Академический Документы

Профессиональный Документы

Культура Документы

Piping Quiz Answer Ed.2009

Загружено:

Ahmed GamalАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Piping Quiz Answer Ed.2009

Загружено:

Ahmed GamalАвторское право:

Доступные форматы

Piping Quiz & Answer

[THINGS YOU SHOULD ! A"A#! A OUT PIPING !NGIN!!#ING$]

Nis%i&%$'%()eri

[2009]

[!*+(i,- nis%i&%./%()eri0re1i22$34+]

PIPING QUIZ & ANSWERS

From: piping-info.blogspot.com

1. What is the pipe size range, per Flu r !aniel stan"ar", # r pipe sp Ans: 3 diameter and larger <2.1/2 and larger> '. What is the pipe size range, per Flu r !aniel stan"ar", # r pipe sp Ans: 2 diameter and smaller (. !e#ine )hat piping is % nsi"ere" #iel" asse*$l+&

ls that are t $e sh p #a$ri%ate"& ls that are t $e #iel" #a$ri%ate"&

Ans: Off-the-shelf components that make-up a piping assem l! and do not re"uire cutting and / or #elding <$f no field fa rication is re"uired> ,. !e#ine )hat piping is % nsi"ere" ra%- l a"e", per Flu r !aniel stan"ar", an" )hat pipe size ranges is in. l.e"& Ans: %iping in the %$%&'A() that crosses t#o or more supports. 3 and larger /. All sh p #a$ri%ate" piping sp ls 0*ar- pie%es1 are shippe" #r * the #a$ri%ati n sh p in a ge *etr+ that is "e#ine" $+ length, )i"th, an" height. Assu*ing it t $e a $ 2, there are t) situati ns that + u *ust a. i" in regar" t the $ 2 an" the *ar- pie%es )ithin. !es%ri$e these t) situati ns an" "es%ri$e the un"esira$le result i# + u " n t a. i" the*& Ans: %iece mark must fit #ithin the shipping shipping o*> 3. !e#ine a #iel" )el" 0FW1 an" )hen it is use"& Ans: -ield .eld is made some#here other than the fa rication shop. /sed to connect t#o mark pieces 0or components1 together 4. !es%ri$e three things + u *ust % nsi"er )hen l %ating a #iel" )el" an" )h+ the+ *ust $e % nsi"ere"& Ans: Accessi ilit!: 2he #eld must e in a place that is accessi le to the #elder (onstructa ilit!: 2he #eld must e placed so the constructors can position the piece mark prior to #elding. +i3e of spool piece to ensure it fits shipping o* and can e transported. &conomics: 4ade in a location that #ould lessen or eliminate the need for additional scaffolding. +elf-supporting so temporar! supports are not re"uired during construction. 4ade on the smaller side of a reducer5 prefera l! made in the hori3ontal. 5. !es%ri$e a #iel" #it6up )el" 0FFW1 an" )hen it is use"& Ans: -ield -it .eld is a #eld made some#here other than the fa rication shop. 2he fa rication shop adds additional length of material to the spool piece. 2his additional length gi,es the field ,ariance for ad6ustment #hen the location of the connecting point is not kno#n. <4a! re"uire field alteration> 7. Per Flu r !aniel stan"ar", )hat is the % nstru%ti n 0#itting t+pe1 #8 Ans: %ipe si3e range 2 7 and larger8 9utt-#eld %ipe si3e range 2 and smaller8 +ocket .elded %ipe si3e range 2 and smaller8 +cre#ed or 2hreaded 19. What is the *ini*u* 0n t a$s lute *ini*u*1 "istan%e $et)een )el"s that Flu r !aniel li-es t use& Ans: 3 inches 11. What is the a$s lute *ini*u* "istan%e $et)een )el"s 0use" nl+ as a last %h i%e1& Ans: %ipe +i3e 0:%+1 4in. distance /# #elds 1/; 3/1< 1 /= 1/= 3/;> ?/1< 1/2> @/1< o* other#ise it ma! not e transported. +ke#ed placement of the piece mark #ithin the shipping o* could result in cro#ding out other piece marks. <%ress fit should e a,oided to ensure piece mark fits

3/=> 1/2 1> 11/1< 1 1/=> 13/1< 1 1/2> 1?/1< 2> 1 3/1< 2 1/2> 1 A/1< 3> 1 3/= 3 1/2> 2 => 2 1/= ?> 2 3/= Balf the outside diameter of pipe 0< and larger1 1'. What " the letters :AZ *ean& Ans: Beat Affected Cone Kavimagi %age 3 of 13 1(. What is the e##e%t # the :AZ& Ans: .eakens the material 0pipe #all1 1,. : ) #ar #r * the )el", is the :AZ& Ans: D or 1 1/. Wh+ " piping "esigners %are a$ ut the :AZ& Ans: $f t#o BACEs o,erlap each other it ma! result in failure of the pipe 13. When is the :AZ % nsi"ere" in threa"e" % nstru%ti n& Ans: .hen threaded connection is seal #elded 14. What are the pressure ratings # # rge" steel S %-et Wel" Fittings& Ans: 3FFFG <FFFG 15. What are the pressure ratings # # rge" steel threa"e" #ittings& Ans: 2FFFG 3FFFG <FFFG 17. What are the pressure ratings # *allea$le ir n threa"e" Fittings& Ans: 1?FG 3FFG '9. What are the pressure ratings # %ast ir n threa"e" #ittings& Ans: 12?G 2?FG '1. ;ist the )all thi%-ness # r pipe, starting )ith the thinnest )all t the hea.iest )all8 Ans: (ar on +teel H Allo! steel 013 schedules1 +ch 1FI +ch 2FI +ch 3FI +ch =FI +td .tI +ch <FI +ch ;FI

J+I +ch 1FFI +ch 12FI +ch 1=FI +ch 1<FI JJ+ +tainless +teel 0= schedules1 +ch ?+I +ch 1F+I +ch =F+I +ch ;F+ ''. What is the te%hni%al ter* use" # r the sag in pipe %ause" $+ gra.it+ an" h ) " es a##e%t piping "esign& Ans: Keflection5 $t go,ern the amount of pipe span <(auses leakage at flanges> <(auses stress on pipe> '(. I# ne ,< %ar$ n steel pipe is s%he"ule ,9 an" an ther ,< %ar$ n steel pipe is s%he"ule 59=.& Whi%h has the greater sag an" )h+& Ans: => sch. =F has the greater sag ecause its #all thickness is less than the #all thickness of the sch. ;F - the thinner the #allI the shorter the length the line #ill span. Whi%h )eighs * re an" )h+& Ans5 => sch. ;F ecause itLs #all thickness is more than that of the sch. =FI more material M more #eight. Whi%h re>uires #e)er supp rt p int an" )h+& Ans: => sch. ;F ecause itLs thicker #all allo#s it to span fartherI reducing the num er of times support is needed. <4ore rigid / stiffer> ',. Pipe)a+?Pipera%- l a"ing?stu##ing "ra)ings. Whi%h lines >uali#+ # r l a"ing?stu##ing& Ans: Nines 3> and larger that cross t#o or more pipe supports. Wh+ is l a"ing?stu##ing " ne 0the a".antages1& Ans: $t pro,ides an earl! start for construction. $t reduces the amount of ground area taken ! storage of pipe '/. ;ine size %hanges When is s)age use" # r a line size %hange& Ans5 .hen reducing from or to socket #elded or threaded construction on at least one end. When is a $utt6)el" re"u%er use" # r a line size %hange& Ans: .hen reducing from or to utt #elded construction on oth ends. When?)here " + u use e%%entri%, $ tt * #lat s)ages r re"u%ers an" )h+& Ans: $n an! hori3ontal run of pipeI that has t#o or more supports #ithin that run. 2o maintain a common ottom of pipe ele,ation for the t#o line si3es. When?)here " + u use e%%entri%, t p #lat s)ages r re"u%ers an" )h+& Ans: /sed at the final reduction on a pump end suction line. 2o pre,ent ca,itations of the pump When?)here " + u use e%%entri%, si"e #lat s)ages r re"u%ers an" )h+& Ans: /sed #hen t#o e"uipment connections are so close that the t#o connectingI ad6acent lines interfere #ith each other after the line si3e change. $f the! are side flat to#ard each otherI the lines ma! clear. </sed on ,ertical pipe to maintain common ack of pipe>

When " + u use $utt6)el" re"u%ing 79 "egree el$ )s an" )h+& Ans: :ormall! it is not -N/O' piping practice to use reducing utt-#eld AF degree reducing el o#s. $f the! are usedI it #ill e #here a si3e change is re"uired and there is insufficient space a,aila le for an el o# and a reducer or an el o# and a reducing flange - or if the client re"uires it. Wh+ ) ul" a sh rt ra"ius $utt6)el" 796"egree el$ ) $e use"& Ans: 2o adhere to -N/O' piping practice FFF 2?F 2<?F #here it states 1F> and larger el o#s at a no33le of a ,ertical ,essel are short radius 0decreases the >l> dimension so a standard ,essel pipe support can e used1. <+pace limitations> Wh+ ) ul" a sh rt ra"ius $utt6)el" 796"egree el$ ) n t $e use"& Ans: $t is eas! to >lose> a short radius el o# if shipped to the 6o site or fa rication shop #ith long radius el o#s of the same si3e. Additional tracking effort ma! result to keep the short radius el o# from eing >lost> or used inad,ertentl! #here it #as not intended to e used. Often the use of a short radius el o# re"uires client appro,alI or process re,ie#I or stress appro,al - all taking time that #ould not e taken for a long radius el o#. <#hen pressure drop is a concern O short radius el o# has more pressure drop. '3. What is a tri**e" el$ ) an" )hen is it use"& Ans: A trimmed el o# is a utt #eld AF degree long radius el o# that is cut and e,eled to match the original e,elI the resulting change of direction is no longer AF degrees ut is a non-standard angle suited for the piping geometr! re"uiring it. 2rimmed el o#s are used #hen a line routing must ha,e a change of direction that is not satisfied ! a AF or =?-degree el o# or ! el o#s eing rolled or offset. '4. !es%ri$e a stu$6 n % nne%ti n an" )hen it is use"& Ans: A stu -on connection is a ranch connection made to a header #ithout the use of fittings - the connection is made from pipe. 2he ranch pipe is contoured 0fish-mouthed1 to match the cur,ature of the header to #hich it #ill e connected 0a fillet #eld1. A hole is made in the header that should match the inside diameter of the ranch pipe. 2he stu -on connection is not the same construction as a stu -in connection - ut the resulting geometr! is the same as a stu -on. +tu -on connections are generall! AF degreeI ut can e other angles. 9ranch ta le '5. !es%ri$e a stu$6in % nne%ti n an" )hen it is use"& Ans: -luor piping does not use the stu -in construction. A stu -in connection is the same as a stu -on connection as far as the resulting geometr! and material goesI ut the construction is different. 2he ranch pipe ma! or ma! not e contoured to match the inside diameter of the header - if it is notI then it is a straight cut. 2he header #ill ha,e a hole cut in it that nearl! matches the outside diameter of the ranch pipe. 2he ranch pipe is inserted into the hole in the header and is connected ,ia a fillet #eld. Nike the stu -onI the stu -in is generall! AF degree and other angles are possi le. (lient re"uest '7. !es%ri$e a rein# r%ing pa" an" )hen it is use"& Ans: 'einforcing pads are made from the same si3eI #all thickness and material as the pipe header to #hich the! are #elded. 'einforcing pads are used at stu -on and stu -in ranch connections and occasionall! at support trunnions #hen specified ! the stress sketchI if re"uired per the line list or if re"uired per the ranch chart in the piping material specification. (9. What " %u*ent 0na*e an" /6"iget nu*$er1 " es a piping "esigner re#er t "eter*ine )hat $ran%h % nne%ti n t use& Ans: %iping material specification (1. What are the t) " %u*ents 0n t spe%i#i%ati ns1 that )ill tell a piping "esigner )hen $ran%h rein# r%e*ent is re>uire"& Ans: +tress sketch Nine list <9ranch chart> ('. What is the pipe size range in )hi%h all #langes are stan"ar"&

