Академический Документы

Профессиональный Документы

Культура Документы

PG Si 0039 en Web

Загружено:

b82monicaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PG Si 0039 en Web

Загружено:

b82monicaАвторское право:

Доступные форматы

R

e

g

.

N

r

.

4

/

4

0

0

-

1

5

0

.

3

/

G

B

-

A

PIERBURG

Service

information

s

si 0039/A GB Troubleshooting exhaust gas recirculation systems

Diesel engines

Vehicle: Product:

all with exhaust gas recirculation system diverse: refer to the catalogs,TECDOC-CD or systems

basing on TECDOC-data.

To comply with the emission

standards in effect since 1994,

modern vehicles are also fitted with

an exhaust gas recirculation system.

These systems reduce NOx values

by up to 50 % and soot particle by

10 %.

The AU only visually inspects the

EGR components. This is insufficient

as faults remain virtually undetected.

Far more sensible is a simple

function test that any workshop can

carry out for pneumatic EGR valves.

In this test, the function and tightness

of the EGR valve is tested mainly

with a manual vacuum pump.

Electric valves require the use of a

multimeter.

Faults on EGR systems are mostly

valves that do not open or close.

Whilst a valve that does not close

gives rise to faults that are noticed by

the driver, valves that do not open

usually go unnoticed. Engine

damage is possible.

As EGR valves have a considerable

influence on pollution emissions, they

are also an integral part of homo-

logation, i.e. changes to EGR valves

or even their rendering inoperational

are impermissible.

Although this may be common

knowledge in any vehicle repair shop,

that faulty EGR valves are not

replaced.

To enable you to work correctly and

clear possible faults quickly and

reliably, locate possible faults

quickly and clear them reliably,

please refer to the table overleaf.

Further information about working

on AGR systems is provided in

P

1

0

0

0

5

/

0

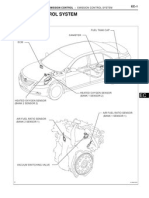

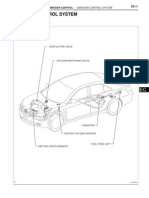

Diesel EGR system (pneumatic)

1 Control unit

2 Air filter

3 Air flow meter (AFM)

4 EGR valve with/without position feedback

5 Electropneumatic pressure transformer

E

m

i

s

s

i

o

n

c

o

n

t

r

o

l

si 0002/A, function testing of

exhaust gas recirculation

components

si 0017/A, exhaust gas

recirculation system with air flow

meter and

si 0027, electric pressure

transformer.

6 Intake air throttling

7 Electric switch valve

8 Vacuum pump

9 Particle filter

P

r

o

c

e

s

s

i

n

g

O

u

t

l

e

t

I

n

l

e

t

Position feedback (optional)

Temperature

Speed

Signal

Subject to change of illustrations and text.

MSI Motor Service International GmbH Hamburger Strae 15 D-41540 Dormagen Phone +49 (21 33) 267-100 Fax +49 (21 33) 267-111

www.msi-motor-service.com

MSI-PG 11.02

Fault

EGR valve does

not open (1)

EGR valve does

not close

Consequences/complaints

Nitrogen oxides increase

considerably

For vehicles with OBD system, a

fault code is set; the fault is

possibly indicated via the fault

lamp of glow control lamp

Incorrect engine performance

characteristics

Poor performance

Top speed is not reached

Poor acceleration

Black smoke

Top speed is not reached

For vehicles with OBD system, a

fault is indicated and a fault code is

set

Engine control assumes

emergency operating conditions

Incorrect engine performance

characteristics

Possible causes

EGR valve is not energised or

was inadmossible inoperatio-

nal (2)

EGR valve sticks/gummed

Leakages on the vacuum side

- Diaphragm faulty

- Diaphragm box damaged

- Vacuum connections leaky or

disconnected

EGR valve damaged through

excessive temperature (4)

- due to incorrect control

- due to high exhaust back

pressure

- due to non-opening blow-off

valve (for turbocharger)

Heavy deposits on tappet or valve

mushroom

Wear in tappet guide

EGR valve damaged through

over heating

- due to incorrect control

- due to high exhaust back

pressure

- due to non-opening blow-off

valve (for turbocharger)

Air flow meter or other sensor

signal faulty

Intake pipe in the area of the

exhaust gas recirculation system

partly constricted by deposits (6)

