Академический Документы

Профессиональный Документы

Культура Документы

NP 6012, 6212 SM

Загружено:

Petrescu CezarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

NP 6012, 6212 SM

Загружено:

Petrescu CezarАвторское право:

Доступные форматы

SERVICE

MANUAL

REVWON 1 SEPT. 1995

Canon

FY8-13DW010

COPtiGHT 1995 CANON I NC.

CANOh NP6012/NP6012F/NP60212 REV, 1 SEPT. 1995 PRI NTED I N J APAN

GENERAL DESCRlPTlONl

,I-. ,

I.

J

1.

2.

3.

4.

,/*--,~

_I

5.

,.-

,

FEATURES

Fixed copyboard with zooming.

l In addition to the default reproduction ratios, a ratio between 70% and 141% may be

selected.

Designed with considerations for the environment.

l The use of a charging roller helps to limit the generation of ozone; average of 0.01 ppm or

less, maximum of 0.02 ppm or less. (i/100 to l/O00 of existing machines)

Uses a SURF fixing assembly.

l The use of the SURF fixing mechanism enables a 0-set wait time.

l In addition, the maximum power consumption is 0.98 kW or less.

Cassette accommodating various types of paper and 2-way pick-up.

l The universal cassette (about 250 sheets) accommodates paper of sizes between

AULTR and A5lSTMT.

l In addition, sheets as large as AWLTR to business card may be used (manual).

Separate top unit.

l The copiers top unit may be opened to make jam removal easy.

COPYRIGHT 0 1335 CANONI NC. CANONNP6012~NPW2F/NP6212 REV.1SEPT. 1995PAWED INJAPAN(IMPRIB~AUJAPONJ l-l

II. SPECIFICATIOMS

A. Copier

1. Type

&. )dy' ~/ '

Desktop

I

Ge~*uir& Fi xed

.Light sowcf? Fluorescent lamp ( 17 W)

l . en$ Fi xed l ens array

Phutow&l vf 9m~dbm OPC ( 24 di a. )

2. System

l-2 COPYRI GHT 0 1995 CANONI NC CANON NP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

GENERAL DESCRlPTlONl

3. Performance

postcard*, transparencies*, business card (ZOO g/m2 or less, 51X88 mm or

Copy Wiy 100 sheets (approx.; A4, 80 g/m* paper)

Elan&qe

k&il@%ddge 2.Ok1.5 mm /0.08kO.O6 in. (two-sided/overlay/one-sided)

@MI LefRighf 0.0+2.0-0.0 (A4), 0.0+4.0-0.0 (LGULTR) (two-sided/overlay/one-sided)

Aitk f3ower oii Available (about 5 min; fixed)

As recommended bv Canon.

Single feeding only.

_-

COPYRIGHT 0 1995 CANON INC. CANON NP60121NP6012FiNP62i2 REV.1 SEPT. 1995 PRINTEDIN JAPAN(IMPRIMi AUJAPON) l-3 (

4. Others

810.60 to 101325hPa

Serial number

NP6012

NUB xxxxx, NUC xxxxx

NP6012F

NUE xxxxx

wwk ; Serial number

2&Q&@+

NP6012 NP6212

: ..r*onlr..

PTF xxxxx, UTG xxxxx, RTG xxxxx, PTH xxxxx

,. ,, TFA xxxxx

0.9 kW or less

about 20 W with scanning lamp heater ON

about 17 W with scanning lamp heater OFF

(approx.; about 5 min; reference only)

cwhi,

0.4 kWh (approx.; reference only)

N&e ti%&m&y ___

.capyh?g ,/

66 dB or less (sound power level under ISO)

OXme

0.01 ppm or less (average), 6.02 ppm or less (max.)

478 mm /I 8.8 in (approx.)

453 mm D7.8 in (approx.)

290 mm 01.4 in (approx.) ,,

20.0 kg /44.0lb (approx.; including cassette)

~ Copy paper Keep wrapped to protect against humidity.

T#r-@r. Avoid direct sunshine; keep at 4OC/85% or less.

l-4 MPYRIGHT 0 1895 CANON INC. CANON NPBOiZ /NP60i2E/NP6212 REV.1 SEPT. 1995 PRINTED IN JAPAN (IMPRIME AU JAPON)

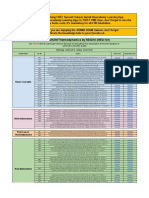

DIRECT

Table l-101

B. ADF

COPVAl Gt i l Q 1995 CANONI NC. CANON NP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PAl NTEDI NJ APAN( I MPRI M~AUJ APON) l - 5

III. NAMES OF PARTS

A. External View

1. NP6012

Static eliminator cleaner

@ Right door

Slide guide

@ Cassette

Multifeeder

@ Copyboard glass

Figure 1.,301

0 Copyboard cover

@I Scanning lamp heater

switch

Figure l-302

Copy density correction

dial

l-6

COPYRI GHT 0 1995 CANONI NC.

CANONNP60121NP6012FI NP6212 REV. 1 SEPT. 1995 PRl NTEOI NJ APAN( I MPRI Mi AUJ APON)

Static eliminator

Delivety guide plate

Figure l-303

@ Copy tray

@ Power cord connector

8 Open/close lever

GENERALDESCAI PTI ONI

2. NP6012F I NP6212

0 ADF

0 Slide guide

@ Multifeeder

@I Right door

0 Cassette

8 Copyboard glass

Figure l-304

Figure l-305

0 Scanning lamp heater

switch

0 Copy density correction

@ Delivery guide plate

@ Open/close lever

Y? dial

@ Copy tray

0 Static eliminator cleaner

II @I Static eliminator

@ Power cord connector

.,.-

Figure l-306

COPYRI GHT 0 1995 CANONI NC

CANONNP60121NP6012F/ NP6212 REV. 1 SEPl . 1995 PRl NTEDI NJ APAN( I MPAI M~AUJ APON)

l-7

B. Cross Section

1. Copier

0 No. 3 mirror

0 No. 2 mirror

@ No. 1 mirror

@ Scanning lamp

@ Heat exhaust fan

@ Drum unit

0 Lens array

@ Pre-exposure lamp

@ No. 1 charging roller

cleaning pad

@ Side blank exposure lamp

@ No. 6 mirror

Reflecting plate

No. 4 mirror

No. 5 mirror

Copyboard glass

Copyboard cover

Multifeeder tray

Cassette pick-up roller

Muttifeeder pick-up roller

Developing assembly

Registration roller

Developing cylinder

Transfer roller

Figure l-307

2.ADF

?

Static eliminator

Photosensitive drum

Feeding assembly

Primary charging roller

Cassette

Fixing film tension roller

Fixing film

Lower fixing roller

Fixing film drive roller

Delivery roller

Delivery tray

@ Delivery roller

@ Delivery tray

@ Pick-up roller

@ Original tray

l-8 COPYRI GKT @ 1995 CANONI NC. CANON NP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI Mi AUJ APDN)

Auxiliary tray

Guide plate

Separation pad

Registration roller

Figure l-308

@ Feeding belt drive roller

@ Feeding belt

QjJ Feeding belt roll

@ Feeding belt link roller

GENERALDESCRI PTI ONI

_~.

/ /\

IV. OPERATIONS

A. Control Panel

1. NP6012

Ad

I

0

@l 000

OB

Figure l-401a (Inch-configuration)

6

Figure l-401 b (ABllnch-configuration)

Figure 1-401~

COPYRI GHT 8 1995 CANONI NC.

CANONNP60121NP6012FI NP6212 REY. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI Mi . AUJ APON)

1-9

2. NP601ZNP6212

Figure 1-40ld (NP6012F)

Figure l-401e (NP6212)

Figure l-40if

,

l-10

COPWOHT 0 19%CANONI NC.

CANONNp~012/ Np6012F/ NP6212 REV. 1 SEPT. 1995 PAl NTEDI NJ APAN( I MPRI Mi AUJ APON)

I

GENERALDESCRI PTI ONI

w.

Nsme )

,+3%+gion fximatsar,,

1 Copy Density Adjust Use it to manually adjust the copy density.

Indicates the selected reoroductiw ratio.

remains on when the drum unit must be

replaced and remains on when the waste

toner must be disposed of.

If the model does not have the function,

flashes when the waste toner must be

13 Jam indicator

14 Paper Select key

Flashes when a jam occurs.

Selects the cassette as the source of paper

or Selects the multifeeder.

Selects a default reproduction ratio.

Prevents delayed first copy time in a cold

Table l-401

COPVRI GHI 0 1995 CANONI NC. CANONNPS012/ NPS012F/ NP62i 2 REV. 1 SEPT. 1995 PRlNTEOINJAPAN(IMPRIMi AUJAPON) l - 11

B. Basic Copying Operations

1) Turn on the power switch.

l The wait time is 0 sec.

l The auto power-off mechanism

becomes activated to automatically

turn off the power if no key is operated

in about 5 min.

