Академический Документы

Профессиональный Документы

Культура Документы

240K-C2-ES-15-001-1 Structural PDF

Загружено:

WaldomiroCanoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

240K-C2-ES-15-001-1 Structural PDF

Загружено:

WaldomiroCanoАвторское право:

Доступные форматы

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

DOCUMENT NO. 240K-C2-ES-15-001 REV. 1

01 DECEMBER 2011

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Document

No. 240K-C2-ES-15-001 Revision 1

FLUOR~)

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

This document has been revised as indicated below. Changes after Revision 0 are identified by vertical bars at the right side of the page, with additions being underlined. Please replace all pages of this specification and destroy the superseded copies.

Rev No. A B

C 0 1

Ori_ginator

Peter Mark Mark Mark Mark Haagen Lasby Lasby Lasby Lasby

Rev Date

19Apr11 13May11 22July11 03Aug11 01 Dec11 Issued for Issued for Issued for Issued for Re-issued

Revision Descri~tion

Combined Review Client Review AQQroval Design for Design

--

J

I

----1 I

New Issue

[g]

Entire Document Re-issued

Fluor A

Proiect Director

rovals

Date

er Area Mana er Process Lead Lead Disci Reviewer Ori inator

---_._ --_._

Ifl'-'-

ft.

#/1

111 i

ineer

_-_._

rovals

SMCVA En

O~iginal Signed By

Date

W:\1 03 _ProLAdmin\1

09 _ENG

DOCS\1 09.6R_ES\1

5-StructuraI\240K-C2-ES-1

5-001_ StructReqMechEquip\240K-C2-ES-1

5-001-'I.doc

Page 1 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

This page is intentionally blank.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 2 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

TABLE OF CONTENTS 1. GENERAL............................................................................................................................................. 5 1.1 Summary ...................................................................................................................................... 5 1.2 References ................................................................................................................................... 8 DESIGN CRITERIA .............................................................................................................................. 9 2.1 Design Loads ............................................................................................................................... 9 2.2 Load Combinations .................................................................................................................... 10 2.3 Structural Steel........................................................................................................................... 11 2.4 Anchor Rods............................................................................................................................... 11 EXECUTION ....................................................................................................................................... 12 ATTACHMENTS................................................................................................................................. 12

2.

3. 4.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 3 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

This page is intentionally blank.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 4 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

1.

GENERAL 1.1 Summary A. Scope of Specification This specification provides structural data for the design of mechanical equipment, and defines structural related requirements that the equipment Supplier shall be expected to furnish as part of the Supplier data submitted. Wherever this specification differs from the referenced codes, standards, or specifications, this specification shall govern. B. Work Not Included This specification is not to be used for the design of vessels and stacks; the engineer shall use 240K-C2-DC-15-001 Structural Engineering Design Criteria, instead. C. Related Specifications The following specifications prescribe items of related work: 240K-C2-DC-10-002 240K-C2-DC-15-001 240K-C2-ES-55-002 D. Provided by Supplier Supplier shall include the following information on drawings or other documents submitted for review: In general terms, in all cases of moving, rotating, impacting or vibrating machinery or equipment, supplier shall indicate best common practices for structural supports, indicate allowances to be made for dynamic effects, such as load factors or otherwise, and indicate clearly any limitations which the supporting structure should comply with, such as limits of settlement, deflection, vibration amplitude, velocity etc. 1. Rotating and Reciprocating Machinery Weighing 2,270 kg (5000 lbs.) or Less a. Outline drawing of the machine assembly with dimensions of skid or mounting plates, and with the location and size of anchor bolts. Required grip for anchor bolts shall be clearly noted. The weight of the total machine assembly and its center of gravity or individual component weights (such as drives, skid, machine) and locations such that the center of gravity may be calculated. A plan showing location and size of base components requiring grout support. For skid mounted machinery, requirements for filling skid with grout and location and size of grout holes. Driver type, horsepower, and operating speed. Machinery Supplier foundation recommendations, such as anchor bolt post tension stress, type of grout, and foundation layout (plan dimensions and elevations). Maximum temperature of machine assembly at grout contact points. General Site Conditions Design Criteria Structural Engineering Design Criteria Paint Equipment Standards

b.

c.

d. e. f.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 5 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

2.