Ans: 2= inch and smaller ((. What is the pipe size range in )hi%h all #langes are n t stan"ar"& Ans: 2< inch and larger (,. ;ist the in# r*ati n t $e pla%e" n the is *etri% that )ill #ull+ "es%ri$e a n n6stan"ar" #lange an" )hat is the reas n )e ) ul" in%lu"e this in# r*ati n& Ans: 'eason for including the information. 2o guaranteeI #ithout failureI the flanges are compati le. $nformation to e placed on $+O4&2'$(+8 A:+$ num er or other industr! num er 0A%$I 4++1 +i3e 'ating -acing Outside diameter of flange 9olt circle diameter 9olt Bole diameter :um er of olt holes -lange ore 4aterial 9olt hole orientation -lange thickness (/. What #a%ing is re>uire" n a steel #lange that )ill $e $ lte" t a %ast ir n #lange an" )h+& Ans: -lat -ace 2here is a risk of reaking the cast iron flange if it is olted to a raised face steel flange. (3. What are t) pressure ratings # %ast ir n #langes an" )hat are the ratings # % *pati$le steel #langes& Ans: 12?G (ast iron to 1?FG steelI 2?FG cast iron to 3FFG steel (4. : ) is %ast ir n #lange atta%he" t steel pipe& Ans: 2he flange is threaded on. (5. What are t) reas ns # r using lap @ int % nstru%ti n& Ans: 2o reduce the cost of components - a less e*pensi,e car on steel flange ma! e used in lieu of a stainless steel flange. -lange can e rotated to aid in olt-hole alignment. (7. What #itting 0n t #lange1 *ust $e use" in lap @ int % nstru%ti n an" )hat are the na*es # this t) t+pes # #ittings& Ans: +tu end <Nap 6oint stu end> A:+$ H 4++ ,9. What is the "i##eren%e $et)een a .an st ne #lange an" a slip n #lange& Ans: 2he shape of the contact point #here the face of flange contacts the lip of the stu end is rounded on the ,an stone flange and is s"uare on the slip on flange. ,1. In lap @ int % nstru%ti n, h ) *an+ )el"s are n a slip #lange& Ans: Cero ,'. In lap @ int % nstru%ti n, h ) *an+ )el"s are n a .an st ne #lange& Ans: Cero ,(. ;ist the t+pes # steel #langes& Ans: .eld neck

+lip on 2hreaded +ocket #elded Pan stone 'educing &*panding 9lind <Nap 6oint> <Orifice> <+lip on reducing> ,,. ;ist the #a%es # steel #langes& Ans: 'aised face -lat face 'ing 6oint 2ongue and groo,e 4ale H -emale ,/. ;ist the ratings # steel #langes& Ans: 1?FG 3FFG =FFG <FFG AFFG 1?FFG 2?FFG ,3. : ) are #lange $ lt6h les riente" n #langes n .erti%al line& Ans: 9olt-holes straddle the north-south-east-#est flange centerlines ,4. : ) are #lange $ lt6h les riente" n #langes n h riz ntal line& Ans: 9olt-holes straddle the ,ertical and hori3ontal flange centerlines ,5. Aal.es are use" # r three $asi% #l ) #un%ti ns 0n t % ntr l .al.es r pressure sa#et+ .al.es1. ;ist three #un%ti ns an" the t+pe # .al.e use" # r ea%h #un%ti n& Ans: -unction 9NO() 2B'O22N& (B&() <+tart / stop> <pre,ent ack flo#> 2!pe QA2&/9ANN/%N/Q/9/22&'-NR <needle> O 9NO() QNO9& <plug or utterfl! or needle> O 2B'O22N& (B&() O (B&() ,7. What are the t) st+les # $utter#l+ .al.es in #lange" piping an" their ass %iate" t+pe # $ lt& Ans: A. .A-&' - +2/K 9ON2/4A(B$:& 9ON2 9. N/Q 2R%& - (A% +('&. /9. What are the t) *ain st+les # %he%- .al.es in #lange" piping an" their ass %iate" t+pe # $ lt& Ans: A. +.$:Q - +2/K 9ON2/4A(B$:& 9ON2 9. .A-&'/+%N$2 K$+( - +2/K 9ON2/4A(B$:& 9ON2 /1. N t using a la""er r plat# r*, h ) is a .al.e perate" that is8

Ans: 2oo high - (BA$: O%&'A2O' 2oo lo# - &J2&:+$O: +2&4 /'. What is the *ini*u* %learan%e $et)een the utsi"e "ia*eter # a .al.e han" )heel an" the ne2t $stru%ti n& Ans: 2hree inches /(. I# a .al.e han" )heel pr @e%ts int an aisle )a+, t )hat ele.ati n *ust the $ tt * # the han" )heel $e raise" a$ .e :PFS 0:igh P int Finishe" Sur#a%e1 r plat# r*& Ans: <L-<> plus or minus 3> 0<L-3> to <L-A>1 /,. What *anuall+ perate" ite* is a""e" t a .al.e that is either t large r is t + u -n ) it )ill $e re>uire" 0gi.e the na*e # the spe%i#i%ati n1& Ans: - A Q&A' O%&'A2O' - 4A2&'$AN +%&($-$(A2$O: //. I# a pressure sa#et+ .al.e has a $l %- .ale upstrea* # it, )hat n te *ust appear n the P&I! relating t this $l %- .al.e an" )h+& Ans: S (+O 0car sealed open1 or NO 0locked open1. S 2o help ensure that the ,al,e is open during normal plant operation so that if a condition resulting in o,er pressuri3ation occursI the ,al,e is open and the relief ,al,e can function properl!. /3. I# a pressure sa#et+ .al.e " )nstrea* # it, )hat n te *ust appear n the P&I! relating t this $l %- .al.e an" )h+& Ans: S (+O 0car sealed open1 or NO 0locked open1 S 2o help ensure that the ,al,e is open during normal plant operation so that if a condition resulting in o,er pressuri3ation occursI the ,al,e is open and the relief ,al,e can function properl!. /4. Bhe piping " )nstrea* # a pressure sa#et+ .al.e that "is%harges t a %l se" s+ste* *ust $e r ute" in a spe%i#i% "ire%ti n, )hat is this "ire%ti n an" )h+& Ans: S 'outed in such a manner as to free drain into the collection header. +o no li"uid can collect and possi l! o struct the free release of pressure. /5. I# a pressure sa#et+ .al.e has a " )nstrea* $l %- .al.e, e2%lu"ing a%%essi$ilit+, h ) is the .ale han" )heel t riente" an" )h+& Ans: S 2he hand #heel is to e located #ithin the lo#er 1;F degrees - hori3ontal to hori3ontal. <hori3ontal or do#n#ard> S 2his is to pre,ent the disc falling into the port if the stem corrodes - there ! closing the ,al,e and pre,enting the free release of pressure. /7. I# a pressure sa#et+ .al.e has a rupture "is% upstrea*, )hat is the purp se # the rupture "is%& Ans: 2he rupture disc isolates the relief ,al,e from the potentiall! corrosi,e atmosphere of the s!stem to e protected - protecting the stem from corrosion. 39. When a pressure sa#et+ .al.e "is%harges .erti%all+ t pipe, )hat size is it an" )h+ is it a""e"& Ans: S A #eep hole. S 1/=> diameter S 2o drain the collection of rain #ater in the open tailpipe that if allo#ed to collect could o struct the free release of pressure 31. What is the en" preparati n # r the en" tailpipe )h+& Ans: S +"uare cut/plain end S 2here is no need to e,el or =?-degree chamfer ecause it is unnecessar! cost. 3'. What is the # r*ula # r %al%ulating the #ree stan"ing 0ungui"e"1 length "is%harging .erti%all+ t at* sphere& Ans: 1.<@ * outside diameter 0in inches1 of the 2ail %ipe M the height in feet. # a tailpipe # a pressure sa#et+ .al.e # a pressure sa#et+ .al.e "is%harging .erti%all+ t at* sphere an" at* sphere, )hat *ust $e a""e" t the l )est part # the tail $e high a pressure t perate an" h ) "

