Академический Документы

Профессиональный Документы

Культура Документы

I) Typical Scenario Steps Under Normal Conditions

Загружено:

Cerón Niño SantiagoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

I) Typical Scenario Steps Under Normal Conditions

Загружено:

Cerón Niño SantiagoАвторское право:

Доступные форматы

Introduction

This document describes a typical scenario under tripping and some contingency procedures that we choose to examine closer for AutoConRig.

Scenario description

I) Typical Scenario Steps under normal conditions:

1. The Drilling Crew will start a manual (ordinary) tripping in. An ordinary drill bit will be connected to the drill string. NB 1: Circulation is not needed under tripping in. What is needed is filling the pipes with mud every 1000 m ca. Neither the mud pump(s) nor the Top drive are connected. 2. After a specified period of time (not during connection), the Operator Control stations will be powered off (hard stop), simulating a remote system power loss. 3. There will be agents as part of the control system that will recognize this and take over the control of the drilling machinery. 4 Major cases are reasonably possible: a. Drill bit above the casing shoe: Meaning that the situation is relatively safe, the reaction should follow these steps: i. The tripping in speed will be reduced to zero following a velocity curve, until stop. ii. Activate in slips sequence: e.g. Lower the drill string and Apply Park Brake. b. Drill bit slightly (less than ones stand) in the open hole section : Meaning that there is a risk of stuck pipe , the reaction should follow these steps: i. Pull out of hole until above the casing shoe following a velocity curve. ii. Velocity is reduced to zero following a velocity curve. iii. Activate in slips sequence as in a). c. Drill bit far in the open hole-section and at least 1 stand far from bottom hole: Meaning that there is a risk of stuck pipe, and that pull out of hole is less of an option, because that would take hours, and that it is possible to elevate and lower the stand. The reaction should follow these steps: i. Elevate or lower the block so that the upper stand is half under the drill floor.

Continuously elevate and lower the stand 10 m up and 10 m down. iii. If Top-drive connection can be detected (if possible, connect it automatically) do rotate at the same time. The RPM should follow a recommended curve. iv. If mud pump connection can be detected (if possible, connect it automatically), pump mud. The pump should be started following a recommended curve. d. Drill bit far in the open hole-section and less than 1 stand far from bottom hole: Meaning that there is a risk of stuck pipe, and that pull out of hole is less of an option, because that would take hours, and that it not possible to elevate and lower the stand. The reaction should follow these steps: i. Pull out of hole as much as the rigs physical implementation allows, in order to be able to get to case c (possibly with a reduced amplitude, minimum amplitude has to be ?? m). ii. Do like in case c. 4. After a while, the Operator Control Stations will be powered on again. When they come back online the driller will se an indicator showing that the drilling machinery is in Auto Controlled Rig mode. The Operator then disables the Auto Controlled Rig mode and restarts manual tripping in.

ii.

II) Alternative 1: Steps Under Pack off

Precondition: Case 3- c occurred, which gave a settled cutting problem. Due to bad hole cleaning, cuttings where not transported properly. After the manual tripping in step 4 (happens without circulation), cuttings fall back down the hole and pack-off around the drill string. 1. When reached the bottom hole, the Operator Control Stations will be powered off again. (NB! This situation is like case 3-d but with a possible pack-off). 2. The agents take over the control of the drilling machinery; recognize that the bit is at the bottom hole. 3. Start pull out of hole 1 stand, in order to get to case 3-c. 4. Detect a possible pack-off due to increasing drag ( can not detected by pump pressure because pump is not connected ) 5. Lower the drill string (opposite direction to pull). 6. Connect the mud pump and apply a reduced flow rate, observer the pump pressure two possible cases:

a. If pump pressure stabilized: i. Increase the flow rate to the recommended flow rate. ii. Continuously move the drill-string, within the distance from bottom hole. iii. Detect better hole condition iv. Pull out of hole 1 stand, in order to get to case 3-c. b. If pump pressure increases: i. Stop the pump following recommended procedure (curve). ii. Power on again. NB 2 Pack off detection and actions are covered in Drilltronics.

