Академический Документы

Профессиональный Документы

Культура Документы

Prosthodontics

Загружено:

AmitАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Prosthodontics

Загружено:

AmitАвторское право:

Доступные форматы

ISSN 2236-8035 Archives of Oral Research, v. 7, n. 2, p. 177-182, May/Aug.

2011 Licensed under a Creative Commons License

[T]

Shear bond strength of porcelain veneer with fresh and recasting Ni-Cr alloy: a comparative in vitro study

[I]

Resistncia de unio ao cisalhamento entre porcelana de recobrimento e liga de Ni-Cr nova e refundida: estudo in vitro comparativo

[A]

Santosh Kumar Rajalbandi[a], Vinaya Kumar[b], Suresh Sajjan[c]

[a] [b] [c]

M.D.S. assistant professor, Department of Prosthodontics, Navodaya Dental College and Hospital, Raichur, Karanataka India, e-mail: drsrajalbandi@gmail.com M.D.S. professor, Department of Prosthodontics, College of Dental Science, Davangere, Karanataka - India. M.D.S. professor, Department of Prosthodontics, Vishnu Dental College, Bhimavaram, Andhra Pradesh - India.

[R]

Abstract

Introduction: Dental alloys are routinely subjected to multiple casting procedures. Repeated casting of the same alloys may cause loss of trace elements (such as Sn, Si, Mn, etc.) that are essential for the metal ceramic bond. A common practice is to include a proportion of new metal with the previously cast metal that is thought to replenish the lost elements. Objective: The study was done to evaluate the effect of variation in percentage of recasted Ni-Cr alloy used and to compare the effects with the shear bond strength of porcelain to the fresh ingot Ni-Cr alloy. Materials and methods: Uniform patterns were fabricated, invested and casting was done in five different combinations of fresh and recast alloy. A hundred percent fresh alloy; 25% recast with 75% fresh alloy; 50% recast and 50% fresh alloy; 75% recast and 25% fresh alloy; 100% recast alloys. After uniform porcelain application and firing, the specimens were subjected to shear bond test using a universal testing machine. Data were statistically analyzed using Duncanss multiple comparison test. Results: The results showed that the mean shear bond strength of the 100% fresh alloy was maximum and 100% recast alloy was least among the groups tested. The mean shear bond strength of castings obtained from 100% fresh, 25% recast, and 50% recast alloy were similar to each other and showed statistically significant difference when compared to the 100% recast group. Seventy five percent recast group did not show statistically significant difference with 100% recast alloy.

Arch Oral Res. 2011 May/Aug.;7(2)177-82

178

Rajalbandi SK, Kumar V, Sajjan S.

[B]

[P]

Conclusion: It can be concluded that minimum of 50% fresh alloy for casting is a safe margin for recasting Ni-Cr alloy. s.#] Keywords: Porcelain. Bond. Dental alloy. Fresh. Recasting.[#]

Resumo

[K]

Introduo: Ligas dentrias so rotineiramente submetidas a procedimentos de fundio mltipla. Fundies repetidas da mesma liga podem causar perda de elementos-trao, tais como Sn, Si e Mn, os quais so essenciais para a unio entre metal e cermica. Uma prtica comum a de incluir uma proporo de liga nova com o metal anteriormente fundido visando repor esses elementos perdidos. Objetivo: O presente estudo avaliou o efeito da variao da porcentagem de liga de Ni-Cr refundida na resistncia de unio ao cisalhamento com porcelana, comparado a liga de Ni-Cr nova. Materials e mtodos: Padres uniformes foram confeccionados, includos e fundidos sob cinco diferentes combinaes de liga nova e refundida: 100% liga nova; 25% liga refundida + 75% liga nova; 50% liga refundida + 50% liga nova; 75% liga refundida + 25% liga nova; 100% liga refundida. Aps a aplicao uniforme da porcelana e sua posterior coco, as amostras foram submetidas ao teste de cisalhamento utilizando uma mquina universal de ensaios. Os dados foram analisados estatisticamente atravs do teste de comparaes mltiplas de Duncan. Resultados: Os resultados mostraram que a maior resistncia de unio ao cisalhamento para a liga 100% nova, e a menor resistncia para a liga 100% refundida. A resistncia de unio ao cisalhamento das fundies com 100% de liga nova, 25% e 50% de liga refundida foi similar e estatisticamente diferente do grupo com 100% de liga refundida. O grupo com 75% de liga refundida no mostrou diferena estatisticamente significante com o grupo de liga 100% refundida. Concluso: Pode-se concluir que o mnimo de 50% de liga nova para a fundio uma margem de segurana para a refundio de ligas de Ni-Cr. [#] Palavras-chave: Porcelana. Unio. Liga dental. Nova. Refundio.