2) If you are not using the ADF, lift the

copyboard cover, and place an original

face down along the size index.

a. Place the original so that its center

is aligned against the arrow (+);

then, bring down the copyboard

cover.

Figure l-402

i Load paper up to here

Figure l-403

l-12 COPYRI GHT 0 1995 CANONI NC. CANONNP60121NP6012F; / NP6212 REV. 1 SEPT. 1495 PRINTEOlNJAPANjIMPRIM~ AUJAPON)

, _\

\,

,

in

/-.

,Y-, i

3)

4)

5)

6)

7)

If you need to manually adjust the copy

density, deselect AE and use the Copy

Density Adjust lever.

As necessary, press the Default Ratio

key or Zoom key.

When you press the Zoom key, %

appears on the Copy Count/Ratio

indicator so that you may set the

ratio between 70% and 141% in 1%

increments.

% disappears if the Copy Count/

Ratio key is not operated in about 3

sec.

When you press the Default Ratio

key, the ratio changes as follows for

each press:

MAX. 141%+

(Inch- configuration)

BSbAS/STMT

1

(AB/lnch- configuration)

If you are using the multifeeder, press

the Paper Select key.

Check that the % notation on the Copy

Count/Ratio indicator has turned off;

then, set the number of copies to make

using the Copy Count/Zoom Set key.

(The count should appear on the Copy

Count indicator.)

Press the Copy Start key.

a. As may copies as you have speci-

fied will be made automatically.

b. No other keys than the Clear/Stop

key or Copy Density adjustment

lever/AE OFF will be accepted until

C.

d.

e.

the last copy has been made.

You may switch from automatic den-

sity adjustment mode to manual

density adjustment mode between

copying has started and the last

copy is made; however, you cannot

switch from manual density adjust-

ment mode to automatic density

adjustment.

When copying is finished, the Copy

Count indicator indicates the initial

copy count. If copying stopped as a

result of the absence of paper, a

press on the Copy Start key after

supplying paper will automatically

make the remaining number of

copies.

To stop copying operation during

continuous copying, press the

Clear/Stop key; the ongoing copy

run is finished before the operation

stops. (At this time, the Copy Count

indicator indicates the initial count.)

If paper jams, the JAM indicator will

flash and copying operation stops;

open the top unit. (The power turns

off when the top unit is opened for

removal of the jam.)

After copying operation is over, the

auto power-off mechanism becomes

activated if the copier is left alone for

about 5 min without further key

operation, automatically turning off

the power.

1. Using Transparencies

1) Shift the delivery guide plate on the copy

tray upright.

Figure l-404

COPYRI GHT Q 19%CANONI NC. CANON NP6012/ NPb0i 2F/ NP6212 REV. 1 SEPT. 1995 PRl NTEOI NJ APAN( I MPAI M~AUJ APON) l-13

2)

3)

4)

5)

6)

7)

6)

Place an original on the copyboard, and

close the copyboard cover.

If you want to manually adjust the copy

density, deselect AE, and operate the

Copy Density Adjust lever.

Press the Default Ratio key or Zoom

Mode key to suit the reproduction ratio

you want.

a. When you press the Zoom key, you

may set the ratio between 70% and

141% in 1% increments.

b. When you press the Default Ratio

key, the ratio changes as follows for

each press:

r MAX. 141%7

MARGIN 86%

LGL b LTR 78%

(Inch- configuration)

L

BSbAS/STMT

A4 b A5

I

(ANInch- configuration)

2)

3)

Place a single transparency on the sin-

glefeeder.

l You must not set more than one trans-

parency on the singlefeeder.

Select the multifeeder using the Paper

Select key.

Set the copy count you want using the

Copy Count/Zoom Set key; then, check

the Copy Count indicator.

Press the Copy Start key.

l Be sure to remove each transparency

delivered to the copy tray before the

next one is delivered.

Figure l-406

1-14 COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

If the Transparency Is Not Picked Up

Smootlily

l Under certain environmental conditions,

transparencies may fail to move into the

machine in response to a press on the

Copy Start key. If this is the case, go

through the following:

1) Place copy paper underneath the trans-

parency with a displacement of about 1

cm.8

Transparency

VCopypaper

Figure l-405

Set the transparency together with the

copy paper on the multifeeder while

holding the trailing edge of the copy

paper.

Press the Copy Start key while still hold-

ing the trailing edge of the copy paper;

hang on to the copy paper, and remove

it when the transparency has disap-

peared into the machine.

N I

/-.-

_-- \

/

_,--

C

2. Making Two-Sided Copies

0

You can make two-sided copies using

the multifeeder; however, you must keep the g

following in mind:

0 After the first copy run, turn over the @

copy paper and set it as shown in Figure

l-406

8

Figure l-407

Make sure the paper is not moist.

Make sure that the paper is not curled.

Make sure that the paper is of 64 to 126

g/m2 (business card, 200 g/m* or less).

In the case of a two-sided copy, each

side may not be used more than once.

After the first copy run, cool the paper

sufficiently and remove the curl before

feeding it for the second copy run.

COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PAl NTEDI NJ APAN( l MPRI M~AUJ APON) l-15

C. User Mode

1. Outline

The copier offers user mode which may be used by the user to change various settings.

-E

a

r

2

3

4

5

-

Ul Primary charging roller

cleaning mode

Executes cleaning of the

primary charging roller.

The cleaning lasts about

3 set, and stops

automatically.

u2 Copy count indication

mode

Indicates the number of Only in model with dr

copies made by the unit replacement time

installed drum unit. automatic indication

function.

Only in model with dr

unit replacement timf

automatic indication

u3 Drum unit replacement

indicator off mode

Turns off the flashing

Replace Drum Unit

indicator.

U6 ADF cleaning mode Clean the ADFs original

feeding path.

u7 Installation/drum unit

replacement mode

Used to enter data Only in model withou

necessary when installing drum unit replacemel

the machine or replacing time automatic indica

the drum unit. function.

Further, execute it after

executing 34 or 37 in

service mode.

urn

urn

)nly.

t

It

tion

Table l-402

l-16 CGPYRIGHT 0 1995 CANON INC.

-

CANON NP60121 NP6012F I NP6212 REV.1 SEPT. 1995 PRINTED IN JAPAN (IMPRIMS AU JAPON)

GENERALDESCAI PTI ONI

2. Using User Mode

1) Turn on the copier, and hold down the

AE key for 4 set or more.

l Ul appears on the count/ratio indica-

tor.

Figure l-408

2) Press the +/- key so that the appropriate

function number (Ul through U7)

appears.

3) To end user mode, press the AE key.

3.

1)

Primary Charging Roller Cleaning

Mode (Ul)

Operate so that Ul appears on the

count/ratio indicator; then, press the

Copy Start key.

l Ui starts to flash to indicate the exe-

cution of cleaning; cleaning takes

about 3 sec.

l Ul stops flashing and remains on

when cleaning is finished.

Figure l-409

2) To end user mode, press the AE key.

l The AE key remains disabled while

user mode is being executed.

COPYRI GHT 0 1995 CANONI NC. CANONNP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PAl Nl EOI NJ APAN( I MPRI Mi AUJ APON) l-17

4. Copy Count Indication Mode* (U2)

*Only for a model with the drum unit

replacement time automatic indication func-

tion

1) Operate so that U2 appears on the

count/ratio indicator; then, press the

Copy Start key.

Figure l-410

l The count/ratio indicator alternately

indicates the 1000s and the 100s; for

example, in the case of 12345, it indi-

cates 1 and 23 alternately.

2) To end user mode, press the Copy Start

key and then the AE key.

l The AE key remains disabled while a

copy count is being indicated.

7

5. Drum Unit Replacement Off Mode*

(U3)!

Only for a model with the drum unit

replacement time automatic indication func-

tion.

1) Operate so that U3 appears on the

count/ratio indicator; then, press the

Copy Start key.

l U3 remains; however, the Replace

Drum Unit indicator stops flashing and

goes out.

Figure 1-411

2) To end user mode, press the AE key.

l-18 COPYRIGHT 0 1995CANONINC. CANONNP60121NP6012Ff NP6212REV.1SEPT. 1995PRlNTEO,INJAPAN(IMPRIMi AUJAPON)

6.

1)

2)

ADF Cleaning Mode (NP6012/NP6212

only)

Place about 10 sheets of white copy

paper on the original tray of the ADF.

Operate so that U6 appears on the

count/ratio indicator; then, press the

Copy Start key.

l The sheets of copy paper on the origi-

nal tray of the ADF will be picked up in

Figurel-412

3) To end user mode, press the AE key.