III) Alternative 2: Steps Under Kick

1. When reached the bottom hole the Operator decides to pull out of hole. 2. Due to wrong geo pressure predictions, the safe guards speed is higher than supposed, generating negative pressure pulls, which leads to gas influx. 3. Power off occurs. 4. The agents detect the power off and take control over the drilling machinery. 5. The agents detect a possible kick, by observing the mud volume change (Gains or Losses). 6. Connects the mud pump and circulates while moving the drill-string (equivalent to case 3-c.). Tow reasonably possible scenarios. a. Large gas Kick i. Well control situation ii. Activate the BOP b. Small gas Kick i. Continue circulating while moving the drill-string. NB 3 The gas kick scenario was covered by CODIO case study 1.

Introduccin Este documento describe un escenario tpico en los viajes y algunos procedimientos de contingencia que elegimos para examinar ms de cerca AutoConRig. Escenario Descripcin

Etapas en un escenario tpico en condiciones normales:

I)

El equipo de perforacin o cuadrilla iniciar un manual (ordinario) de viaje. Una broca ser conectada a la sarta de perforacin. NB 1: La Circulacin no se necesita para la condiciones del viaje. Lo que se necesita es llenar la tubera cada 2000 ft aprox. Ni las bombas de lodos ni el TDS se conectarn. Despus de un perodo especificado de tiempo (no incluye coneciones), el perforador har una parada rpida, para simular un sistema remoto de prdida de potencia.

II)

III)

Habr agentes como parte del sistema de control que reconocern esto - y asumirn el control de la perforacin. 4 casos ms importantes razonablemente posibles: a) Broca arriba del zapato: Significa que la situacin es relativamente segura, la reaccin debe seguir los siguientes pasos:

i. ii.

La velocidad del viaje se reduce a cero siguiendo una curva de velocidad, hasta parar. Activar la secuencia en las cuas: por ejemplo, Baje la sarta de perforacin y aplique el freno de parqueo. Broca en el open hole, menos de un stand : significa que hay un riesgo de stuck pipe, la reaccin debe seguir estos pasos: i. POOH hasta por encima del zapato siguiendo una curva de velocidad. ii. La velocidad se reduce a cero siguiendo una curva de velocidad. iii. Activar la secuencia en las cuas como en ii. Broca lejos en la seccin de open hole y/o ms de 1 stand encima del bottom hole: Lo que significa que hay un riesgo de stuck pipe, y que POOH no es una opcin, debido a que eso nos llevara horas, y que es posible levantar y bajar el stand. La reaccin debe seguir los siguientes pasos: i. Levantar o bajar el bloque de modo que la parada superior quede la mitad bajo la RT.

b)

c)

ii.

Continuamente levante 30 ft y baje 30 ft la parada (10 m up y 10 m hacia abajo).

Si posible conecte el TDS y rote al mismo tiempo. Las RPM deben seguir una curva recomendada. iv. Si posible conecte las bombas de lodos. Las bombas deben iniciar siguiendo una curva recomendada. d) Broca lejos en la seccin de open hole y menos que 1 stand encima del bottom hole: Lo que significa que hay un riesgo de stuck pipe, y que POOH no es una opcin, porque eso nos llevara horas, y que no es posible levantar y bajar el stand. La reaccin debe seguir los siguientes pasos:

i.

iii.

POOH tanto como la aplicacin de la plataforma fsica lo permita, con el fin de alcanzar el caso c (posiblemente con una amplitud reducida, la amplitud mnima tiene que ser? pies).

Es similar al caso c ?. iv) Despus de un tiempo, el operador re-activa la potencia. Cuando regresan en lnea - el perforador indicar que el taladro de perforacin est en modo "Auto Rig controlada" . El Operador a continuacin, desactiva la funcin "Auto Rig controlada" modo manual y se reinicia el viaje manual.

ii.