Introduction The Development of Taggarts technique of casting by lost wax process into the Dentistry gave an impetus to use alloyed metals as a restoration (1). Most of the dental laboratories commonly use the sprue and button from a previous casting as a part of the melt for the new casting (2, 3). This practice is especially detrimental with ceramometal alloys, which contain trace elements essential for bonding to porcelain. Repeated casting of these alloys may cause sufficient quantities of these elements to be lost so as to affect the bond between the metal and the porcelain (4-6). Studies have shown that recasting the used alloy up to 25% did not show any deleterious effects on the bond strength of porcelain (2). A combination of cast alloy with 50% new alloy produced the highest bond strength values. Further use of pooled alloy with an unknown casting history was not recommended since reduced bond strength were observed in their study (6). Among all the base metal alloys systems, the most popular are Ni-Cr

Arch Oral Res. 2011 May/Aug.;7(2)177-82

alloy (1). The properties of fresh and used alloys are not well understood and also there is sparse experimental justification for the amount of fresh and used Ni-Cr alloy to be composed for casting in porcelain fused to metal restorations. The objective of this study was to evaluate the effect of recasting NiCr alloy on the metal ceramic shear bond strength. materials and methods

Preparation of two piece mold

Shear bond testing was accomplished using a steel mold, which consisted of two parts. The upper part was a cylinder of diameter 20 mm x 20 mm height and had a through hole at center of diameter 6 mm. The lower part had a base of similar diameter as the upper part and a semi circular bar or half cylinder of diameter 6 mm x 20 mm height extending from the center of the base. It was so designed that the extended portion of the lower part fits into the

Shear bond strength of porcelain veneer with fresh and recasting Ni-Cr alloy

179

space present in the upper part to create a half cylinder space of diameter 6 mm x 20 mm height. This acted as a mold space for the fabrication of wax pattern (Figure 1). Further, the same mould was used as jig for shear testing and termed as 2 piece jig.

6 mm 6 mm

with fresh ingot alloy to prepare specimens of the other groups by changing the alloy percentage for the respective group. Alloy groups tested were:

20 mm 20 mm

Group 1: Control group - (100% fresh ingot alloy); Group 2: 25% recast (9.80 g) + 75% fresh ingot alloy (30.06 g); Group 3: 50% recast (18.35 g) + 50% fresh ingot alloy (18.13 g); Group 4: 75% recast (28.53 g) + 25% fresh ingot alloy (9.47 g); Group 5: 100% recast alloys.

Ceramic veneering

20 mm

20 mm

Lower piece

Upper piece

Figure 1 - Two piece mould or jig

Note: The extension of the lower piece is inserted into the cylindrical space of the upper piece, the arrangement creates the half cylindrical space for the fabrication of wax patterns and further the same space helped in shear testing.

Fabrication of the alloy specimen

The inlay pattern wax was melted in wax bath and flown into the mold. Total of 60 wax patterns for 5 groups with 12 patterns in each group of equal dimensions were obtained. Following manufacturers instruction, each group were invested separately with phosphate bonded investment material and casting was done (7). An induction casting machine was used to prevent any contamination by gas torch (8) and fresh crucible for each group was used for casting to prevent the possibility of contamination. After casting, specimens were retrieved and cleaned by sand blasting with 110 Al2O3. The separated specimens were finished using tungsten carbide bur such that these castings fit into the mold space present in two piece mould. Precisely fitting specimens were selected for the study. After air particle abrasion and ultrasonic cleaning, the sprue, runner bar and the button were used for recasting along