Remedial actions

Check connections and control as

well as electric or

electropneumatic pressure

transformer and clear faults

Renew and clean valve if

necessary (3)

Locate leakages and stem, renew

valve if necessary

Check and repair if necessary

- control

- exhaust system for continuity

- blow-off valve (wastegate) of

turbocharger (5)

Renew EGR valve

Renew EGR valve

Renew EGR valve

- check control

- check exhaust system for

continuity and repair if

necessary

- check blow-off valve and control

and repair if necessary

Check sensors for set values and

renew if necessary

Clean intake pipe or renew and

check turbocharger according to

manufacturers specifications,

replace if necessary

Remarks

(1) Unnoticed by drivers of older vehicles

(2) Vehicle no longer complies with homologation

(3) Cleaning only in emergencies

(4) Diaphragm box of valve is discoloured

(5) In some cases, actions were carried out to

increase the boost pressure

(6) Turbocharger has oil leak

EGR system faults for diesel engines

4/4 00-150.3 GB

Вам также может понравиться

- Cat C15 SDP Testing and Adjusting Manual 2 PDFДокумент138 страницCat C15 SDP Testing and Adjusting Manual 2 PDFDragan Krsmanovic100% (1)

- Automotive Electronics - Vol 2Документ40 страницAutomotive Electronics - Vol 2Victor Balas100% (14)

- 6.0 Late 2004 Hardstart - Nostart - DiagnosticsДокумент1 страница6.0 Late 2004 Hardstart - Nostart - DiagnosticsvixentdОценок пока нет

- Cat C15 SDP Testing and Adjusting Manual 2 PDFДокумент138 страницCat C15 SDP Testing and Adjusting Manual 2 PDFDragan Krsmanovic100% (2)

- Troubleshootig GuideДокумент12 страницTroubleshootig GuideTony Wilden Angelo PeñaОценок пока нет

- Short Moritz - LiverGB PDFДокумент3 страницыShort Moritz - LiverGB PDFPetra JobovaОценок пока нет

- Ford RS Cosworth Engine Management Fault FindingДокумент59 страницFord RS Cosworth Engine Management Fault FindingMiodrag Bogojevic Gaga100% (1)

- Undercowl Pocket Guide RRДокумент32 страницыUndercowl Pocket Guide RRbnmmauricio100% (3)

- The Seventh House in AstrologyДокумент6 страницThe Seventh House in Astrologytratak100% (1)

- 7.1. Emission Control SystemДокумент18 страниц7.1. Emission Control SystemChristian Icaza SamaniegoОценок пока нет

- ElectricalДокумент540 страницElectricalCaza GeorgeОценок пока нет

- Reservoir Rock PropertiesДокумент148 страницReservoir Rock Propertiesiscribdusername100% (7)

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleДокумент8 страницAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- Air ConditioningДокумент108 страницAir ConditioninglogammicОценок пока нет

- ExhaustДокумент39 страницExhaustFernando CidreОценок пока нет

- Mold Maintenance StepДокумент0 страницMold Maintenance StepMonica JoynerОценок пока нет

- Hyundai D6GA Fuel SystemДокумент53 страницыHyundai D6GA Fuel SystemBigfair HD78100% (11)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Maintenance and Electric ChartДокумент9 страницMaintenance and Electric Chartakamalapuri388100% (1)

- Ruger MKIIДокумент1 страницаRuger MKIIMike Pape100% (1)

- ABS System - Bosch 2E ABSДокумент14 страницABS System - Bosch 2E ABSngelectronic5226100% (1)

- Kangoo ECU-DCU3R NT3303A PDFДокумент42 страницыKangoo ECU-DCU3R NT3303A PDFFlorian Leordeanu92% (13)

- VW Passat B5 21 (38) Charge Air SystemДокумент47 страницVW Passat B5 21 (38) Charge Air SystemJosé Luis OrmeñoОценок пока нет

- SPEEDTRONIC MARK VI - Maintenance: Training Manual - Vol IiДокумент201 страницаSPEEDTRONIC MARK VI - Maintenance: Training Manual - Vol Iighdjjd100% (6)

- DPWH ReviewerДокумент597 страницDPWH Reviewercharles sedigoОценок пока нет

- Information Service: Electric EGR Valves (Renault, Opel)Документ3 страницыInformation Service: Electric EGR Valves (Renault, Opel)Popa AurelОценок пока нет