II) Alternative 1: Steps Under Pack off

II) Alternativa 1: Etapas previstas para el Empaquetamiento: Requisito: Caso 3 - c ocurrido, lo cual dio un problema de asentamiento de cortes. Debido a las malas condiciones de limpieza del hueco, los cortes no fueron transportados adecuadamente. Despus de que el manual de viajes en el paso 4 (que hacemos sin circulacin), los cortes caen hueco abajo y se presenta el packoff-alrededor de la sarta de perforacin. Cuando se llega al fondo del hueco, el Operador apaga de nuevo. (NB! Esta situacin es semejante al caso 3-d, pero con un posible pack-off). Los agentes toman el control de la perforacin; reconocen que la bit est en el bottom hole. Comience a POOH del hueco 1 stand, con el fin de llegar al caso 3-c.

Detectar un posible packoff debido al incremento del drag (no se puede detectar con la presin de la bomba porque la bomba no est conectada, sacando sin back-reaming) Baje la sarta de perforacin (en direccin opuesta a pull out. Conecte la bomba de lodo y aplique una rata de flujo reducido (KRS), observe en la presin de la la bomba dos casos posibles: Si la presin de la bomba se estabiliza:

Aumentar la velocidad de flujo a la velocidad de flujo recomendada. Continuamente mueva la sarta, dentro de la distancia desde el fondo. Detectar la mejor condicion del hueco. POOH 1 stand, con el fin de llegar al caso 3-c. Si la presin de la bomba se incrementa:

Parar la bomba siguiendo el procedimiento recomendado (de la curva). Encienda de Nuevo (Power on again) NB 2: deteccin del packoff y las acciones se tratan en Drilltronics III)

Alternative 2: Etapas previstas para un

Kick

Cuando se lleg al fondo del pozo el operador decide POOH. Debido a predicciones errneas de GEO-presines, la velocidad de los guardias de seguridad es mayor que lo supuesto, la generacin de presin negativa al sacar, conduce a la afluencia de gas. Apagado ocurre. Los agentes detectan el apagado y toman el control de la perforacin. Los agentes detectan una patada de pozo (kick), mediante la observacin del cambio en el volumen de lodo (ganancias o prdidas). Se conectan las bombas de lodo y se circula mientras se mueve la sarta de perforacin (equivalente al caso 3-c.). Escenarios posibles:

Kick gas grande Well control situacin Activar el BOP Kick gas Small Continuar circulando mientras se mueve la sarta. NOTA 3 El escenario patada gas fue cubierto por estudio de caso CODIO 1. Would you mind answering some questions to help improve translation quality? Google Translate for Business:Translator ToolkitWebsite TranslatorGlobal Market Finder

PACK-OFF EARLY WARNING Figure 3 shows pressure change as a function of time for six different pressure sensors( marked 1-6) distributed along the drillstring of a Gulf of Mexico well in 5400 ft of water that experienced a packoff while drilling at about 14520 ft. The sensor positioned deepest in the well registered the first pressure increase, and 5 min., later the increase was registered by a pressure sensor positioned further up the string. Next, 20 min., later, the third sensor noted the pack-off by measuring a pressure increase; 15 min., after that, the fourth sensor observed the pack-off passing up the annulus. Finally, the fifth sensor recorded a pressure increase, while the sixth and shallowest sensor showed a pressure decrease, which resulted from the reduction of the circulation rate by the driller in response to the annulus being packed off. The plot illustrates that the packoff occurred inside casing, somewhere between the fifth sensor (at 9520 ft) and the sixth sensor (at 8136 ft). Early warning of the event allowed the operator to perform response planning that helped minimize the effects of the mud losses associated with the pack-off.

Figure 3.-Annular pressure measurements recorded along the drillstring. The deepest sensor registered the first pressure increase, followed by subsequent pressure registration at the shallower sensors indicating the

onset of a pack.off, which eventually occurred between the fifth and sixth sensor.