3(. I# a pressure sa#et+ .al.e has a s*all, .al.e" an" plugge" % nne%ti n in the area $et)een the $l %- .al.e an" the pressure sa#et+ .al.e, "es%ri$es the purp se an" perati n # this .al.e& Ans: -or leeding pressure and ,enting an! trapped commodit! soI the relief ,al,e can e safel! remo,ed for maintenance. 3,. Per Flu r !aniel Stan"ar", )hat is the rule # r esta$lishing the height "is%harges t at* sphere& Ans: 2he top of a tailpipe discharging to atmosphere must e a minimum of ;L-F> a o,e an! platform #ithin a 2?L-F> radius of the tailpipe. 3/. Bhe spring n a pressure sa#et+ .al.e *ust $e riente" in )hi%h "ire%ti n an" )h+& Ans: S Perticall! up#ardI to keep the spring out of an! li"uid that could corrode the spring. 33. C ling )ater piping at the %hannel si"e # a shell an" tu$e heat e2%hanger that is l %ate" utsi"e in the sunlight )ill t+pi%all+ ha.e a B:ERDA; RE;IEF AA;AE l %ate" $et)een the e2%hanger n zzle an" the $l %- .al.e. Wh+ is this " ne& Ans: 2o protect the tu es of e*changer from splitting due to o,er pressuri3ation #ithin the s!stem #hen the ,al,eEs upstream and do#nstream of the e*changer are closed. +unlight can cause a temperature rise of the trapped li"uidI causing a rise in pressure. 34. What is the * st % ** n $ "+ st+le # r % ntr l .al.es& Ans: Qlo e Pal,e 35. In a % ntr l .al.e *ani# l" )ith $l %- .al.es upstrea* an" " )nstrea* # the % ntr l .al.e, )hat is pla%e" $et)een the upstrea* $l %- .al.e an" the % ntr l .al.e an" )hat is its purp se& Ans: S 3/=> ,al,e H plugged leed ,al,e. S 2o drain and depressuri3e the ,olume of trapped li"uid for the safe remo,al of the control ,al,e for maintenance. 37. I# a % ntr l .al.e *ani# l" has a $+pass line )hat is the "istan%e $et)een the $+pass .al.e an" the *ain line an" )h+& Ans: S 4inimum distance. S 2o pre,ent a dead leg in the !pass line. 49. What is the *ini*u* %learan%e $et)een the t p # the "iaphrag* n a % ntr l .al.e an" the nearest $stru%ti n a$ .e it& Ans: 1E-F 012 inches1 41. In a % ntr l .al.e *ani# l" )ith upstrea* an" " )nstrea* $l %- .al.es& A. What is the $rea- ut sp l pie%e # r& l pie%e an" )h+& Ans: &as! remo,al of the control ,al,e E. What is the pre#erre" % n#igurati n # the $rea- ut sp Ans: S %referred configuration is #ith an el o#. S $t is easier to remo,e than a straight spool piece that re"uires a flange spreader. 2he >l> shape el o#s gra,it! to aid in its remo,al. 4'. Wh "eter*ines the size # the % ntr l .al.e& Ans: %rocess 4(. Wh "eter*ines the size # the $+pass .al.e& Ans: %rocess 4,. Wh "eter*ines the upstrea* an" " )nstrea* $l %- .al.es& Ans: %rocess 4/. I# + u are esta$lishing the .erall length # a % ntr l .al.e *ani# l" # r all %ati n # spa%e an" + u " n t ha.e a .en" r "ra)ing gi.ing the #a%e6t 6#a%e "i*ensi n # the % ntr l .al.e, )hat .al.e )ill + u use as a su$stitute #a%e6t 6#a%e "i*ensi n 0assu*e the % ntr l .al.e is 3<6(99F RF1& Ans: S A <>-3FFG QNO9& PANP& O' %$%$:Q %'A(2$(& FFF 2?F 2@F1 S <1@ 7 inches> # a tailpipe # a pressure sa#et+ .al.e that

43. When a % ntr l .al.e an" its " )nstrea* $l %- .al.e are the sa*e size an" rating, the+ %an $e $ lte" t gether. What p ssi$le pr $le* %an %%ur )hen these t) .al.es are $ lte" t gether& Ans: 2he hand #heel of the lock ,al,e ma! interfere #ith the top #orks of the control ,al,e. Also gi,e me t#o solutions that could correct the pro lem. S $f the olt holes permit - rotate the lock ,al,e so the interference is gone. S Add t#o flanges ack-to- ackI andI if necessar! add a spool piece to gi,e the necessar! clearances. F. S <place ,al,e in the ,ertical> 44. Bhere are three things that esta$lish the height # a .al.e "rain 0$ tt * # "rain t p # #inishe" sur#a%e1. Gne thing that sets this height is Flu r !aniel stan"ar" 03<1, )hat are t) Ans: S (learance for rodding out the drain. S (learance re"uired for the addition of a ucket to catch the li"uid. 45. What are t) in"ustr+ ter*s )hen a threa"e" % nne%ti n is als )el"e"& Ans: +eal #elding 9ack #elding 47. What *ust $e use" n a threa"e" % nne%ti n i# it is t re%ei.e the )el" re#erre" int >uesti n 37, an" )h+ sh ul" it n t $e use"& Ans: S 2hread compound or >pipe dope.> $f thread compound/pipe dope is present and the connection is to e seal #eldedI the heat could cause a small e*plosionI in6uring the #elder. 59. What are the steps in sele%ti n # .al.e& Ans : .hat to handleI li"uidI gas or po#derI fluid natureI functionI construction materialI disc t!peI stem t!peI ho# to operateI onnet t!peI od! endsI deli,er! timeI costI #arrant!. 51. What are #un%ti ns # .al.es& Ans: $solationI regulationI non-return and special purposes. 5'. What are is lating .al.es& Ans: QateI allI plugI pistonI diaphragmI utterfl!I pinch. 5(. What are regulati n .al.es& Ans: Qlo eI needleI utterfl!I diaphragmI pistonI pinch. 5,. What are n n6return .al.es& Ans: check ,al,eI 5/. What are spe%ial .al.es& Ans: multi-portI flush ottomI floatI footI pressure reliefI reather. 53. What *aterials are use" # r % nstru%ti n # .al.es& Ans: (ast ironI ron3eI gun metalI car on steelI stainless steelI allo! car on steelI pol!prop!lene and other plasticsI special allo!s. 54. What is tri*& Ans: 2rim is composed of stemI seat surfacesI ack seat ushing and other small internal parts that normall! contact the surface fluid. 55. Whi%h stan"ar" spe%i#ies tri* nu*$ers # r .al.e& Ans: A%$ <FF. 57. What are )ette" parts # .al.e& Ans: All parts that come in contact #ith surface fluid are called #etted parts. thers&

;0

79. What is )ire "ra)ing& Ans : 2his term is used to indicate the premature erosion of the ,al,e seat caused ! e*cessi,e ,elocit! et#een seat and seat discI #hen ,al,e is not closed tightl!. 71. What is straight thr ugh .al.e& Ans: Pal,e in #hich the closing operation of ,al,e is achie,ed ! AF degrees turn of the closing element. 7'. What pressure tests are %arrie" ut n .al.es& Ans : +hell-h!drostaticI seat-h!drostaticI seat-pneumatic 7(. What are a.aila$le .al.e perat rs& Ans: Band le,erI hand #heelI chain operatorI gear operatorI po#ered operator likes electric motorI solenoidI pneumatic and h!draulic operatorsI Tuick acting operators for non-rotar! ,al,es 0handle lift1.

7,. What are t) t+pes # $all .al.e& Ans : -ull port design and regular port designI according to t!pe of seatI soft seat and metal seat. 7/. What are $all .al.e $ "+ t+pes& Ans: +ingle pieceI dou le pieceI three pieceI the short patternI long patternI sand#ich and flush ottom design. 73. Wh+ $all .al.es are n r*all+ #lange"& Ans: 9ecause of soft seat %2-& #hich can damage during #elding. 74. What are $utter#l+ .al.e t+pes& Ans: Kou le flange t!peI #afer lug t!pe and #afer t!pe. 75. What are t+pes # %he%- .al.e& Ans: Nift check ,al,es and s#ing check ,al,es. 77. What are n n6sla* %he%- .al.es& Ans: +#ing check ,al,eI con,entional check ,al,eI #afer check ,al,eI tilting disc check ,al,eI piston check ,al,eI stop check ,al,eI all check ,al,e. 199. Where st p %he%- .al.e is use"& Ans: $n stem generation ! multiple oilersI #here a ,al,e is inserted et#een each oiler and the main stream header. $t can e optionall! closed automaticall! or normall!. 191. Where "iaphrag* .al.es are use"& Ans: /sed for lo# pressure corrosi,e ser,ices as shut off ,al,es. 19'. What is Earst %- Aal.e& Ans: An! ,al,e ha,ing a od! machined from solid metal 0 arstock1. /suall! needle or glo e t!pe. 19(. What is EIEE Aal.e& Ans: A small ,al,e #ith turned do#n endI like a faucet. 19,. What is Elee" Aal.e& Ans: +mall ,al,e pro,ided for dra#ing off li"uid. 19/. What is El ) " )n Aal.e& Ans 'efers to a plug t!pe disc glo e ,al,e used for remo,ing sludge and sedimentar! matter from the ottom of oiler drumsI ,esselsI drip-legs etc.I 193. What is Ereather Aal.e& Ans: A special self acting ,al,e installed on storage tanks etc. to release ,apor or gas on slight increase of internal pressure 0in the region of 7 to 3 ounces per s"uare inch1. 194. What is !rip Aal.e& Ans: A drain ,al,e fitted to the ottom of a drip leg to permit lo# do#n.

;;

195. What is Flap Aal.e& Ans: A non return ,al,e ha,ing a hinged disc or ru

er or leather flap used for lo# pressure lines.

197. What is : se Aal.e& Ans: A gate or glo e ,al,e ha,ing one of its ends e*ternall! threaded to one of the hose thread standards in use in the /+A. 2hese ,al,es are used for ,ehicular and fire#ater connections. 119. What is Paper6St %- Aal.e& Ans: A single disc single seat gate ,al,e 0+lide gate1 #ith knife edged or notched discussed to regulate flo# of paper slurr! or other fi rous slurr!. ('. What is R t Aal.e& Ans: A ,al,e used to isolate a pressure element or instrument from a line or ,esselI or a ,al,e placed at the eginning of a ranch from the header.

((. What is Slurr+ .al.e& Ans: A knife edge ,al,e used to control flo# of non-a rasi,e slurries. (,. What is Spiral s %- .al.e& Ans: A ,al,e used to control flo# of po#ders ! means of a t#ista le fa ric tu e or sock. 11,. What is Bhr ttling .al.e& Ans: An! ,al,e used to closel! regulate flo# in the 6ust-open position. 11/. What is Aa%uu* $rea-er& Ans: A special self-acting ,al,e or na! ,al,e suita le for ,acuum ser,ice operated manuall! or automaticall!I installed to admit gas 0usuall! atmospheric air1 into a ,acuum or lo#-pressure space. +uch ,al,es are installed on high points of piping or ,essels to permit draining and sometimes to pre,ent siphoning. 113. What is Qui%- a%ting .al.e& Ans: An! on/off ,al,e rapidl! opera leI either ! manual le,erI spring or ! pistonI solenoid or le,er #ith heat-fusi le link releasing a #eight #hich in falling operates the ,al,e. Tuick acting ,al,es are desira le in lines con,e!ing flamma le li"uids. /nsuita le for #ater or for li"uid ser,ice in general #ithout a cushioning de,ice to protect piping from shock. 114. What is "i.erting .al.e& Ans: 2his ,al,e s#itches flo# from one main line to t#o different outlets. .R& t!pe and pneumatic control t!pe #ith no mo,ing part. 115. What is sa*pling .al.e& Ans: /suall! of needle or glo e patternI placed in ranch line for the purpose of dra#ing all samples of process material thru the ranch. 117. What are $l ) ## .al.e& Ans: $t is a ,ariet! of glo e ,al,e confirming #ith oiler code re"uirements and speciall! designed for oiler lo#-off ser,ice. .R& pattern and angle t!peI used to remo,e air and other gases from oilers etc. 1'9. What is relie# .al.e& Ans: Pal,e to relie,e e*cess pressure in li"uids in situations #here full flo# discharge is not re"uiredI #hen release of small ,olume of li"uid #ould rapidl! lo#er pressure. 1'1. What is sa#et+ .al.e& Ans: 'apid opening0popping action1 full flo# ,al,e for air and other gases. 1''. What is # t .al.e& Ans: Pal,e used to maintain a head of #ater on the suction side of sump pumpI asicall! a lift check ,al,e #ith integrated strainer. 1'(. What is #l at .al.e& Ans: /sed to control li"uid le,el in tanksI operated ! floatI #hich rises #ith li"uid le,el and opens the ,al,e to control #ater le,el. $t can also remo,e air from s!stemI in #hich caseI air flo#s out of s!stem in ,al,e open conditionI ut #hen #ater reaches ,al,eI float inside ,al,e raises to close the ,al,e and stop flo# of #ater. /sed in drip legs.

