Академический Документы

Профессиональный Документы

Культура Документы

City College of New York Final Project Design of Piping System Me 35600: Fluid Mechanics

Загружено:

Salman ZaidiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

City College of New York Final Project Design of Piping System Me 35600: Fluid Mechanics

Загружено:

Salman ZaidiАвторское право:

Доступные форматы

City College of New York Final Project Design of Piping System Me 35600: Fluid Mechanics

Salman Zaidi 3727 Professor Gonzalez December 13, 2013

Table of Contents Piping System Schematic................................................................................................................ 1 Description of System: .................................................................................................................... 2 Lengths and Diameters of Pipes: .................................................................................................... 2 Description and Location of Valves: .............................................................................................. 2 Flow Rates, Velocities, and Reynolds Numbers............................................................................. 3 Head Loss and Total Flow Rate for the Pump ................................................................................ 3 Pump Selection ............................................................................................................................... 4 Pump Performance Curve ............................................................................................................... 5 EES Programming Code ................................................................................................................. 7

Piping System Schematic Globe Valve Gate Valve Check Valve

Legend:

Elbow

Tee

AHU 4

AHU 3

AHU 2

AHU 1B

AHU 1A

Reservoir Pump Chiller

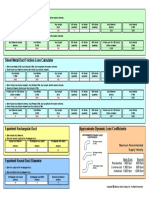

Description of System: The system was designed so that the Air Handling Units (AHUs) were in parallel. The AHUs were placed near the center of each floor. In order to supply the necessary flow rates to the floors, a pump was used. Ninety degree elbows were used in the basement and on the fourth floor, whereas tees were used on the other floors. On each floor, valves were added to regulate the flow to its proper amount. Lengths and Diameters of Pipes: Schedule 40 Commercial steel pipes were used in the piping system. Three different pipe diameters were utilized: one for the supply and return, one for floor 1, and one for the remaining three floors. The following is a list of the diameters: Diameter (in) 6 3.5 3 3 3

Supply and Return Floor 1 Floor 2 Floor 3 Floor 4

The total lengths of the pipes were as follows: Length (ft) 105 105 100 100 100 100

Supply Return Floor 1 Floor 2 Floor 3 Floor 4

Description and Location of Valves: A check valve, gate valve and globe valve were added before each AHU. A check valve was also added after the water went through the AHU. The check valve ensures that the fluid flows in one direction, the gate valve is used for on/off control and to isolate each AHU if necessary, and the globe valve is used to regulate the flow to the AHU.

Flow Rates, Velocities, and Reynolds Numbers Through the use of EES the following flow rates, velocities and Reynolds numbers were obtained for each floor: Flow Rate (GPM) Velocity (ft/s) Reynolds Number Floor 1 100 3.34 66,000 Floor 2 61.40 2.79 47,000 Floor 3 56.22 2.55 43,300 Floor 4 50.58 2.30 39,000 These values affirm that the velocity is below 10 ft/s, that the flow is maintained to be turbulent, and that each floor obtains the proper amount of fluid. Head Loss and Total Flow Rate for the Pump The head loss of the pump was the summation of the head loss due to the flow of the fluid, the head loss from the various components in the system, and the potential energy required to raise the fluid to the fourth floor. Due to the system being designed in parallel, the head loss from the flow of the fluid was equal on each floor. The following values were calculated: Head loss (ft) 0.985 22.16 55 78.14

Piping System Components Height Total

The total flow rate required for the pump is the summation of the flow rates to each floor. Thus, the pump is required to pump a minimum of 268 GPM with a head loss of 78 ft.

Pump Selection A pump that is required to pump 268 GPM with a head loss of 78 ft requires a minimum power of 4 kW. The following pump coverage curve from Gould's Reference was used to select the appropriate pump:

Based on the graph, the appropriate pump to use is the 92 SV.

