Академический Документы

Профессиональный Документы

Культура Документы

Applying Aluminum Foil Under Insulation

Загружено:

gabozcИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Applying Aluminum Foil Under Insulation

Загружено:

gabozcАвторское право:

Доступные форматы

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

NORM:

TOEPASSING VAN ALUMINIUM FOLIE ONDER ISOLATIE VOOR STAINLESS STEEL EQUIPMENT EN PIPING (PERNIS)

Objective & scope

CD&A Classificatie CMS HSE kritisch MOC

: : : : :

Nee Unrestricted Nee Ja Nee

Noodplan Risico Veiligheidsrapport WWW-Aannemers

: : : :

Nee M Nee Ja

Objective Prevention of external chloride stress corrosion of stainless steel equipment and piping. Scope Description of the requirements for application of aluminum foil under thermal insulation for austenitic stainless steel equipment and piping.

Parties involved

The performers of the work process: Shell Pernis plants The local process owners (Department Process focalpoints) OMC

Questions or improvements

For questions about the activities in this amendment or ideas on how to improve them, please contact: OMC van jouw afdeling, of met Inspection and Materials Manager (DMS/742) This document is, according to the Risk Matrix, potential (M)iddle. The risk is covered by this document and by training and application of this document. Last revision A Date 01-11-2012 Reason What: Why: Where: Target: More revision information Eerste uitgave, hiermee vervalt 04.00.3049 Gesplitst van Moerdijk en over naar een ander BBS proces -

Risk

Revision info

Ownership & Administration

Owner and content manager of this document are - respectively - the Site Process Owner (SPO), the Site Process Focalpoint (SPFP). The Work Process Team (WPT) consists of the Department Process Focalpoints (DPFPs) and Subject Matter Experts (SMEs) from the work process Pressure Equipment Integritry (PEI). Function (Reference Indicator) Owner Engineering Assurance Manager (DMS/74) Administrator Inspection and Materials Manager (DMS/742) Members of the WPT OMC (DMS/71OD4) OMC (DMS/71DU4) HOPTA (DMS/71WH3) Role in the workprocess SPO PEI

SPFP PEI

DPFP voor PEI (vertegenwoordiger OMC-netwerk) DPFP voor PEI (vertegenwoordiger OMC-netwerk) SME voor TA & Projects (vertegenwoordiger HOPTA-netwerk)

Pagina: 1 van 9 Niveau: 2

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

Coordinating Inspector ROM & RHP (DMS/7422) Maintenance Supervisor RHP (DMS/723) Production Supervisor (DMS/71BO1)

SME voor Inspectie (vertegenwoordiger DMS/74) SME voor Maintenance (vertegenwoordiger DMS/72) SME voor Operatie (vertegenwoordiger Supervisor-netwerk)

Inhoudsopgave

1. 2. 3. 4.

INTRODUCTION ................................................................................. 3 CONTEXT AND REFERENCES ......................................................... 3 DEFINITIONS AND ABBREVIATIONS ............................................... 3 DOCUMENT TEXT .............................................................................. 4

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 2 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

1.

INTRODUCTION

Coating of equipment and piping shall be selected and applied in accordance with BBS 04.00.4054 (new equipment) or BBS 04.00.4053 (maintenance). The preferred option for protection against chloride stress corrosion cracking of stainless steel equipment and piping shall be application of thermal sprayed aluminium (TSA). Aluminium foil can be used as an alternative in lieu of TSA to provide a physical barrier between austenitic stainless steel and the thermal insulation, but only after consultation with and approval of the civil engineering department. Organic coatings to protect stainless steel equipment and piping from external stress corrosion cracking shall only be considered when neither TSA nor its alternative of aluminium foil wrapping are technically viable options.

2.

CONTEXT AND REFERENCES

Engineering guides and specification 19 GS-51.

3.

DEFINITIONS AND ABBREVIATIONS

-

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 3 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

4.

DOCUMENT TEXT

19 GS-51 Application of Aluminum Foil Under Insulation for Stainless Steel Equipment and Piping Approved Aug 05

Engineering Guides and General Specifications

19 GS-51 Application of Aluminium Foil Under Insulation for Stainless Steel Equipment and Piping Table of contents

1. General 1.8 Existing Equipment and Piping 2. 3. Materials Application 1.1 Scope 1.2 References 1.3 Related Documents 1.4 Definitions 1.5 External Chloride Stress Corrosion Cracking 1.6 Temperature Considerations 1.7 New Equipment and Piping Appendix 1 Suppliers List Appendix 2 Application DOs and DONTs

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 4 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

1.