7. Installation/Drum Unit Replacement

Mode (U7)

*Only for a model with the drum unit

replacement time automatic indication func-

tion.

1) Operate so that U7 appears on the

count/ratio indicator; then, press the

Copy Start key.

l The indication changes to 71.

2) Using the +I- key, enter the value of

PRIMARY recorded on the drum unit.

l Appears in the top left of the

count/ratio indicator while a value is

being entered.

Figure 1-414

3) After entering the value of PRIMRY,

press the Copy Start key to store the

value.

l A press on the Copy Start key

changes the indication to 72.

Figure l-415

Figure 1-413

COPYRI GHT 0 19%CANONI NC. CANON NP60121NW012F/ NP6212 REV. 1 SEPT. 1995 PRi NTEOt NJ APAN( I MPAI M~A' J J APON) l-19

4) Using the +I- key, enter the value under

IP_OFST recorded on the drum unit.

l Appears in the top left of the

count/ratio indicator while a value is

being entered.

I

Figure 1-416

5) After entering the value of IP_OFST,

press the Copy Start key to store the

value.

l A press on the Copy Start key

changes the indication to 73.

Figure 1-417

6) Press the Copy Start key to execute

drum sensitivity automatic adjustment

and toner stirring.

l The main motor will rotate, and drum

sensitivity automatic adjustment and

toner stirring will start.

l After the execution, the copier ends

user mode automatically and stops

operation in about 1 min.

l A press on the AE key while the above

execution is taking place ends user

mode; however, the AE key will not be

accepted while a setting is displayed

or the main motor is rotating.

I I

Figure 1-416

l-20 COPVRf f i I i l 0 1995 CANONI NC. CANON NP6012/ NP60i 2F/ NP6212 REV. 1 SEPT. 1995 PRl NTEOI NJ ~~( I MPRI MCAUJ ~ON)

,i_

-.

/

/-

D. Removing Jams E. Adding Paper

The Jam indicator flashes to indicate the

presence of a jam inside the machine.

The Add Paper indictor P turns on in

resoonse to the followina conditions:

g

0

1)

2)

3)

When the cassette hgs run out of paper.

When the cassette is in the cassette

holder.

a

1)

2)

3)

Remove the jam with care so as not to

tear it. Be sure to remove all pieces of

paper if it has torn.

Check the multifeeder for a jam. To

remove, pull the paper slowly out of the

multifeeder.

Open the right cover, and check if there

is copy paper. Remove the paper if

found.

Shift the open/close lever to open the

body.

Figure 1-419

4) Pull out any jam from inside the machine

with care.

When the Copy Start key is pressed

without paper on the multifeeder.

Check if paper is set in the cassette.

If the cassette is out of paper, set copy

paper.

If there is paper in the cassette, go

through the following:

0 Open the right door, and check if

there is a jam. Remove it if any.

@ Take out the stack of paper from the

cassette, put the sheets in order,

and set the stack back in.

@ Make sure that the cassette is prop-

erly set in the cassette holder.

Press the Copy Start key.

0 The P indication should go off, and

the copier will make the remaining

number of copies.

Figure l-420

COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~Al J J APONJ l-21

F. Replace Toner Cartrid

e

lndlcator (m) and Action 1

o

Take

The replace toner cartridge indicator (m)

starts to flash when toner runs out; perform

the following to replenish the cartridge:

1) Lift the body open/close lever to open

the body.

3) Hold the toner cartridge level. and shake

Y

it left and right several times.

>

Figure 1-421

2) Turn the toner cartridge clockwise until it

stops, and pull out the cartridge.

Figure l-423

4) Insert the toner cartridge carefully until it

stops.

Figure l-424

Figure l-422

l-22 COPYRI GHT 0 1995 CANONI NC. CANON NP60i 2/ NWOl ZF/ NP6212 REV. 1 SEPT. 1995 PAl NTEDI NJ APAN( l MPRI M~AUJ APON)

,,--.

,--

5) While holding the toner cartridge in

place, pull the OPEN seal straight to the

front to peel it.

Figure l-425

6) Turn the toner cartridge counterclock-

wise until it stops.

Figure l-426

7) Press on the 6 mark on the body to

close it firmly.

G. Using the Density

Correction Dial

If the copy density is too,high, i.e., the

image is too dark, in density adjustment

mode (AE or manual), you may adjust the

copy density using the Density Correction

dial.

1) Shift up the open/close lever to open the

body.

2) Adjust the position of the density correc-

tion dial.

Figure l-427

ACaution:

Do NOT throw the toner cartridge into fire;

it can burst or explode.

COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012F/ NP6212 AEY. 1 SEPT. 1995 PAl NTEOI NJ APAN( I MPRI M~AUJ APON) l-23

H. Using the Scanning Lamp

Heater Switch

If the site of installation is subject to low

temperature or the first time copy is subject

to a delay, make use of the scanning lamp

heater to prevent problems.

heater switch

Figure l-428

l-24 COPYRI GHT 0 199. 5 CANONI NC. CANON NP6012/ NP6012Ff NP6212 REV1 SEPT. 1995 PAl NTEDI NJ APAN( I YPRI Mi AUJ APON)

I. Cleaning

If the images tend to be soiled or copy

paper tends to jam frequently, advise the

user to clean the following parts:

I - I

.

1. If Images are Soiled

a. Copyboard Glass/Copyboard Cover

Wipe it with a moist cloth; then, dry wipe

it. If the dirt cannot be removed, wipe it with

a cloth moistened with mild detergent solu-

tion, and dry wipe it.

b.

1)

2)

3)

Cassette Pick-Up Roller

Remove the cassette.

Open the right cover.

Keep the separation pad down, wipe the

cassette pick-up roller with a cloth moist-

ened with alcohol or water* while rotat-

ing the roller in the direction of pick-up.

*Be sure to wring it well.

Cassette pick-up roller

,--_

Separation

pad

Figure l-429

C.

1)

2)

3)8

Multi Pick-Up Roller

Lift the open/close lever to open the

body.

Place one sheet of copy paper (A4) in

the feeding path.

Keep the separation pad down, and

wipe the multi pick-up roller with a cloth

moistened with alcohol or water* while

rotating the multi pick-up roller in the

direction of pick-up.

*Be sure to wring it well.

Separation pad

\

Multi pick-up roller

/

Copypaper

Figure l-430

d.

1)

e.

1)

2)

Feeding Belt (NP6012F/NP6212 only) I

Wipe the feeding belt while moving It rn

the direction of the arrow with a cloth

moistened with water; be sure to wring

the cloth well.

Figure 1-431

Separation Pad(NP6012F/NP6212 only)

Remove the ADF from the copier. (See

IX. of CHAPTER 4 for the steps to fol-

low.)

Detach the separation pad cover using a

coin or the like.

\

Separation pad

Figure l-432

COPYRI GHT 0 1995 CANONI NC.

CANONNP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI MtAUJ APON)

l-25

3) Remove the separation pad unit.

Figure l-433

Dry-wipe the surface of the separation

pad.

Surf ace of the

Figure l-434

Install the separation pad unit while ori-

enting it as indicated.

Figure l-435

l-26 COPYRI GHT 0 1995 CANONI NC CANONNP6012l NP6012FI NP6212 AEV. l SEPT. 1995 PRl NTEOI NJ APAN( I MPRI M~AUJ APON)

f. Pick-Up Roller

You must clean the pick-up roller when-

ever vou have reolaced the seoaration Dad.

1)

2)

demove the separation pad unit.

Wipe the pick-up roller while moving it in

pick-up direction with a cloth moistened

with alcohol or water; be sure to wring

the cloth well before bringing it into con-

tact with the roller.

Pi ck- up

rol l er

Figure l-436

2. Frequent Jams

a. Static Eliminator

1) Open the copyboard cover, and remove

the static eliminator cleaner.

1

Figure l-437(NP6012)

2)

3)

Shift up the open/close lever to open the

body.

Clean the static eliminator with the static

eliminator cleaner.

0 Brush out any dirt (paper lint, for

example) from the groove in the

static eliminator.

Figure l-439

4) Close the body as soon as you have fin-

ished cleaning.

Figure l-438(NP6012F/NP6212)

COPYRI GHT 0 1995 CANONI NC.

CANON NP60121NP6012F/ NP6212 REV. 1 SEPT. 1995 PRlNTEDINJAPAN(IMPRIM~ AUI I APON)

l-27

I GENERALDESCRI PTI ON

J. Points to Note When

Closing the Top Unit

Make sure of the following three points

before closing the top unit.

1. The drum unit has been installed, and

the drum unit lever is at the LOCK posi-

tion.