Pump Performance Curve

From the pump performance curve the following information is obtained: 4 total stages and 1 reduced stage is required in the pump The pump operates at an efficiency of 75% The full diameter stages operate at 2 HP and the reduced diameter stage operates at 1.5 HP. The NPSH (Net Positive Suction Head) is 7 ft

EES Programming Code

Вам также может понравиться

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- B&G Sizing Cooling Tower Pumps and Piping TEH-275Документ12 страницB&G Sizing Cooling Tower Pumps and Piping TEH-275ChowKC03100% (3)

- ATF Project II Group 8Документ28 страницATF Project II Group 8John AlvarezОценок пока нет

- Guidelines For Sizing: FeaturesДокумент8 страницGuidelines For Sizing: FeaturesApih Ibrahim100% (1)

- Calculating Pump HeadДокумент8 страницCalculating Pump HeadPascal SayahОценок пока нет

- Guideto Submersible Pump SelectionДокумент1 страницаGuideto Submersible Pump SelectionAhmed Fgt KaasehgОценок пока нет

- Student Surname: Student Name: Student IDДокумент6 страницStudent Surname: Student Name: Student IDKumail Al KhuraidahОценок пока нет

- Pump Head CalculationДокумент15 страницPump Head CalculationYashapuja100% (1)

- R - AC Lecture 38Документ22 страницыR - AC Lecture 38Narulita B. PutriОценок пока нет

- Candu Fuel Management PDFДокумент324 страницыCandu Fuel Management PDFSuresh Kumar VickuОценок пока нет

- Pump CharacteristicsДокумент8 страницPump CharacteristicsgeocaustasОценок пока нет

- Basic of Hydronics SystemsДокумент7 страницBasic of Hydronics SystemskzyahtunОценок пока нет

- Sizing Water Supply SystemДокумент16 страницSizing Water Supply SystemArnel AlvarezОценок пока нет

- Dry Pipe Sprinkler SystemsДокумент12 страницDry Pipe Sprinkler SystemsAdil Mohd100% (1)

- Hydraulics Lab ManualДокумент12 страницHydraulics Lab ManualArman OlaОценок пока нет

- Piping Systems Srac 1994Документ6 страницPiping Systems Srac 1994maheshОценок пока нет

- The Mathematics of Pumping Water: AECOM Design BuildДокумент9 страницThe Mathematics of Pumping Water: AECOM Design BuildAdel SharifiОценок пока нет

- The Specific Objectives of This Chapter Are To:: 38.2 - General Rules For Duct DesignДокумент6 страницThe Specific Objectives of This Chapter Are To:: 38.2 - General Rules For Duct DesignSalehAfadlehОценок пока нет

- KRT Planing Information-DataДокумент110 страницKRT Planing Information-DataNicolas Alvarez GomezОценок пока нет

- Catalog HydroДокумент4 страницыCatalog HydroZy RoldaОценок пока нет

- Spe 194597 MS PDFДокумент17 страницSpe 194597 MS PDFMANISH GUPTAОценок пока нет

- Development of Heat Exchangers For Use As Replacement Plates in Distillation Columns: Proof of Concept and Collection of Design InformationДокумент22 страницыDevelopment of Heat Exchangers For Use As Replacement Plates in Distillation Columns: Proof of Concept and Collection of Design Informationkirandevi1981Оценок пока нет

- 38 Design of Air Conditioning DuctsДокумент20 страниц38 Design of Air Conditioning Ductsteo1285Оценок пока нет

- Design of Air Conditioning Ducts: LessonДокумент20 страницDesign of Air Conditioning Ducts: LessonAkhileshkumar PandeyОценок пока нет

- Paddle Powered Water PumpДокумент35 страницPaddle Powered Water PumpJahanzaib Khan100% (1)

- Design of Water Based Fire Protection SystemsДокумент43 страницыDesign of Water Based Fire Protection SystemsKumararaja Konikki94% (33)

- Water Base ProtectionДокумент42 страницыWater Base ProtectionandreasbudiОценок пока нет

- Hyd Calcs Class 3Документ30 страницHyd Calcs Class 3Jerry Tom100% (2)

- CE362 Lab ManualДокумент12 страницCE362 Lab ManualDEEPAK KUMAR MALLICKОценок пока нет

- Ag 31-011 120407 1Документ91 страницаAg 31-011 120407 1Klich77Оценок пока нет

- DryPipeSystems RevДокумент24 страницыDryPipeSystems RevCostel BalasoiuОценок пока нет