Rotating Machinery Weighing More than 2,270 kg (5000 lbs.) a. b. c. d. e. f. g. h. i. j. k. l. Information listed in Section 1.1D.1 of this specification Weight of machine rotor components and the center of gravity of each. Dynamic unbalanced force Short-circuit load if motor-driven Location of rotor bearings Range of machine speeds and operating speed Equivalent static load at each bolt corresponding to peak machine loads For turbo generators, condenser flange/vacuum load Design torque load Vertical and horizontal impact loads Machine thermal expansion force Turbine accident load due to bowed rotor, bucket break, or valve tripping Mass moment of inertia of the total machine about the CG (Center of Gravity) of the machine or sufficient data on individual components and their CGs to calculate the mass moment of inertia about 3 axes Required anchor bolt post tension stress Seismic, wind and dynamic reactions at each support point

m. n. 3.

Reciprocating Machinery Weighing More than 2,270 kg (5000 lbs.) a. b. c. d. e. f. g. Information listed in Section 1.1D.1 of this specification Magnitude, direction, point of application, and frequency of primary and secondary unbalanced forces and moments, both vertical and horizontal Required anchor bolt post tension stress Equivalent static load at each bolt corresponding to peak machine loads Mass moment of inertia about the CG of the machine or sufficient data on individual components and their CGs to calculate the mass moment or inertia Range of machine speeds and operating speed Seismic, wind and dynamic reactions at each support point

4.

Vibrating Screens a. b. c. d. e. f. Information listed in Section 1.1D.1 of this specification Static forces at structural supports Operating frequency of the screen Horizontal and vertical dynamic forces at structural supports at operating speed Resonant frequencies of the screen Unbalanced mass and eccentricity of rotating drive shaft(s)

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 6 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

g. h. i. j. k. 5.

Total mass and center of gravity of the upper parts of the screen, which move essentially as a rigid body on flexible elements Equivalent spring constants for flexible elements connecting rigid upper part of screen to structural supports (horizontal and vertical constants) Speed versus time curve for speed-up of motor during start-up Speed versus time curve for slow down of motor after shut down Seismic, wind and dynamic reactions at each support point

Primary Crushers (gyratory or cone crushers) a. b. c. d. e. f. g. h. Information listed in Section 1.1D.1 of this specification Weight of crusher and motor and reaction at each support point Weight of operating equipment (at max. capacity) and reaction at each support point Maximum horizontal dynamic force and location Maximum dynamic moment and location Recommended minimum ratio of total foundation weight to the total crusher weight Requirements for grouting and anchor bolt post tensioning Seismic, wind and dynamic reactions at each support point

6.

Grinding Mills a. b. c. d. e. f. g. h. i. j. k. l. m. n. o. Information listed in Section 1.1D.1 of this specification Weight of mill including liner plates at each support point Weight of motor, reducer/gear box assembly at each support point Charge load acting eccentrically when dynamic equilibrium is reached Centrifugal force due to rotating charge loads Maximum unbalanced mass and eccentricity due to wearing of rotating liner plates, etc. Fluctuating lateral and vertical loads due to cascading and cataracting of the charge Thermal loads during start-up and shut-down Inching loads Loads due to reverse rotation (inching or operating loads) if applicable Axial, lateral and vertical pinion loads Fixed end jacking loads Free end jacking loads Approximate characteristics for start up of loaded mill including buildup of angular velocity versus time for starting, inching etc. Recommended mass ratio: total concrete divided by rotating mass of mill. Rotating mass is mill weight, including materials and charge.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 7 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

p. q. r. s. t. 7.

Recommended mat rigidity ratio: thickness of mat divided by greatest plan dimensions between piers Recommended mat rigidity ratio: thickness of mat divided by least plan dimensions between piers and edge of mat. Limits of displacement at top of piers under full static and dynamic loads in lateral or longitudinal directions, including differentials between any two piers Requirements for grouting and anchor bolt post tensioning Seismic, wind and dynamic reactions at each support point

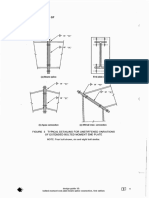

Tanks, Boiler, Sphere, and Miscellaneous Equipment a. b. c. d. Outline drawing with plans and elevations of equipment, support structure, and the sizes of the structural members Location, size, and grip of anchor bolts Magnitude of equipment load, wind load, and earthquake load at each support Thermal expansion movement at each support and the shell temperature for horizontal vessel, heater, and boiler

8.