Drum unit lever

Figure l-440

2. The toner cartridge has been turned and

positioned as specified.

3. The fixing lever is at the LOCK position.

/Fixing lever

Figure l-442

Unless the above three points are satis-

fied, the lock mechanism will activate, pre-

ventingthe top unit from closing.

Figure 1-441

l-28 COPYRI GHT 8 1995 CANONI NC

CANONNP6012/ NP6012f / NP6212 REV. 1 SEPT. 1995 PRl NTEOI NJ APAN( I MPRI Mi AUJ APON)

, 1\

I. IMAGE FORMATION

A. Outline

The copier uses a direct charging/transfer system with each component block arranged as

shown in Figure 2-101.

,,-.

Copyboard glass

W Transfer charging roller

Static eliminator

Lower fixing roller

Figure 2-101

Latent static Image Formation

I-----

_~_________--------~-_

4. Development

- : Flow of copy paper

Casselteimanual feed

t-_ : Rotation of photosensitive drum

Figure 2-102

COPYRIGHT Q 1995 CANON INC. CANONNP6012/ NP60i 2FI NP6212 REV. 1 SEPT. 1995 PRl Nl EDI NJ APAN( I MPRl MbAUJ APON) 2-1

The copiers image formation block con-

sists of the following steps; see the descrip-

tions for each step given under its respective

heading:

Step 1: pre-exposure

Step 2: primary charging (-)

Step 3: image exposure

Step 4: development (AC + DC bias)

Step 5: transfer (-)

Step 6: separation (+)

Step 7: fixing

Step 8: drum cleaning

The photosensitive drum consists of two

layers: the outer layer being a photoconduc-

tive layer made of organic photoconductor

(OPC) and inner layer, a substrate made of

aluminum (conductor).

onducting

ate

Figure 2-103

B. Static Latent Image

Formation Block

The static latent image formation block

consists #of tow steps: primary charging and

image exposure. At the end of, this block, the

areas on the photosensitive drum corre-

sponding to the black areas of the original

are left with negative charges and those cor-

responding to the white areas of the original

are rid of negative charges.

These images created by negative

charges are not visible to the human eye

and, therefore, are called static latent

images.

Time (t) -----)

~ 0

1

z

3

-500

E

d

x

8

1

E

cz

- 1000

Light area

,,...._......~...

,

Primary

1

charging

(step 1)

Dark area

Image exposure

(step 2)

Figure 2-104

2-2 COPYRI GHT 0 19%CANONI NC. CANON NP6012l NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

,- ~\, C. Pre-Exposure (step 1)

43

Pre-exposure

Figure 2-105

Prior to primary charging, the light of the

pre-exposure lamp is directed to the surface

of the photosensitive drum for pre-exposure,

thereby removing the residual charges from

the surface of the photoseneitive drum to

prevent uneven copy density.

A

D. Primary Charging (step 2)

imary corona roller

Figure 2-106

The surface of the photosensitive drum

is charged to a uniform negative potential in

preparation for the formation of static latent

images.

The copier uses its primary charging

roller to directly charge the photosensitive

drum (primary charging).

The primary charging roller is made of

conducting rubber, and a DC bias is applied

to the roller.

Reference:

A direct charging system provides such

advantages as low application voltage

and aenerates little. if anv. ozone.

COPYRI GHT 0 1995 CANONI NC. CANON NP6Ql 2/ NP6Ql ZF/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON) 2-3

E. Image Exposure (step 3)

F. Development (step 4)

Optical image

Figure 2-107

In this step, the optical image of the orig-

inal is projected to the photosensitive drum

to neutralize the charges in the light area.

, Blade

1

kf

Figure 2-108

As shown in Figure 2-108, the develop-

ing assembly consists of a rubber blade and

a developing cylinder constructed of a fixed

magnet and a cylinder that rotates around it.

The coprers toner is a one-component toner

made mostly of magnetite and resins. The

toner has insulating characteristics and

becomes positively charged by the friction

between the rotating cylinder and the blade.

The toner is moved between the rotating

developing cylinder and a blade, where it is

charged to a positive potential and deposited

on the developing cylinder in a thin, uniform

layer.

The developing cylinder receives both

AC bias and DC bias (negative component)

at the same time; the resulting bias is called

developing bias. For this reason, the nega-

tive component of the developing bias is

greater than the positive component.

Figure 2-l 09

2-4 COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NPC012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

,.--.,

During copying, the toner is attracted to

, \

the photosensitive drum by the photosensi-

tive drum surface potential and the develop-

ment bias (positive component), thus turning

the static latent image into a visible image.

Any excess toner is repelled by the photo-

sensitive drum by the photosensitive drum

surface potential and the developing bias

(negative component).

A DC bias affects copy density and the

degree of fogging; the higher, i.e., closer to 0

V, it is, the darker the images will be-how-

ever, with an increased tendency toward fog-

ging.

G. Transfer (step 5)

er

sfer charging roller

Figure 2-110

A negative voltage is applied to the back

of copy paper to transfer toner from the sur-

face of the transfer drum to the copy paper.

The copier uses a roller transfer system,

which has the following advantages when

compared with the conventional corona

transfer system:

l Generates virtually no ozone.

l Provides good feeding, since copy

paper is retained by both the transfer

charging roller and the photosensitive

drum.

Reference:

Toner may collect on the transfer roller if

the image on the photosensitive drum

fails to transfer to the copy paper

because of a jam or the like.

The copier turns the transfer voltage to

positive during initial rotation, while the

scanner is moving in reverse, and during

post rotation to return the positively

charged toner adhering to the transfer

roller to the photosensitive drum.

Figure 2-111

COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012Fi NP6212 REV. 1 SEPT. 1995 PRl NTEOI NJ APAN( I MPRI Mi AUJ APON) 2-5

H. Separation (step 6)

\

Static eliminator

Pressure roller dleaning roller

Figure 2-112 Figure 2-113

Copy paper is separated from the photo-

sensitive drum using the rigidity of the paper.

Thin paper, however, has low rigidity and

can wrap around the photosensitive drum.

To prevent such a problem, the copier

applies a positive voltage to the separation

static eliminator to weaken the static attrac-

tion between the photosensitive drum and

copy paper, thereby facilitating separation.

After transfer, the toner image is fixed to

the paper while the copy paper moves

through the fixing film and the pressure

roller.

The fixing film has a seamless construc-

tion and is made of special material so that

melting toner will not stick to the film-fur-

ther, the surface of the pressure roller is

cleaned by a cleaning roller.

I. Fixing (step 7)

Theryistor

The fixing heater is a flat heater and

heats only the area where the fixing film

comes into contact; this design eliminates

the need for warm-up time.

The temperature of the fixing heater is

monitored by the thermistor (THl) located

more or less at the center of the fixing heater

and serves to make sure that the heater is

controlled to a specific temperature.

_

-

2-6 COPYRI GHT 0 1995 CANONI NC CANON NP6012l NP6012FI NP6212 AEV! l SEPT. 1995 PAl NTEDI NJ APAN( I MPRI M~AUYPON)

,< -X\

J. Drum Cleaning (step 8)

Cleanina blade

Scoop-;p sheet

Figure 2-114

In preparation for the next copy run, the

cleaning blade scrapes off the residual toner

from the photosensitive drum by way of

cleaning the photosensitive drum surface.

The scoop-up sheet then is used to collect

such toner.

i \

COPYRIGHT 0 1995CANONINC. CANONNP5412lNP6012FINP6212 REV.1SEPI 1995PRINTEDINJAPAN(IMPRIMt AUJAPON) 2-7

II. AUXILIARY PROCESS

1. Side Blank Exposure

Side blank exposure is used to prevent

adhesion of excess toner to the drum by

removing the residual potential in the non-

image areas (front, rear) of the drum. See p.

3-35 for details.

2. Nip Exposure

In nip exposure, part of the light from the

pre-exposure lamp is directed to the area

where the photosensitive drum is in contact

with the primary charging roller, thereby

ensuring the stability of primary charging.

Preexposure

lamp

Primary charging roller

_ : path of light (nip exposure)

------ : path of light (pre-exposure)

Figure 2-115

2-8 COPYRl Gtl T8 19%CANONI NC. CANONNP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PAl NTEDI NJ APAN( I MPRI Mi AUJ APON)

.A--_,

\

I. BASIC OPERATION

A. Functional Construction

The copier c&n roughly be divided into four functional blocks: namely, pick-up/feeding,

exposure, image formation, and control.

I I

Control panel

f

Control

circuitry

,...........................................,

~ Exposure block

Optical path

_...................