- Homoeopathy and MigraineДокумент4 страницыHomoeopathy and MigraineEditor IJTSRDОценок пока нет

- 17 Engine and Emission ControlДокумент38 страниц17 Engine and Emission ControlJoaoBorgesОценок пока нет

- NumerologieДокумент22 страницыNumerologieJared Powell100% (1)

- Anti Pollution FualtДокумент3 страницыAnti Pollution FualtSuntorn SuwannashomОценок пока нет

- Toyota - Paseo - Workshop Manual - 1990 - 1991Документ3 179 страницToyota - Paseo - Workshop Manual - 1990 - 1991cginternet.ofcОценок пока нет

- 444 - Fuel System Fi1Документ10 страниц444 - Fuel System Fi1Chim ConОценок пока нет

- MR 360 Clio 6Документ29 страницMR 360 Clio 6eutraОценок пока нет

- VW Passat B5 Secondary Air Injection, Engine Aug AwmДокумент14 страницVW Passat B5 Secondary Air Injection, Engine Aug AwmNPОценок пока нет

- SPN Mot-edc17-Bosch v01 4025Документ6 страницSPN Mot-edc17-Bosch v01 4025qusayabuqamarОценок пока нет

- Egr DiagnosticsДокумент3 страницыEgr DiagnosticsFelipe Perez YañezОценок пока нет

- Fuel Injection Afc SystemДокумент124 страницыFuel Injection Afc SystemSaulius VinОценок пока нет

- VW Test Procedure No CompressorДокумент9 страницVW Test Procedure No CompressorCristi CrisОценок пока нет

- Emerson 028Документ5 страницEmerson 028Celso FernandesОценок пока нет

- Hyundai Accent CRDI EGR Inspection and Testing 2Документ3 страницыHyundai Accent CRDI EGR Inspection and Testing 2George AranzasoОценок пока нет

- Understanding Exhaust Gas Recirculation SystemsДокумент4 страницыUnderstanding Exhaust Gas Recirculation SystemsPrasanna HasyagarОценок пока нет

- Emission ControlДокумент26 страницEmission ControllogammicОценок пока нет

- Csa NewДокумент8 страницCsa Newpeterpunk75Оценок пока нет

- Curso Caterpillar Material Del Estudiante Dispositivos ElectronicosДокумент109 страницCurso Caterpillar Material Del Estudiante Dispositivos ElectronicosWilmar Raul Hancco ZaraviaОценок пока нет

- EGR Flow TestДокумент5 страницEGR Flow TestJulian mezaОценок пока нет

- Technical Service Bulletin: Exhaust Gas Recirculation (Egr) System DiagnosisДокумент13 страницTechnical Service Bulletin: Exhaust Gas Recirculation (Egr) System DiagnosisWilliam J. BurnoreОценок пока нет

- Heating and Ventilation PDFДокумент73 страницыHeating and Ventilation PDFsunilsunny317Оценок пока нет

- Cip 0100Документ4 страницыCip 0100morus100% (1)

- Exhaust Gas RecirculationДокумент15 страницExhaust Gas RecirculationJesus FloresОценок пока нет

- 16H Ats PDFДокумент37 страниц16H Ats PDFMiguel Marquez KongОценок пока нет

- Elantra 91 Emission Control SystemДокумент49 страницElantra 91 Emission Control Systemahmad adelОценок пока нет

- SSP 296 1.4 & 1.6 FSi EngineДокумент24 страницыSSP 296 1.4 & 1.6 FSi Engineภูเก็ต เป็นเกาะ100% (3)

- Operating Manual Manual de Instrucciones Manuel D'utilisationДокумент16 страницOperating Manual Manual de Instrucciones Manuel D'utilisationCarlos EscalonaОценок пока нет

- 2GR-FE Emission ControlДокумент23 страницы2GR-FE Emission ControlLuks FernandezОценок пока нет

- R35 Procedures Without CodesДокумент6 страницR35 Procedures Without CodesÁdámTrojákОценок пока нет

- Chapter 4 Part D: Emission Control SystemsДокумент3 страницыChapter 4 Part D: Emission Control SystemsJhon HancockОценок пока нет

- DTC P0505 Idle Control System Malfunction: Circuit DescriptionДокумент3 страницыDTC P0505 Idle Control System Malfunction: Circuit DescriptionRC VilledaОценок пока нет