Conveyors and Feeders a. b. c. d. e. Outline drawing with plans and elevations of equipment, support structure, and the sizes of the structural members Location, size, and grip of anchor bolts Belt tension reactions under all operating conditions Magnitude of equipment operating load, wind load, and earthquake load at each support Maximum, or break down level belt tensions and maximum capacity of belt

1.2

References The publications listed below form part of this specification to the extent referenced in this specification. If there is a discrepancy between the references and the specifications, the specifications shall govern. ACI American Concrete Institute ACI 318-05 Building Code Requirements for Structural Concrete AISC American Institute of Steel Construction Manual of Steel Construction, Thirteenth Edition, 2005 ANSI/AISC 360-05 Specification for Structural Steel Buildings, March 9, 2005 ASCE American Society of Civil Engineers ASCE 7-05 (ASCE7) Minimum Design Loads for Buildings and Other Structures

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 8 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

ASTM

American Society for Testing and Materials A992/A992M Standard Specification for Structural Steel Shapes A36/36M Standard Specification for Carbon Structural Steel A500 Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds or and Shapes A53-10/A53M-10 Standard Specification for Pipe, Steel, Black and HotDipped, Zinc-Coated, Welded and Seamless A307 Standard Specification for Carbon Steel Bolts and Studs, 60000 psi Tensile Strength A325 Standard Specification for Structural Bolts, Steel, Heat Treated 120/105 ksi Minimum Tensile Strength A563M Standard Specification for Carbon and Alloy Steel Nuts F436M Standard Specification for Hardened Steel Washers F1554M Standard Specification for Anchor Bolts, Steel, 36, 55 and 105 ksi Yield Strength A786/786M Standard Specification for Hot-Rolled Carbon Low Alloy, High Strength Low Alloy and Alloy Steel Floor Plates

AWS

American Welding Society D1.1 Structural Welding Code

ICC

International Code Council International Building Code (IBC), 2006 Edition

NAAMM

National Association of Architectural Metal Manufacturers MBG 531-00, Metal Bar Grating Manual Sixth Edition, February 21, 2001

OSHA 2. DESIGN CRITERIA 2.1 Design Loads

Occupational Safety and Health Administration

Loads and forces used for design shall be as defined in the codes specified below and as modified herein. Load definitions are in accordance with the International Building Code (2006 Edition), hereafter referred to as the IBC. A. Wind Loads Wind loads shall be calculated based on IBC 2006 and ASCE 7-05. For basic wind speed refer to related specifications under Section 1.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 9 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

B.

Earthquake Loads Earthquake loads shall be calculated based on IBC 2006 and ASCE 7-05. For design parameters refer to related specifications under Section 1.

C.

Live Loads 1. 2. 3. 4. 5. Storage areas Operating platforms Access areas Stairs and ramps Handrail 7.2 kPa (150 psf) (minimum) 4.8 kPa (100 psf) 2.9 kPa (60 psf) 4.8 kPa (100 psf) or 4.5 kN (1000 lbs.) moving concentrated load 0.9 kN (200 lbs.) to any direction at the top rail

D.

Snow Loads 1. 2. No snow requirements. In no case shall the minimum design roof load be less than 1.0 kPa (20 psf).

E.

Thermal Loads 1. 2. Thermal loads and displacements caused by operating conditions shall be based on the design temperature of the equipment rather than the operating temperature. For ambient temperature ranges refer to related specifications under Section 1.

