Академический Документы

Профессиональный Документы

Культура Документы

Bhatt Tang Dong Wang Whitepaper

Загружено:

api-247208605Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bhatt Tang Dong Wang Whitepaper

Загружено:

api-247208605Авторское право:

Доступные форматы

Production process improvement

Running Head- Production process improvement

ProPlanner software- a Tool for Production Process Improvement

Animish Bhatt Chao Tang Ethan Wang Yue Dong White Paper for Professional Writing (GEB5212: 0199) Dr. Priscilla Berry University of Florida 28 January 2014

Production process improvement

ProPlanner Software- a Tool for Production Process Improvement

Author: Animish Bhatt Chao Tang Ethan Wang Yue Dong

Production process improvement

Executive Summary

Today TATA MOTORS is competing to be the best at all facets of operation. Without a doubt, production planning and inventory control are the most difficult stages of manufacturing. Minor errors in predicting demand and planning resources can lead to costly mistakes. To avoid these problems, it is essential to be accurate in the planning and management of the available resources. The ongoing method of production planning proving to be inadequate to meet up with the customer demand and increasing unnecessary wastages. So it is a proper time to switch to a more cost-effective option. ProPlanner, a production planning software developed by ProModel Technologies proves to be a perfect solution for this problem. It provides the organization with objective information and scientific insights to improve the overall performance based on its deterministic, probabilistic and dynamic simulation problem solving techniques. This paper cites the weaknesses of the present production planning methodology and provides a production and inventory planning solution custom designed for TATA MOTORS in line with their immediate operational needs.

Production process improvement Introduction

Scheduling and sequencing are important aspects in manufacturing which aims to maximize the efficiency of operations and reduce costs. Inventory carrying cost is one of the major components of losses faced by automobile industry. Improving the scheduling and sequencing pattern could reduce this cost.

Backward Scheduling is a process that schedules the activities by commencing with the deadlines and working backwards in reverse order. This technique allows to identify the potential bottlenecks and problems in advance which helps in controlling the inventory and the costs related to it. The installation of ProPlanner software which works on the fundamentals of backward scheduling would help TATA MOTORS to solve the problems related to production planning methods and inventory costs. This paper will provide a thorough insight about the proper balance between production planning and reduction of unnecessary expenses.

Phases of production planning

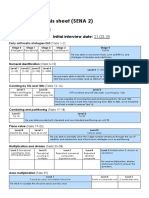

In this section we study the planning phases in detail. The basic idea of production planning cycle along with its four phases are shown in Figure 1.

Figure 1: Production Planning Cycle

Production process improvement Current Problem

TATA MOTORS, currently using Forward scheduling method for production is facing a problem of high vehicle roll-out lead time. The production starts on a fixed date without considering the market delivery due date, leading to increment in the annual inventory carrying cost and loss of customers.

The major areas of concerns are1. Vehicle Drop-in Sequence 2. Post Roll-out activities 3. Assembly line balancing The Annual Average Lead-time for vehicles to roll out resulted to be around 5 days (Bhatt, Kulkarni & Raut, 2013) for the year 2012, as shown in Figure 2.

10 9 8 7 6 5 4 3 2 1 0

Days

Source: Business Excellence Department

Figure 2: Lead-time for vehicle roll-out in 2012

Solution

ProPlanner software is developed by ProModel Technologies to offer remedies to the problems emerging in the sequencing and scheduling for production lines. It is capable of generating different types of production models depending upon the data provided by the manufacturer.

Production process improvement

The software works on the principle of backward scheduling and addresses all the problems discussed above offering the best possible solution. Thus, increasing the productivity, reliability and cutting down inventory carrying cost.

The Annual Average Lead-time for vehicle roll-out was calculated to be 3.5 days (Bhatt et al., 2013) by ProPlanner for the demand in 2012 which is 20% better than current situation, as shown in Figure 3.