;2

1',. What are #lush $ tt * .al.es& Ans: +pecial t!pe of ,al,es used to drain out the pipingI reactors and ,esselsI attached on pad t!pe no33les. 1'/. What are t+pes # #lush $ tt * .al.es& Ans: Pal,es #ith discs opening into the tank and ,al,es #ith disks into the ,al,e. 1'3. What are the uses # three6)a+ .al.e& Ans: Alternate connection of the t#o suppl! lines to a common deli,er! ,ice-,ersaI isolating one safet! ,al,eI di,ision of flo# #ith isolation facilit!. 1'4. What are uses # # ur )a+ .al.e& Ans: 'e,ersal of pump suction and deli,er!I 9! pass of strainer or meterI re,ersal of flo# through filterI heat e*changer or dr!er. 1'5. What is *etal seate" lu$ri%ate" plug .al.e& Ans: A plug ,al,e #ith no plastic materialI #here grease is applied to contacting surfaces for eas! operation. 1'7. What are three patterns # plug .al.e "esign& Ans : 'egular patternI short pattern and ,enture pattern. 1(9. What is regular pattern plug .al.e& Ans: 'ectangular portI area almost e"ual to pipe oreI smooth transition from round od! to rectangular portI for min. pressure loss. 1(1. What are sh rt pattern plug .al.e& Ans: Pal,es #ith face to face dimension of gate ,al,eI as a alternati,e to gate ,al,e. 1('. What are .enture pattern plug .al.e& Ans: (hange of section through the od! throat so graded to ha,e ,enture effectI minimum pressure loss. 1((. What are in.erte" plug "esign .al.e& Ans: %lug ,al,e #ith taper portion up of plug. -or ; and higher si3e 1(,. What is pressure $alan%e" plug .al.e& Ans: .ith holes in port top and ottom connecting t#o cham ers on top and ottom of plugI to reduce turning effort. 1(/. What are Be#l n slee.e" plug .al.e& Ans: %2-& slee,e et#een plug and od! of ,al,eI lo# turning effortI minimum frictionI temperature limitationI anti static design possi le. 1(3. What are per*asil plug .al.e& Ans: %lug ,al,es #ith 2eflon seat instead of slee,esI for on off applicationsI can handle clean ,iscous and corrosi,e li"uidsI Qraphite seat for high temperature applications. Krip tight shut off not possi le. 1(4. What are e%%entri% plug .al.e& Ans: Off center plugI corrosi,e and a rasi,e ser,iceI on off actionI mo,es into and a#a! from seat eliminating a rasi,e #ear. 1(5. What is "i*ensi nal stan"ar" # r plug .al.e& Ans: A%$ ?AA. 1(7. What is pin%h .al.e& Ans: +imilar to diaphragm ,al,eI #ith slee,es of ru er or %2-&I #hich get s"uee3ed to control or stop the flo#I (ast iron od!I for ,er! lo# ser,ice pressures like isolation of hose connectionsI manufacture standard. 1,9. What is nee"le .al.e& Ans: -ull p!ramid discI same design as glo e ,al,eI smaller si3esI s# or threadedI flo# controlI disc can e integral #ith stemI inside scre#I orged or arstock od! and onnetI manufacturers standard. 1,1. : ) t install a gl $e .al.e& Ans: Qlo e ,al,e should e installed such that the flo# is from the underside of the diskI usuall! flo# direction is marked on the glo e ,al,e.

;5

1,'. What are gl $e .al.e p rt t+pes& Ans: -ull port: 4ore than ;?U of ore si3eI 'educer port: One si3e less than the connected pipe. 1,(. What are gl $e .al.e "is- t+pes& Ans: -lat faced t!pe for positi,e shutoffI loose plug t!pe for plug rene#al or needle t!pe for finer control. 1,,. What are %hara%teristi%s # gl $e .al.e ste*& Ans: Al#a!s rising designI #ith disk nut at the lo#er end and hand#heel at upper end. 1,/. What are t+pes # gl $e .al.e& Ans: Angle glo e ,al,eI plug t!pe disc glo e ,al,eI #!e- od! glo e ,al,eI composite disc glo e ,al,eI dou le disc glo e ,al,e. 1,3. What is angle gl $e .al.e& Ans: &nds at AF degree to sa,e el o#I higher pressure drop. 1,4. Where plug t+pe "is% gl $e .al.e is use"& Ans: -or se,ere regulating ser,ice #ith gritt! li"uids such as oiler feed-#ater and for lo# off ser,ice. 1,5. Where WHE $ "+ gl $e .al.e is use"& Ans: $n line ports #ith stem emerging at =? degreeI for erosi,e fluids due to smoother flo# pattern. 1,7. What is " u$le "is% gl $e .al.e& Ans: Bas t#o discs earing on separate seats spaced apartI on a single shaftI for lo# tor"ueI used for control ,al,es. 1/9. What are p rt t+pes # r gate .al.es& Ans: -ull port and reduced port. Kefault is reduced ore. -ull port has to e specified in 9O4. 1/1. : ) t %l se a gate .al.e& Ans: 2urn the hand #heel in clock#ise direction. 1/'. What is lantern ring& Ans: $tEs a collection point to drain off an! ha3ardous see pages or as a point #here lu ricant can e in6ectedI it is in the middle of packing rings. 1/(. What are t+pes # gate .al.es& Ans: +olid plane #edgeI solid fle*i le #edgeI split #edgeI dou le disc parallels seatsI dou le disc #edgeI single disc single seat gate or slideI single disc parallel seatsI plug gate ,al,e. 1/,. What are the t+pes # $ nnets& Ans: 9olted onnetI ello# sealed onnetI scre#ed on onnetI union onnetsI A /- olt and clamp t!pe onnetI reechlock onnetI pressure seal onnet 1//. What is the ASDE % "e # ll )e" # r "esign # piping s+ste*s in Pr %ess piping 0Re#ineries & Che*i%al In"ustries1& 0i1 931.1 0ii1 931.3 0iii1 931.? 0i,1 931.A

Answer (III)

1/3. What " + u *ean $+ # ll )ing ite*s& i.1 $+N9-=FF ii1 $+49-<FF iii1 $+B9-3?F i,1 $+4(-3FF ,1 $+V9-1?F ,i1 $+N9-2FF ,ii1 $+49-=?F ,iii1 $+.9-=FF i*1 $+V(-2FF *1 $+N(-3?F *ii1 $+4(-2?F Ans)er8 i. $ndian +2K light #eight eamI .e si3e O =FF ii. $ndian +2K medium #eight eamI .e si3e O <FF iii. $ndian +2K WBE eamI .e si3e O 3?F i,. $ndian +2K medium #eight channelI .e si3e O3FF ,. $ndian +2K 6unior eamI .e si3e O 1?F ,i. $ndian +2K light #eight eamI .e si3e O 2FF ,ii. $ndian +2K medium #eight eamI .e si3e O =?F ,iii. $ndian +2K #ide flange eamI .e si3e O =FF i*. $ndian +2K 6unior channelI .e si3e O 2FF *. $ndian +2K light #eight channelI .e si3e O 3?F

;6

*i. $ndian +2K medium #eight channelI .e si3e O 2?F 1/4. What is this ite*& i1 $+A-1FFJ1FFJ12 ii1 $+A-;FJ?FJ1F iii1 $+N2-1FFJ1FF Ans)er8 i. &"ual angle si3e 1FF*12 2B) ii. /ne"ual angle si3e ;F*?F*1F 2B) iii. $ndian +2K light #eight tee ar si3e 1FF*1FF 1/5. What is the "i##eren%e $et)een stu$ in an" stu$ n $ran%hes& !es%ri$e )ith S-et%h& Whi%h ne is pre#erre"&

Ans:

s For branching of one size lesser of run pipe, Stub On is preferred. For other branching less than one size of run pipe stub in is preferred. The Design is based on ANSI/ASME B 31.3

1/7. What is the "i##eren%e $et)een Pipe an" Bu$e& Ans: %ipe is identified ! :9 and thickness is defined ! +chedule #hereas 2u e is identified ! OK. 139. Fr * )hi%h size n)ar"s NE # pipe is e>ual t G! # Pipe& Ans: -rom the si3e 1= and on#ards :9 M OK of pipe. 131. Write " )n the utsi"e "ia*eter # # ll )ing pipe& i. 3 inch ii1 < inch iii1 1F inch i,1 1= inch Ans)er8 i. 3 inch M ;;.Amm ii1 < inch M 1<;.2;mm iii1 1F inch M 2@3.F<mm i,1 1= inch M 3?? mm 0OKM +i3e J 2?.=1 13'. What is the "i##eren%e $et)een *a%hine $ lt an" stu" $ lt&

Ans- Machine bolt has a head on one side and nut on other side but stud bolt have nuts on both sides.

13(. What is s lu$le "a*& Ans: +olu le dam is a #ater-solu le material used for restricting the purging gas #ithin the pipe. 13,. While )el"ing # pipe trunni n t pipe?rein# r%e*ent pa" + u ha.e t )h+& Ans: -or ,enting of hot gas #hich ma! get generated due to #elding 13/. What " + u *ean $+ # ll )ing t+pe # )el"ing& i1 +4A. ii1 2$Q Ans: ii. +4A. M +B$&NK&K 4&2AN A'( .&NK$:Q iii. 2$Q M 2/:Q+2&: $:2&' QA+ .&NK$:Q 133. Fin" ut the ele.ati n # *ar-e" p int IAJ& put a h le r lea.e s *e p rti n # )el"ing