- GEMI Equations ToolДокумент10 страницGEMI Equations TooljnmanivannanОценок пока нет

- GEMI Equations Tool PumpsДокумент10 страницGEMI Equations Tool PumpsggdgdfgdfgdfgdgddddОценок пока нет

- Flow Measurement in Closed ConduitДокумент65 страницFlow Measurement in Closed ConduitjohnmayardОценок пока нет

- Report Wind Tunnel - FinalДокумент22 страницыReport Wind Tunnel - FinalRavi Kant100% (1)

- APV DESMI CARL BRO Optimisation of Pump - and Cooling Water Systems PDFДокумент36 страницAPV DESMI CARL BRO Optimisation of Pump - and Cooling Water Systems PDFaminОценок пока нет

- ME Sessional ThermofluidДокумент9 страницME Sessional Thermofluidnadimduet1Оценок пока нет

- All Code Jurisdictions Have Maximum Allowable Turnover Times For FiltrationДокумент13 страницAll Code Jurisdictions Have Maximum Allowable Turnover Times For FiltrationCamilo RochaОценок пока нет

- Design of Sewage Pumping StationДокумент10 страницDesign of Sewage Pumping StationPriyanka Rupasinghe67% (3)

- FlocculationДокумент5 страницFlocculationZeinaFarhatОценок пока нет

- Determination of Pressure Drop in A Natural Flowing Gas Well Using Nodal AnalysisДокумент14 страницDetermination of Pressure Drop in A Natural Flowing Gas Well Using Nodal AnalysisJoseph IRANZIОценок пока нет

- Sizing A Pump (English Units)Документ4 страницыSizing A Pump (English Units)norgrentОценок пока нет

- Analysis of The Flow Field Into A Two Stages and Double Entry Storage Pump Taking Into Account Two Geometries of Stator BladesДокумент11 страницAnalysis of The Flow Field Into A Two Stages and Double Entry Storage Pump Taking Into Account Two Geometries of Stator BladesIan AsОценок пока нет

- Jonas Biteus - Mean Value Engine Model of A Heavy Duty Diesel EngineДокумент34 страницыJonas Biteus - Mean Value Engine Model of A Heavy Duty Diesel EngineMuhidin ArifinОценок пока нет

- REPORTpp 1Документ16 страницREPORTpp 1gajulavamshikrishna02Оценок пока нет

- Axial Flow Pump TestДокумент12 страницAxial Flow Pump TestOnye WalsonОценок пока нет

- BMT7L1-Fluid Power Automation LabДокумент37 страницBMT7L1-Fluid Power Automation LabvamshimohanОценок пока нет

- Koomey S&s ManualДокумент0 страницKoomey S&s Manualborregocr90% (10)

- ISUZU 4HK1 6HK1 Type Engine PDFДокумент48 страницISUZU 4HK1 6HK1 Type Engine PDFЙОРДАН ГЕОРГИЕВ90% (21)

- Control of DC Motor Using Different Control StrategiesОт EverandControl of DC Motor Using Different Control StrategiesОценок пока нет

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- Variable Speed Pumping: A Guide to Successful ApplicationsОт EverandVariable Speed Pumping: A Guide to Successful ApplicationsРейтинг: 3 из 5 звезд3/5 (2)

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingОт EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingРейтинг: 5 из 5 звезд5/5 (9)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesОт EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesРейтинг: 5 из 5 звезд5/5 (1)

- CH - 7 Heat ExchangersДокумент51 страницаCH - 7 Heat Exchangershailegebreselassie24Оценок пока нет

- Wellbore Stability AnalysisДокумент148 страницWellbore Stability Analysishagh1234Оценок пока нет

- Fluid Mechanics and Hydraulics 4th EditionДокумент285 страницFluid Mechanics and Hydraulics 4th EditionZachary Angelo Gustav100% (1)

- Methane Properties: Erty Value Unit Value Unit Value UnitДокумент6 страницMethane Properties: Erty Value Unit Value Unit Value UnitdОценок пока нет

- CBB 2024 Chapter 4-Second Law of Thermo V2Документ90 страницCBB 2024 Chapter 4-Second Law of Thermo V2Ameer Muhammad100% (1)