10 9 8 7 6 5 4 3 2 1 0

Forward Scheduling

ProModel Results

Source: Business Excellence Department

Figure 3: ProPlanner results for lead-time in 2012

Working of ProPlanner

This section describes the advantages of using ProPlanner software over the current method in detail. It also focuses on the technical aspects of ProPlanner which simulates solutions for1. Alternate production methods 2. Line Balancing 3. Inventory cost reduction

Additional Features

ProPlanner software incorporates three additional functionalities, which provides remedy to the problems of Production and Distribution engineers. These functionalities are:

Production process improvement

1. Supply Chain Optimizer: ProPlanner helps to accurately analyze all of the stages of the supply chain, including production, warehousing and distribution. 2. Manufacturing Performance Improver: ProPlanners predictive technology helps to reduce the risk in optimizing an organizations performance.

3. Lean & Six Sigma Initiator: ProPlanner accurately predicts the impact of Lean methodologies and Six Sigma changes considering the effect of variability and uncertainty with time.

Conclusion

For many years, Inventory carrying cost has become one of the most critical component of wastage in automobile industry which is primarily driven by the production planning. A thoughtful investment is needed to overcome this problem and to reduce the business risk. Implementation of ProPlanner as a production planning system will reduce the complexities and will enable the organization to cut down on their annual inventory carrying costs and improve the overall efficiency. Best in the manner in which we operate, best in the products we deliver, and best in our value system and ethics. (TATA MOTORS, 2012)

Production process improvement References

1. Chugh, T (2008). Backward scheduling- An effective way of scheduling warehouse activities Retrieved from: http://www.tcs.com/sitecollectiondocuments/white%20papers/Backward%20Scheduling %20%20An%20effective%20way%20of%20scheduling%20Warehouse%20activities.pdf 2. Singleton, D (2011). How MRP and production planning and scheduling software differ. Retrieved from: http://blog.netronic.com/guest-blog-mrp-production-planningscheduling-software-differ

3. Figure 1, Production planning cycle, Retrieved from: http://www.parmarlabs.com/wp-content/gallery/production-planning-23nov-2011/production-planning.jpg 4. ProModel, 2014, URL: http://www.promodel.com/solutions/capacity-planning.asp 5. Business Excellence Department, TATA MOTORS, Pune (2013) URL: http://www.tatamotors.com/ 6. Core Logistics Consulting, 2013, URL: http://www.corelogistics.com.au/Inventory_management_lead_time_reduction.html

Вам также может понравиться

- Ijaiem 2013 06 12 035Документ10 страницIjaiem 2013 06 12 035International Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Unit 5Документ34 страницыUnit 5ShrutiОценок пока нет

- Prioritizing Production Planning Problems and Normalizing Percent Plan Complete Data Using Six Sigma - Beary and Abdelhamid - 2006Документ11 страницPrioritizing Production Planning Problems and Normalizing Percent Plan Complete Data Using Six Sigma - Beary and Abdelhamid - 2006Jhonny H. Franke OrellanaОценок пока нет

- Cost of Poor Quality 1Документ7 страницCost of Poor Quality 1Shavin AvinОценок пока нет

- 14 Midterm ExamДокумент167 страниц14 Midterm Examapi-2978344330% (1)

- Chapter 1. Introduction: 1.1. BackgroundДокумент92 страницыChapter 1. Introduction: 1.1. BackgroundSanjay KmrОценок пока нет

- Thesis On Production Planning and ControlДокумент6 страницThesis On Production Planning and Controldwtnpjyv100% (2)

- Total Productive Maintenance (TPM) Concepts and Literature ReviewДокумент7 страницTotal Productive Maintenance (TPM) Concepts and Literature ReviewafduaciufОценок пока нет

- Assignement of PMSДокумент10 страницAssignement of PMSahmadhanif82845Оценок пока нет

- APQP RevisitedДокумент5 страницAPQP RevisitedRita LepesiwthОценок пока нет

- Improve Capability Process To Optimizing Productivity Case 2lwjt80rg5Документ8 страницImprove Capability Process To Optimizing Productivity Case 2lwjt80rg5jumawanjevren02Оценок пока нет