1.1

GENERAL

Scope This General Specification (GS) covers requirements for application of aluminum foil under thermal insulation for austenitic stainless steel equipment and piping. Comment: Aluminum foil can be used in lieu of conventional organic coatings that are used to provide a physical barrier between the austenitic stainless steel and the thermal insulation. Aluminum foil provides some physical barrier but acts primarily as a sacrificial anode to provide electrochemical (cathodic) protection against external chloride stress corrosion cracking. References Applicable requirements in the following referenced standards and specifications shall be considered an integral part of this GS. Unless otherwise specified, the latest edition/revision of the standards/specifications shall be used. Steel Structures Painting Council (SSPC) SP-1 Solvent Cleaning International Organization for Standardisation (ISO) EN-ISO 12944 Paints and Varnishes Corrosion Protection of Steel Structures by Protective Paint Systems for EU

1.2

1.2.1

1.2.2

1.3

Related Documents CINI Handbook Insulation for Industries 2005. BS 5970:2001 Code of Practice for Thermal Insulation of Pipework and Equipment in the Temperature Range of -100C to +870C.

1.4

Definitions 1 mil .001 inch 40 mils equals 1000 microns or one millimeter

1.5

External Chloride Stress Corrosion Cracking 1. External chloride stress corrosion cracking (ECSCC) is cracking that may occur in austenitic stainless steel with or without insulation. 2. If there is corrosion under insulation (CUI), ECSCC is the result of ingress of water and chlorides. Chlorides are introduced if the insulation contains chlorides from manufacture and/or ingress of chloride containing water.

Comment: ECSCC is the same as chloride stress corrosion cracking (Cl-SCC) that can occur in austenitic stainless steels and certain other austenitic alloys exposed to aqueous, chloridecontaining environments above 120F (50C). 1.6 Temperature Considerations Applicable temperature range for use of aluminum foil under insulation is 120F (50C) to 400F (200C) for continuous service and 900F (480C) for cyclic conditions. Comment: Aluminum melts at 1215F (657C). Austenitic stainless steel is not susceptible to Liquid Metal Embrittlement (LME) when in contact with pure grades of molten aluminum. Zinc must be present in the aluminum to cause LME. 1.7 New Equipment and Piping 1. New uncoated austenitic stainless steel surfaces to be covered with aluminum foil shall be cleaned in accordance with SSPC SP-1 or EN-ISO 12944. 2. 3. 4. Cleaning shall remove all dirt, oil, grease, salts, moisture, chemicals, and other contamination. Chlorinated solvents shall not be used for cleaning. Abrasive blasting is not required.

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 5 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

1.8

Existing Equipment and Piping 1. Existing coated austenitic stainless steel surfaces to be covered with aluminum foil shall be washed with low pressure water cleaning (LPWC). 2. LPWC shall remove grime, loose and chalky paint, salt contaminants, and loose rust. If fresh water (water with less than 250 ppm chlorides) is used for LPWC, the surfaces shall be rinsed with water containing less than 10 ppm chlorides. LPWC shall be done with the water nozzle approximately perpendicular to the surface. Comment: Using excessive pressure and low nozzle angle may cause undue damage to the existing coating. Comment: Demineralized water may be used to clean chloride contamination from uncoated stainless steel. 4. 5. Existing aluminum foil shall be completely removed. Surfaces to be covered with aluminum foil shall be inspected for sharp edges, weld spatter, and protuberances. If any such conditions exist, the purchaser shall have them ground smooth or rounded.

3.

2.

MATERIAL

1. 2. 3. Aluminum foil shall have an aluminum content of 99%, equivalent to Alloy 1100. Aluminum foil shall have a minimum nominal thickness of 2.5 mils (64 micrometer) or 46 swg. Self-adhesive foil may be used for complex configurations, such as vessel heads and attachments. Adhesive shall contain less than 10 ppm chlorides. No other adhesive or sticky tape is allowed unless it contains less than 10 ppm chlorides.

