницыOmfb MTC 11.12.23obviousplatinum2Оценок пока нет

- Boiler Safety ProgramДокумент8 страницBoiler Safety ProgramHussain KhanОценок пока нет

- Tech Note 1034 - XY Plotter ActiveX Control Demo ApplicationДокумент9 страницTech Note 1034 - XY Plotter ActiveX Control Demo ApplicationAbakash DasОценок пока нет

- Carrier SelectionДокумент13 страницCarrier SelectionRanesh SinglaОценок пока нет

- GERMAN Embassy ContractДокумент79 страницGERMAN Embassy ContractVE.03 QELОценок пока нет

- CVision AVR Man3 PDFДокумент513 страницCVision AVR Man3 PDFsigiloОценок пока нет

- CHEN3000 Process Plant Engineering: Semester 2 2016Документ30 страницCHEN3000 Process Plant Engineering: Semester 2 2016Max Yee Min JueyОценок пока нет

- br604 PDFДокумент5 страницbr604 PDFmartinpellsОценок пока нет

- Irgb 4064 DPBFДокумент11 страницIrgb 4064 DPBFKrista TranОценок пока нет

- Example Pump CalcsДокумент4 страницыExample Pump CalcsSourav ChattopadhyayОценок пока нет

- Schneider ElectricCahier Technique No. 199Документ36 страницSchneider ElectricCahier Technique No. 199Alda EnglandОценок пока нет

- SHEET #1 Title Sheet Site Safety Logistic Plan ForДокумент5 страницSHEET #1 Title Sheet Site Safety Logistic Plan ForRadha BuildtechОценок пока нет