- A Modern Course in Transport Phenomena by Venerus OttingerДокумент538 страницA Modern Course in Transport Phenomena by Venerus OttingerJoshelyn Mariangela Paredes ZavalaОценок пока нет

- CY6151 - Engineering Chemistry - I - 2 MarksДокумент11 страницCY6151 - Engineering Chemistry - I - 2 Markssunil1237Оценок пока нет

- Lista de Precios VendedorДокумент12 страницLista de Precios VendedorSugeily MatosОценок пока нет

- Iadc Bullhead Field 012214Документ3 страницыIadc Bullhead Field 012214Muhammad Afrizal KautsarОценок пока нет

- Reinforced Concrete I Midterm Exam: C20 - S420 D 4cmДокумент1 страницаReinforced Concrete I Midterm Exam: C20 - S420 D 4cmAhmad ThaherОценок пока нет

- Internal Energy and Energy Transfers 2Документ39 страницInternal Energy and Energy Transfers 2muhammadshadid4Оценок пока нет

- Exergy and Economic Analysis of Dual Pressure Waste Heat Recovery BoilerДокумент8 страницExergy and Economic Analysis of Dual Pressure Waste Heat Recovery BoilerÜmit GüneşОценок пока нет

- Lecture4 PDFДокумент21 страницаLecture4 PDFCarlos Aparisi CanteroОценок пока нет

- 03 Structural Analysis PresentationДокумент30 страниц03 Structural Analysis PresentationMohammed AnwhazОценок пока нет

- Co GenerationДокумент13 страницCo GenerationashokparikhОценок пока нет

- Definitions - Topic 4 Mechanics and Materials - AQA Physics A-LevelДокумент3 страницыDefinitions - Topic 4 Mechanics and Materials - AQA Physics A-LevelLaud FumhandaОценок пока нет

- Tuned Liquid Dampers For Control of Earthquake Response: 13 World Conference On Earthquake EngineeringДокумент12 страницTuned Liquid Dampers For Control of Earthquake Response: 13 World Conference On Earthquake EngineeringDavid SantiagoОценок пока нет

- Heat Exchangers: The Effectiveness - NTU MethodДокумент15 страницHeat Exchangers: The Effectiveness - NTU MethodVenkitaraj K PОценок пока нет

- Handbook - RefrigerationДокумент67 страницHandbook - Refrigerationmnt617692% (12)

- Simulation of Vars Component (Evaporator) Using Ansys SoftwareДокумент22 страницыSimulation of Vars Component (Evaporator) Using Ansys SoftwareSanket BhilareОценок пока нет

- Drilling Fluids Planning and Execution For A World Record Water Depth WellДокумент13 страницDrilling Fluids Planning and Execution For A World Record Water Depth WellAthaurrohman Alfaina Shidiq100% (1)

- Duct CalculationДокумент1 страницаDuct CalculationDan Nugraha100% (1)

- Behavior of Gases: Charles' LAWДокумент33 страницыBehavior of Gases: Charles' LAWJennifer MagangoОценок пока нет

- Thermo BookДокумент145 страницThermo BookShahla GondalОценок пока нет

- Measurement of Lift and Drag of An Aerofoil at Different Angles of AttackДокумент10 страницMeasurement of Lift and Drag of An Aerofoil at Different Angles of AttackSidrak MekuriaОценок пока нет

- The Third Law of ThermodynamicsДокумент10 страницThe Third Law of ThermodynamicssamygoldОценок пока нет

- Shear Force and Bending MomentДокумент3 страницыShear Force and Bending MomentDej AdmasuОценок пока нет

- SLR Metaliks Limited: Motor Greasing ScheduleДокумент3 страницыSLR Metaliks Limited: Motor Greasing ScheduleprasadОценок пока нет

- Unit-IV-Shear Reinforcement and Bond by Limit State MethodДокумент50 страницUnit-IV-Shear Reinforcement and Bond by Limit State MethodAshish KaleОценок пока нет

- Experiment Number 2 Coffee Cup CalorimetryДокумент7 страницExperiment Number 2 Coffee Cup Calorimetryapi-529605052Оценок пока нет