Академический Документы

Профессиональный Документы

Культура Документы

Casing Integrity Testing

Загружено:

Kim MissonАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Casing Integrity Testing

Загружено:

Kim MissonАвторское право:

Доступные форматы

Casing Integrity Testing

II

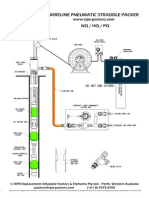

Casing integrity testing involves the testing of an entire borehole via a single packer or via a straddle packer system allowing the testing of specially sele d zones. Both methods provide reliable results with the use of each system dependant n the situation. The reliability of casing is extremely important for many reasons including support for the id loss into or dontamination of production nes, provides a drilled hole, preve smooth surface fo i tailing production equipment, all w the flow roduction of oil & ell. gas wells witho kage into the formation through t of casing i freshly drilled hole is dependant on do e conditions. recent years PVC has beco more common especially in watS. levels er of the well, pressures and tempera throughout the well, high or ay become corrosive), Dissolved solids such as It may also become corrosive to steel casing. Poor earthing of downhole pumps will cause r id corrosion through electrolys the current finds the shortest possible path to earth (steel asing). Dissimilar metals in a electrolyte such as salt water will also cause galvanic corro ion. PVC is resistant to pH corro e ectroFigi-alvanic corrosion. i4 Choosing between steel or i ercndant of the above issu s however even if the correct choice of casing was taken there . 'stil ay be problems Ath the ntegrity of a borehole such as liunaan-zrrorpr unforeseen circumst nces. PVC must be insta led correctly to retain its integrity, this creates a problem where 'Hers are under strict ti e constraints to finish a borehole. Co rion problems with PVC iistallation are related t the joins whereby a thread and ozzini*(ve used to seal, the o-ring ma be forgotten or the t ead miss-aligned. Also sealing pi-bblems occur in socket and glu joins where bad glue as been used or seating issues between the c ing \ \No Casing integrity testin thAPsingle packer is performed by lowering a single inflatable packer to the desired depth, inflating t e packer to Great al. At the surface a bulkhead o other sealing mechanism is required ater is then pumped o to a predetermined whiv pressure, a leak is thereby determ ed by a pressure drop. Identi where a leak is coming rom i as simple as starting a e bottom of a bor hole and slowly raising the packer te stroPii the up. -, 1111111 oratectint asing integrity testing w o oiliff cker ere down a- oreho with a peforated pipe creating the straddle. ''he strad pipe length may vary with std S and lengths from lm 6m. Once the packers hare been inflated water is pump iledown under pressure to the 'straddle zone' typically located over joins in casing and any specific leak locations as identified by downhole cameras.

411110111i-

Replacement Inflatable Packers and Elements Pty Ltd 29 Wheeler St Belmont 6104, Perth Western Australia Tel: (+61 (08) 9475 0700 Fax: +61 (08) 9475 0770 packers@ripe-packers.com

www.ripe-packers.com

Supplier and rrianufacturers of well screen PVC rubber k-packers, well packer tri-seals, equipment and services.

Вам также может понравиться

- Diverter Drilling System For Well Control Full GuideДокумент19 страницDiverter Drilling System For Well Control Full GuiderahulОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Corpro Coring PresentationДокумент80 страницCorpro Coring PresentationemmanuelОценок пока нет

- 7" Liner - Cementing Preparation and Procedure ChecklistДокумент2 страницы7" Liner - Cementing Preparation and Procedure ChecklistYougchu LuanОценок пока нет

- CTU ComponentsДокумент28 страницCTU ComponentsRufo WuarnerОценок пока нет

- Stabilizer TypeДокумент14 страницStabilizer TypeAdin PraviMoški PartAdisОценок пока нет

- Spe 196232 MSДокумент18 страницSpe 196232 MShijoetigreОценок пока нет

- Windowmaster G2 Whipstock System With Glyphaloy AMT-Dressed Mills Created Window and Drilled Rathole in Single TripДокумент1 страницаWindowmaster G2 Whipstock System With Glyphaloy AMT-Dressed Mills Created Window and Drilled Rathole in Single TripOgbadiboОценок пока нет

- 7in 29ppf 13Cr-80 JFE BearДокумент1 страница7in 29ppf 13Cr-80 JFE BearYeit HauОценок пока нет

- Baghjan Well No. 5 Blowout: Sequence of EventsДокумент3 страницыBaghjan Well No. 5 Blowout: Sequence of EventsbhupenderОценок пока нет