Figure 3-101

,,--

COPYRI GHT 0 1995 CANONI NC. CANONNP6012l NP6012FI NPS212 REV. 1 SEPT. 1995 PAl NTEOI NJ APAN( I MPRI Mi AUJ APON) 3- 1

B. Electrical Circuitry

The copiers major electrical control mechanisms are driven by the microprocessor on the

DC controller PCB. The microprocessor reads input signals from the sensors and the operation

keys in response to the instructions of the program stored in advance and generates signals

used to drive such loads as motors, solenoids, and lamps. ~

DC controller PCB

Composite power

supply PCB

Scanner home position

detection

Lens home position detection

Preregistration roller paper

detection

Delivery paper detection

Film displacement detection

Waste toner detection

Cassette detection

(model with drum unit

replacement time automatic

indicator function only)

I QIOI I

I CPU 1+5

+24V

t

i

j

1

Primary charging

roller

Developing cylinder

. Transfer charging

I.

roller

f Static eliminator

Pick-up solenoid

Registration clutch solenoid

jyi solenoid

Scanner/lens drive switching

Cassette/multifeeder pick-up

switching solenoid (PC750/770)

Primary charging roller cleaning

solenoid

. Transfer roller escape solenoid

\

I

Side blank exposure lamp

t

Scanner/lens drive motor

Pre-exposure lamp

-I

Counter

Figure 3-l 02

3-2 COPYRIGHT 0 1995 CANON INC. CANON NP6012/NP9012F/NP6212 REV.1 SEPT.1995 PAINTEDIN JAPAN (IMPRIME AUJAPON)

,,- .

I

i

C. Inputs to and Outputs from the DC Controller

1. Inputs to the DC Controller (l/2)

DC controller PCB

Scanner home position

sensor

Lens home position

sensor

Mjlogl:j

Delivery sensor

MT

Fixing film

displacement sensor

Waste toner sensor ME

Pre;registration

roller paper sensor

Cassette paper

sensor

Main thermistor

(thermal control)

Sub thermistor

(overheating)

+

-I

A +5v

SCHP

7,

j +5v

LHP

2

DIG3

DPD

:

+5v

FFD

-;I,

3 +5v

when scanner is at home position, 0.

(when light-blocking plate is at PSI, 0)

when lens is at home position, 1.

(when light-blocking plate is at PSZ, 1)

when PS3 detects paper, 1:

(when light-blocking plate is at PS3, 0)

when PS4 detects fixing film, 0.

(when light-blocking plate is at PS4, 0)

TNFULL when toner reaches specific level, 1.

2

(when light-blocking plate is at PS5, 0)

2 +5v

RPD when Q751 detects paper, 1.

(when light-blocking plate is at Q751, 0)

DIG2

CPD

2

THI

X

TH2

-;I,

when paper is present in cassette, 0.

(when light-blocking plate is at Q752, 0)

when surface temperature of fixing heater

rises, voltage lowers.

when temperature of the rear end of fixing

heater rises, voltage lowers.

Figure 3-103

COPYRIGHT 0 1995 CANON INC. CANON NP6012/NP6OlZF/NP6212 REV.1 SEPT. 1995 PRINTED IN JAPAN (IMPRIMg AU JAPON) 3-3

IOPERATIONS AND TIMING

2. Inputs to the DC Controller (2/2)

/*y

DC controller PCB

/

AE sensor Intensity

PCB sensor

PCB

Control

panel

Jii

r\

I/

I

1 J301

I I

00 SW409

,-

Main switch

J I OZ- :

p

Drum cartridge :

I:

PGP

PCB

(model with drum unit

replacement automatic

indicator function only)

Toner level Composite

detection power supply

PCB PCB

3-4 COPYAI GHT 0 1995 CANONI NC.

>

Q4V

_t

4EREF

4E

=LEXP

ns

3lG1

iEAT

IGI

z$tT

iEAT

rNMONl

when reflected light increases, voltage lowers.

when light from fluorescent lamp increases,

voltage lowers.

Keys and LEDs are wired in a matrix on the control

panel PCB; the DC controller reads the key inputs

and turns on or flashes the LEDs.

Combinations of 3-bit signals are used to correct

the variations in the resistance of the fixing heater

in 7 settings.

-

when toner level drops, 0.

Figure 3-l 04

CANONNP6012/ NP6Ol ZF/ NP6212 REV. 1 SEPb1995 PAl NTEDI Nl l . 4PAN( I MPAI Mi AUJ APON)

D. Outputs from the DC Controller

1. Outputs from the DC Controller(V2)

Composite power supply PCB DC controller PCB

Main motor/ m J901-! J205-$!+24V

Scanning lamp

J206-1 1 ,

I

,---\

\

Fixing heater Hi

m J207-1

-2

AC

driver

J204-7 J104-.

Fluo-

rescent _~ Micro.

lamp

txocessor

Primary charging roller

Developing cylinder

Transfer charging roller

Static eliminator

driver 1 11

I

High-

voltage

circuit

1-i +!a t24V

Door switch

Figure 3-105

dt

ITRD

1MD

tLOC~ See p. 3-7.

r

Fixing heater drive

signal; used to control

the temperature of the

fixing heater.

1

Micro-

processor

I

Communication with

composite power supply

PC0

COPYAl GHl 0 1995 CANONINC. CANONNP6012 I NP6012FINP6212 REV.1SEPT. 19%PRIWEO INJAPAN(lMPMM6 AU JAPON) 3;5

2. Outputs from the DC Controller (2/2) . \

DC controller PCB

Pick-up clutch solenoid

when o, pick-up clutch

solenoid turns on.

Registration clutch solenoid

when I, registration clutch

solenoid turns on.

Lens drive solenoid

when 9, lens drive solenoid

turns on.

Cassette/Multifeeder pick-up

switching solenoid

Scanner/lens drive motor

Jl IO-I f SC-COMB

-2 SC-B*

-3 SC-B

during operation,

-4

alternates between

+ SC-COMA soa and ml\,

(See p. 3-16 for details.)

Side blank exposure lamp (rear)

KII=F61 sB-Lp*

Side blank exposure lamp (front)

Primary charging roller

cleaning solenoid

Transfer charging roller

escape solenoid

J121-1 PEXP*

Pre-exposure lamp PCB

-2 +24V

J119-1 TCNTD*

Total copy counter

MCI

-2 +24V

~..............

when O, primary charging

roller cleaning solenoid turns

on.

when 0, transfer charging

roller escape solenoid turns

on.

when 0, pre-exposure lamp

turns on.

when O, total counter turns on

~..............i

Drum unit

(model with drum unit replacement

time automatic indication function only)

*Negative logic.

Figure 3-106

when O, blank exposure

lamp on.

3-6 COPYRIGHT 0 1995 CANON INC. CANON NP60121NP6012FINP6212 AEV.1 SEPT. 1995 PRINTED IN JAPAN(IMPRIM~AU JAPON)

,r.- >

E. Main Motor Control Circuit

I

1. Outline

~

~

1

Figure 3-107 shows the circuit that con-

trols the main motor (Ml); the circuit has the

following functions:

0 turns on and off the main motor.

@ controls the rotation of the main motor to

a specific revolution.

The main motor (Ml) is a DC motor with

a built-in clock pulse generator. When the

motor rotates, clock pulse signals (MMCLK)

are generated according to the revolution of

the motor. The speed control circuit matches

the phases of the frequency of these clock

pulses and the frequency of the reference

signal to control the rotation of the main

I motor (Ml) to a specific revolution.

2. ODeration

When the main motor drive signal

(MMD) from the DC controller circuit goes

l, the drive circuit of the motor driver turns

on, thereby rotating the main motor (Ml) at a

specific revolution.

While the main motor is rotating at a

specific revolution, the main motor driver

PCB sends the speed state signal

(MLOCK=O) to the DC controller PCB. If, for

some reason, fluctuations occur in the rota-

tion of the main motor, the MLOCK signal

goes I.

If MLOCK=l continues about 1 set

while the main motor drive signal (MMD) is

l, the DC controller identifies an error in the

main motor, stops the main motor and, at the

same time, indicates EOIO on the display.

,,- -.\I

\

DC

1lrOllE

J 20

103- 6 - 7

104

- 6 J 204-

r

ic

I

I

31

+

(

$

I

I

I

I

I

,_

:omposite

power

SUPPlY

1

iJ:

+

I

1

I

7

I

i

I

I

I

I

I

I

j

! 05 J 90'

, - 6 24V - '

- 2 ov - :

- 2 MMD - !

- 1 MLOCK - t

1

PLL control

drive circuit

I

57

int

Clock pulse

MMCLK

I

Reference signal

Main motor driver PCE

Figure 3-107

COPYRIGNT 6 1895 CANONI NC.