Вам также может понравиться

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Lab Manual For Drilling SimulatorДокумент8 страницLab Manual For Drilling SimulatorLemony Snickit50% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Questions WellcontrolДокумент10 страницQuestions WellcontrolZ Babar KhanОценок пока нет

- Shut in ProceduresДокумент11 страницShut in ProceduresGhavban DavidОценок пока нет

- Generic Drill Stem Test ProcedureДокумент6 страницGeneric Drill Stem Test Procedureadi nugrohoОценок пока нет

- Workover Operations ManualДокумент17 страницWorkover Operations ManualAbdelhak Hadji100% (1)

- Drilling Simulator Lab Report FinalДокумент18 страницDrilling Simulator Lab Report Finalnasreldin3100% (1)

- LwsДокумент36 страницLwscrni rokoОценок пока нет

- Workover Operations ManualДокумент17 страницWorkover Operations ManualMoayad Bilal80% (5)

- Workover Operations ManualДокумент17 страницWorkover Operations ManualFawzi Al-RubasiОценок пока нет

- P and P Quiz 1 at 2Документ30 страницP and P Quiz 1 at 2Jeneesh ShanmughanОценок пока нет

- Volumetric-Lubricate-Stripping-Bullheading TechnicsДокумент38 страницVolumetric-Lubricate-Stripping-Bullheading TechnicsAmine MimoОценок пока нет

- 27 - Iwcf Ss Sample Questions - AnswersДокумент9 страниц27 - Iwcf Ss Sample Questions - Answersshoaib Khalil100% (1)

- IWCF Practice 1 (With Answer)Документ22 страницыIWCF Practice 1 (With Answer)syazwan80% (5)

- Well Control Drills and Exercises WIPER TRIPДокумент3 страницыWell Control Drills and Exercises WIPER TRIPmanuelperdomotОценок пока нет

- Drilling Simulation LabДокумент20 страницDrilling Simulation LabJacinto Siqueira100% (1)

- Bop Dril: Drills and TrainingДокумент3 страницыBop Dril: Drills and TrainingNazrul AminОценок пока нет

- Tripping Operations - Best PracticesДокумент3 страницыTripping Operations - Best PracticesYougchu Luan100% (1)

- 200 Drilling Engineering PDFДокумент10 страниц200 Drilling Engineering PDFJesus De la RosaОценок пока нет

- 22 - IWCF Review Questions 2014 - MSA PDFДокумент9 страниц22 - IWCF Review Questions 2014 - MSA PDFFoued NasriОценок пока нет

- Troubleshooting Mold FlashДокумент2 страницыTroubleshooting Mold FlashjazОценок пока нет

- 6 Well ControlДокумент11 страниц6 Well Controlahmed abdul razaqОценок пока нет

- Operator Questions - Docx Version 1Документ5 страницOperator Questions - Docx Version 1MOHIT TIWARIОценок пока нет

- L11-Leak Off Test, Kick Tolerance & Kick Circulation MethodsДокумент45 страницL11-Leak Off Test, Kick Tolerance & Kick Circulation MethodsLaxmi Kant PrasadОценок пока нет

- LD2 Drilling Practices & Lessons Learned - A.boubeniaДокумент8 страницLD2 Drilling Practices & Lessons Learned - A.boubeniaAli BoubeniaОценок пока нет

- Assessor Course Final Test Version 3Документ5 страницAssessor Course Final Test Version 3tunglx.seОценок пока нет

- Well Control Manual: Chapter 3 - Tripping ProceduresДокумент6 страницWell Control Manual: Chapter 3 - Tripping ProceduresMahrouz MadoОценок пока нет

- Cementing Procedures: Second Stage Cementing With Single Plug SystemДокумент3 страницыCementing Procedures: Second Stage Cementing With Single Plug SystemfarajОценок пока нет

- P and P As Topics1Документ43 страницыP and P As Topics1ahmed mohamed orabiОценок пока нет

- Plunger LiftДокумент17 страницPlunger LiftShelo Rosas100% (5)

- Exercise 3 AnswersДокумент13 страницExercise 3 AnswersadeelsnОценок пока нет

- Discharge 03Документ39 страницDischarge 03გიორგი არძენაძეОценок пока нет

- Iwcf l4 SupervisorДокумент42 страницыIwcf l4 SupervisorZakaria NacefОценок пока нет

- Procedure If Shallow Gas Is EncounteredДокумент5 страницProcedure If Shallow Gas Is EncounteredTaufik HidayatОценок пока нет

- Interview QuestionsДокумент4 страницыInterview QuestionsAbdelkader Fattouche100% (1)

- 7 X 9.625 With TSP, DWPДокумент5 страниц7 X 9.625 With TSP, DWPRahima RahoumaОценок пока нет