- API Non Upset EndДокумент1 страницаAPI Non Upset EndChoerunnisa Firli FitriahОценок пока нет

- WR Retrievable Bridge Plug - Operating InstructionsДокумент19 страницWR Retrievable Bridge Plug - Operating InstructionsEvolution Oil Tools100% (4)

- Well Control - Combined Stripping and Volumetric MethodДокумент3 страницыWell Control - Combined Stripping and Volumetric MethodAbdul Hameed Omar100% (1)

- Ch04 WELL HEAD EQUIPMENTS AND FLOW CONTROL DEVICESДокумент16 страницCh04 WELL HEAD EQUIPMENTS AND FLOW CONTROL DEVICESWhiskey /Оценок пока нет

- Drilling Tools CatalogДокумент96 страницDrilling Tools CatalogRzvn100% (1)

- Cameron Drilling Products Overview CatalogДокумент587 страницCameron Drilling Products Overview CatalogJayro LeninОценок пока нет

- Completion Equipment1Документ32 страницыCompletion Equipment1MUHAMMAD AKRAMОценок пока нет

- Rig DesginДокумент25 страницRig DesginImam PranadipaОценок пока нет

- 03 Shut-In ProcedureДокумент15 страниц03 Shut-In Proceduresitemaster60Оценок пока нет

- Packer Testing Program Design and Management: August 2013Документ7 страницPacker Testing Program Design and Management: August 2013wily784Оценок пока нет

- RTTS Packer: Technical Data SheetДокумент5 страницRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Stuck Pipe BookДокумент60 страницStuck Pipe BookAhmed100% (1)

- 00087167Документ11 страниц00087167JohnSmith100% (1)

- Rubicon D455 Safety JointsДокумент12 страницRubicon D455 Safety JointsEmad JamshidiОценок пока нет

- Well CommanderДокумент8 страницWell Commanderice_PLОценок пока нет

- Drop Gyro Survey Procedure-ConvincerДокумент2 страницыDrop Gyro Survey Procedure-ConvincertnampvepОценок пока нет

- Centralizers & StopCollarsДокумент19 страницCentralizers & StopCollarsSaurabh Parihar100% (1)

- SPE-25499-MS Fishing With Coiled TubingДокумент16 страницSPE-25499-MS Fishing With Coiled TubingirhaniefОценок пока нет

- Casing Cup TesterДокумент3 страницыCasing Cup TesterWei ShangОценок пока нет

- CF Diverter BrochureДокумент2 страницыCF Diverter BrochureRobertok1234Оценок пока нет

- Cup Tester Torque ValuesДокумент3 страницыCup Tester Torque ValuesDorin Radu100% (1)

- 2-36, TMC Jar, OpДокумент15 страниц2-36, TMC Jar, OpAli HosseiniОценок пока нет

- 9 - What Is A Special Drift CasingДокумент2 страницы9 - What Is A Special Drift CasingLuis David Concha CastilloОценок пока нет

- Casing & CementingДокумент13 страницCasing & CementingBharat Kumar HaraniОценок пока нет

- NT40637 Casing Running in High Angle Wells 2005 NovДокумент11 страницNT40637 Casing Running in High Angle Wells 2005 NovkameliooОценок пока нет

- Drilling Tools - 1Документ269 страницDrilling Tools - 1berrouiОценок пока нет

- Drawworks and Rig Sizing PDFДокумент8 страницDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- Squeeze Cementing PresentationДокумент15 страницSqueeze Cementing PresentationAhmed Ali AlsubaihОценок пока нет

- Tubing Stretch FormulasДокумент2 страницыTubing Stretch Formulaszapspaz80% (5)

- DRT Motor Manual 6-16-10Документ55 страницDRT Motor Manual 6-16-10sumsolcaggОценок пока нет

- Jars and Accelerators.Документ10 страницJars and Accelerators.gaddasalimОценок пока нет

- How To Calculate The Balanced Plug 1Документ2 страницыHow To Calculate The Balanced Plug 1islam atifОценок пока нет

- Drilling String CalculationДокумент3 страницыDrilling String CalculationriobmОценок пока нет

- Back Off String ShotДокумент16 страницBack Off String ShotChoayb Seller100% (1)

- Maintenance Steps of Mud Gas SeparatorДокумент1 страницаMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- EXTENDED Well Control ChecklistДокумент14 страницEXTENDED Well Control ChecklistAdam InesОценок пока нет

- Series 150 Overshots: Instruction Manual 1150Документ28 страницSeries 150 Overshots: Instruction Manual 1150Raul BlancoОценок пока нет