CANONNP6012~NP6012FINP6212 REY.1SEPT. 1895PRINTEDINJAPAN(IMP& AUJAPONJ 3-7

F. Basic Sequence of Operations (DIRECT, 2 copies, continuous) -.

1. Copy Start Key On 3.2 Set (approx.) After Power-On

,.

Power switch Copy Start key

ON ON

L?ZZEl: reverse

I : scanner home position detection

II : lens home position detection

Figure 3-108

,-

I

3-8 COPYRIGHT 0 19%CANONINC. CANONNP.50121NP6012FI NP6212REV.1SEPT. 1995PRINTEDINJAPAN(IMPRIMAUJAPON)

2. Copy Start Key On Immediately After Power-On (less than 3.2 set)

@Z: reverse

I : scanner home posi ti on detecti on

I I : l ens home posi ti on detecti on

Figure 3-109

I--

/---Y

COPYRI GHT 0 1995 CANONI NC. CANONNPMl 2/ NPS012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ A~ON) 3-9

iTBY

standby)

\lTR

nitial rotation)

CFW

scanner forward)

SCRV

(scanner reverse)

FWM

Between when the power

switch is turned on and

when the Copy Start key is

pressed.

Between when LSTR is

over and when the Copy

Start key is pressed.

or about 3.5 set after the

:opy Start key is pressed.

while the scanner is moving

orward.

The distance traveled

forward varies depending

on the copy paper size ant

reproduction ratio.

The speed of forward

travel varies depending on

the reproduction ratio.

rVhile the scanner is moving

n reverse.

The speed of reverse

travel is about 3.4 times as

fast as forward travel in

DIRECT.

-or about 1 set after SCRV

or the last copy is over.

Waits until the Copy Start key

becomes valid.

. Removes the residual

charges from the photo-

sensitive drum and stabilizes

the sensitivity of the photo-

sensitive drum in preparatior

for cpying operation.

l Pre-heats the scanning lamp

and makes preparations unti

the drive intensity becomes

stabilized.

The scanning lamp illuminates

the original, and the reflected

optical image is projected on

the photosensitive drum by

way of mirrors and lenses.

The scanner is returned to the

home position in preparation

for the next copy run.

The last copy paper is

discharged.

Table 3-101

1

E

E

F

I

,

I

I 1

1:

c

t

i

! I

t

g

F

Remarks /

-he pick-up signal is

lenerated, and the firs

sheet of copy paper is

xcked up.

-he registration signal

s generated, and the

:opy paper is moved

o the transfer

assembly.

f in continuous mode,

he pick-up signal is

generated, and copy

japer is picked up.

3- 10 COPYRIGHT 0 1995 CANON INC.

CANON NP6012/NP6012F/NP6212 REV.1 SEPT. 1995 PRINTEDIN JAPAN (IMPRIME AU JAPON)

., --

II. EXPOSURE SYSTEM

A. Varying the Reproduction

Ratio

The reproduction ratio in the direction of

the drum axis is varied by the lens drive sys-

tem and that around the drum, by the scan-

ner drive system.

The lens drive system holds a lens array

and changes the location of the lens and the

optical path length as shown in Figure 3-201

to vary the reproduction ratio in the direction

of the drum axis; the length of the optical

path is changed by moving the No. 4 and

No. 5 mirror units as shown in Figure 3-202.

The scanner drive system changes the

reproduction ratio around the drum by mov-

ing the No. 1 mirror faster (reduction) or

slower (enlargement) relative to the periph-

eral speed of the drum.

Reference:

1. In DIRECT, the speed at which the

No. 1 mirror is moved is the same as

the peripheral speed of the drum.

2. The length of the optical path is longer

in both REDUCE and ENLARGE than

in DIRECT.

p&h I*

length

Optical

path I4

length

Optical

path I*

length

Optical path: Li< L2, Li< L3

Figure 3-201

COPYRI GHT 0 1995 CANONI NC. CANON NP6012l NP6012Fi NP6212 AEV. 1 SEPT. 1995 PAl NTEDI NJ APAN( I MPAI M~AUJ APON) 3-11

Copyboard glass /-~ .,

N N N

ENLARGE REDUCE ~

Movement in

-0

ENLARGE. REDUCE

1

L

No. 45 mirror unit

Figure 3-202

/-

3-12 COPYRI GHT 0 1995 CANONI NC. CANONNPS012/ NP6012F/ NP62i 2 REV. 1 SEPT. 1995 PAl NTEOI NJ APAN( I MPRI M~AUJ APON)

1

,

/- -

8. Lens Drive System

1. Outline

The lens drive system is driven by the scanner motor (M2). When the lens solenoid (SL3)

turns on, the switching gear is pushed in the direction of the arrow 0. When the scanner motor

rotates in reverse (3) in this condition, the lens unit moves in REDUCE direction by the work

of gears and lens cable.

At the same time, the No. 4/5 mirror unit moves according to the travel (reproduction ratio)

of the lens unit, changing the length of the optical path.

At this time, the side blank exposure lamp also moves in relation to the lens to perform

black erasure at the front and the rear.

0.4/5 mirror unit

Lens travel detecting shaft for

side blank exposure lamp

DC controller PCB

Figure 3-203

COPYRIGHT 8 1995CANONINC. CANONNP6012I NP6012F/NP6212 REV.1SEPT. 19%PRINTEDINJAPAN(IMPRIMt AUJAPON)

3-13

C. Scanner Drive System

1. Outline

The scanner drive system is driven by the scanner motor (M2), which changes its direction

of rotation so that the scanner moves forward or in reverse. The revolution at which the scanner

is moved forward changes continuously according to the selected reproduction ratio, and the

revolution at which the scanner is moved in reverse remains constant regardless of the select-

ed reproduction ratio (about 3.4 times as fast as in forward in DIRECT).

The distance over which the scanner travels varies according to the length

of copy paper

and the selected reproduction ratio.

The scanner motor drives the lens drive system in addition to the scanner system.

Scanner home

position sensor (PSI)

Figure 3-204

Mot or dr i ver ci r cui t

DC cont r ol l er PC6

3-14 COPYRI GHT 0 19%CANONI NC.

CANON NP60121NP6012FI NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

2. Relationship between the Scanner Sensor and Signals

I II 1 Ref erence used to determine the f orward

Scannerhome

It I

travel distance.

posi ti on sensor SCHP

I I

PSI) II I

The scanner stops traveling i n reverse i n

1 L I O. 1 sec.

Table 3- 201

3. Basic Sequence of Scanner Operations

Power switch Copy Start key

ON ON

@Vj : reverse

0 : detects scanner home position

(3 : detects lens home posi ti on

Figure 3-205

The microprocessor on the DC controller PCB controls the forward travel distance of the

scanner with reference to the rising edge of the scanner home position signal. The forward trav-

el distance varies depending on the length of copy paper* and the selected reproduction ratio in

ENLARGE: if the ratio is less than 130%, the scanner is moved forward for A4 (297 mm); if the

ratio is 130% or more, the scanner is moved for LTR (279 mm).

*For a discussion of how the length of copy paper is checked, see p. 3-49.

_-

COPYRI GHT 0 1995 CANONI NC. , CANON NP6012/ NP60i 2FI NP6212 I 7EV. i SEPT. 1995 PRl NTEDI NJ APAN( I MPAI M~AUJ APON) 3-15

4. Driving the Scanner/Lens Drive Motor

a. Outline

The scanner/lens drive motor (M2) is a

4-phase stepping motor. It is turned on or off

and its direction and speed of rotation is

changed by controlling the output timing of

the drive power supply SC-COMA and SC-

COMB and pulse signals A, A*, 8, and B*.

b. Operation

The microprocessor (QlOl) on the DC

controller PCB receives such instructions as

_- ._

The scanner/lens drive motor is a 4-

phase stepping motor, and controls the

direction and speed of scanning by changing

the frequency and the sequence of drive

pulses (SC-A through SC-B*).

The: motor drive voltage on/off switching

circuit supplies power to drive the motor and

removes power to stop it. The current

switching circuit sets the current flowing to

the motor according to the speed of rotation;

the motor driver circuit is used to control the

copying modes and reproduction ratios from rated current according to the setting.

the control panel circuit; and, in response, it

sends drive pulses to the scanner motor

(M2) through the motor drive circuit.

DC controller PCB

!

!

!

!

I*

!

L

i.

i

1

I

!

!

,

I

i _

+

/

i -

*

!

I

I

i _

+

I

i -

i

!

!

!

!

!

,

!

!

!

!

I

Figure 3-206

1110

4

1

3-16 COPYRIGHT 8 1995 CANON INC. CANON NP60121 NPH2FI NP6212 REV.1 SEPT. 15% PRINTED IN JAPAN (IMPAIMC AU JAPON)

OPERATIONS AND TIMING-

III. IMAGE FORMATION SYSTEM

A. Outline

The copiers image formation system performs the following functions:

l controls the pre-exposure lamp.

l controls the scanning lamp.

l controls the primary/transfer corona current.

l controls the developing bias.

l measures the density of the original.

l controls side blank exposure.