Ans-

;7

Elevation of marked point A is 100.050

134. What sh ul" $e the ra"ius # l ng ra"ius el$ )& Ans: 1.? * K 0.here XK is the diameter of the pipe1 135. N r*all+ )here " )e use the # ll )ing& i1 &ccentric reducer ii1 (oncentric reducer Ans: i. &ccentric reducers M %ump suction to a,oid ca,itationsE to maintain ele,ation 09O%1 in rack. ii. (oncentric reducers M %ump dischargeI ,ertical pipeline etc. 137. C n%entri% re"u%er is use" in pu*p su%ti n. 0Hes ? N 1, E2plain& Ans: :o. Air pockets ma! form if concentric reducer is used at pump suctionI #hich results in ca,itationsEI and cause damage to %ump. 2o a,oid this pro lemI &ccentric 'educer #ith -lat +ide /p 0-+/1is used in %ump +uction. 149. What " + u *ean $+ Ca.itati ns in Pu*p& Ans: A pump is designed to handle li"uidI not ,apor. Papor forms if the pressure in the pump falls elo# the li"uidEs ,apor pressure. 2he ,apor pressure occurs right at the impeller inlet #here a sharp pressure drop occurs. 2he impeller rapidl! uilds up the pressure #hich collapses ,apor u les causing ca,itationsE and damage. 2his is a,oided ! maintaining sufficient :%+B. 0(a,itations impl! ca,ities or holes in the fluid #e are pumping. 2hese holes can also e descri ed as u lesI so ca,itationsE is reall! a out the formation of u les and their collapse. 9u les form #hen e,er li"uid oils. $t can e a,oided ! pro,iding sufficient 0:%+B1. 141. What " + u *ean $+ NPS:& : ) " + u %al%ulate it& Ans :%+B: :et %ositi,e +uction Bead 0:%+B1 is the pressure a,aila le at the pump suction after ,apor pressure is su tracted. $t is calculated as: +tatic head Y surface pressure head - the ,apor pressure of !our product - the friction losses in the pipingI ,al,es and fittings. $t thus reflects the amount of head loss that the pump can sustain internall! efore ,apor pressure is reached. 14'. What is the ASBD % "e # r the # ll )ing& i1 (+ pipe ii1 (+ fittings iii1 (+ flanges i,1 A+ pipe %?/%11 ,1 (ast (+ Pal,es Ans: i. (+ pipe M A1F< Qr. 9 ii. (+ fittings M A23= Qr..%9/.%9. iii. (+ flanges M A1F? i,. A+ pipe M A33? Qr. %1/%11 ,. (ast (+ Pal,es M A21< Qr..(9 14(. What is the thu*$ rule t %al%ulate spanner size # r gi.en $ lt& Ans: 1.? * diameter of 9olt. 14,. What is the thu*$ rule t %al%ulate Current re>uire" # r Wel"ing& Ans: (urrent 0Amp1 M ZKiameter of &lectrode 0mm1 J =F[ 2F

14/. What is stea* tra%ing& : ) " )e "e%i"e the l %ati n # SSD & CRD&

;8

Ans: +team 2racing is a process #hich is used to pre,ent the fluid passing through a process line from free3ing ! keeping the temperature high enough for free flo# of fluid and thus maintaining pump a ilit!. ++4 and ('4 are generall! located 3;4 ma* for open s!stem and 2= 4 ma* for closed s!stem #hen #e use N% +team up to 3.? kg/s" cm. as a heating media. 143. Whi%h piping ite*s )ill + u "r p " )n $e# re % n"u%ting Flushing an" :+"r test& Ans: $tems like (ontrol Pal,eI Orifice platesI 'otametersI safet! ,al,es5 2hermo#ells are dropped or replaced #ith temporar! spools efore h!dro test. 144. Why do we provide a Dampner in the Piping of Reciprocating Pump? Ans: 2o take care of %ulsation. 145. Wh+ " )e pr .i"e Full E re Aal.e in % nne%ting pipeline # ;aun%her?Re%ei.er& Ans: -or %igging. 147. Whi%h para*eters )ill u %he%- "uring %he%-ing Piping Is *etri%s& Ans: 9ill of 4aterialI %ipe 'outing #.r.t QAKI +upporting arrangement I details of insulationI h!dro test pressureI painting specs and pro,ision of Pent and Krains at appropriate locations. 159. What is the ANSI?ASDE "i*ensi nal stan"ar" # r steel #langes & #ittings& 0i1 91<.3 0ii1 91<.? 0iii1 91<.A 0i,1 91<.1F

Ans: (II)

151. : ) %an #langes $e %lassi#ie" $ase" n #a%ing& Ans5 a. -lat -ace . 'aised -ace c. 2ongue and groo,e d. 'ing t!pe 6oint 15'. What " + u *ean $+ AAR: 0Flange Finish1& Ans: Arithmetic A,erage 'oughness Beight. 15(. Whi%h are the "i##erent t+pes # Gas-ets& Ans: -ull -aceI +piral .oundI Octagonal 'ing 2!peI 4etal Vacketed and $nside 9olt (ircle. 15,. What sh ul" $e the relati.e har"ness $et)een the RBK gas-et an" #lange gr .e& Ans: -or a '2V flangeI the 6oint ring should ha,e a 3F-=F Pickers hardness less than that of the mating face of flange.09rinnel hardness for '2V groo,e shall e 2F-?F 9B: more than the corresponding gasket hardness1 15/. Fr * )hi%h si"e # pipe )ill + u ta-e a $ran%h % nne%ti n& Ans: .hen -luid is QasI Air or +team and (r!ogenic +er,ice O 2opside. .hen -luid is Ni"uid O 9ottom +ide 153. Wh+ " nJt )e ta-e a $ran%h # r Cr+ geni% Ser.i%e #r * $ tt * si"e th ugh the #lui" is in li>ui" state& Ans: 2here is the chance of $ce formation during normal operation and since ice flo#s from the ottom of the pipe it #ill lock the ranch pipe connection. 154. Wh+ " )e pr .i"e !rip ;eg in Stea* ;ine& Ans: 2o remo,e (ondensate #hen there is a rise in the pipe along the flo# direction. $f #e do not pro,ide the drip leg in steam lineI the condensate #hich forms inside the pipe #ill result in .ater Bammer effect causing damage to piping s!stem. 155. : ) " + u supp rt an+ s*all size :!PE?PAC 0Plasti%1 pipe& Ans: $t should e supported continuousl! ! using channel or Angle so that line should not +ag or fall from the sleeper/rack due to une,en e*pansion ecause of Bot 2emp. 157. Wh+ " )e pr .i"e :igh P int Aent 0:PA1 an" ; ) P int !rain 0;P!1 in piping& Ans8 B%P O for remo,ing Air during B!dro-test. N%K O for draining #ater after conducting B!dro-test 179. Whi%h stan"ar" an" % "es )ill + u re#er )hile "esigning the piping& Ans: -ollo#ing are the codes and standards O \ A+4& +&( $ : 'ules for construction of %o#er 9oilers. \ A+4& +&( P$$$ : 'ules for construction of %ressure Pessels. \ A+4& 9 31.1: %o#er %iping \ A+4& 9 31.3: %rocess %iping \ A+4& 9 31.=: %ipeline 2ransportation s!stem for li"uid h!drocar on and Other li"uids. \ A%$ '% ?2F: +i3ing selection and installation of %ressure 'elie,ing

;9

Ke,ices in refineries \ A%$ +2K <1F: (entrifugal %umps for %etroleumI Bea,! Kut! (hemical and Qas $ndustr! +er,ices. \ A:+$/:&4A +4 23: +team 2ur ines for 4echanical Kri,e +er,ices. \ A%$ +td <1@: (entrifugal (ompressor for %etroleumI (hemical and Qas $ndustr! +er,ice. \ &V4A: &*pansion Voints 4anufacturerEs Association. \ O$+K O 11;: Na!out for Oil and Qas $nstallations. \ $9': $ndian 9oiler 'egulations. \ :A(& 4' O F1@?: +ulfide +tress (racking 'esistant 4etallic 4aterials for Oilfield &"uipment. \ :A(& 4' O F2;=: &,aluation of %ipeline and %ressure Pessel +teel for 'esistance to B!drogen $nduced (racking. \ :A(& 24 O F1@@: Na orator! 2esting of 4etals for 'esistance to +ulfide +tress (racking in B2+ &n,ironment. 171. What " + u *ean $+ IER an" )hi%h lines % *es un"er IER pur.ie)& Ans: $9': $ndian 9oiler 'egulation Act. +team lines #ith conditions listed ello# comes under $9' pur,ie# O \ Nines for #hich design pressure is 3.? kg/s" cm and a o,e. \ Nine si3e a o,e 1F ha,ing design pressure 1.F kg/s" cm and a o,e. \ 9oiler feed #ater lines to steam generatorI condensate lines to steam generator and flash drum. 17'. What are Wel" let an" S %- let& An" )here the+ are use"& Ans: .eldolet and +ockolet are asicall! self reinforced fittings. .eldolet is used for 9utt #eld ranch connection #here standard tee is not a,aila le due to si3e restrictions and the piping is of critical / high pressure ser,ice. +ockolet is used for socket #elding ranch connectionI #hich re"uire reinforcing pad. 17(. What is the DGC # r Superheate" high pressure Stea* ;ines& Ans: A 33? Qr % $ / % $$ (omposition: F.? 4o 0%11 /1.2? U (r-.? 4o 0%111 17,. What is the n r*al upstrea* an" " )nstrea* straight length # ri#i%e #l ) *eter& Ans: /pstream - 1?K Ko#nstream - ?K. 17/. What are the essential "ata re>uire" # r the preparati n # e>uip*ent la+ ut& Ans: 11 %-K and %H$K 21 %ro6ect Kesign data 31 &"uipment +i3es H 9uildings 173. What are the .ari us statut r+ re>uire*ents t $e % nsi"ere" "uring la+ ut& Ans: +tate $ndustrial Ke,elopment (orporation 0+$K(1 (entral / +tate &n,ironmental %ollution (ontrol 9oards 0%(9+1 -actor! $nspectorate +tate &lectricit! 9oards (hief (ontroller of &*plosi,es 0((O&1 +tatic H %ressure Pessel 'ules 0+4%P1 2ariff Ad,isor! (ommittee A,iation Na#s (hief $nspector of 9oilers 0($91 Oil $ndustr! Kirectorate 0O$+K1 -ood and Krug Administration 0-KA1 4inistr! of &n,ironment and -orest 04o&-1 174. What " + u *ean $+ C *p site Flange& Ans: 2he flange that is made up of more than one 4O( is called a (omposite flange. a. Nap Voint -langes $nsert -langes are a specialt! in the arena of pipe si3e flanges and consist of t#o parts - the insert and the flange ring. 2he flange ring is the outer part of the insert flange assem l!I containing the olt holes. 2he t#o piece construction of the insert flange also offers the econom! of matching the insert material to the process pipe 0usuall! some corrosion resistant allo!1 #hile the outer flange ring ma! e manufactured from steel. .hen the en,ironment re"uires the flange ring to e made of some allo! the rotating feature is still maintained. . '- flanges #ith 'aised of one 4O( and rest of the flange #ith different 4O( c. '- lind flange #ith an o,erla! of AF/1F (uni for +ea #ater ser,ice. 175. What " + u *ean $+ Insulate" K int& Ans: $nsulating Voints are a prefa ricatedI non separa le union used to isolate specific sections of %ipelines to pre,ent corrosion caused ! stra! electrical currents or interference from other pipelines and po#er transmission ca les.

;:

177. What are Insulating Gas-et Lits& Ans: $nsulation gasket kits are designed to com at the effects of corrosion often found in flanged pipe s!stems. Qal,anic corrosion et#een dissimilar metal flanges 0flo# of currents1 I flange insulation associated #ith cathodic protection of underground piping are also the places #here $nsulating gasket kits are used. $t consists of Qasket :eoprene faced %henolic/Qlass 'einforced &po*! 0Q1F1 $nsulation slee,e 'einforced %henolic/:!lon/%ol!eth!lene/0Q1F1 $nsulation #asher 'einforced %henolic/:!lon/%ol!eth!lene/0Q1F1 %lated .asher &lectro plated steel #asher.