2.2

Load Combinations A. The following loads and forces shall be considered in any structural design: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. B. Dead loads Operating loads (including upset conditions) Live loads Impact and vibration forces Belt tension forces Thermal forces including piping expansion forces Erection loads Maintenance loads Wind load Earthquake load Transport load

Every portion of a structure shall be designed to resist the following load combinations with load and combination factors applied in accordance with the governing code: 1. 2. Dead load consisting of the weight of the equipment including all attachments and internals Operating load (consisting of the dead load and the operating content weight), design live loads, impact and vibration forces, belt tension forces, thermal forces, maintenance loads and any other loads indicated by the equipment supplier, specific to this equipment.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 10 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

3. 4. 2.3

Dead load and either wind or earthquake load, whichever governs Operating load and either wind or earthquake load, whichever governs

Structural Steel A. Codes: AISC American Institute of Steel Construction Manual of Steel Construction, Thirteenth Edition, 2005 360-05 Specification for Structural Steel Buildings, March 9, 2005 B. Material: Structural Steel Wide Flange Shapes & WT Shapes: Structural Shapes, Plates and Bars: Hollow Structural Sections Structural Pipe Structural Tube Material Steel Floor Plates Steel Grating C. D. E. ASTM A992M ASTM A36/A36M ASTM A500 Grade C ASTM A53 Grade B ASTM A500 Grade C ASTM A786/786M NAAMM MBG 531-00

For surface preparation, priming, and painting, refer to Painting Specification listed under Section 1.1C. Stairs, platforms, and ladders shall be designed in accordance with Project standard drawings. Platforms or walkways shall be covered generally with 32 mm x 5 mm (1-1/4 in. by 3/16 in.) nongalvanized non-serrated welded grating for horizontal internal application. Grating shall be serrated for sloped or external application. Stair treads shall be the same size as grating, with non-slip nosing. Minimum headroom over platforms, walkways, and stairways shall be 2135 mm (7-0) to the lowest point of any overhead obstruction. The weight of removable flooring sections shall not exceed 68 kg (150 lbs.). Fabricated assemblies, platforms, skids etc., shall prevent pockets allowing accumulation of any liquid or water used in the process or wash down.

F. G. H. 2.4

Anchor Rods A. Anchor Rods less than or equal to 50 mm shall conform to ASTM F1554M, Grade 36. Anchor Rods greater than 50 mm and less than 100 mm shall conform to ASTM A307, Grade C. Anchor Rods shall be headed type with metric coarse threads. Nuts for Anchor Rods shall conform to ASTM A563M. Washers shall conform to ASTM F436M Type 1. Anchor plates shall conform to ASTM A36. Anchor Rods shall be sized based on ACI 318-05 Appendix D, taking into account environment to which its use will be subjected. Bolts larger than 2 (50 mm) will be specially purchased for specific applications.

B.

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 11 of 12

Document No. 240K-C2-ES-15-001 Revision 1

STRUCTURAL DATA REQUIREMENTS FOR MECHANICAL EQUIPMENT

3.

EXECUTION Not applicable.

4.

ATTACHMENTS Not applicable. End of Document

Z:\103_Proj_Admin\109_ENG DOCS\109.6R_ES\15-Structural\240K-C2-ES-15-001_StructReqMechEquip\240K-C2-ES-15-001-1.doc

Page 12 of 12

Вам также может понравиться

- Ars13120 PDFДокумент24 страницыArs13120 PDFSergio SmithОценок пока нет

- 3DG C13 00012 PDFДокумент53 страницы3DG C13 00012 PDFquanta1983Оценок пока нет

- 000.215.1216 20aug2009Документ63 страницы000.215.1216 20aug2009Anonymous ya6gBBwHJFОценок пока нет

- 000.200.1067 3rd Gen Modular Execution Material Handling Strategy - ZipДокумент9 страниц000.200.1067 3rd Gen Modular Execution Material Handling Strategy - ZipMuhammad Fatah ShaikОценок пока нет

- Design Example of Pipe Rack StructureДокумент16 страницDesign Example of Pipe Rack StructureJimit PayОценок пока нет

- Guidelines For Pipe Support AnalysisДокумент31 страницаGuidelines For Pipe Support AnalysisgvlanushaОценок пока нет

- Report Pipe RackДокумент16 страницReport Pipe RackMochammad ShokehОценок пока нет

- Civil 2019 v22 Release NoteДокумент25 страницCivil 2019 v22 Release NoteNilay GandhiОценок пока нет

- AISC Shapes Database v14.1 OfficialДокумент18 страницAISC Shapes Database v14.1 Officialstapler9100% (1)

- Fluor. 000.215.1234. Vibrating Machinery Foundations On Soil. 2005Документ89 страницFluor. 000.215.1234. Vibrating Machinery Foundations On Soil. 2005NicolasОценок пока нет