Copyboard glass

I

;P%

( Scanning lamp

I

1, I\ I

, Light adjustment sensor

Developing

cylinder

3

Preexposure lamp *

Primary charging roller

Static

Transfer

eliminator

roller

Fluorescent

lamp driver

I

I Q501 I

High-voltage

circuit

DC controller PCB / ,

I

Microprocessor

Composite power supply PCB

Figure 3-301

COPYRIGHT 0 1995 CANON INC! CANON NP9012lNP6012F/ NP6212 REV.1 SEPT. 1995 PAINTED IN JAPAN (IMPRIME AU JAPON) 3-17

B. Sequence of Operations (image form&ion system)

DIRECT, 2 Copies, Continuous

Power switch

ON

Copy Start key

ON

@ZZ : reverse

Figure 3-302

DIRECT, 2 Copies, Continuous; Copy Start key pressed immediately after power-on

,-.

BZ2 : reverse

Figure 3-303

3-18 COPYRIGHT 0 1995CANONINC.

CANON NP6012/NP6012F/NP6212 REV.1SEPT. 1995PRINTEDIN JAPAN(IMPRIMi AUJAPON)

OPERATIONS AND TIMING-

\

\

C. Controlling the Pre-

Exposure Lamp

1. Outline

The intensity of the pre-exposure lamp

must remain constant at all times during

APVC measurement and to ensure stable

image reproduction (primary charging). To

ensure stable intensity, the copier corrects

variations among individual pre-exposure

lamps and fluctuations in the drive voltage.

2. Operation

The PWM reference value used to deter-

mine, the intensity of the pre-exposure lamp

is stored in the CPU on the DC controller

PCB.

The CPU on the DC controller PCB

detects the voltage used to drive the pre-

exposure lamp and corrects the PWM refer-

ence value so that the pre-exposure lamp

may be driven at a specific intensity.

Reference:

You must enter the PWM reference value

(PREX_LP) in service mode whenever

you have replaced the pre-exposure

lamp.

+

t

COPVRIGHl 0 1995CANONINC.

4GiziFfG~

Pre-exposure lamp (LAZ)

J

DC controller PCB

Figure 3-304

CANON NP6012/NP6Oi2FINP6212 REV.1 SEPT. 1995PRINTEDINJAPAN(IMPRIMi AUJAPON)

3-19

D. Controlling the Scanning

Lamp

1. Outline

Figure 3-305 shows the circuit that con-

trols the scanning lamp (fluorescent lamp:

FLl); the circuit has the following functions:

l controls pre-heating of the scanning

lamp.

l turns on and off the scanning lamp.

l controls the intensity of the scanning

lamp.

l automatically corrects the intensity of

the scanning lamp.

The copiers scanning lamp is a fluores-

cent lamp.

_,--

When not controlled. the fluorescent

lamp tends to be dark immediately after it is

turned on, glowing brighter only gradually;

moreover, its intensity does not stabilize for

some time if its ambient temperature is low.

In consideration of these, characteristics

of the fluorescent lamp, the copier is

equipped with an intensity sensor so that the

originals may be illuminated only after the

intensity of the fluorescent lamp has stabi-

lized.

The copier does not start copying opera-

tion until the intensity of the fluorescent lamp

has been checked and verified that it has

reached a specific value.

Scanning lamp

Intensity sensor PC

P

/ /

Main

transformer

( Ti Ol )

Fluorescent

lamp driver

Intensity signal1

FLPRHT

DC controller PCS 1 1 Composite power supply PCB

Figure 3-305

3 - 20 COPYRI GHT 0 1995 CANONi l K CANONNP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1935 PRl NTEDI NJ AP~( I MPRI MCAUJ APON)

2. Controlling the Scanning Lamp for

Pre-Heating

Preheating is controlled for the follow-

ing:

l before the scanning lamp turns on.

l while the scanning lamp remains on.

a. Controlling Pre-Heating before the

Scanning Lamp Turns On

When the Copy Start key is pressed, the

microprocessor (QlOl) on the DC controller

PCB sends the pre-heating voltage control

signal (FLPRHT) to the pre-heating voltage

control circuit on the composite power sup-

ply PCB. In response, the pre-heating volt-

age control circuit supplies 4 Vrms (effective

value) to the filament of the scanning lamp.

About 3 set later, the microprocessor on

the DC controller causes the pre-heating

voltage control signal (FLPRHT) to go O, to

end the pre-heating operation executed

before the scanning lamp turns on.

b. Controlling Pre-Heating While the

-\

Scanning Lamp Remains On

While the scanning lamp remains on, the

microprocessor (Q501) on the composite

power supply PCB sends the duty ratio of

the on control signal to the microprocessor

(QlOl) on the DC controller PCB. In

response, the microprocessor (QlOl) on the

DC controller sends the pre-heating control

signal (FLPRHT) to the pre-heating voltage

control circuit to execute pre-heating control

suited to the duty ratio of the on control sig-

nal for pre-heating control.

Reference:

Activation of the Fluorescent Lamp

The fluorescent lamp repeats turning on

and off in specific cycles. While it is off,

voltage is applied to its filament so that it

will turn on smoothly, and the period dur-

ing which such a voltage is being applied

is called pre-heating period.

. .

3 Off (pre-heating)

Figure 3-306

The intensity of the fluorescent lamp

changes within a single cycle depending on

how long the lamp remains on:

l longer on time I) higher intensity

l shorter on time w lower intensity

The ratio of on time within a single cycle

is called duty ratio, and may be expressed

by the following formula:

ON time

Duty ratio= ~

1 cycle

l higher duty ratio w increased intensity

l lower duty ratio I) decreased intensity

COPYRI GHT 0 1995 CANONI NC. CANON NP60i 2/ NP6012FI NP6212 REV1 SEPT. 1995 PRl NTEOI NJ APAN( I MPRI M~AUJ APON) 3-21

3. Turning On and Off the Scanning

Lamp

a. Outline

When pre-activation pre-heating is over,

the microprocessor (QlOl) on the DC con-

troller PCB instructs the microprocessor

(Q501) on the composite power supply PCB

to generate the scanning lamp on signal

(FLAON*). At this time, the fluorescent lamp

driver circuit operates to apply the output of

the primary side of the main transformer

(T102) to both ends of the scanning lamp so

as to turn on the scanning lamp at a high fre-

quency.

5. Controlling (automatic) the Fluorescent

Lamp Intensity (ALVC control)

The ,copier executes ALVC control in which

the ON voltage of the scanning lamp is automati-

tally corrected to prevent changes in the copy

images caused by deterioration of the photosen-

sitive drum.

4. Controlling the Intensity of the

Scanning Lamp

a. Outline

The intensity of the scanning lamp is

controlled by the microprocessor (Q501) on

the composite power supply PCB.

The intensity sensor checks the intensity

of the scanning lamp and generates activa-

tion power to suit the intensity. The micropro-

cessor, on the other hand, finds out the

intensity of the scanning lamp based on the

activation power to send the scanning lamp

on signal (FLON*) to the on control circuit.

b. Intensity Lower Than the Specified

Value

The microprocessor increases the duty

ratio of the scanning lamp on signal (FLON*)

sent to the fluorescent lamp driver. The fluo-

rescent lamp driver, in turn, increases the

current flowing to the scanning lamp, there-

by increasing the intensity of the scanning

lamp.

c. Intensity Higher Than the Specified

Value

The microprocessor decreases the duty

ratio of the scanning lamp on signal (FLON*)

sent to the fluorescent lamp driver. The fluo-

rescent lamp driver, in turn, decreases the

current flowing to the scanning lamp, there-

by decreasing the intensity of the scanning

lamp.

3-22 COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012FI NP6212 AEV. I SEPT. 1995 PRl NTEDI NJ APAN( I MPAI Mi AUJ APON)

E. Controlling the Primary

Charging Roller Bias

1. Outline

Figure 3-307 shows the circuit that con-

trols the application voltage of the primary

charging roller, and the circuit has the follow-

ing functions:

l turns on and off the DC bias.

l controls the AC bias to a constant volt-

age.

l switches the DC bias voltage level.

l controls the scanning lamp ON voltage

level.

The primary charging roller is given a

DC bias so as to maintain the surface poten-

tial of the photosensitive drum to a specific

value. The DC bias is switched according to

whether or not a copy image is being

formed.