'99. What " + u *ean $+ Ka%-ete" Piping& Ans:

'91. What is the *in. "istan%e t $e *aintaine" $et)een t) )el"s in a pipe& Ans: 2he rule of thum is that the minimum distance et#een ad6acent utt #elds is 1K. $f notI it is ne,er closer than 1-1/2>. 2his is supposedl! to pre,ent the o,erlap of BACEs. 4inimum spacing of circumferential #elds et#een centerlines shall not e less than = times the pipe #all thickness or 2? mm #hiche,er is greater. '9'. What are the "i##erent har"ness tests %arrie" ut& Ans: 9rinell Bardness 2est5 'ock#ell Bardness test5 Pickers Bardness 2est. '9(. What is the relati n $et)een Erinell :ar"ness N an" R %-)ell :ar"ness N & Ans: 22 B'( 0'ock#ell Bardness1 M 23; 9B: 09rinell Bardness :o1 Barder %iping #hich is recogni3ed as pro,iding the most uniform application of heat to the processI as #ell as maintaining the most uniform processing temperatures #here steam tracing is not capa le of maintaining the temperature of fluid constant. /suall! used for molten sulphurI %ol!mers ser,ice.

;9

'9,. !uring #a$ri%ati n + u $ser.e" that ne s*all %ra%- has appeare" n a #resh plate, )hat t+pe # *easure + u )ill ta-e t $tain "esire" >ualit+ )ith *ini*u* )astage& Ans: -irst identif! the e*act length of crack ! K% test. Krill on the end point to resist further crack. 'emo,e the crack portion ! cutting the strip.

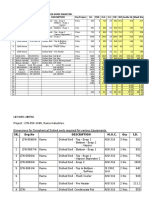

'9/. ISGDEBRIC 86 Ans: i. .hat are the fittings re"uired for fa rication of the isometric. ii. -ind out the length of pipe re"uired. iii. Ko 6oint num ering and sho# the follo#ing things in the isometric. a1 +hop 6oint 1 -ield 6oint c1 +pool no

34, '999 Krilling %oint (rack N 14(55, &N Y1F=2;F &N Y1F3?3F &N Y1F2<3F : 1@3<?FF & 31;2FFF 2 -ield Voint +hop Voint 4/9

Ans)er8 \ 2 $:(B &N9O. O =:O+

20

\ 2 $:(B .:'- -NA:Q& O 2:O+ \ 2 $:(B QA2& PANP& O 1:O \ 2 * 1 $:(B (O:(. '&K/(&' O 1:O \ 1 $:(B &N9O. AF K&Q O 1 :O \ 2 $:(B %$%& - =.21F 42'+ \ 1 $:(B %$%& O 1.=2= 42'+ '93. !es%ri$e "i##erent t+pes # "estru%ti.e an" n n6"estru%ti.e tests& Ans8 K&+2'/(2$P& 2&+2: 9end testI 2ensile testI $mpact testI and Bardness test. :O:-K&+2'/(2$P& 2&+2: K%2I 4%2, Radiography and ultrasonic test '94. What is *ean $+ IPW:BJ& Wh+ it is re>uire"& Ans: X%O+2 .&NK B&A2 2'&A24&:2 0%.B21 his is done to remo,e residual stress left in the 6oint #hich ma! cause rittle fracture. '95. What is the *ini*u* thi%-ness # pipe that re>uires stress relie.ing t $e " ne as per E(1.(& Ans: 1A mm thickness. '97. What is the "i##eren%e $et)een Bher* stati% an" Bher* "+na*i% Stea* Brap& Ans: 2hermostatic 2rap is actuated ! 2emp differential and is economic at steam pressure less than < %+$. $t is operated ! the mo,ement of li"uid filled ello#s or ! imetal element #hich ma! get damaged ! .ater Bammer. 2hermod!namic traps are most suited to applications #here the pressure do#nstream of trap is al#a!s less than a out 7 the upstream pressure. 2hese are suita le for pressure higher than ; %+$. .ater hammer doesnEt affect it. '19. What is the C "e # r S ur Ser.i%e& Ans: (ode for +our +er,ice is :A(& 0:A(& 4' O F1@?1 NACE8 :ational Association of (orrosion &ngineers. '11. : ) *u%h sh ul" $e the pressure # r :+"r 6Best& Ans: B!dro test pressure should e calculated as follo# e*cept as pro,ided against point no-=.1. 1.? * Kesign %ressure. & 31;F<FF & 31;1=FF 1 line 2. -or a design temperature a o,e the test temperatureI minimum test pressure can e calculated as: %t M 01.? J % J +t1 / + Where86 %t: 4inimum 2est %ressure. %: $nternal design pressure. +t: Allo#a le stress at test temperature. +: Allo#a le stress as design temperature. 0+ee +& in ta le A-1 or + in ta le 9-1/2/31 3. $f a test pressure as per a o,e #ould produce a stress in e*cess of the !ield strength at test temp. 2he test pressure ma! e reduced to ma*imum pressure that #ill not e*ceed the !ield strength at test temp. =. $f the test pressure of piping e*ceeds the ,essel pressure and it is not considered practica le to isolate piping from ,esselI the piping and ,essel ma! e tested together at test pressure of the ,essel #hen appro,ed ! o#ner and pro,ided the test pressure for ,essel is not less than 11?U of piping design pressure ad6usted for temperature as per point no 2. '1'. : ) " + u %al%ulate the pipe spa%ing& Ans: %ipe +pacing 0mm1 M 0Ko Y Kt1 / 2 Y 2?mm Y 2hickness of $nsulation 0mm1 .here: Ko: OK of +mall si3e %ipe 0mm1 Kt: OK of -lange of Narge si3e %ipe 0mm1. '1(. : ) " + u %al%ulate the )i"th # Pipe ra%-& Ans: . M 0f * n * s1 Y A Y 9. .here: sM f: +afet! -actor M 1.? if pipes are counted from %-K M 1.2 if pipes are counted from %H$K n: num er of lines in the densest area up to si3e =?F :9 M 3FF mm 0estimated a,erage spacing1 M 22? mm 0if lines are smaller than 2?F :91 A: Additional .idth for O \ Nines larger than =?F :9. \ -or instrument ca le tra! / duct. \ -or &lectrical ca le tra!. s: 3FF mm 0estimated a,erage spacing1 : 22? mm 0if lines are smaller than 2?F :91

2;

9: future pro,ision M 2FU of 0f J n J s1 Y A '1,. Whi%h #lui" is use" in :eat E2%hanger in shell si"e an" tu$e si"e& Ans: Qenerall! corrosi,e fluid is used from the tu e side 0as tu e can e easil! replaced1 and cleaner fluid is used from shell side. +ometimes Bot fluid is also used from the shell side. '1/. What is Re+n l"Js nu*$er an" )hat is the .alue # Re+n l"Js nu*$er up t )hi%h the #l ) is la*inar& Ans: $tEs a dimensionless num er to classif! the nature of flo#.

'13. What are Glan"less Pist n Aal.es& Where these are use"& Ans: Qlandless piston ,al,es are maintenance free ,al,es used in the steam ser,ice. '14. : ) " + u %arr+ ut Esti*ati n& Ans: 1. Input #r * Ei"86 \ %H$dI Nine listI 2emperatureI %ressure. \ O,erall %lant Na!out and %iping corridor plan. \ +cope of #ork and the +pecifications for the Vo . \ +pecifications for materials like %4+ and P4+. '. Aalue A""iti n86 \ $tems like Pal,esI -langesI +pecialt! itemsI 'educers can e estimated from %H$K. \ Nength of %ipesI &l o#sI #idth of %ipe 'ack can e estimated ! referring %H$K and O,erall %lot %lan. \ :o of 2ires 0on rack1 can e estimated ! referring the spacing re"uired for pipes and also the space a,aila le. \ 42O for +team 2rapsI Pal,es 0for Pent and drain1 can e calculated ! using 2hum 'ules. (. ; a"s86 \ :+"r Best ; a"s8 (an e estimated ! assuming all the %ipes 0on a grid1 empt! e*cept some igger si3e lines filled #ith .ater. \ A%tual Gperating ; a"s8 Qas lines to e considered as empt! and rest of the lines to e considered as filled #ith the -luid 0#hich the! are suppose to carr! in operating condition1. Bhe l a"s )hi%he.er is higher #r * a$ .e t) %ases sh ul" $e re#erre" # r stru%tural l a"ing.

SBRESS

'15. What is the $@e%ti.e # stress anal+sis& Ans: 1. 2o ensure that the stresses in piping components in the s!stem are #ithin allo#a le limits 2. 2o sol,e d!namic pro lems de,eloped due to mechanical ,i rationI fluid hammerI pulsationI relief ,al,esI etc 3. 2o sol,e pro lems associated due to higher or lo#er operating temperature such as a1 Kisplacement stress range 1 :o33le loading on connected e"uipments c1 %ipe displacements d1 Noads H moments on supporting structure '17. What are the steps in. l.e" in stress anal+sis 0 r an+ stress pa%-age %arries ut1& Ans: 1. $dentif! the potential loads that the piping s!stem #ould encounter during the life of the plant 2. 'elate each of these loads to the stresses and strains de,eloped 3. Qet the cumulati,e effect of the potential loads in the s!stem =. Kecide the allo#a le limits the s!stem can #ithstand #ithout failure as per code ?. After the s!stem is designed to ensure that the stresses are #ithin safe limits ''9. What are the "i##erent t+pes # stresses that *a+ get generate" )ithin pipe "uring n r*al perati n& Ans: A*ial +tresses 02ensile / (ompressi,e1I +hear +tressesI 'adial +tressesI BoopEs +tresses. ''1. : ) are the l a"s %lassi#ie" in stress anal+sis pa%-age& Ans: a. +ustained Noads 2. Occasional Noads 3. Kisplacement Noads 0+elf limiting stresses due to thermal effects1 .hat are the $nputs for stress anal!sis of a piping s!stem i1 %ipe +i3e ii1 -luid 2emperature iii1 %ipe 4aterial i,1 Kesign pressure ,1$nsulation 2hickness ,i1+pecific gra,it! ,ii1-riction coefficient ,iii1 4odel.