3.

APPLICATION

1. 2. 3. 4. 5. 6. 7. Aluminum foil shall be applied as soon as practical after the surfaces are cleaned. Foil shall not be applied if the cleaned surface temperature is less than 5F (3C) above the dew point. Unless otherwise specified, foil shall not be applied if the relative humidity is greater than 85%. Personnel who apply the foil shall wear gloves to avoid touching the stainless steel surfaces with bare hands. Torn or damaged foil shall not be used. Foil shall be applied as tightly as possible without any creases. Where partial coatings exist, stainless steel wire shall be used to hold the foil in place. Wire shall be grounded to equipment/piping flanges. Comment: The aluminum foil cannot provide electrochemical protection against chloride stress corrosion cracking unless there is elektrical contact between the foil and the metal. Paintings or coatings may act as an insulator and should preferably be removed unless sufficient elektrical contact exists between the aluminum wrapping and the austenitic stainless steel. 8. 9. Foil shall be applied prior to installing elektrical or steam tracing. Foil shall be applied bottom to top so that it sheds water.

10. Foil shall be applied so that it has a minimum overlap of 2 in. (5 cm) at joints. 11. Insulation and weatherproof finish shall be applied immediately after the foil is applied. 12. Application DOs and DONTs are provided in Appendix 2.

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 6 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

APPENDIX 1: SUPPLIERS LIST

Alcan Aluminum Corp. Alcan Light Gauge Products 5901 North 13th St, Terre Haute, IN 47805 440 423-6800 http://www.alcan.com Alcoa Inc. Alcoa flexible Packaging, Louisville Foil Plant Louisville, KY 41211 412- 553-4545 or Richmond, VA 23224 804- 230-5200 Coastal Aluminum Rolling Mills, Williamsport, PA 17701 570-323-4430 Corus Aluminium Rolled Products Cap-de-la-Madeleine, Quebec, GBT 7W9 819-373-6363 Ekco Products, Clayton, NJ 856-881-3600 J W Aluminum Co Holly, SC 29419 Charleston, SC 843-572-1100 Norandal USA, Inc Franklin, TN 615-778-2000 Premium Foil Products Co Louisville, KY 502-459-2820 Republic Foil Danbury, CT 203-743-2731 EU (NL) Supplier Hanko Handelmaatschappij BV Postbus 6904 4802 HX BREDA Charles Petitweg 39 4827 HJ BREDA bedrijfsnummer 9530

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 7 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

19 GS-51 Application of Aluminum Foil Under Insulation for Stainless Steel Equipment and Piping Approved Aug 05

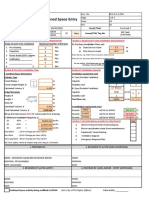

Appendix 2 Application DOs and DONTs

DOs

A p p l y f o i l b o tto m to to p so it sh e d s w a t e r

D O N T s

F o i l sh a l l b e a p p li e d so t h a t it h a s a m i n i m u m ov e r l a p o f 2 a t j o in ts. F o i l sh a l l b e a p p lied a s ti g h tly a s p os si b l e w i t h ou t a n y c r e a se s o r w r i n k l e s.

>2

F o i l sh a l l b e a p p li e d p r i o r t o i n st a l l i n g st e a m or e l e c t r ic a l tr a c in g

F o i l sh a l l b e a p p li e d p r i o r t o i n st a l l i n g su p p or t s or ot h e r b ol t e d ob j e c t s.

A d a p t f o i l si z e t o d i a m e te r t o p r e v e n t w r in k l e s.

W h e r e p a r t ia l c o a ti n g s e x i st , st a i n l ess st e e l w i r e sh a l l b e u se d t o h old t he f o i l i n p la c e . W i r e sh a l l b e g r ou n d e d t o e q u i p m e n t /p i pi n g f l a n ge s.