- Packer CatalogДокумент37 страницPacker CatalogVictor Alejandro Clavijo Salazar0% (1)

- Drilling Abbreviations For ReportingДокумент10 страницDrilling Abbreviations For ReportingLeon Monsalve100% (1)

- Drill Stem Test Part 1Документ31 страницаDrill Stem Test Part 1Abdullah IshaqОценок пока нет

- A Guide To Successful Backreaming - Real-Time Case Histories) - SPE-116555-PA-PДокумент12 страницA Guide To Successful Backreaming - Real-Time Case Histories) - SPE-116555-PA-PReginaldo de SousaОценок пока нет

- Drilling NotebookДокумент96 страницDrilling NotebookOmar Rosado Roldan0% (1)

- ToolfaceДокумент15 страницToolfaceAdin PraviMoški PartAdis0% (1)

- Drill Pipe Spec SheetДокумент2 страницыDrill Pipe Spec SheetVijay KotiОценок пока нет

- Side Pocket MandrelДокумент3 страницыSide Pocket MandrelSyameer109Оценок пока нет

- DC Make-Up TorqueДокумент5 страницDC Make-Up TorquepatelsujanОценок пока нет

- Rtts Packer: Simple, Versatile Means For Testing, Treating and Squeeze Cement OperationsДокумент4 страницыRtts Packer: Simple, Versatile Means For Testing, Treating and Squeeze Cement OperationsEmad JamshidiОценок пока нет

- Replacements and RebuildsДокумент1 страницаReplacements and RebuildsKim MissonОценок пока нет

- Wireline Pneumatic Straddle PackerДокумент1 страницаWireline Pneumatic Straddle PackerKim MissonОценок пока нет

- Wireline Hydraulic Single PackerДокумент1 страницаWireline Hydraulic Single PackerKim MissonОценок пока нет

- Wireline Hydraulic Straddle PackerДокумент1 страницаWireline Hydraulic Straddle PackerKim MissonОценок пока нет

- Ripe K Packers and Telescopic SealsДокумент1 страницаRipe K Packers and Telescopic SealsKim MissonОценок пока нет

- Wireline Pneumatic Single PackerДокумент1 страницаWireline Pneumatic Single PackerKim MissonОценок пока нет

- Grab Packer MetricДокумент1 страницаGrab Packer MetricKim MissonОценок пока нет

- K PackersДокумент1 страницаK PackersKim MissonОценок пока нет

- Permeability TestingДокумент1 страницаPermeability TestingKim MissonОценок пока нет

- RIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsДокумент1 страницаRIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsKim MissonОценок пока нет

- Kpackers MetricДокумент1 страницаKpackers MetricKim MissonОценок пока нет

- 30 Bridge Plug Metric Sliding EndДокумент1 страница30 Bridge Plug Metric Sliding EndKim MissonОценок пока нет

- Mini Hydrualic Frac PackersДокумент1 страницаMini Hydrualic Frac PackersKim MissonОценок пока нет

- Hydraulic Fracturing Inflatable PackersДокумент1 страницаHydraulic Fracturing Inflatable PackersKim MissonОценок пока нет

- 54 DST Packer Test ToolДокумент2 страницы54 DST Packer Test ToolKim MissonОценок пока нет

- Drill Able Bridge PlugsДокумент1 страницаDrill Able Bridge PlugsKim MissonОценок пока нет

- Grab Packer ImperialДокумент1 страницаGrab Packer ImperialKim MissonОценок пока нет

- 60 Standard Wireline Packer System ReplacementsДокумент1 страница60 Standard Wireline Packer System ReplacementsKim MissonОценок пока нет

- 72 DST Packer Test ToolДокумент2 страницы72 DST Packer Test ToolKim MissonОценок пока нет

- 73 DST Packer Test ToolДокумент2 страницы73 DST Packer Test ToolKim MissonОценок пока нет

- 43 DST Packer Test ToolДокумент2 страницы43 DST Packer Test ToolKim MissonОценок пока нет

- 42 Standard Wireline Packer System ReplacementsДокумент1 страница42 Standard Wireline Packer System ReplacementsKim MissonОценок пока нет

- 42 DST Packer Test ToolДокумент2 страницы42 DST Packer Test ToolKim MissonОценок пока нет

- 83 Standard Wireline Packer System ReplacementsДокумент1 страница83 Standard Wireline Packer System ReplacementsKim MissonОценок пока нет