- PIP STF05121 Anchor Fabrication and Installation Into ConcreteДокумент6 страницPIP STF05121 Anchor Fabrication and Installation Into Concretecarrimonn11Оценок пока нет

- Xcpipe PDFДокумент6 страницXcpipe PDFalberto rodriguezОценок пока нет

- Anchor Bolt Design CriteriaДокумент45 страницAnchor Bolt Design CriteriaRicardoОценок пока нет

- 000 215 1221 A04 31mar05Документ11 страниц000 215 1221 A04 31mar05Felipe FloresОценок пока нет

- A FEDS Structural BoltsДокумент6 страницA FEDS Structural BoltsCrimsonPoshОценок пока нет

- Analysis and Design On Pipe RacksДокумент43 страницыAnalysis and Design On Pipe RacksAmanpreet Singh67% (3)

- Checklist of Support DesignДокумент2 страницыChecklist of Support DesignSakshi AgrawalОценок пока нет

- Bottom LugДокумент7 страницBottom LugAjiri IvoviОценок пока нет

- Non Critical Lines SupportingДокумент8 страницNon Critical Lines SupportingKKОценок пока нет

- Steelwise PDFДокумент3 страницыSteelwise PDFYan Naung KoОценок пока нет

- Din 6914-10.9Документ2 страницыDin 6914-10.9vpjagannaathОценок пока нет

- Technical Information HSL3Документ10 страницTechnical Information HSL3William VillamizarОценок пока нет

- Engineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe RacksДокумент8 страницEngineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe Racksger80Оценок пока нет

- Review of AISI Design Guide For Cold-Formed Steel Purlin Roof Framing SystemsДокумент17 страницReview of AISI Design Guide For Cold-Formed Steel Purlin Roof Framing SystemsapirakqОценок пока нет

- Clinton Glanville - CSG Facility Pipe Support Options Piping Stress Analysis Approach PDFДокумент23 страницыClinton Glanville - CSG Facility Pipe Support Options Piping Stress Analysis Approach PDFTKASHIQUEОценок пока нет

- Steel Buildings: Ferenc PappДокумент29 страницSteel Buildings: Ferenc PappThinn Thida HtayОценок пока нет

- White Paper DIN FittingsДокумент7 страницWhite Paper DIN FittingsSiddhant JoglekarОценок пока нет

- RRC 271 DДокумент64 страницыRRC 271 Drfuentes73Оценок пока нет

- SC348-ME-FDN-006 - RE - Foundation DrawingДокумент6 страницSC348-ME-FDN-006 - RE - Foundation DrawingsajanОценок пока нет

- Anchor Bolt Design PhilosophyДокумент6 страницAnchor Bolt Design Philosophyprabhu81100% (1)

- Paolacci Reza Bursi PDFДокумент23 страницыPaolacci Reza Bursi PDFMUHAMMAD UMAR RIAZОценок пока нет

- Design Model For Non-Bearing Column SplicesДокумент15 страницDesign Model For Non-Bearing Column SplicesBobaru MariusОценок пока нет

- SABP003 - Vertical Vessel Found DesignДокумент39 страницSABP003 - Vertical Vessel Found DesigngiovanniОценок пока нет

- Machine Foundation GuideДокумент64 страницыMachine Foundation GuideTarique MosharrufОценок пока нет

- Rational Design of Pipe Racks Used For Oil Sands and Petrochemical FacilitiesДокумент11 страницRational Design of Pipe Racks Used For Oil Sands and Petrochemical Facilitieseddie eddОценок пока нет

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Документ1 страницаASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjОценок пока нет

- Seismic Design of Structural Steel Pipe RacksДокумент5 страницSeismic Design of Structural Steel Pipe Racksandradeinsua0% (1)

- Design of Tail Lug & Basering Reinforcement-FLUORДокумент34 страницыDesign of Tail Lug & Basering Reinforcement-FLUORALONSO GOMEZ100% (1)

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Документ11 страницPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Tarek AbulailОценок пока нет

- Process Industry Practices PipingДокумент5 страницProcess Industry Practices Pipingalberto rodriguezОценок пока нет

- Structural Steel PTD ModuleДокумент91 страницаStructural Steel PTD ModulefaridОценок пока нет