22

'''. What are the s ur%es # sustaine" l a"s generate" in piping s+ste*& Ans: a. %ressure . Kead #eight of %ipe and attachments +ustained load is calculated as .eight of %ipe #ith -luid Y %ressure load Y Noad due to springs .Y%1. ''(. : ) " + u %al%ulate the perating l a"& Ans: .Y%1Y21 21 O Noad due to thermal e*pansion. '',. Gi.e s *e E2a*ples # r %%asi nal ; a"s& Ans: .indI #a,e H earth"uake. ''/. Denti n s *e # Pri*ar+ ; a"s 0:a.e their rigin in # r%e1& Ans: Kead .eightI %ressureI forces due to relief or lo#-do#nI force due to #ater hammer effects. ''3. Denti n s *e # se% n"ar+ ; a"s 0:a.e rigin in "ispla%e*ent1& Ans: -orce on piping due to tank settlement Pessel no33le mo,ing up due to e*pansion of ,essel %ipe e*pansion or contraction Pi ration due to rotational e"uipments ''4. What is the #ailure the r+ su$s%ri$e" un"er ASDE E(1.(& 0i1 4a*imum principal stress theor! 0'ankiness 2heor!1 0ii1 4a*imum +hear 2heor! 0iii1 2resca 2hor! Ans8 0I1 ''5. What are the t+pes # #ailures en% untere" in Piping& Ans: 1. (atastrophic -ailure 2. -atigue -ailure ''7. Sele%t the #ailure stress range # r #atigue #ailure "ue t ther*al e2pansi n as per E(1.( 0i1 01.<+cY1.<+h1f 0ii1 F.@; +h 0iii1 01.2? +cYF.2?+h1f 0i,1 +cY+h Ans8 0III1 +c and +h O9asic Allo#a le material stress in cold H hot conditions respecti,el!. f ---- is the stress range reduction factor01 for @FFF c!cles1 '(9. What is "esire" li#e %+%le # r Piping in perati n& Ans: Kesired life c!cle for %iping in operation is 2F Rears 0@FFF (!cles1. 2he normal no. of c!cles for #hich the displacement or thermal stresses are designed is @FFF c!cles. '(1. : ) " + u %al%ulate the stress "e.el pe" "ue t ther*al e2pansi n& Ans: +tress de,eloped M & * e/N & O RoungEs 4odulus e- $ncrease in length due to thermal e*pansion N O Original Nength of the pipe '('. : ) " + u %al%ulate the ther*al e2pansi n in a pipe& Ans8 '((. What " + u *ean $+ Stress Intensit+ Fa%t r 0SIF1& Gi.e s *e e2a*ples& Ans: +tress $ntensit! -actor 0+$-1 is the ratio of ma*imum stress intensit! to normal stress. $t is used as safe factor to account for the effect of locali3ed stress on piping under respecti,e loading. $n piping it is applied to #eldsI fittingsI ranch connections etc #here stress concentration and possi le fatigue failure ma! occur. e.g.I +$- for 'educer and .eldneck -lange: 1.F +$- for socket #eld flange: 1.3 '(,. Whi%h is the Criteria # r Pipe Supp rting& Ans: -ollo#ing are the points #hich should e taken into account for proper supporting O \ Noad of are pipe Y fluid Y insulation 0if an!1. \ Noad of are pipe Y #aterfill. \ Noad of ,al,es and online e"uipment and instrument. \ 2hermal loads during operation. \ +team out conditionI if applica le. \ .ind loads for piping at higher ele,ationI if re"uired. \ -orced ,i ration due to pulsating flo#. 9are pipe #ith si3e a o,e 12 shall e supported #ith %ad or +hoe.

25

'(/. What is the $asi% span # supp rts # r '<?3<?19<?',< pipe& Ans8 9asic +pan is ?.?m / Am / 11.?m / 1?m respecti,el!.

'(3. : ) " )e "e%i"e the an%h r ? %r ss gui"e an" gui"e # r ##site ra%- piping& Ans: Anchor is pro,ided to restrict all the a*ial and rotational mo,ements of %ipeI #hereas (ross Quide is pro,ided to restrict displacements of %ipe along #ith the a*is perpendicular to its centerline and Quide is pro,ided to restrict the longitudinal mo,ements of pipes along #ith its a*is. '(4. !e#ine a t+pi%al 3! l Ans: p supp rting "etails 0An%h r?Gui"e1&

'(5. Pr .isi n # an%h r?%r ss gui"e # r % ntr l .al.e& Ans:

'(7. What are the things t $e ta-en %are # )hile " ing pu*p piping& Ans: %ipe strain ma! distort e"uipment alignmentI so #elding should e done in such a #a! that the tension in the e"uipment flange is minimi3ed. ',9. What is the Stea* ut % n"iti n& Ans: B!drocar on lines are usuall! su 6ected to +team Out condition and designed and anal!3ed at lo# pressure steam design temperature 0should e minimum 1;F degree (1 or design temp. .hiche,er is more8 Nines ha,ing negati,e design temp. $s anal!3ed for oth conditions separatel!. ',1. Where " + u pr .i"e An%h r an" Sl tte" Supp rt # :eat E2%hanger& Ans: Anchor support of Beat e*changer is pro,ided on the side from #hich 2u e 9undle #ill e pulled out for the purpose of 4aintenance #ork also it is ased on the gro#th of the connecting piping as e*changer should gro# #ith the piping. ','. What " + u *ean $+ : p Stresses an" h ) " + u %al%ulate it& Ans: +tresses #hich are generated circumferentiall! due to the action of $nternal pressure of pipe are called as Boop +tress. $t is calculated !: Boop +tress 0+h1 M % * do / =t .here % M -orce Acting from $nside. Ko M OK of %ipe. tM %ipe 2hickness. ',(. : ) " es : p Stress a##e%t the s+ste*& Ans: As per mem rane theor! for pressure design of c!linderI as long as hoop stress is less than !ield stress of 4ocI the design is safe. Boop stress induced ! thermal pressure is t#ice the a*ial stress 0+N1. 2his is #idel! used for pressure thickness calculation for pressure ,essel. ',,. What is the "esign stan"ar" # ll )e" # r the %al%ulati n % *press r & Stea* tur$ines n zzle& # all )a$le # r%es?D *ents in n zzles # %entri#ugal

26

Ans: -or strain sensiti,e e"uipment piping to e routed and supported to limit no33le loadings and moments in e"uipment #ithin allo#a le limits furnished ! respecti,e ,endors or in a sence of ,endor data A%$ ?<F/<1F/<1?/<21/<<1 H :&4A +423. :&4A O +4 23 0'eferred ! A%$ <1@1 is used for compressor H steam tur ine no33le. ',/. What is the *ill t leran%e t $e % nsi"ere" # r the thi%-ness # pipe "uring stress anal+sis as per ASDE E(1& 0i1 1U 0ii1 2.?U 0iii1 @.?U 0i,1 12.?U Ans8 i. ',3. What is the purp se # pr .i"ing Graphite Pa"s in supp rts $el ) sh es& Ans: 2o reduce the friction factor. 2he co-efficient of friction for Qraphite %ads is F.1 ',4. : ) is piping t Ban- inlet n zzle is supp rte" an" )h+& Ans: %iping to 2ank :o33le is supported #ith +pring t!pe support 0first support from :o33le1 in order to make the :o33le safe from the loads #hich occurs due to the displacement of pipe 0thermal e*pansion of pipe / tank materialI tank settlement etc1. ',5. What are the t) t+pes # #le2i$le spring hangers& Ans5 1. (onstant +pring and 2. Paria le +pring ',7. What is the "i##eren%e $et)een Aaria$le Spring :anger an" C nstant Spring :anger& Ans: Paria les use coiled springs to support a load and allo# mo,ement. 2he resistance of the coil to a load changes during compressionI #hich is #h! these de,ices are called >,aria les>. (onstant +pring Banger pro,ides constant support force for pipes and e"uipment su 6ected to ,ertical mo,ement due to thermal e*pansion at locations #here maintaining a constant stress is critical. 2his constant resistance is achie,ed ! ha,ing t#o moment arms pi,oted a out a common point. 2he load is suspended from one of these armsI and a spring is attached to the other. .ith an appropriate choice of moment arms and spring propertiesI a resisting force can e pro,ided that is nearl! independent of position. (onstant support hangers are principall! used to support pipes and e"uipment su 6ected to ,ertical mo,ement due to thermal e*pansion at locations #here transfer of stress to other supports or e"uipment can e critical. 2he ma*imum recommended ,ariation according to 4++ standard from the operating load is 2?U for ,aria le spring hangers. $f the ,ariation e*ceeds 2?UI a constant support hanger should e used. 2he constant resistance to a load is achie,ed ! com ining a spring coil #ith a cam #hich rotates a out a main pi,ot point. 2he cam is designed such that the distances from the main pi,ot changes to compensate for the ,aria le resistance during compression of the coil. 2he 4++ standard pro,ides for a tolerance of <U in the constant load through the tra,el range. (onstant support hangers are designed per 4++I A:+$I and A+4& standards. 2he si3ing of constants primaril! depends on the total tra,el and load. '/9. : ) *u%h sh ul" $e the "i##eren%e $et)een the l a" )hi%h )ill $e ta-en $+ Aaria$le Spring :anger "uring C l" an" : t % n"iti n # Pipe& Ans: $t should e 4a*imum 2?U of Noad for #hich spring is designed. '/1. !i##erentiate $et)een stati% l a" an" "+na*i% l a"& Ans: A piping s!stem ma! respond far differentl! to a d!namic load than it #ould to a static load of the same magnitude. +tatic loads are those #hich are applied slo#l! enough that the s!stem has time to react and internall! distri ute the loadsI thus remaining in e"uili rium. $n e"uili riumI all forces and moments are resol,ed 0i.e.I the sum of the forces and moments are 3ero1I and the pipe does not mo,e. .ith a d!namic load]a load #hich changes "uickl! #ith time]the piping s!stem ma! not ha,e time to internall! distri ute the loadsI so forces and moments are not al#a!s resol,ed]resulting in un alanced loadsI and therefore pipe mo,ement. +ince the sum of forces and moments are not necessaril! e"ual to 3eroI the internall! induced loads can e different]either higher or lo#er]than the applied loads. '/'. Gi.e "i##erent t+pes # "+na*i% l a"s )ith e2a*ple& Ans: 1. 'andom O .indI &arth"uake 2. Barmonic O &"uipment Pi rationI %ulsationI Acoustic Pi ration $mpulse O -luid BammerI relief ,al,e openingI slug flo# '/(. What is !+na*i% Anal+sis an" )h+ it is use"& Ans: K!namic anal!sis is performed for all t#o phase lines in order to ensure that the line supported is safe from ,i rations loads #hich ma! occur during normal operation as #ell as in start up or an! upset condition.0Kiesel mi*ed #ith h!drogen in KBK2 process1 '/,. What is WRC 194 ? WRC '74& Ans: Nocalised stresses at :o33le to +hell are calculated ! .'( 1F@ / 2A@ and these computed stress ,alues shall e limited in accordance #ith A+4& +ec P$$$ for %ressure Pessels.