- PQMДокумент5 страницPQMRahul SoniОценок пока нет

- A Business-Based Approach To Developing An Effective ProgramДокумент8 страницA Business-Based Approach To Developing An Effective ProgramWojtek MaczynskiОценок пока нет

- The Value of Early Analysis (Part 1) : by Gregory RothДокумент4 страницыThe Value of Early Analysis (Part 1) : by Gregory RothanandakoeОценок пока нет

- Cost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsОт EverandCost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsОценок пока нет

- Single Piece FlowДокумент8 страницSingle Piece FlowUchral TseОценок пока нет

- PM PRojectДокумент92 страницыPM PRojectnagarkar_123Оценок пока нет

- How To Use Real-Time Analytics To Achieve Operational ExcellenceДокумент6 страницHow To Use Real-Time Analytics To Achieve Operational ExcellenceAbilio JuniorОценок пока нет

- Preventive Maintenance Expanded DefinitionДокумент5 страницPreventive Maintenance Expanded DefinitionCadcamdestek CukurocaОценок пока нет

- Lean Manufacturing in BajajДокумент16 страницLean Manufacturing in BajajArjun K BhagatОценок пока нет

- Eng-Productivity Improvement-A Case Study-Pramod A. DeshmukhДокумент8 страницEng-Productivity Improvement-A Case Study-Pramod A. DeshmukhImpact JournalsОценок пока нет

- ResearchДокумент8 страницResearchKunal DhotreОценок пока нет

- Cover Story - Pharmaceutical Automation Project Management - ISAДокумент6 страницCover Story - Pharmaceutical Automation Project Management - ISAcleitonmoyaОценок пока нет

- Research Paper On Overall Equipment EffectivenessДокумент7 страницResearch Paper On Overall Equipment Effectivenessluwop1gagos3Оценок пока нет

- Improvement in Productivity Through TPM Impleme 2020 Materials Today ProceeДокумент10 страницImprovement in Productivity Through TPM Impleme 2020 Materials Today ProceeKb sandoval sandovalОценок пока нет

- Total Quality Management JUNE 2022Документ11 страницTotal Quality Management JUNE 2022Rajni KumariОценок пока нет

- JIT JustДокумент21 страницаJIT Justsurusworl281Оценок пока нет

- UKFM QRMS 11EB02 Yuvanesan MuthukumaresanДокумент27 страницUKFM QRMS 11EB02 Yuvanesan MuthukumaresanYuvanesh Yuvan100% (1)

- Critical Study On Vital Factors Influencing Productivity ImprovementДокумент8 страницCritical Study On Vital Factors Influencing Productivity ImprovementIJRASETPublicationsОценок пока нет

- Midterm ExamДокумент167 страницMidterm Examapi-297834433Оценок пока нет

- Research Paper On Production Planning and ControlДокумент8 страницResearch Paper On Production Planning and Controlh03318kj100% (1)

- Controlling The Cost of Poor Quality in The Maintenance Process of The Narrow Body Base Maintenance Department Using The DMAIC Method at PT. GMF AeroAsiaДокумент21 страницаControlling The Cost of Poor Quality in The Maintenance Process of The Narrow Body Base Maintenance Department Using The DMAIC Method at PT. GMF AeroAsiaSidik purnomoОценок пока нет

- Enterprise Resource PlanningДокумент4 страницыEnterprise Resource PlanningMuhammad UmairОценок пока нет

- Manufacturing Engineering Processes For Off-Road Buggy'S Fuel Tank ProductionДокумент12 страницManufacturing Engineering Processes For Off-Road Buggy'S Fuel Tank ProductionTJPRC PublicationsОценок пока нет

- Production Planning Using Simulation and Genetic Algorithms in Multi-Criteria Scheduling OptimizationДокумент10 страницProduction Planning Using Simulation and Genetic Algorithms in Multi-Criteria Scheduling OptimizationAshwani KumarОценок пока нет