- Engineering Standard For Industrial Stairs, Ladders, Platforms PDFДокумент97 страницEngineering Standard For Industrial Stairs, Ladders, Platforms PDFsri_amartОценок пока нет

- Pipe Rack Loading Data - 2 PDFДокумент55 страницPipe Rack Loading Data - 2 PDFGalih PrianggodoОценок пока нет

- Reiddc6a PDFДокумент31 страницаReiddc6a PDFETОценок пока нет

- Carbon Steel Pipe and Fittings PDFДокумент10 страницCarbon Steel Pipe and Fittings PDFavazcОценок пока нет

- AWWA D100 Tension TableДокумент1 страницаAWWA D100 Tension Tablejojo_323Оценок пока нет

- Itt Grinnell Pipe Hanger Design & Engineering 2008Документ80 страницItt Grinnell Pipe Hanger Design & Engineering 2008ITT GRINNELLОценок пока нет

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionДокумент4 страницыConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionVenu GopalОценок пока нет

- STRUMIS - Implementation Survey V2.0Документ11 страницSTRUMIS - Implementation Survey V2.0Mohammad AdilОценок пока нет

- Structural List of PipДокумент1 страницаStructural List of Pipstr_designОценок пока нет

- Steel Road Plate DesignДокумент1 страницаSteel Road Plate DesignAshraf KhanОценок пока нет

- MonorailДокумент14 страницMonorailZain AndabloОценок пока нет

- Pip STF-05520Документ7 страницPip STF-05520mahmoodhassan79563100% (2)

- Piperack PresentationДокумент23 страницыPiperack PresentationOmar AlkubaiciОценок пока нет

- .Analysis Fondasi DinamisДокумент30 страниц.Analysis Fondasi DinamisFerdinand PaneОценок пока нет

- Influence of Elastic Foundation Structures On The Rotor DynamicsДокумент8 страницInfluence of Elastic Foundation Structures On The Rotor DynamicsVodanh Tieutot100% (1)

- Optimized Skid Design For Compress Sor PackagesДокумент5 страницOptimized Skid Design For Compress Sor Packagessantosh kumarОценок пока нет

- Is 3177 1977Документ66 страницIs 3177 1977Avijit Dey100% (1)

- Statement Method For PDA TestДокумент15 страницStatement Method For PDA Testmarwan ayadОценок пока нет

- Optimized Skid Design For Compressor PackagesДокумент9 страницOptimized Skid Design For Compressor PackagesjdfdfererОценок пока нет

- Code Requirements For Certification of NDE PersonnelДокумент1 страницаCode Requirements For Certification of NDE PersonnelWaldomiroCanoОценок пока нет

- 175 Welding and Steel FabricationДокумент57 страниц175 Welding and Steel FabricationWaldomiroCanoОценок пока нет

- Mapeo ISO 17024Документ11 страницMapeo ISO 17024WaldomiroCanoОценок пока нет

- Palfinger 56000Документ3 страницыPalfinger 56000WaldomiroCanoОценок пока нет

- Pipe Support FluorДокумент79 страницPipe Support FluorWaldomiroCano100% (8)

- Maintenance Wagon-Tippler En-Rev3Документ34 страницыMaintenance Wagon-Tippler En-Rev3WaldomiroCano50% (2)

- Simpson CatalogДокумент235 страницSimpson Catalogasghar7Оценок пока нет

- G 75 - 95 Rzc1lvjfra - PDFДокумент22 страницыG 75 - 95 Rzc1lvjfra - PDFWaldomiroCanoОценок пока нет

- Dalamatic Insertable: Replacement Parts ListДокумент20 страницDalamatic Insertable: Replacement Parts ListWaldomiroCanoОценок пока нет

- D 5715 - 00Документ3 страницыD 5715 - 00ipkm123Оценок пока нет

- Large Hadron ColliderДокумент23 страницыLarge Hadron ColliderPrakhar AgrawalОценок пока нет

- Fundamentals of Noise and Vibration Analysis For Engineers: Second EditionДокумент9 страницFundamentals of Noise and Vibration Analysis For Engineers: Second EditionjeyaselvanОценок пока нет

- E 140Документ23 страницыE 140Luna Hernandez Ricardo100% (1)

- Solution Thermodynamics LecturesДокумент74 страницыSolution Thermodynamics LecturesS S S REDDY100% (1)