As per manufacturer instructions (Heraeus Kulzer Metal Ceramics Manual) (7), the specimens were sand blasted with 110 Al2O3 at approximately 50 Psi pressure in a sand blasting machine for 30 sec. The surface of the casting was cleaned before oxidation in a ultrasonic cleaning bath for 10 min (9). For uniform application of the porcelain, an acrylic block was prepared, which had half cylinder shaped depression at the center that exactly received the casting. Two ridges one on either side of the depression with 1.4 mm height and 3 mm width gave the optimal ceramic thickness of 1.1 1.2 mm after completion of firing). The casting was placed into the depression present in the acrylic block. Glass slides covered the block on either side of the ridge in such a way that it leaves a slot of 6 mm x 3 mm x 1.4 mm (width of the casting x width of the ridge on the acrylic block x height of the ridge) into which layers of porcelain were placed and subjected to firing. The dentine material was applied and was condensed by vibration and liquid was blotted out before subjecting to firing (Figure 2). As the material shrinks after firing, the level of the porcelain became less than the level of the glass slides, and the difference was filled with enamel porcelain and were subjected to firing. Excess ceramic other then the veneered surface was trimmed off using an alpine stone and the porcelain surface was subjected to glaze firing. This completed the preparation of the specimens for one group. Similarly, the veneering of specimens of other groups was prepared. The prepared samples of all the groups were subjected to shear stress to compare the bond strength of different groups.

Arch Oral Res. 2011 May/Aug.;7(2)177-82

180

Rajalbandi SK, Kumar V, Sajjan S.

Figure 2 - Ceramic build up using acrylic block

Shear bond test

The two piece jig was mounted on to the base of a universal testing machine (Model 0195 H5KS Series, Hounsfield, UK). The test specimens were inserted into the half cylinder space of the jig. The part of the specimen below the veneered area was inserted into the jig, the veneered part remained outside (Figure 3). The load was applied to test the bond strength at a cross head speed of 0.5 mm /min to the head of the specimen in the direction parallel to the specimen and the mold space in the jig. As the load was applied, the upper part was forced into the jig with generation of forces at the porcelain metal interface created shearing stress at the interface of the fired porcelain and the alloy. Maximum shear load at the point of failure was recorded and shear bond strength were calculated by dividing the force at which the bond failure occurred with the bonding area (10).

Figure 3 - Specimen mounted in jig for shear testing in

universal testing machine

Shear bond strength = Force recorded/area (6 mm x 3 mm) Similarly, the strength required for the bond failures for all the specimens were calculated. Results The results were analyzed by Duncanss multiple comparison test at a confidence level of 5% (Table 1).

Table 1 - Mean, standard deviation (SD) and pair wise comparison of groups with respect to shear bond strength (NF/ mm2) by Duncans multiple comparison tests procedure

Groups Group 1 Group 2 Group 3 Group 4 Group 5

Mean (SD) Group 2 Group 3 Group 4 Group 5

16.92 (3.60) 0.8819 0.8056 0.1135 0.0155*

16.696 (4.02) 0.9092 0.1338 0.0193*

16.52 (3.22)

14.25 (1.99)

12.71 (1.45)

0.1407 0.0212* 0.3153 -

Note: * Significant at 5% level of significance (p < 0.05) Source: Research data.

Arch Oral Res. 2011 May/Aug.;7(2)177-82

Shear bond strength of porcelain veneer with fresh and recasting Ni-Cr alloy

181

The mean shear bond strength of 100% fresh ingot alloy was maximum and the 100% re-casted alloy was the least among the groups tested. The mean shear bond strength of castings obtained from 100% fresh, 25% recast, and 50% recast alloy were not statistically significant different among each other (p > 0.05), but showed statistically significant difference when compared to the 100% recast group (p < 0.05). The 75% recast group did not show statistically significant difference with 100% recast alloy (p > 0.05). Discussion Ceramic metal restorations combine the beauty of porcelain and the strength of metal substructure. Most of the dental laboratories commonly use the sprue and button from a previous casting as a part of the melt for the new casting (2, 3). The rationale for reusing of casting alloys is based on economy, since it reduces reclaim costs and alloy inventory (11). The hardness, tensile strength and percentage of elongation of non-precious metal alloy used repeatedly for fixed partial denture castings showed no significant differences between the four generations of castings for any of the physical properties tested, indicating that the metal can be recasted for at least four generations (12). However, this practice is especially important with ceramic alloys, which contain trace elements essential for bonding to porcelain. Repeated casting of these alloys may cause loss of these elements and affect the bond between the metal and porcelain (4, 5). The present study was designed to achieve uniform thickness of different ceramic layers with the help of acrylic block. The flat portion of the half cylinder casting provided a good surface for uniform application of the ceramic layers. Custom made two piece mould used for making uniform wax patterns and also for shear bond testing where it acted as jig. The designing of the mould helped to achieve precise fit of the specimens into the jig yet without having any frictional resistance that may alter the outcome of the results. The obtained results showed the bond strength of group 1 was maximum and group 5 was the least. It could be due to the presence of trace elements in required proportions and have less or