- 56 DST Packer Test ToolДокумент2 страницы56 DST Packer Test ToolKim MissonОценок пока нет

- 30 Bridge Plug Imperial Sliding EndДокумент1 страница30 Bridge Plug Imperial Sliding EndKim MissonОценок пока нет

- 30 Bridge Plug Metric Fixed EndДокумент1 страница30 Bridge Plug Metric Fixed EndKim MissonОценок пока нет

- 26 Bridge Plug Imperial Sliding EndДокумент1 страница26 Bridge Plug Imperial Sliding EndKim MissonОценок пока нет

- 30 Bridge Plug Imperial Fixed EndДокумент1 страница30 Bridge Plug Imperial Fixed EndKim MissonОценок пока нет

- 26 Bridge Plug Metric Sliding EndДокумент1 страница26 Bridge Plug Metric Sliding EndKim MissonОценок пока нет

- SurveyingДокумент26 страницSurveyingDenise Ann Cuenca25% (4)

- Reflection in Sexually Transmitted DiseaseДокумент1 страницаReflection in Sexually Transmitted Diseasewenna janeОценок пока нет

- Enrico Fermi Pioneer of The at Ted GottfriedДокумент156 страницEnrico Fermi Pioneer of The at Ted GottfriedRobert Pérez MartinezОценок пока нет

- Honda IzyДокумент16 страницHonda IzyTerry FordОценок пока нет

- Quanta To QuarksДокумент32 страницыQuanta To QuarksDaniel Bu100% (5)

- 35 Electrical Safety SamanДокумент32 страницы35 Electrical Safety SamanSaman Sri Ananda RajapaksaОценок пока нет

- Computer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Документ19 страницComputer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Carl John GomezОценок пока нет

- Brosur YSIO X.preeДокумент20 страницBrosur YSIO X.preeRadiologi RSUD KilisuciОценок пока нет

- PGCRSM-01-BLOCK-03 Research Design ExperimentalДокумент29 страницPGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanОценок пока нет

- Concrete Specification (BS8500)Документ3 страницыConcrete Specification (BS8500)teh100% (1)

- Impact of Government Policies and EthicsДокумент24 страницыImpact of Government Policies and EthicsGunveen AbrolОценок пока нет

- Microfinance Ass 1Документ15 страницMicrofinance Ass 1Willard MusengeyiОценок пока нет

- Science and Technology in Ancient India by NeneДокумент274 страницыScience and Technology in Ancient India by NeneAshok Nene100% (1)

- Guided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaДокумент9 страницGuided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaAlexander DeckerОценок пока нет

- The First Voyage Round The World by MageДокумент405 страницThe First Voyage Round The World by MageGift Marieneth LopezОценок пока нет

- Accounting Students' Perceptions On Employment OpportunitiesДокумент7 страницAccounting Students' Perceptions On Employment OpportunitiesAquila Kate ReyesОценок пока нет

- Angel C. Delos Santos: Personal DataДокумент8 страницAngel C. Delos Santos: Personal DataAngel Cascayan Delos SantosОценок пока нет

- EX200Документ7 страницEX200shubbyОценок пока нет

- Riqas Ri RQ9142 11aДокумент6 страницRiqas Ri RQ9142 11aGrescia Ramos VegaОценок пока нет

- ST3 ManualДокумент48 страницST3 ManualRon FosterОценок пока нет

- Existentialism in LiteratureДокумент2 страницыExistentialism in LiteratureGirlhappy Romy100% (1)

- Benjamin Franklin - The Indian Treaties (1938)Документ450 страницBenjamin Franklin - The Indian Treaties (1938)Spiritu SanctoОценок пока нет

- Iec Codes PDFДокумент257 страницIec Codes PDFAkhil AnumandlaОценок пока нет

- I Pmtea 2020 HandoutДокумент94 страницыI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- CAREДокумент11 страницCARELuis SementeОценок пока нет

- 9881 enДокумент345 страниц9881 enSaid BenОценок пока нет

- Psychoanalytic Theory byДокумент43 страницыPsychoanalytic Theory byjoy millano100% (1)

- Persuasive Speech 2016 - Whole Person ParadigmДокумент4 страницыPersuasive Speech 2016 - Whole Person Paradigmapi-311375616Оценок пока нет

- KMKT Pra PSPM ANS SCHEMEДокумент16 страницKMKT Pra PSPM ANS SCHEMEElda AldaОценок пока нет

- Paper 1 AnalysisДокумент2 страницыPaper 1 AnalysisNamanОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)