- Drilling 16 Inch Section - Best PracticesДокумент2 страницыDrilling 16 Inch Section - Best PracticesYougchu Luan100% (1)

- Well Killing ProceduresДокумент28 страницWell Killing ProceduresYeho ShuaОценок пока нет

- P AND P AS TOPICS1 Supervisor LevelДокумент37 страницP AND P AS TOPICS1 Supervisor LevelJaber AlbaajОценок пока нет

- Cover Letter PT AJSДокумент5 страницCover Letter PT AJSLEFRANCQОценок пока нет

- Oil Well Kicks Questions and Answers Part2Документ8 страницOil Well Kicks Questions and Answers Part2mariafernandamolinaoteroОценок пока нет

- Shallow Gas Recommended Practices Repsol - TIHS-1 Specific v.1Документ13 страницShallow Gas Recommended Practices Repsol - TIHS-1 Specific v.1Ricardo Hurtado HernándezОценок пока нет

- Mud LoggingДокумент16 страницMud LoggingShamia EssamОценок пока нет

- Drilling in Vietnam: Volume 2 - Drilling Operations Procedure ManualДокумент55 страницDrilling in Vietnam: Volume 2 - Drilling Operations Procedure ManualMotlatsi RaiyoОценок пока нет

- Mud LoggingДокумент15 страницMud Loggingspydaman4uОценок пока нет

- Drilling Note BookДокумент100 страницDrilling Note Booksalcedopozas100% (2)

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesДокумент3 страницыHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890Оценок пока нет

- The Tripping ProcessДокумент3 страницыThe Tripping ProcessFabrizioLaVitaОценок пока нет

- Dosing PumpДокумент10 страницDosing PumpniceseshaОценок пока нет

- 13A HPHT Procedure Presentation 20130420Документ21 страница13A HPHT Procedure Presentation 20130420JohnSmith100% (2)

- Well Control GuidelinesДокумент11 страницWell Control GuidelinesDian Sikumbang100% (1)

- Kick Drill While Drilling - Pit Drills ProcedureДокумент3 страницыKick Drill While Drilling - Pit Drills Proceduremontacer badreddine100% (1)

- 04-ATT (DP 2) - Ensure Safe Working Practices (A)Документ5 страниц04-ATT (DP 2) - Ensure Safe Working Practices (A)malikiauОценок пока нет

- Well Control SystemДокумент7 страницWell Control SystemKulodipОценок пока нет

- Appendixc Well Drilling ProcedureДокумент7 страницAppendixc Well Drilling Proceduremartahan manurungОценок пока нет

- SnubbingДокумент40 страницSnubbingFranky Alexander Siregar100% (2)

- 13 - Surf. Mock Test Pap - Sup - EquipДокумент49 страниц13 - Surf. Mock Test Pap - Sup - Equipcoldi123Оценок пока нет

- Well Control Questions and Answers Part 2Документ8 страницWell Control Questions and Answers Part 2Rizwan FaridОценок пока нет

- Bop Drill: Drills and TrainingДокумент2 страницыBop Drill: Drills and TrainingShofwan HilalОценок пока нет

- Emergency Planning PDFДокумент2 страницыEmergency Planning PDFCerón Niño SantiagoОценок пока нет

- Reach Assistance PDFДокумент2 страницыReach Assistance PDFCerón Niño SantiagoОценок пока нет

- Hydrablast Howco H02323 PDFДокумент2 страницыHydrablast Howco H02323 PDFCerón Niño SantiagoОценок пока нет

- Rig Evaluation Cover SheetДокумент29 страницRig Evaluation Cover SheetCerón Niño SantiagoОценок пока нет

- ALASKA Aquifer Aeo6a PDFДокумент4 страницыALASKA Aquifer Aeo6a PDFCerón Niño SantiagoОценок пока нет

- CaraCara6B - Service ReportДокумент3 страницыCaraCara6B - Service ReportCerón Niño SantiagoОценок пока нет

- GRAVEL Packer Tool OperationДокумент7 страницGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- Effect of Well Control On Constrained Sparse Spike Seismic InversionДокумент9 страницEffect of Well Control On Constrained Sparse Spike Seismic InversionCerón Niño SantiagoОценок пока нет