no contaminated alloy (4, 5). Some trace elements like Si, Sn and Mn were found to show the peak at the interface of metal to ceramic and they play a important role in the bonding of porcelain to metal (13, 14). The bond strength values of group 2 and 3 were near to group 1 and did not show statistically significant difference when compared with each other. Group 4 showed lower strength values than group 1, 2 and 3, which were not statistically significant different when compared with each other. The bond strength values of group 1, 2 and 3 showed statistically significant difference when compared with group 5. The reason could be the presence of adequate trace elements required for the bond (2, 3). The bond strength values of group 4 had no statistical difference with group 5. The decreased bond strength values of group 4 and 5 can be attributed mainly due to the loss of some of the elements required for bonding (13), or change in the thickness of the oxide layer. It is a known fact that increased oxide layer thickness decreases the bond strength (4). Studies indicated that alloys containing a high Cr content (16%-27%) and a minimum of 6% Mo exhibited a uniform oxide layer. Whereas alloys containing lower levels of Cr and Mo did not exhibit homogeneous surface oxide layer (14). During the process of recasting some of the key ingredients similar to Cr-Mo may have lost or altered that resulted in change in the properties of the oxide layer. Although the buttons and sprues may be sand blasted and cleaned, the contents of the metal oxides cannot be completely eliminated under normal laboratory conditions (4). The results obtained in the study indicate recasting 75% of Ni-Cr alloy decreases the shear bond strength of the metal ceramic restoration. Keeping in mind the deleterious effect of 75% of alloy in the present study, we can suggest that recasting up to 50% Ni-Cr alloy is economical with simultaneous maintenance of optimum properties. However, further clinical trials are recommended to confirm the results of this study. Conclusion It can be concluded that 50% fresh alloy for casting is adequate for recasting Ni-Cr alloy.

Arch Oral Res. 2011 May/Aug.;7(2)177-82

182

Rajalbandi SK, Kumar V, Sajjan S.

References

1. 2. Anusavice KJ, Phillips RW. Science of dental materials. 11th ed. St. Louis: W.B. Saunders; 2003.

3. 4. 5. 6. 7. 8. 9.

Moffa JP, Lugassy AA, Guckes AD, Gettleman L. An evaluation of precious alloys for the use with porcelain veneers. Part I. Physical properties. J Prosthet Dent. 1973;30(4):424-31.

10. Piwowarczyk A, Lauer HC, Sorensen JA. In vitro shear bond strength of cementing agents to fixed prosthodontic restorative materials. J Prosthet Dent. 2004;92(3):265-73. 12. Hesby DA, Kobes P, Garver DG, Pelleu GB. The physical properties of repeatedly used non- precious metal alloys. J Prosthet Dent. 1980;44(3):291-3.

11. Jochen DG, Caputo AA, Matyas J. Reuse of silver-palladium ceramic metal. J Prosthet Dent. 1991;65(4):588-91.

Rasmussen ST, Doukoudakis AA. The effect of using recast metal on the bond between porcelain and gold palladium alloy. J Prosthet Dent. 1986;55(4):447-53. Hong JM, Razzoog ME, Lang BR. The effect of recasting on the oxidation layer of a palladium-silver Porcelain alloy. J Prosthet Dent. 1988;59(4):420-5. Zhang K, Watanabe LG. Bond strength of ceramo metal after repeated castings and firings. J Dent Res. 1989;68:303.

13. Anusavice KJ, Ringle RD, Fairhurst CW. Adherance controlling elements in ceramic metal system II in non precious alloys. J Dent Res. 1977;56(9):1053-61. 14. Bruggers K, Corcoran C, Jeansonne EE, Sarkar NK. Role of manganese in alloy-porcelain bonding. J Prosthet Dent. 1986;55(4);453-6.