Reference:

DC component: -9OO/-1376V

Microprocessor

Composite power supply PCE

DC controller PCB

Figure 3-307

COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012Fl NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPAI Mi AUJ APON)

3-23

2. Operation

a. Turning On and Off the DC Bias

When the Copy Start key is pressed, the

microprocessor on the DC controller PCB

instructs the microprocessor on the compos-

ite power supply PCB to turn on the DC bias.

The microprocessor on the composite

power supply PCB drives the main trans-

former (T102).

The DC bias is generated by rectifying

the voltage from the main transformer

(T102) and is sent to the primary charging

roller.

c. Switching the DC Bias Voltage Level

The copier switches the level of the DC

bias voltage according to whether or not

copy images are being formed.

The DC bias voltage is switched by the

microprocessor on the composite power

supply PCB by varying the DC bias control

signal (PDCPWM) according to the DC bias

switching timing signal sent by the micropro-

cessor on the DC controller PCB.

during copying: -900 V

other: -1376 V

b. Controlling the DC Bias to a Specific

Voltage

The DC bias is controlled to a specific

voltage by the microprocessor on the com-

posite power supply PCB. The microproces-

sor on the composite power supply PCB

constantly monitors the DC voltage. The

microprocessor serves to maintain the DC

bias voltage to a constant value by varying

the DC bias control signal (PDCPWM)

based on measurements of voltage taken.

Copy Stan key

o_N

/--

Figure 3-308

3 - 24 COPVAI GHT 0 1995 CANONI NC. CANONNP6012/ NP6012F/ NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

OPERATIONS AND TlMlNGl

d. Controlling (automatic) the Primary

Charging roller Bias Application Voltage

Level and the Scanning Lamp ON

Voltage Level (APVC, ALVC control)

Copy images will suffer changes if

changes occur in their static latent images,

which in turn are caused by thefollowing:

l changes in drum sensitivity; and

l changes in the degree of charge by

the primary charging roller.

These symptoms are brought about by

changes in the site environment (tempera-

ture, humidity) deterioration, wear, or dirt on

parts.

The copiers light area potential (VL) and

dark area potential (VD) have a tendency to

increase; to compensate for this tendency,

the copier corrects the primary charging

roller bias application voltage level (APVC

control) and the scanning lamp ON voltage

level (ALVC control), thereby ensuring a spe-

cific light area potential (VL) and dark area

potential (VD) at all times.

Study the following for an idea of how

the mechanism is activated (after power-on,

during initial rotation for 1st copy):

. Flow

A specific voltage of about -1.376 kV is

applied to the primary charging roller for about

I .3 sec.

1

The current value at this time is detected by

the current detection circuit, &d sent to the

microprocessor (Q501).

I

The microprocessor (Q501) in turn sends the

current value to the microprocessor (QIOI) on

the DC controller so that the application

voltage for the primary charging roller bias

may be determined based on the Ivalue.

I

COPYRIGHT 0 1995 CANON INC. CANON NP6012 I NP60i2F/NPS212 REV.1 SEPT. 1995 PRINTED IN JAPAN (IMPRIM~ AU JAPON)

3-25

I

F. Controlling the Developing/

Separation Static

Eliminator Bias

1. Outline

Figure 3-309 shows the circuit that con-

trols the developing/separation static elimi-

nator bias, and the circuit has the following

functions:

l turns on and off the DC component.

l turns on and off the AC component.

l controls the voltage level of the DC

bias according to type of developing

assembly.

AC power

SUPPlY

l controls the voltage level of the DC

bias according to the copy density set-

tings.

The:developing cylinder is given AC and

DC biases during copying operation.

While the photosensitive drum is rotat-

ing, except during development, about -500

V is applied to the developing cylinder

regardless of the position of the density

adjusting lever, thereby preventing adhesion

of excess toner to the surface of the photo-

sensitive drum.

r ansf or mer

T102

L

Tr ansf or mer _

Microprocessor

Microprocessor

Figure 3-309

St at i c

el i mi nat or

3 - 26 COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012FI NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRI M~AUJ APON)

-\

2. Turning On and Off the DC

Component

As soon as the Copy Start key is

pressed, the microprocessor on the DC con-

troller PCB sends the developing DC bias on

signal (DVDCON) to the microprocessor on

the composite power supply PCB.

In response, the microprocessor on the

composite power supply PCB drives the

main transformer (T102) to generate a DC

bias for the developing cylinder.

When the developing DC bias on signal

(DVDCON) from the microprocessor on the

DC controller is cut, the microprocessor on

the composite power supply PCB stops the

,--,

drive to the main transformer (T102), there-

, \\

by cutting off the DC bias.

3. Turning the AC Component On and

Off

About 3.5 set after the Copy Start key is

pressed, the microprocessor on the DC con-

troller PCB sends the developing AC bias on

signal (DVACON) to the microprocessor on

the composite power supply PCB.

The microprocessor on the composite

power supply sends the AC bias oscillation

signal (ACBIAS) to the amplifier, which in

turn drives the transformer (T301) and gen-

erates an AC bias for the developing cylin-

der.

The AC output of the transformer (T301)

is transformed/rectified and then supplied to

the static eliminator.

When the developing AC bias on signal

(DVACON) from the microprocessor on the

DC controller PCB is cut off, the micropro-

cessor on the composite power supply PCB

stops the AC bias oscillation signal

(ACBIAS) to cut off the AC bias supply.

COPYRI GHT 0 1995 CANONI NC. CANON NP6012/ NP6012FI NP6212 REV. 1 SEPT. 1995 PRl NTEDI NJ APAN( I MPRl Mi AUJ APON) 3-27

4. Controlling the Voltage Level of the

DC Bias to Suit the Copy Density

Setting

The copier varies the DC bias control

signal (DCBPWM) according to the settings

shown below to vary the DC component volt-

age, thereby controlling the copy density.

l setting, of the density adjusting lever

(manual control mode)

l output of the AE sensor (automatic

control mode)

l setting of density correction dial

(VR107)

l type of developing assembly

DC bias: -50V to -550V

The density correction dial (VRl07) on

the DC controller PCB may be used to

adjust the DC bias voltage, there by correct-

ing foggy images caused by changes in the

sensitivity of the photosensitive drum. The

density correction dial functions when the

density is adjusted in manual mode or during

automatic density adjustment mode.

Figure 3-310

See Figures 3-311 and 312 for changes

in the DC bias according to the setting of the

density adjusting lever in manual mode and

to the changes in the AE sensor output in

automatic mode.

Density of

.

0 /

Test Chart Newspaper original

/

3

i.

I

-100 -~

-200 --

-300

-400 --

-500 --

V

Developing

bias DC

component (V)

AE mode ON

Figure 3-311

Copy density lever

1 5 9

Manual Density adjustment

Figure 3-312

3-28 COPYRIGHT @ 1996 CANON INC. CANON NP6012/NP60i2F/NP6212 AEV.1 SEPT. 1995 PRIMEDIN JAPAN(IMPRlM~AUJ APON)

G. Developing

Assembly/Cleaning

Assembly

1. Outline

The developing assembly is locked or

released manually by operating the locking

lever.

The primary charging roller is cleaned by

the cleaning pad operated by the cleaning

solenoid.

The developing assembly and the waste

toner feeding blade are driven by the drive of

the main motor (Ml) transmitted by the drive

gear. The waste toner scraped by the clean-

ing blade is forwarded inside the drum unit

by the toner feeding blade for collection,

The level of toner inside the developing

assembly is monitored by the toner antenna.

T

DC controller PCB

Composite power supply PCB

detection PCB

Drum unit

COPYRIGHT @ 1995 CANON INC.

1 dleaning blade

Toner antenna

assembly

Waste toner feeding blade

Figure 3-313

CANON NPHZI NPBOlZFI NP6212 REV.1 SEPT. 1995 PRINTED IN J APAN (IMPRIM~ AU J APON)

3 - 29

2. Monitoring the Level of Toner

a. Outline

The level of toner inside the developing

assembly is monitored by the toner level

antenna and the toner level detecting circuit.

The toner level antenna is found inside

the developing assembly, and an AC bias is

applied to the developing cylinder so that the

toner level antenna and the developing cylin-

der are bonded by static electricity whose

size varies according to the level of toner.

The copier uses the changes in the size

of this static electricity to monitor the level of

toner.

b. Mechanism

The toner level detecting ,PCB receives

an AC b/as equal to the AC bias applied to

the developing cylinder and an AC bias that

represents the level of toner by the toner

level antenna. The AC bias applied to the

developing cylinder is used as a reference

signal, and the AC bias from the toner level

antenna is used as the toner level signal.

The toner level detection PCB compares

these two types of signals and sends the

results of comparison to the DC controller

PCB as the toner level signal (TNMONI).

Developing bias

Reference signal

z

I I I

I

3