- Rig Evaluation Rules of Inspection: Item Action Safety Issue Assistance RequiredДокумент3 страницыRig Evaluation Rules of Inspection: Item Action Safety Issue Assistance RequiredCerón Niño SantiagoОценок пока нет

- IADC Well Control Audit/Test Subcommittee: August 27, 2008 Joe Levine MMSДокумент13 страницIADC Well Control Audit/Test Subcommittee: August 27, 2008 Joe Levine MMSCerón Niño SantiagoОценок пока нет

- Essential Tips For Well Control Success: Aberdeen Drilling SchoolsДокумент4 страницыEssential Tips For Well Control Success: Aberdeen Drilling SchoolsCerón Niño SantiagoОценок пока нет

- Wild Well Control - Technical Date BookДокумент57 страницWild Well Control - Technical Date Bookgabriel851007Оценок пока нет

- Rig Evaluation MiSWACO New-LogoDay 2Документ72 страницыRig Evaluation MiSWACO New-LogoDay 2Cerón Niño SantiagoОценок пока нет

- 00 - IWCF - Equipment B&W PDFДокумент19 страниц00 - IWCF - Equipment B&W PDFCerón Niño SantiagoОценок пока нет

- Spot Heavy MudДокумент1 страницаSpot Heavy MudCerón Niño SantiagoОценок пока нет

- Gavel Packer Technical GP Proposal Bengala 5 V1Документ16 страницGavel Packer Technical GP Proposal Bengala 5 V1Cerón Niño SantiagoОценок пока нет

- PETREVEN Eng PDFДокумент1 страницаPETREVEN Eng PDFCerón Niño SantiagoОценок пока нет

- Surface Stack Questions: IWCF Well Control Practice Test KeyДокумент2 страницыSurface Stack Questions: IWCF Well Control Practice Test KeyCerón Niño SantiagoОценок пока нет

- Drilling Rig ComponentsДокумент2 страницыDrilling Rig ComponentsCerón Niño SantiagoОценок пока нет

- Introduccion - W1 Lecture1 PDFДокумент49 страницIntroduccion - W1 Lecture1 PDFCerón Niño SantiagoОценок пока нет

- Tutorials in Complex Photonic Media SPIE Press Monograph Vol PM194 PDFДокумент729 страницTutorials in Complex Photonic Media SPIE Press Monograph Vol PM194 PDFBadunoniОценок пока нет

- Vocabulary Ladders - Grade 3 - Degree of FamiliarityДокумент6 страницVocabulary Ladders - Grade 3 - Degree of FamiliarityfairfurОценок пока нет

- Yahoo Tab NotrumpДокумент139 страницYahoo Tab NotrumpJack Forbes100% (1)

- Case Study Diverticulosis PaperДокумент12 страницCase Study Diverticulosis Paperapi-381128376100% (3)

- Histology Solution AvnДокумент11 страницHistology Solution AvnDrdo rawОценок пока нет

- Mohit Maru 4th Semester Internship ReportДокумент11 страницMohit Maru 4th Semester Internship ReportAdhish ChakrabortyОценок пока нет

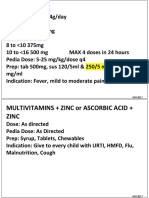

- CNS Drugs Pharmaceutical Form Therapeutic Group: 6mg, 8mgДокумент7 страницCNS Drugs Pharmaceutical Form Therapeutic Group: 6mg, 8mgCha GabrielОценок пока нет

- Caste & PoliticsДокумент4 страницыCaste & PoliticsGIRISHA THAKURОценок пока нет

- Presente Progresive TenseДокумент21 страницаPresente Progresive TenseAriana ChanganaquiОценок пока нет

- Lesson Plan in Science III ObservationДокумент2 страницыLesson Plan in Science III ObservationTrishaAnnSantiagoFidelОценок пока нет

- Ghosh, D. P., 1971, Inverse Filter Coefficients For The Computation of Apparent Resistivity Standard Curves For A Horizontally Stratified EarthДокумент7 страницGhosh, D. P., 1971, Inverse Filter Coefficients For The Computation of Apparent Resistivity Standard Curves For A Horizontally Stratified EarthCinthia MtzОценок пока нет