Jochen GD, Caputo AA, Matyas J. Effect of opaque porcelain application on strength of bond to silverpalladium alloys. J Prosthet Dent. 1990;63(4):414-8. Heraeus K. Metal ceramics manual. 5th ed. Philadelphia: W.B. Saunders; 2003. Prado RA Panzeri H, Fernandes AJ Neto, Neves FD, Silva MR, Mendonca G. Shear bond strength of dental porcelains to Ni-Cr alloys. Braz Dent J. 2005;16:202-6. Baran GR. The metallurgy of Ni-Cr alloys for fixed prosthodontics. J Prosthet Dent. 1983;50(5):639-49.

15. Anusavice KJ, Ringle RD, Fairhurst CW. Identification of fracture zones in porcelain-vereered-to-metal bond test specimens by ESCA analysis. J Prosthet Dent. 1979;42(4):417-21. 16. Roach MD Wolan JT, Parsell DE, Bumgardner JD. Use of x-ray photoelectron spectroscopy and cyclic polarization to evaluate the corrosion behavior of six nickel-chromium alloys before and after porcelain-fusedto-metal firing. J Prosthet Dent. 2000;84(6):623-33.

Approved: 06/24/2011 Aprovado: 24/06/2011

Received: 11/15/2010 Recebido: 15/11/2010

Arch Oral Res. 2011 May/Aug.;7(2)177-82

Вам также может понравиться

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášОценок пока нет

- E TransactionДокумент8 страницE TransactionpenandpensilОценок пока нет

- Journal Homepage: - : Manuscript HistoryДокумент12 страницJournal Homepage: - : Manuscript HistoryIJAR JOURNALОценок пока нет

- Defect FormationДокумент12 страницDefect FormationcarlosОценок пока нет

- Amp 05Документ4 страницыAmp 05dgdhan5339Оценок пока нет

- Bond Strength of Wire-Composite Resin Interface of Dental Splints Using Different Wire Surface Treatments - An in Vitro StudyДокумент8 страницBond Strength of Wire-Composite Resin Interface of Dental Splints Using Different Wire Surface Treatments - An in Vitro StudyDimas PermanaОценок пока нет

- J BalvinabstractДокумент8 страницJ BalvinabstractCecySoriaОценок пока нет

- Effect of Al2O3 NanoparticlesДокумент11 страницEffect of Al2O3 NanoparticlesmirelamanteamirelaОценок пока нет

- An Improved Etchant For Copper and Copper Alloys: METALLOGRAPHY 9, 51-61 (1976)Документ11 страницAn Improved Etchant For Copper and Copper Alloys: METALLOGRAPHY 9, 51-61 (1976)Michael Vincent MirafuentesОценок пока нет

- Mechanical Properties and Corrosion Resistance of Ti-6Al-7Nb Alloy Dental CastingsДокумент8 страницMechanical Properties and Corrosion Resistance of Ti-6Al-7Nb Alloy Dental Castingsalaa jaleelОценок пока нет

- Jeong Translucency of Zirconia-Based Pressable Ceramics With Different Core and Veneer ThicknessesДокумент5 страницJeong Translucency of Zirconia-Based Pressable Ceramics With Different Core and Veneer ThicknessesBrunaGОценок пока нет

- Ref 9Документ11 страницRef 9raisajoyОценок пока нет

- Literature ReviewДокумент13 страницLiterature ReviewDavid RajaselvamОценок пока нет

- Compositional Influence On The Strength of Dental Porcelain: Prosthodont 1993:6:291-297Документ7 страницCompositional Influence On The Strength of Dental Porcelain: Prosthodont 1993:6:291-297jinny1_0Оценок пока нет

- SoldaduraДокумент8 страницSoldaduraAndrea GarcíaОценок пока нет

- Effect of Copper Content On The Mechanical and Sliding Wear Properties of Monotectoid-Based Zinc-Aluminium-copper AlloysДокумент6 страницEffect of Copper Content On The Mechanical and Sliding Wear Properties of Monotectoid-Based Zinc-Aluminium-copper AlloysuzairmetallurgistОценок пока нет

- Auomotivr Fuel TanksДокумент9 страницAuomotivr Fuel Tankscolumba_mcОценок пока нет

- Effect of Artificial Saliva-No AffДокумент4 страницыEffect of Artificial Saliva-No Affshihap2020738650988Оценок пока нет