- Accepted JIT PaperДокумент8 страницAccepted JIT PaperHappy SinghОценок пока нет

- Home Assignment Report (MASE) Final1Документ34 страницыHome Assignment Report (MASE) Final1manan hudeОценок пока нет

- World Class Operation December 2021 ExaminationДокумент11 страницWorld Class Operation December 2021 ExaminationAmrita JhaОценок пока нет

- World Class Operation ZvvixfДокумент11 страницWorld Class Operation ZvvixfAmrita JhaОценок пока нет

- PH 2 IPДокумент6 страницPH 2 IPKevin F BakerОценок пока нет

- OTC-28118-MS Planned Shutdown Time Optimization Using Lean Six SigmaДокумент10 страницOTC-28118-MS Planned Shutdown Time Optimization Using Lean Six SigmaAymenОценок пока нет

- Total Productive MaintenanceДокумент34 страницыTotal Productive MaintenanceJyoten Panditpautra100% (1)

- Six Sigma Approach To Reduce The Te/Fe Defects in Optical Disc (DVD)Документ7 страницSix Sigma Approach To Reduce The Te/Fe Defects in Optical Disc (DVD)International Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Module 3Документ47 страницModule 3ashir807Оценок пока нет

- IntroductionДокумент7 страницIntroductionariaОценок пока нет

- WCE2015 pp847-852Документ6 страницWCE2015 pp847-852VicenteОценок пока нет

- Book Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementОт EverandBook Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementОценок пока нет

- Impact of TPMДокумент16 страницImpact of TPMPanch BОценок пока нет

- Lalit Mohan Sharma: Phone: 0120 4296502 / +91 9811550080 (M)Документ3 страницыLalit Mohan Sharma: Phone: 0120 4296502 / +91 9811550080 (M)SAMSON GLOBALОценок пока нет

- Research Papers On Production and Operations ManagementДокумент6 страницResearch Papers On Production and Operations ManagementyvunfevgfОценок пока нет

- Thesis Production Operations ManagementДокумент5 страницThesis Production Operations Managementlynnwebersaintpaul100% (2)

- Production and Performance Management WP enДокумент7 страницProduction and Performance Management WP enbautistagian057Оценок пока нет

- Analysis of Automobile Industry: Six Sigma Approach: IjarcceДокумент5 страницAnalysis of Automobile Industry: Six Sigma Approach: IjarcceAbhishek D MahaleОценок пока нет

- Daptiv PPM BuyerguideДокумент16 страницDaptiv PPM BuyerguidechuxingОценок пока нет

- Analysis PhaseДокумент10 страницAnalysis PhaseRaj CircleОценок пока нет

- CooperДокумент7 страницCooperSanaSyedОценок пока нет

- 10 Activity 1Документ3 страницы10 Activity 1Hanna LyОценок пока нет

- QFD HomeworkДокумент5 страницQFD Homeworkafedthktn100% (1)

- Utilization of Six Sigma (DMAIC) Approach For Reducing Casting DefectsДокумент11 страницUtilization of Six Sigma (DMAIC) Approach For Reducing Casting DefectsUNITED CADDОценок пока нет

- Inspection and Quality Control Ensuring Excellence in ManufacturingДокумент2 страницыInspection and Quality Control Ensuring Excellence in ManufacturingSuhailShaikhОценок пока нет

- Consultation Field ExperienceДокумент9 страницConsultation Field Experienceapi-285240070Оценок пока нет

- CLIL Session C1.2.2. Evaluation ActivityДокумент1 страницаCLIL Session C1.2.2. Evaluation ActivityEloi NadalОценок пока нет

- Supplemental Math High School Grade 9 Q1Документ5 страницSupplemental Math High School Grade 9 Q1Abby T. Trajano100% (1)

- Video Game Has Many Positive Effects On Teenager NowadaysДокумент2 страницыVideo Game Has Many Positive Effects On Teenager NowadaysEva SherinОценок пока нет