Engineering Guides and General Specifications

Page 7 of 7

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 8 van 9 Niveau: 2

UNCONTROLLED INDIEN GEPRINT

BBS norm 02.05.3028

terug naar voorblad Revisie informatie Revisie Datum Reden

Filenaam: 02053028.docx

Rev.: A

Administrator: Inspection and Materials Manager (DMS/742) Owner: Engineering Assurance Manager (DMS/74)

Pagina: 9 van 9 Niveau: 2

Вам также может понравиться

- Painting SpecificationДокумент27 страницPainting SpecificationMohamed Thasim100% (1)

- Astm B633-19Документ3 страницыAstm B633-19Cj Elamparo100% (1)

- Astm A780Документ4 страницыAstm A780Raúl Venegas Munita100% (5)

- A M 09 Metalwork July 09Документ21 страницаA M 09 Metalwork July 09suneethmohanОценок пока нет

- TL 233, 11-2010, enДокумент8 страницTL 233, 11-2010, enMiguel QueirosОценок пока нет

- 3 - SWCC Specification M02 Polyethylene Coating Rev0Документ30 страниц3 - SWCC Specification M02 Polyethylene Coating Rev0EngineerSajidAlam100% (1)

- DSM 1510002 SP 20 - V1.0Документ28 страницDSM 1510002 SP 20 - V1.0Kalaivani Arunachalam100% (2)

- Painting SpecДокумент54 страницыPainting Specashim_scribd100% (4)

- T-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentДокумент59 страницT-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentMichael CovillОценок пока нет

- Law As A Command of SovereignДокумент12 страницLaw As A Command of SovereignAdv BL Dewasi100% (2)

- INFOSTEEL - Guide To Protection of Steel Against CorrosionДокумент8 страницINFOSTEEL - Guide To Protection of Steel Against CorrosionA87_navjОценок пока нет

- Insulation RequirementsДокумент8 страницInsulation RequirementslsaishankarОценок пока нет

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesОт EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesОценок пока нет

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОт EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОценок пока нет

- Procedure WrappingДокумент6 страницProcedure Wrappingyogacruise100% (1)

- Problem set 1 covers energy, heat, gases, and thermodynamicsДокумент15 страницProblem set 1 covers energy, heat, gases, and thermodynamicsFikret BazОценок пока нет

- Practical Guidelines Inspect Repair HDG Coatings 2008Документ24 страницыPractical Guidelines Inspect Repair HDG Coatings 2008forbeskaОценок пока нет

- Vessel Linings SpecДокумент8 страницVessel Linings SpechiyeonОценок пока нет

- Corrosion Swimming)Документ6 страницCorrosion Swimming)skenny1Оценок пока нет

- Coating Selection & Application RequirementsДокумент93 страницыCoating Selection & Application RequirementsHarish Kumar Kannepalli50% (2)

- Ventilation Plan For Confined Space EntryДокумент9 страницVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Muglad Basin Oil Development Project Insulation SpecificationsДокумент23 страницыMuglad Basin Oil Development Project Insulation Specificationsamalhaj2013Оценок пока нет

- Document E202 - 2008: Building Information Modeling Protocol ExhibitДокумент9 страницDocument E202 - 2008: Building Information Modeling Protocol ExhibitAndres Cedeno TutivenОценок пока нет

- Insulation and Design Rev 1Документ32 страницыInsulation and Design Rev 1pigfly2012Оценок пока нет

- Corus - A Corrosion Protection GuideДокумент6 страницCorus - A Corrosion Protection GuideBellana SirishОценок пока нет

- Iso 12944 Painting Systems For Atmospheric Corrosion Cotntrol Part 1Документ49 страницIso 12944 Painting Systems For Atmospheric Corrosion Cotntrol Part 1Yousuf Memon100% (1)

- Ecco AДокумент5 страницEcco Aouzun852Оценок пока нет

- Process Industry Practices Coatings: PIP CTSL1000 Application of Internal LiningsДокумент23 страницыProcess Industry Practices Coatings: PIP CTSL1000 Application of Internal LiningsSujita Sah100% (1)

- ISO 8501-3 Preparation Grades of Welds, Cut Edges and Other Area With Surface ImperfectionsДокумент9 страницISO 8501-3 Preparation Grades of Welds, Cut Edges and Other Area With Surface ImperfectionsPn Thanh100% (2)

- APTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedДокумент13 страницAPTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedAshutosh SharmaОценок пока нет

- Din ISO 1461Документ24 страницыDin ISO 1461Prateek100% (3)

- Et WHP02 0000 Mec TPB 1003 - Ar 0001Документ60 страницEt WHP02 0000 Mec TPB 1003 - Ar 0001orea1Оценок пока нет