- 30prasad EtalДокумент7 страниц30prasad EtaleditorijmrhsОценок пока нет

- An Evaluation of The Effect of Different Surface Treatment On Hardness and Smoothness of Pressable Ceramic (In Vitro Study)Документ6 страницAn Evaluation of The Effect of Different Surface Treatment On Hardness and Smoothness of Pressable Ceramic (In Vitro Study)International Organization of Scientific Research (IOSR)Оценок пока нет

- Dry Sliding Friction Wear ZAДокумент8 страницDry Sliding Friction Wear ZAmohammedОценок пока нет

- 2nd Review Paper (1111,2222,3333)Документ8 страниц2nd Review Paper (1111,2222,3333)SHAIKJAFARОценок пока нет

- Jap 10 132Документ6 страницJap 10 132MairaMaraviChavezОценок пока нет

- TMP 3 BC1Документ6 страницTMP 3 BC1FrontiersОценок пока нет

- Polymer TestingДокумент5 страницPolymer TestingjimoteОценок пока нет

- Magne 2006Документ8 страницMagne 2006valperlunОценок пока нет

- Book Chapter 1Документ6 страницBook Chapter 1Prasoon ChoudharyОценок пока нет

- Astm C 579Документ4 страницыAstm C 579Rodrigo Andres Aguirre Delgado100% (2)

- Squeeze CastingДокумент38 страницSqueeze Castingjishnus100% (1)

- Tribology International: S. Kumar, V. BalasubramanianДокумент9 страницTribology International: S. Kumar, V. Balasubramaniannarayananx5Оценок пока нет

- Nou Met Cer 17Документ7 страницNou Met Cer 17Ahab SilenceОценок пока нет

- Parametric Experimental Analysis of Erosion Wear On Mild Steel Material - Response Surface MethodologyДокумент7 страницParametric Experimental Analysis of Erosion Wear On Mild Steel Material - Response Surface MethodologyGRD JournalsОценок пока нет

- Asbestos SheetДокумент5 страницAsbestos SheetPraveenkumar ShanmugamОценок пока нет

- Velocity in MetalsДокумент30 страницVelocity in MetalsChegwe CorneliusОценок пока нет

- PROJECT PPT B1 Nihal Murugesh Libin SandeepДокумент20 страницPROJECT PPT B1 Nihal Murugesh Libin SandeepKiran SNОценок пока нет

- C267Документ6 страницC267Rufo CascoОценок пока нет

- The Effect of Defects in Tubes: Part 1. Mode I Delamination ResistanceДокумент17 страницThe Effect of Defects in Tubes: Part 1. Mode I Delamination ResistanceHassan HabibОценок пока нет

- Ductile Iron NodularityДокумент34 страницыDuctile Iron NodularitykarthikkandaОценок пока нет

- Contemporary All-Ceramic Fixed Partial Dentures: A Review: Ariel J. Raigrodski, DMD, MSДокумент14 страницContemporary All-Ceramic Fixed Partial Dentures: A Review: Ariel J. Raigrodski, DMD, MSNiaz AhammedОценок пока нет

- Structures: Baofeng Zheng, Ganping Shu, Lianchun Xin, Ran Yang, Qinglin JiangДокумент12 страницStructures: Baofeng Zheng, Ganping Shu, Lianchun Xin, Ran Yang, Qinglin JiangNasarKhanОценок пока нет

- D.D.S., M.S.D.": University of Manitoba, Faculty of Dentistry, Winnzpeg, ManДокумент4 страницыD.D.S., M.S.D.": University of Manitoba, Faculty of Dentistry, Winnzpeg, ManAmar BhochhibhoyaОценок пока нет

- Mill Scale 2Документ7 страницMill Scale 2viswaprasad005Оценок пока нет

- ASTM-Designation G109 99aДокумент5 страницASTM-Designation G109 99aJorge LeconaОценок пока нет

- Wei2018 - MOLD SLSДокумент30 страницWei2018 - MOLD SLSjanakОценок пока нет

- Camasuire Stalp Cu FerocimentДокумент8 страницCamasuire Stalp Cu FerocimentChelemen MaryaОценок пока нет

- Improvement in Durability of Ferrocement Using Fly Ash and Silica Fume Modified MortarДокумент4 страницыImprovement in Durability of Ferrocement Using Fly Ash and Silica Fume Modified MortarijsretОценок пока нет