- Educational TechnologyДокумент24 страницыEducational TechnologyFeb Rose Dela CruzОценок пока нет

- ARTS AND DESIGN - v4Final-K-to-12-MELCS-with-CG-CodesДокумент25 страницARTS AND DESIGN - v4Final-K-to-12-MELCS-with-CG-Codessheila_pedrajas0% (1)

- Topic 3 Knowledge AcquisitionДокумент44 страницыTopic 3 Knowledge AcquisitionAy SyОценок пока нет

- HTH Training Programme Geography Project Grade 10Документ12 страницHTH Training Programme Geography Project Grade 10api-193311681Оценок пока нет

- Term Paper Topics For Social PsychologyДокумент8 страницTerm Paper Topics For Social Psychologyafdttjujo100% (1)

- Benjamin B. Lahey - Psychology - An Introduction (2012, McGraw-Hill Higher Education)Документ721 страницаBenjamin B. Lahey - Psychology - An Introduction (2012, McGraw-Hill Higher Education)vivi77% (13)

- Group 3Документ72 страницыGroup 3alex setegn100% (1)

- Ai SyllabusДокумент2 страницыAi SyllabusraniОценок пока нет

- Design and Technology G 5 7Документ27 страницDesign and Technology G 5 7Tahpehs PhiriОценок пока нет

- Health and Safety OfficerДокумент24 страницыHealth and Safety OfficerAminur HaqiemОценок пока нет

- 7th Grade Math Scope and Sequence 2Документ13 страниц7th Grade Math Scope and Sequence 2api-466205055Оценок пока нет

- A Cognitive Modeling Approach To Strategy Formation in Dynamic Decision MakingДокумент18 страницA Cognitive Modeling Approach To Strategy Formation in Dynamic Decision MakingmaziyarmalekiОценок пока нет

- Standard 5 Sena-AnalysisДокумент10 страницStandard 5 Sena-Analysisapi-509143566Оценок пока нет

- A Study On The Human Resource Management Procedures at Cambodia Asia BankДокумент12 страницA Study On The Human Resource Management Procedures at Cambodia Asia BankHikki KeatОценок пока нет

- Quality Control Circle QCC & 7 QC Tools Training Course OutlineДокумент4 страницыQuality Control Circle QCC & 7 QC Tools Training Course OutlineeddiekuangОценок пока нет

- Steve Null PresentationДокумент41 страницаSteve Null PresentationGhada AjourОценок пока нет

- Amazon Resume ExamplesДокумент8 страницAmazon Resume Examplesvepybakek1t3100% (2)

- CSCI203 Algorithms and Data StructuresДокумент13 страницCSCI203 Algorithms and Data StructuresJonathan RonquilloОценок пока нет

- Escolhendo o CursoДокумент10 страницEscolhendo o Cursocello_medeirosОценок пока нет

- How To Bounce Back From Just About AnythingДокумент55 страницHow To Bounce Back From Just About AnythingMetall Andrei100% (2)

- Teacher Well-Being PDFДокумент174 страницыTeacher Well-Being PDFWalid Walid67% (3)

- Use of Heuristic Strategies To Increase The Ability of Mathematical Problem SolvingДокумент6 страницUse of Heuristic Strategies To Increase The Ability of Mathematical Problem SolvingChusna AmaliaОценок пока нет

- Session 2A Problem-Solving Using Heuristics at P3 and P4Документ64 страницыSession 2A Problem-Solving Using Heuristics at P3 and P4vaniОценок пока нет

- Mba Student Handbook enДокумент15 страницMba Student Handbook enzero3ightОценок пока нет

- Guide To Review of Basic Nursing Curriculum (WHO) PDFДокумент53 страницыGuide To Review of Basic Nursing Curriculum (WHO) PDFLliryc Sotnas OleusnocОценок пока нет

- Sr. Process Engineer CVДокумент6 страницSr. Process Engineer CVTayebASherif50% (2)