- 10 Fonts For A Better WebsiteДокумент3 страницы10 Fonts For A Better WebsiteAlyzza Kara AcabalОценок пока нет

- Medical Surgical Nursing Nclex Questions 5Документ18 страницMedical Surgical Nursing Nclex Questions 5dee_day_8Оценок пока нет

- A Management and Leadership TheoriesДокумент43 страницыA Management and Leadership TheoriesKrezielDulosEscobarОценок пока нет

- NURS 406 Concept Map HyperparathyroidismДокумент1 страницаNURS 406 Concept Map HyperparathyroidismshyannОценок пока нет

- Common RHU DrugsДокумент56 страницCommon RHU DrugsAlna Shelah IbañezОценок пока нет

- ENG101 Final Term NOTES by VU LearningДокумент15 страницENG101 Final Term NOTES by VU LearningAbdul WahabОценок пока нет

- Faust Part Two - Johann Wolfgang Von GoetheДокумент401 страницаFaust Part Two - Johann Wolfgang Von GoetherharsianiОценок пока нет

- Microsoft Official Course: Installing and Configuring Windows Server 2012Документ18 страницMicrosoft Official Course: Installing and Configuring Windows Server 2012jttodorovОценок пока нет

- Đại Từ Quan Hệ Trong Tiếng AnhДокумент5 страницĐại Từ Quan Hệ Trong Tiếng AnhNcTungОценок пока нет

- Disciplines, Intersections and The Future of Communication Research. Journal of Communication 58 603-614iplineДокумент12 страницDisciplines, Intersections and The Future of Communication Research. Journal of Communication 58 603-614iplineErez CohenОценок пока нет

- Introduction To Professional School Counseling Advocacy Leadership and Intervention Ebook PDF VersionДокумент62 страницыIntroduction To Professional School Counseling Advocacy Leadership and Intervention Ebook PDF Versionmary.krueger918100% (50)

- Victor Nee (Editor) - Richard Swedberg (Editor) - The Economic Sociology of Capitalism-Princeton University Press (2020)Документ500 страницVictor Nee (Editor) - Richard Swedberg (Editor) - The Economic Sociology of Capitalism-Princeton University Press (2020)Tornike ChivadzeОценок пока нет

- Edir AdminДокумент916 страницEdir AdminSELIMОценок пока нет

- Cambridge IGCSE: BIOLOGY 0610/31Документ20 страницCambridge IGCSE: BIOLOGY 0610/31Balachandran PalaniandyОценок пока нет

- The First Step Analysis: 1 Some Important DefinitionsДокумент4 страницыThe First Step Analysis: 1 Some Important DefinitionsAdriana Neumann de OliveiraОценок пока нет

- Mee2006 QaДокумент80 страницMee2006 QaJames Stallins Jr.100% (1)

- Does Moore Succeed in Refuting IdealismДокумент5 страницDoes Moore Succeed in Refuting IdealismharryОценок пока нет

- A Portrayal of Gender and A Description of Gender Roles in SelectДокумент429 страницA Portrayal of Gender and A Description of Gender Roles in SelectPtah El100% (1)

- An Improved Version of The Skin Chapter of Kent RepertoryДокумент6 страницAn Improved Version of The Skin Chapter of Kent RepertoryHomoeopathic PulseОценок пока нет

- Learn Spanish for beginners 6 in 1: Speak Spanish in an Easy Way with language lessons that You Can Listen to in Your Car. Vocabulary, Grammar, Conversations, and Spanish Short Stories up to Intermediate Level.От EverandLearn Spanish for beginners 6 in 1: Speak Spanish in an Easy Way with language lessons that You Can Listen to in Your Car. Vocabulary, Grammar, Conversations, and Spanish Short Stories up to Intermediate Level.Рейтинг: 5 из 5 звезд5/5 (1)

- Automatic Fluency Latin American Spanish for Conversation: Level 1: 8 Hours of Intense Spanish Fluency InstructionОт EverandAutomatic Fluency Latin American Spanish for Conversation: Level 1: 8 Hours of Intense Spanish Fluency InstructionРейтинг: 4.5 из 5 звезд4.5/5 (15)