- Stainless Steel Chloride Corrosion PDFДокумент8 страницStainless Steel Chloride Corrosion PDFSaut Maruli Tua SamosirОценок пока нет

- EFD-Info No. 20 Corrosion Protection TestingДокумент4 страницыEFD-Info No. 20 Corrosion Protection TestingNenad DeusicОценок пока нет

- Technical Data Sheet and Application Guide SummaryДокумент10 страницTechnical Data Sheet and Application Guide SummaryMohanadОценок пока нет

- APP110Документ9 страницAPP110Dave LiОценок пока нет

- General Technical Requirements For Aluminium Constructionsps1005341-30201.Doc Conveyed Confidentially As Trade SecretДокумент8 страницGeneral Technical Requirements For Aluminium Constructionsps1005341-30201.Doc Conveyed Confidentially As Trade SecretHoangОценок пока нет

- ISO-12944-2-corrosion ProtectionДокумент9 страницISO-12944-2-corrosion Protectionmatan dvirОценок пока нет

- Anodized Coatings Spec for AluminumДокумент19 страницAnodized Coatings Spec for AluminumEnise GöçerОценок пока нет

- Corrosion Protection For Cold-Formed Structural STДокумент8 страницCorrosion Protection For Cold-Formed Structural STethiwaОценок пока нет

- K.muhlberg Corrosion Protection For WindmillsДокумент12 страницK.muhlberg Corrosion Protection For WindmillsTiago Lopes100% (1)

- Standard Corrosion Protection Systems For Buildings - Steelconstruction PDFДокумент11 страницStandard Corrosion Protection Systems For Buildings - Steelconstruction PDFRahul RaoОценок пока нет

- D153 PSSC2010RWhiteДокумент17 страницD153 PSSC2010RWhiteJamesОценок пока нет

- E1300 - Corrosion and CoatingsДокумент3 страницыE1300 - Corrosion and Coatingsgerrzen64Оценок пока нет

- 55 Samss 004Документ12 страниц55 Samss 004Moustafa BayoumiОценок пока нет

- FRS Electrical Panel Spec EOIДокумент20 страницFRS Electrical Panel Spec EOITravis WoodОценок пока нет

- Protective Coating Specification for Elgin/Franklin Wellhead TopsidesДокумент46 страницProtective Coating Specification for Elgin/Franklin Wellhead TopsidesmatmarcantonioОценок пока нет

- Aws C2Документ8 страницAws C2dehamanezОценок пока нет

- Chemflake SpecialДокумент10 страницChemflake SpecialNabeel K SОценок пока нет

- 6-68-0033 Rev 7 PDFДокумент16 страниц6-68-0033 Rev 7 PDFRaj Sri100% (1)

- Painting Specification for Piping, Equipment and Structural SteelДокумент15 страницPainting Specification for Piping, Equipment and Structural SteelFares ateОценок пока нет

- Plant InspectionДокумент9 страницPlant InspectionSyed SulaimanОценок пока нет

- 084413-Glazed Aluminum Curtain Walls (MultiWall HS 2700)Документ12 страниц084413-Glazed Aluminum Curtain Walls (MultiWall HS 2700)Catharina SusantoОценок пока нет

- AN 400 Part 2 - Corrosion Protection of Purchased PartsДокумент15 страницAN 400 Part 2 - Corrosion Protection of Purchased PartschristopherОценок пока нет

- Baltoflake: Technical Data Sheet Application GuideДокумент11 страницBaltoflake: Technical Data Sheet Application GuideNurmalinda SihombingОценок пока нет

- Maxatec 111 A07 A09 Series Eurocode sc15 - F9dc6fdeДокумент7 страницMaxatec 111 A07 A09 Series Eurocode sc15 - F9dc6fdepipat .sОценок пока нет

- MS-4005 - Rev - DДокумент5 страницMS-4005 - Rev - DEngenharia APedroОценок пока нет

- Iso 08502-1Документ12 страницIso 08502-1Hassan FekiОценок пока нет

- 08 63 00 PDFДокумент11 страниц08 63 00 PDFAnonymous hk1fhAkwyОценок пока нет

- PDFДокумент12 страницPDFThamaraikani ManiОценок пока нет

- SPC-FXI-009 OBC Ducting MaterialsДокумент8 страницSPC-FXI-009 OBC Ducting MaterialsHemant ChauhanОценок пока нет