- Shot Peening Effect On Fatigue Life of EN GJS 600Документ9 страницShot Peening Effect On Fatigue Life of EN GJS 600karthegreОценок пока нет

- Chaiyabutr2008 PDFДокумент9 страницChaiyabutr2008 PDFAline PereiraОценок пока нет

- Performance of Ferrocement Panels in Different EnvironmentsДокумент8 страницPerformance of Ferrocement Panels in Different EnvironmentsSulaiman Mohsin AbdulAzizОценок пока нет

- Friction Stir WeldingДокумент12 страницFriction Stir WeldingelmardaОценок пока нет

- V 16 N 3 A 06Документ5 страницV 16 N 3 A 06Ghanshyam GaurОценок пока нет

- 10.1007@s00170 015 7586 0Документ9 страниц10.1007@s00170 015 7586 0Zigit Sang Aruniero EzpadaОценок пока нет

- Accepted ManuscriptДокумент29 страницAccepted ManuscriptMartín KunuschОценок пока нет

- Effect of Nano-Silica On Properties of Blended Cement: G.Reddy BabuДокумент6 страницEffect of Nano-Silica On Properties of Blended Cement: G.Reddy BabuInternational Journal of computational Engineering research (IJCER)Оценок пока нет

- Effect of Air Abrasion On The Marginal Configuration of Titanium Crowns After CastingДокумент5 страницEffect of Air Abrasion On The Marginal Configuration of Titanium Crowns After CastingNengsi YusufОценок пока нет

- Metallography Bwelch11Документ9 страницMetallography Bwelch11Paviter SinghОценок пока нет

- By Measuring The Gap Dimension Between The Crowns Margin and Finishing Line of The Prepared ToothДокумент7 страницBy Measuring The Gap Dimension Between The Crowns Margin and Finishing Line of The Prepared ToothNaveen S YadavОценок пока нет

- 07-Hull Cell R-10-14Документ22 страницы07-Hull Cell R-10-14Alejandro AvalosОценок пока нет

- Microstructures of Plasma-Sprayed Hydroxyapatite-Coated Ti-6Al-4V Dental ImplantsДокумент14 страницMicrostructures of Plasma-Sprayed Hydroxyapatite-Coated Ti-6Al-4V Dental ImplantsMedstudОценок пока нет

- Anterior Point of ReferenceДокумент9 страницAnterior Point of ReferenceAmitОценок пока нет

- Dental Caries - BasicДокумент35 страницDental Caries - BasicAmitОценок пока нет

- 1000 MCQ Bank QuestionsДокумент157 страниц1000 MCQ Bank Questionsapi-2629165193% (59)

- Dentist CV TemplateДокумент2 страницыDentist CV TemplateMarcus ValentineОценок пока нет

- Dentist CV TemplateДокумент2 страницыDentist CV TemplateMarcus ValentineОценок пока нет

- MistakesДокумент12 страницMistakesAmitОценок пока нет

- Shear Bond Strength Test Using Different Loading Conditions - A Finite Element AnalysisДокумент4 страницыShear Bond Strength Test Using Different Loading Conditions - A Finite Element AnalysisAmitОценок пока нет

- Smile DesignДокумент20 страницSmile DesignAmit100% (1)

- New Text DocumentДокумент2 страницыNew Text DocumentAmitОценок пока нет

- Jacobson A Contemporary Review of The Factors Involved in CD Retentio Stability Support PT I 1983Документ11 страницJacobson A Contemporary Review of The Factors Involved in CD Retentio Stability Support PT I 1983Amit0% (1)

- ZirconiaДокумент8 страницZirconiaAmitОценок пока нет

- AkДокумент5 страницAkAmitОценок пока нет

- Flexrl STNRGTH On Cermc CoreДокумент9 страницFlexrl STNRGTH On Cermc CoreAmitОценок пока нет

- Comparative Investigation of Organic CompundsДокумент6 страницComparative Investigation of Organic CompundsKizer Dela Cruz100% (1)

- Exp-Function Method For Nonlinear Wave Equations: Ji-Huan He, Xu-Hong WuДокумент9 страницExp-Function Method For Nonlinear Wave Equations: Ji-Huan He, Xu-Hong Wufalcon_vamОценок пока нет

- Prime Cut MsdsДокумент2 страницыPrime Cut MsdsMarvin BarahonaОценок пока нет

- Front Page To Chapter 5Документ28 страницFront Page To Chapter 5Alex DGОценок пока нет