- 14sPACE WAGONДокумент20 страниц14sPACE WAGONrafaelcruzgjaОценок пока нет

- EGR Temperature SensorДокумент6 страницEGR Temperature SensorAdrian SchembriОценок пока нет

- Star MazdaДокумент40 страницStar MazdastvnscottОценок пока нет

- Instructions (43385) : Three Year WarrantyДокумент3 страницыInstructions (43385) : Three Year WarrantyprogramaincОценок пока нет

- 2AZ-FE Emission ControlДокумент25 страниц2AZ-FE Emission ControlLuks FernandezОценок пока нет

- Ec (2jz-Gte) PDFДокумент12 страницEc (2jz-Gte) PDFAshokОценок пока нет

- Compresor Tuflo 550Документ6 страницCompresor Tuflo 550Ramón José Aponte FrancoОценок пока нет

- 189 010 - en 15.710057 V3.0Документ12 страниц189 010 - en 15.710057 V3.0balzac191Оценок пока нет

- 793D Off-Highway Truck FDB00001-UP (MACHINE) POWERED by 3516B Engine (SEBP3976 - 204) - Verificações OperacionaisДокумент7 страниц793D Off-Highway Truck FDB00001-UP (MACHINE) POWERED by 3516B Engine (SEBP3976 - 204) - Verificações OperacionaisDouglas GomesОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- SDS Super PenetrantДокумент5 страницSDS Super Penetrantaan alfianОценок пока нет

- Ansi/Isa - 75.08.04-2001 (R2013) Face-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Class 4500)Документ16 страницAnsi/Isa - 75.08.04-2001 (R2013) Face-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Class 4500)Horas CanmanОценок пока нет

- SC4860-48120 (-MPV) User Manual EN 202107Документ23 страницыSC4860-48120 (-MPV) User Manual EN 202107Nattachai BoonchooОценок пока нет

- Geology and Mineralization of The Maggie Creek DistrictДокумент28 страницGeology and Mineralization of The Maggie Creek DistrictRockstone Research Ltd.Оценок пока нет

- Nastran Preference Guide Volume 1 Structural AnalysisДокумент724 страницыNastran Preference Guide Volume 1 Structural AnalysisGuido RossiОценок пока нет

- 9 Quw 9 CjuДокумент188 страниц9 Quw 9 CjuJavier MorenoОценок пока нет

- Module III Rural MarketingДокумент30 страницModule III Rural MarketingNikita YadavОценок пока нет

- Construction Companies in AlbaniaДокумент17 страницConstruction Companies in AlbaniaPacific HRОценок пока нет

- Aircraft Structures - Ii (AER18R372)Документ15 страницAircraft Structures - Ii (AER18R372)sarathkumar sebastinОценок пока нет

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsДокумент21 страницаEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoОценок пока нет

- Jetline: Theoretical Working Point Performance ChartДокумент1 страницаJetline: Theoretical Working Point Performance ChartMohamed GamalОценок пока нет

- Origami Undergrad ThesisДокумент63 страницыOrigami Undergrad ThesisEduardo MullerОценок пока нет

- Using A Wet Film ThicknessДокумент2 страницыUsing A Wet Film ThicknesssanoopvkОценок пока нет

- Module II Activated Sludge Math ProblemsДокумент5 страницModule II Activated Sludge Math ProblemsArashОценок пока нет

- MHT-CET 2021 Question Paper: 25 September 2021Документ3 страницыMHT-CET 2021 Question Paper: 25 September 2021Sank DamОценок пока нет

- Hypomineralised Second Primary Molars May Be Indicative of Future Molar Incisor Hypomineralisation PDFДокумент6 страницHypomineralised Second Primary Molars May Be Indicative of Future Molar Incisor Hypomineralisation PDFnha khoa NHƯ NGỌCОценок пока нет

- Donali Lalich Literature ReviewДокумент4 страницыDonali Lalich Literature Reviewapi-519746057Оценок пока нет

- Research On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesДокумент7 страницResearch On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesJames PhillipsОценок пока нет

- 16950Документ16 страниц16950uddinnadeemОценок пока нет

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationДокумент10 страницSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaОценок пока нет

- Indian Standard: Application Guide For Voltage TransformersДокумент16 страницIndian Standard: Application Guide For Voltage TransformersGnanavel GОценок пока нет