- Post-Coating Treatments of Steel For Reducing The Risk of Hydrogen EmbrittlementДокумент3 страницыPost-Coating Treatments of Steel For Reducing The Risk of Hydrogen EmbrittlementLeo CostaОценок пока нет

- Spot Welding Interview Success: An Introduction to Spot WeldingОт EverandSpot Welding Interview Success: An Introduction to Spot WeldingОценок пока нет

- Spatial data analysis with GIS (DEMДокумент11 страницSpatial data analysis with GIS (DEMAleem MuhammadОценок пока нет

- A.3s Scheme Used in Managing Epp ClassДокумент35 страницA.3s Scheme Used in Managing Epp Classpixie02100% (2)

- CASE ANALYSIS: DMX Manufacturing: Property of STIДокумент3 страницыCASE ANALYSIS: DMX Manufacturing: Property of STICarmela CaloОценок пока нет

- AS-9100-Rev-D Internal-Audit-Checklist SampleДокумент4 страницыAS-9100-Rev-D Internal-Audit-Checklist Samplesaifulramli69Оценок пока нет

- Map Book 4Документ58 страницMap Book 4executive engineerОценок пока нет

- Series Portable Oscilloscopes: Keysight DSO1000A/BДокумент15 страницSeries Portable Oscilloscopes: Keysight DSO1000A/BNestor CardenasОценок пока нет

- Usg Sheetrock® Brand Acoustical SealantДокумент3 страницыUsg Sheetrock® Brand Acoustical SealantHoracio PadillaОценок пока нет

- A Simple Method To Transfer The SelectedДокумент2 страницыA Simple Method To Transfer The SelectedrekabiОценок пока нет

- AS 2 Communication in Health, Social Care and Early Years Settings EguideДокумент25 страницAS 2 Communication in Health, Social Care and Early Years Settings EguideAmy liliet BajahaОценок пока нет

- Research Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGДокумент3 страницыResearch Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGFiya ShahОценок пока нет

- Formulation and Evaluation of Lansoprazole Delayed Release PelletsДокумент20 страницFormulation and Evaluation of Lansoprazole Delayed Release PelletsUmair MazharОценок пока нет

- Factors Affecting Drying Rates and MechanismsДокумент4 страницыFactors Affecting Drying Rates and MechanismsMahesh VoraОценок пока нет

- Strategic Management Impact on Unilever PerformanceДокумент7 страницStrategic Management Impact on Unilever PerformanceWachira kabugiОценок пока нет

- Line BalancingДокумент21 страницаLine Balancingarno6antonio6spinaОценок пока нет

- Transmission Line Surge Impedance Loading ExplainedДокумент3 страницыTransmission Line Surge Impedance Loading ExplainedviksoniОценок пока нет

- Legal Opinion WritingДокумент53 страницыLegal Opinion WritingBenedict AnicetОценок пока нет

- Load of Pedstrain On FobДокумент26 страницLoad of Pedstrain On FobPOOJA VОценок пока нет

- Standard OFR NATIONAL L13A BDREF Ed1.1 - 24 - JanvierДокумент640 страницStandard OFR NATIONAL L13A BDREF Ed1.1 - 24 - JanvierosmannaОценок пока нет

- Rosalind FranklinДокумент1 страницаRosalind FranklinMichael SmithОценок пока нет

- 8279Документ32 страницы8279Kavitha SubramaniamОценок пока нет

- Electonics Final HandoutsДокумент84 страницыElectonics Final HandoutsDiane BasilioОценок пока нет

- Sick GM31Документ54 страницыSick GM31Magdy SalehОценок пока нет

- Lesson 5: Cultural Relativism: Learning OutcomesДокумент4 страницыLesson 5: Cultural Relativism: Learning OutcomesGanda GandaОценок пока нет

- Cisco and Duo Presentation 8.2.18Документ8 страницCisco and Duo Presentation 8.2.18chris_ohaboОценок пока нет

- Hegemonic Masculinity As A Historical Problem: Ben GriffinДокумент24 страницыHegemonic Masculinity As A Historical Problem: Ben GriffinBolso GatoОценок пока нет