Академический Документы

Профессиональный Документы

Культура Документы

GUIDELINE of High Pressure C02 Fixed Fire Extinguishing System

Загружено:

ir_azlan_aziz860Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GUIDELINE of High Pressure C02 Fixed Fire Extinguishing System

Загружено:

ir_azlan_aziz860Авторское право:

Доступные форматы

1.

CO2 CYLINDER Quantity of CO2 should be accordance to SOLAS and their

calculation approved by SCM. Cylinder and cylinder valve must be approved type. Marked with followin information! Manufacturer Serial number "ype of as Capacity "est presurre #mpty wei ht $ate of test "est stamp

2. FLEXIBLE HOSE AND CHECK VALVE

Check valve to be fitted between the cylinder and the main manifold. %le&ible hose should be approved type.

3. MANIFOLD (piping)

Should be 'rotected medium. 'ipe line ') *++. 'ipe line -+. made from weldable material. e&ternally by paintin or other anti corrosion from cylinder to master valve ( workin from master valve to no,,le ( workin pressure of pressure of ')

Si,e of CO2 manifold. .efer to %i ure(2/ ne&t pa e. Minimum steel pipe thickness for CO2. .efer to %i ure(0/ ne&t pa e.

4. MASTER VALVE

Made of seawater(resistance material. 'ossible to see clearly whether the valve is open or close. Operated remotely from release cabinet and !"# capable for local manual operation for emer ency used. 1i$ $i##%& in"i&% #'% CO2 ()) 2. Should not locate inside CO2 protected spaces. Should be protected a ainst unauthori,ed unintentional actuatin . 'osted with si ns indicatin the space protected. 1if the spaces protected more than one2

*. MAN+AL ,+LL HANDLE

Operated remotely from release cabinet and local manual operation for emer ency used. !"# capable for

N) in-. &i- %#%( in0'%" *3 2+ 23 02 -+ 3+ 93 6+ :+ *++ **+ *23 *3+ 3 9 0 2 0 * * 2

4 5 7 4 4 4 4

/%ig'# )$ CO2 $)( -0'in%(1 -n& 2)i.%( "p-0%" (3g) -3 *++ *03 283 -3+ **++ *3++ 2+++ 023+ -83+ 96*+ :3++ *323+

/%ig'# )$ CO2 $)( 0-(g) ').&" $)( )#)( 4%'i0.%" (3g) -++ 6++ *2++ 23++ 08++ 82++ **3++ 2++++

Fig!(% 2

2*.0 ; 29.: 0+.+ ( -6.0 3*.+ ; 9+.0 90.3 ; 89.* 62.3 ; 66.: *+*.9 *+6.+ ; **-.0 *28.+ *00.+ ; *0:.8 *32.- ; *96.0

F() 01.in&%( #) -"#%( 4-.4% ( ) 0.2 -.+ -.3 3.+ 3.9 9.0 8.* 6.+ 6.+ 6.6

F() -"#%( 4-.4% #) n)55.%" ( ) 2.9 0.2 0.9 0.9 -.+ -.+ -.3 -.3 3.+ 3.9

Fig!(% 3.

6. TIME DELAY +NIT

"o ensure the period necessary to evacuate the protected space. "he time should be not less than 2+ sec. Other means of time delay scheme also to be considered. 1<f the system fitted other than pilot cylinder.2

7. CO2 ALARM

"o be automatically actuated when the release cabinet bein opened. A suitable time actuated before floodin occurs. Should be distin uishable from other alarm si nals. Should continue to sound as lon floodin valves are opened. =isual alarm to be installed where necessary. "he power supplies to be backup with emer ency power supplies. 1<f electrical operated2. Cable used to be marine approved type/ <#C 9++:2(002(0 1fire retardant cable2. <f the alarm is pneumatically/ a permanent supply of compressed air to the system is to be ensured.

8. RELEASE CABINET

Located close to entrance outside from CO2 protected area. "o be lockable type and the key is kept in a clearly position ne&t to cabinet in a locked case with a lass panel.

9. SHORE CONNECTION

Located inside CO2 room or suitable area. Consist of check valve/ shut off valve and with a pipe connector 4 inches thread on free end. >ose pipe sufficient len th to reach from connection valve to open deck and fitted at both ends with sleeve nuts with 4 inches internal thread to be kept in the CO2 room to ether with two adaptors. One adaptor shall have 4 inches e&ternal thread and * inches internal thread. Other adaptor shall have 4 inches e&ternal thread and 2*.6mm 1 *?*- inches2 internal @hitworth thread.

1:.DISCHAR;E NO<<LE

Sufficient number and position to be provided to ensure even distribution of CO2.

11./ARNIN; SI;N

"o be posted at the release cabinet. = DO NOT O,ERATE RELEASE +NTIL ,ERSONNEL HAVE LEFT THE S,ACE> THE VENTILATION HAS BEEN SH+T OFF AND THE S,ACE HAS BEEN SEAL? "o be posted in the CO2 .oom. =BEFORE FLOODIN; /ITH THE CO2 SH+T OFF VENTILATION AND CLOSE AIR INTAKES. O,EN MASTER VALVE FIRST> THEN THE CYLINDER VALVE.

"o be posted in CO2 .oom and at the entrance of protected area. =/ARNIN;? =IN THE CASE OF ALARM OR RELEASE OF CO2 LEAVE THE S,ACE IMMEDIATELY (DAN;ER OF S+FFOCATION).THE S,ACE MAY BE RE@ENTER ONLY AFTER THRO+;H VENTILATIN; AND CHECKIN; OF ATMOS,HERE?