- LTB Part2 F14 OptДокумент15 страницLTB Part2 F14 OptNejib GhazouaniОценок пока нет

- Penerapan Metode Tuning Pid Ziegler-Nichols Dalam Pengendalian Temperature Crude Studi Kasus Di Epc Project PT Tripatra Engineers andДокумент13 страницPenerapan Metode Tuning Pid Ziegler-Nichols Dalam Pengendalian Temperature Crude Studi Kasus Di Epc Project PT Tripatra Engineers andDzhokarОценок пока нет

- Direct Shear Test of Soils Under Consolidated Drained ConditionsДокумент9 страницDirect Shear Test of Soils Under Consolidated Drained ConditionsKoppolu SrinivasuluОценок пока нет

- XSteam Excel v2.6Документ3 страницыXSteam Excel v2.6pchanycОценок пока нет

- Utkarsh ChromatographyДокумент17 страницUtkarsh ChromatographyUtkarsh Pratap SinghОценок пока нет

- MMT-002 2012Документ5 страницMMT-002 2012arocalistus6367Оценок пока нет

- Assignment 1 Solution (Doctor) PDFДокумент14 страницAssignment 1 Solution (Doctor) PDFAhmed KhairiОценок пока нет

- Chlor-Alkali Membrane Cell ProcessДокумент213 страницChlor-Alkali Membrane Cell Processdow2008Оценок пока нет

- Synthesis of Bicyclo (2.2.l) Heptene Diels-Alder AdductДокумент2 страницыSynthesis of Bicyclo (2.2.l) Heptene Diels-Alder AdductJacqueline FSОценок пока нет

- Catalogue Axces Silenciadores de EscapeДокумент47 страницCatalogue Axces Silenciadores de EscapeBenjamín AlainОценок пока нет

- Equilibrium Stage Processes - Perpindahan MassaДокумент30 страницEquilibrium Stage Processes - Perpindahan Massaj0haNN3sОценок пока нет

- Torsion of Reinforced Concrete MembersДокумент34 страницыTorsion of Reinforced Concrete Membersprabhu8150% (2)

- Mathcad FormulasДокумент2 страницыMathcad FormulasRicardo O. Casimiro Jr.Оценок пока нет

- Dynamic Analysis Using FEMДокумент47 страницDynamic Analysis Using FEMB S Praveen BspОценок пока нет

- Analytical Method ValidationДокумент14 страницAnalytical Method Validationyashpandya01100% (1)

- Experiment - 6 Four-Quadrant Operation of DC MotorДокумент12 страницExperiment - 6 Four-Quadrant Operation of DC Motoreng_abdelghany1979Оценок пока нет

- A Strategy To Determine A Heating CurveДокумент8 страницA Strategy To Determine A Heating CurveHatef HajianОценок пока нет

- Microbiological Precipitation of CaCO3 1999 PDFДокумент9 страницMicrobiological Precipitation of CaCO3 1999 PDFmsohailashrafОценок пока нет

- Delta Design TaskДокумент4 страницыDelta Design TaskErwin SutionoОценок пока нет

- 9701 s09 QP 32 PDFДокумент12 страниц9701 s09 QP 32 PDFtess_15Оценок пока нет

- Analyses of Fat Oil and Grease in Wastewater or Receiving WaterДокумент26 страницAnalyses of Fat Oil and Grease in Wastewater or Receiving WaterFlorin Sorin Bolboaca100% (1)

- Introduction To Multiaxial FatigueДокумент12 страницIntroduction To Multiaxial FatigueSankara RaoОценок пока нет

- Ap Physics 1investigation4conservationofenergy PDFДокумент17 страницAp Physics 1investigation4conservationofenergy PDFMir'atun Nissa QuinalendraОценок пока нет

- Equilibrium Powerpoint Physics 12 LectureДокумент25 страницEquilibrium Powerpoint Physics 12 LectureQueenielyn TagraОценок пока нет

- Position Control of AC Servomotor Using Internal Model Control StrategyДокумент5 страницPosition Control of AC Servomotor Using Internal Model Control Strategyhossein mohajeryОценок пока нет

- Seminar MehkaДокумент23 страницыSeminar MehkaRudi HermanaОценок пока нет