- Electrostatics PDFДокумент17 страницElectrostatics PDFcolorado wildernessОценок пока нет

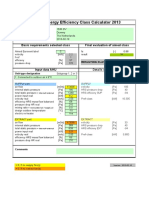

- Eurovent Energy Efficiency CalculatorДокумент1 страницаEurovent Energy Efficiency CalculatorPradeep Sukumaran100% (1)

- 13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureДокумент2 страницы13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureAlyssaRamosОценок пока нет

- 1.principles of Chemistry, E. ElectrolysisДокумент7 страниц1.principles of Chemistry, E. ElectrolysisDr.AndrewMatovuОценок пока нет

- Effect of Nodule CountДокумент5 страницEffect of Nodule Countdinesh529Оценок пока нет

- Introduction To Plunger Lift Feb 2013 PDFДокумент48 страницIntroduction To Plunger Lift Feb 2013 PDFMendoza Franz CondoriОценок пока нет

- Science of The Total Environment: M. Andersson, T.E. Finne, L.K. Jensen, O.A. EggenДокумент13 страницScience of The Total Environment: M. Andersson, T.E. Finne, L.K. Jensen, O.A. EggenSyahrul RamadhanОценок пока нет

- Reactive DyesДокумент24 страницыReactive DyesrehanabbaciОценок пока нет

- AMP16602P032Документ6 страницAMP16602P032Ravi TejaОценок пока нет

- High Temprature and High Pressure 2Документ16 страницHigh Temprature and High Pressure 2Sushmita SatiОценок пока нет

- Graphitisation Cast IronДокумент28 страницGraphitisation Cast IronKurnia BijaksanaОценок пока нет

- Tl-Isover S en PDFДокумент2 страницыTl-Isover S en PDFBogdan MucenicaОценок пока нет

- Question Bank of ESTДокумент5 страницQuestion Bank of ESTKishor PatilОценок пока нет

- Cost Unit Februri 2017dddddddddddgДокумент563 страницыCost Unit Februri 2017dddddddddddgHatlan RizalОценок пока нет

- (Courseware) ICSE: Mendeleev's Periodic TableДокумент39 страниц(Courseware) ICSE: Mendeleev's Periodic Tableorigami ninjaОценок пока нет

- 3 - Casting Procedures For Fixed Partial DentureДокумент76 страниц3 - Casting Procedures For Fixed Partial Dentureyabhatia100% (1)

- Students Guide For Entry Test Info)Документ13 страницStudents Guide For Entry Test Info)Sunny MudassarОценок пока нет

- Product Development Processes A Case Study in Sustainable Product Design: Herman Miller, IncДокумент2 страницыProduct Development Processes A Case Study in Sustainable Product Design: Herman Miller, Incarbitid01Оценок пока нет

- Transparent Films On Polymers For Photovoltaic Applications: J. Herrero, C. Guill !enДокумент6 страницTransparent Films On Polymers For Photovoltaic Applications: J. Herrero, C. Guill !enAnand Sreekantan ThampyОценок пока нет

- 04 Determining Molar Mass by FP DepressionДокумент16 страниц04 Determining Molar Mass by FP DepressionMuhammad IqbalОценок пока нет

- Materials For Bridge Deck Waterproofing Membrane SystemsДокумент2 страницыMaterials For Bridge Deck Waterproofing Membrane SystemstenОценок пока нет

- Amali 3Документ9 страницAmali 3Aiman FarhanОценок пока нет

- Bio-Fuels: A Blessing in Disguise: O. Surriya, Syeda Sarah Saleem, K. Waqar, A. Gul Kazi and M. ÖztürkДокумент21 страницаBio-Fuels: A Blessing in Disguise: O. Surriya, Syeda Sarah Saleem, K. Waqar, A. Gul Kazi and M. ÖztürkcmuruganОценок пока нет

- Tunnelling in Soft GroundДокумент19 страницTunnelling in Soft Groundiman safiyaОценок пока нет

- AND From AND: FOR Rhodium, For Their GravimetricДокумент13 страницAND From AND: FOR Rhodium, For Their GravimetricshahinОценок пока нет

- Astm f136 Rev AДокумент4 страницыAstm f136 Rev AAhmad BrianОценок пока нет