"o be posted in CO2 .oom. =THIS S,ACE MAY BE +SED ONLY FOR STORA;E OF CO2 CYLINDERS FOR FIRE EXTIN;+ISHIN; SYSTEM. THE TEM,ERAT+RE OF THE S,ACE IS TO BE MONITORED? "o be at release cabinet for car o pump A as compressor room. 1)n.1 $)( #-n3%("2 =RELEASE DEVICE TO BE O,ERATED ONLY AFTER O+TBREAK OF FIRE IN AAAAAAAAAAAAAAAAAAAAS,ACE.?

12.TESTIN;

After installation. o 'ipin from cylinder to master valve/ hydraulic tests at *2+ bar. o 'ipin passin throu h accommodation spaces/ hydraulic tests at 3+ bar. o Other pipin / hydraulic tests at *+ bar. o B)in# C%.&%&/ also reBuired hydraulic test at appropriate pressure. o D) N)# +"% /-#%( as a medium. o Tig'#n%"" #%"# to be carried out/ usin air or other suitable media. o C'%03 #'% piping from free passa e and ti htness. Compressed air connection with non(return valve and a shut off valve to be fitted at suitable point

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Proposal Teknis Project. GITC Duri Pulo - Fire PumpДокумент25 страницProposal Teknis Project. GITC Duri Pulo - Fire PumpSyncroFlo IndonesiaОценок пока нет

- Group 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Документ8 страницGroup 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Dado OgameОценок пока нет

- Performance CurvesДокумент1 страницаPerformance CurveskapsarcОценок пока нет

- Aircraft Hydraulic SystemДокумент23 страницыAircraft Hydraulic SystemmaruliОценок пока нет

- Adoc - Tips - Analisa Prestasi Electrical Submersible Pump Di SuДокумент6 страницAdoc - Tips - Analisa Prestasi Electrical Submersible Pump Di Suadi SaputraОценок пока нет

- Valve Seat Leakage TestДокумент3 страницыValve Seat Leakage Testtaeyun hwngОценок пока нет

- API 610 Pump Type Classification PDFДокумент4 страницыAPI 610 Pump Type Classification PDFMagico Nino100% (1)

- Gas Pressure Control Unit: TYPE 132Документ12 страницGas Pressure Control Unit: TYPE 132Mohamed El Hadi RedjaimiaОценок пока нет

- Morton Water Softener Valve-Assembly ReplacementДокумент2 страницыMorton Water Softener Valve-Assembly ReplacementBenjamin DoverОценок пока нет

- 1 S90 Service 9947Документ88 страниц1 S90 Service 9947Kadir Koray BozyelОценок пока нет

- Pipe Flow Expert Quick Start GuideДокумент12 страницPipe Flow Expert Quick Start Guidemetasoniko2014Оценок пока нет

- Series Flat Socket Weld Bolt FlangesДокумент1 страницаSeries Flat Socket Weld Bolt FlangesDerick MendozaОценок пока нет

- Specifications Systems Operation Testing & Adjusting Disassembly & AssemblyДокумент26 страницSpecifications Systems Operation Testing & Adjusting Disassembly & Assemblybenjamin100% (2)

- Pipe & FittingДокумент28 страницPipe & Fittinghelman novrandoОценок пока нет

- API - Valve StandardsДокумент1 страницаAPI - Valve StandardszzapiecheОценок пока нет

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)Документ1 страницаService: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)AliZenatiОценок пока нет

- KSB Family CurvesДокумент1 страницаKSB Family CurvesHarshad Athawale100% (1)

- SeminarДокумент14 страницSeminarPrajjawal SinghОценок пока нет

- Caleffi Decoupler PipingДокумент1 страницаCaleffi Decoupler PipingdokundotОценок пока нет

- 006.2 - CAT-6040 - Servo System A11-ServopumpДокумент28 страниц006.2 - CAT-6040 - Servo System A11-Servopump----Оценок пока нет

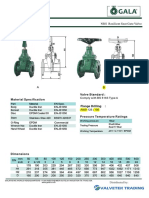

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Документ1 страница1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamОценок пока нет

- 28 27 - Bell - Gossett - HistoricalДокумент7 страниц28 27 - Bell - Gossett - HistoricalthepimpoОценок пока нет

- WM 113 Manual Hydraulic DiagramДокумент5 страницWM 113 Manual Hydraulic DiagramCarlos FigueredoОценок пока нет

- Check Valves: CV, CH, CO, CA, COA, CL and CW SeriesДокумент17 страницCheck Valves: CV, CH, CO, CA, COA, CL and CW SeriesEdwin ArguelloОценок пока нет

- Timberpro P/N 50690: Optional Auxiliary Cooler Return Logic Block Load Sense ValveДокумент2 страницыTimberpro P/N 50690: Optional Auxiliary Cooler Return Logic Block Load Sense ValveЕвгений МакаровОценок пока нет

- Cost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFДокумент24 страницыCost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFFayaz MohammedОценок пока нет

- Bomba Sumergible Grundfos 1100S PDFДокумент4 страницыBomba Sumergible Grundfos 1100S PDFCarlos Roberto TamarizОценок пока нет

- Pro PDF p27Документ1 страницаPro PDF p27Андрей НавОценок пока нет

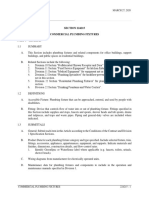

- 224215, Commercial Plumbing FixturesДокумент13 страниц224215, Commercial Plumbing Fixturessrp. mohammed100% (1)

- REL-BFW-300 FM & UL Wafer Butterfly Valve: Material List Component MaterialДокумент2 страницыREL-BFW-300 FM & UL Wafer Butterfly Valve: Material List Component MaterialSavy PhanethОценок пока нет