27

'//. : ) t get the F un"ati n ; a"s& Ans: 1st CASE8-oundation Noads for pipe rack should include the loads of %ipesI (a le 2ra!s and $nstrumentation duct at that location and also the design load for future tier shall e full load of the most hea,il! loaded tier in addition to all other #ind/seismic/fraction and piping thermal loads for future pipes. Noad of pipes filled #ith #ater 0Nargest of 1st %ase O Kuring h!dro-testing dead #eight 0#t/m J piperack spacing1 of pipes Y 2 O3 ma*imum si3e pipes filled #ith #ater. 'n" %ase O Actual commissioned condition e*cept the gas lines1 Y %roportionate #t of e*tra space re"uired ! client 0normal 3FU1 Y Noad of 1 hea,il! loaded tier Y &lectrical ca les Y $nstrument duct Y Quide load for ?FU of lines Quide Noad M F.3 * 0Kead #t. of pipes at including #ater1 2he ma*imum induced thermal loads on the Anchor at the atter! limit shall e limited to - in kg <M 1?F J :9 of pipe in inches 0$t should e <2 tonnes1 4 in )gm <M@? J :9 of pipe in inches. Bori3ontal Noad M F.3 J 0Kead #t of pipes including #ater1 2his load is used for designing of foundation olts. -oundation loads for an! ,essel ha,ing agitator mounted on top should contain #eight of tank at operating or design condition 0#hiche,er is more1 plus 2FU of it for d!namic loading. '/3. What is the *a2i*u* e2pansi n a$s r$e" in l Ans: 1F $nches ps in n r*al "esign&

'/4. What is the li*iting #a%t r in "e%i"ing the length # the sp l in Ka%-ete" piping& Ans: -orce e*erted ! dissimilar e*pansion of inner pipe M -orce e*erted ! dissimilar e*pansion of 6acket pipe. 2he stress de,eloped due to this should e #ithin limits as per A:+$ 931.3 0Also fa rication constraints1. '/5. What is the #a%t r t $e %he%-e" % n%erning the e2pansi n # hea"er atta%he" t air % ler piping& Ans: Pendor dra#ing to e checked to see ho# much mo,ement is permitted to compensate line e*pansion. 2o accommodate the diff. &*pansion et#een inlet and outlet 02he inlet temperature >2he outlet temperature1 offset can e uilt in to outlet piping to compensate for diff. e*pansion. +ince the tu es are of floating design the no33le flange is of 1?FG and loads transferred are to e kept min. +ince the tu es are of floating designI the no33le flange is 1?FG. Noad of the no33le to e kept min. '/7. What is the *a2i*u* n . # %ell n zzles % nne%te" t a single hea"er # air % Ans: +i* nos. ler piping hea"er in n r*al pra%ti%e&

'39. What is #lui" ha**er an" h ) it is generate"& Ans: .hen the flo# of fluid through a s!stem is suddenl! halted at one pointI through ,al,e closure or a pump tripI the fluid in the remainder of the s!stem cannot e stopped instantaneousl! as #ell. As fluid continues to flo# into the area of stoppage 0upstream of the ,al,e or pump1I the fluid compressesI causing a high pressure situation at that point. Nike#iseI on the other side of the restrictionI the fluid mo,es a#a! from the stoppage pointI creating a lo# pressure 0,acuum1 situation at that location. -luid at the ne*t el o# or closure along the pipeline is still at the original operating pressureI resulting in an un alanced pressure force acting on the ,al,e seat or the el o#. 2he fluid continues to flo#I compressing 0or decompressing1 fluid further a#a! from the point of flo# stoppageI thus causing the leading edge of the pressure pulse to mo,e through the line. As the pulse mo,es past the first el o#I the pressure is no# e"uali3ed at each end of the pipe runI leading to a alanced 0i.e.I 3ero1 pressure load on the first pipe leg. Bo#e,er the un alanced pressureI ! passing the el o#I has no# shifted to the second leg. 2he un alanced pressure load #ill continue to rise and fall in se"uential legs as the pressure pulse tra,els ack to the source 0or for#ard to the sink1. 2he ramp up time of the profile roughl! coincides #ith the elapsed time from full flo# to lo# flo#I such as the closing time of the ,al,e or trip time of the pump. +ince the leading edge of the pressure pulse is not e*pected to change as the pulse tra,els through the s!stemI the ramp do#n time is the same. 2he duration of the load from initiation through the eginning of the do#n ramp is e"ual to the time re"uired for the pressure pulse to tra,el the length of the pipe leg. '31. What is the purp se # e2pansi n $ell )s& Ans: &*pansion ello#s are used a sor a*ial compression or e*tensionI lateral shear or angular torsion de,eloped in the pipes 0speciall! near no33les1 '3'. H u ha.e t % nne%t a '9< pipe t a *anh le # e2isting tan-, h ) )ill + u g a$ ut in %arr+ing ut the suita$ilit+ # the *anh le #lange& '3(. What sh ul" $e the *aterial # sh es # r supp rting AS pipes & )h+& Ans: $f (+ shoes are used %ad in contact #ith the pipe to e of Allo! steel to a,oid dissimilar #elding at pipe. 2o a,oid allo! steel #elding and dissimilar #elding fa ricated clamps either of (+ or ++ can e used. '3,. What is the all )a$le stress range # r CS pipes8 Ans: 2F@F kg/cm2

'3/. What are s)a+ $ra%es&

28

Ans: +#a! 9races are essentiall! a dou le-acting springI housed in a canister. /nlike ,aria le effort supportsI +#a! 9races are not intended to carr! the #eight of pipe #ork5 their purpose is to limit undesira le mo,ement. +#a! 9races act like a rigid strut until a small preload is reachedI #here after the restraining force increases in proportion to the applied deflection. Fig. 1 /ndesira le mo,ement can occur due to man! phenomenaI such as #ind loadingI s!mpathetic ,i rationI rapid ,al,e closureI relief ,al,es openingI t#o phase flo# or earth"uake. $t ma! e necessar! to limit this t!pe of deflection to pre,ent the generation of unaccepta le stresses and e"uipment loadings. 2he +#a! 9race is a cost-effecti,e means of limiting pipe #ork deflection. $t should e noted ho#e,er that it does pro,ide some resistance to the thermal mo,ement of the pipe #ork and care should e taken #hen specif!ing to ensure that this is accepta le. $nstallation of +#a! 9races #ill ha,e the effect of raising the fundamental fre"uenc! of ,i ration of a pipe #ork s!stem5 this is likel! to reduce undesira le deflections. +#a! 9races are often used to sol,e unforeseen pro lems of resonant ,i ration. -or situations #here the resistance to thermal mo,ement pro,ided ! +#a! 9races is unaccepta leI !ou are referred to %ipe +upports NimitedEs range of h!draulic snu ers and dampers. '33. Gi.e a t+pi%al stress rep rt in%lu"ing input an" utput an" )hat is interprete" # r* the utput& '34. F r ##sh re stru%tures )hat anal+sis is per# r*e" $+ Caesar& '35. In an ##site pipe ra%- %hange in "ire%ti n "uring anal+sis it is # un" t) a"@a%ent pipes are ha.ing une>ual e2pansi n )ith the inner pipe ha.ing /9 %* ther*al e2pansi n. What %an $e " ne t eli*inate % llisi n "uring h t % n"iti n& Ans: /se (old %ull techni"ue. (alculate the thermal e*pansion of the inside pipeI cut an e"ual length form the el o# 6oint and then re-#eld #ith a shorter length to take care of e*pansion in hot condition. '37. What are the Insulati n *aterial use" # r piping s+ste*s8 Ans: 1. -i rous O 'ock H Qlass .ool 2. 'igid - (alcium silicateI %ol!isoc!anurateI cellular Qlass .

29

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Asme B16.5Документ11 страницAsme B16.5jacquesmayol100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Valves HandbookДокумент51 страницаValves Handbookedhy_0367% (3)

- Introduction - Metallic Expansion Joint PDFДокумент16 страницIntroduction - Metallic Expansion Joint PDFsdmel100% (2)

- Goulds Pump Selection GuideДокумент24 страницыGoulds Pump Selection GuidecladonellОценок пока нет

- Dished EndДокумент3 страницыDished EndHaresh JoganiОценок пока нет

- High Pr. PipeДокумент1 страницаHigh Pr. PipeHaresh JoganiОценок пока нет

- Damper DimnДокумент1 страницаDamper DimnHaresh JoganiОценок пока нет

- Holding Tubes KMFДокумент7 страницHolding Tubes KMFHaresh JoganiОценок пока нет

- Catalogue 6 English 06.2012 Pacific HoseflexДокумент24 страницыCatalogue 6 English 06.2012 Pacific HoseflexHaresh JoganiОценок пока нет

- Bonney Forge BrochureДокумент22 страницыBonney Forge BrochureAnonymous dvrhf5Оценок пока нет

- How To Make Pipe Specifiction PDFДокумент9 страницHow To Make Pipe Specifiction PDFHaresh JoganiОценок пока нет

- Indian Rolled Sections 756Документ1 страницаIndian Rolled Sections 756Haresh JoganiОценок пока нет

- Seat MaterialДокумент3 страницыSeat MaterialDeyci Yamile Peña SantosОценок пока нет

- A B C Outside Dia D Inside Dia E Ang of Development F Remaining Angle G Dist-X H Dist-YДокумент2 страницыA B C Outside Dia D Inside Dia E Ang of Development F Remaining Angle G Dist-X H Dist-YnileshОценок пока нет

- Piping Catalogues and Specifications Tm-1202Документ253 страницыPiping Catalogues and Specifications Tm-1202Haresh Jogani67% (6)

- WeldSymbolsProof PDFДокумент1 страницаWeldSymbolsProof PDFHaresh JoganiОценок пока нет

- Pressure Proced TestДокумент6 страницPressure Proced Testjamaljamal20Оценок пока нет

- Is 1364 1 2002Документ20 страницIs 1364 1 2002harikrishnanmveplОценок пока нет

- Doc. No: Client: Project: S. NO. Eq. No. Description RemarksДокумент2 страницыDoc. No: Client: Project: S. NO. Eq. No. Description RemarksHaresh JoganiОценок пока нет

- M22T AVEVA Plant - 12 Series - Создание каталогов элементов трубопроводов - Rev 0.6 -Документ161 страницаM22T AVEVA Plant - 12 Series - Создание каталогов элементов трубопроводов - Rev 0.6 -Ionut Catoiu100% (1)

- Rubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Документ15 страницRubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Haresh JoganiОценок пока нет

- FVC Nozzle 2Документ14 страницFVC Nozzle 2Haresh JoganiОценок пока нет

- Hydro TestДокумент3 страницыHydro TestjkahamedОценок пока нет

- Corporate Compliance Broschüre Englisch FinalДокумент14 страницCorporate Compliance Broschüre Englisch FinalHaresh JoganiОценок пока нет

- StairДокумент2 страницыStairHaresh JoganiОценок пока нет

- Pdms PMLДокумент31 страницаPdms PMLHaresh JoganiОценок пока нет

- Is-4263.1967 RF2002Документ26 страницIs-4263.1967 RF2002Haresh JoganiОценок пока нет

- AutoDRAFT User GuideДокумент68 страницAutoDRAFT User GuidesimplekelechiОценок пока нет

- OpenSteel User GuideДокумент112 страницOpenSteel User GuideHaresh JoganiОценок пока нет

- Overall Layout ModelДокумент1 страницаOverall Layout ModelHaresh JoganiОценок пока нет