- Spanish Short Stories: 20 Captivating Spanish Short Stories for Beginners While Improving Your Listening, Growing Your Vocabulary and Have FunОт EverandSpanish Short Stories: 20 Captivating Spanish Short Stories for Beginners While Improving Your Listening, Growing Your Vocabulary and Have FunРейтинг: 4.5 из 5 звезд4.5/5 (20)

- Spanish Short Stories: Immerse Yourself in Language and Culture through Short and Easy-to-Understand TalesОт EverandSpanish Short Stories: Immerse Yourself in Language and Culture through Short and Easy-to-Understand TalesРейтинг: 5 из 5 звезд5/5 (1)

- Learn Spanish with Paul Noble for Beginners – Complete Course: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachОт EverandLearn Spanish with Paul Noble for Beginners – Complete Course: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachРейтинг: 5 из 5 звезд5/5 (136)

- Meditación Guiada Para La Hora De Dormir: Hipnosis Para Sueño Profundo Con Música Para Aliviar El Estrés Diario, Relajarse, Reducir La Ansiedad, Y Lograr Mejores Noches De Descanso (Meditaciones Guiadas en Español - Guided Meditations in Spanish)От EverandMeditación Guiada Para La Hora De Dormir: Hipnosis Para Sueño Profundo Con Música Para Aliviar El Estrés Diario, Relajarse, Reducir La Ansiedad, Y Lograr Mejores Noches De Descanso (Meditaciones Guiadas en Español - Guided Meditations in Spanish)Рейтинг: 5 из 5 звезд5/5 (44)

- Learn Spanish: Mexican Spanish Survival Phrases, Volume 1: Lessons 1-25От EverandLearn Spanish: Mexican Spanish Survival Phrases, Volume 1: Lessons 1-25Рейтинг: 5 из 5 звезд5/5 (1)

- Spanish Short Stories for Beginners Book 3: Over 100 Dialogues and Daily Used Phrases to Learn Spanish in Your Car. Have Fun & Grow Your Vocabulary, with Crazy Effective Language Learning LessonsОт EverandSpanish Short Stories for Beginners Book 3: Over 100 Dialogues and Daily Used Phrases to Learn Spanish in Your Car. Have Fun & Grow Your Vocabulary, with Crazy Effective Language Learning LessonsРейтинг: 4 из 5 звезд4/5 (1)

- Learn Spanish Bundle - Easy Introduction for BeginnersОт EverandLearn Spanish Bundle - Easy Introduction for BeginnersОценок пока нет

- Practice Makes Perfect: Complete Spanish Grammar, Premium Fourth EditionОт EverandPractice Makes Perfect: Complete Spanish Grammar, Premium Fourth EditionРейтинг: 5 из 5 звезд5/5 (49)

- Learn Spanish with Paul Noble for Beginners – Part 1: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachОт EverandLearn Spanish with Paul Noble for Beginners – Part 1: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachРейтинг: 5 из 5 звезд5/5 (159)

- Conversational Phrases Spanish Audiobook: Level 1 - Absolute BeginnerОт EverandConversational Phrases Spanish Audiobook: Level 1 - Absolute BeginnerРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Spanish Short Stories For Beginners (Vol 1): Use short stories to learn Spanish the fun way with the bilingual reading natural methodОт EverandSpanish Short Stories For Beginners (Vol 1): Use short stories to learn Spanish the fun way with the bilingual reading natural methodРейтинг: 4 из 5 звезд4/5 (18)

- First Spanish Reader: A Beginner's Dual-Language BookОт EverandFirst Spanish Reader: A Beginner's Dual-Language BookРейтинг: 4.5 из 5 звезд4.5/5 (6)

- 3-Minute Mexican Spanish: Everyday Spanish for BeginnersОт Everand3-Minute Mexican Spanish: Everyday Spanish for BeginnersРейтинг: 4 из 5 звезд4/5 (11)

- Intermediate Spanish Short Stories: Take Your Vocabulary and Culture Awareness to the Next LevelОт EverandIntermediate Spanish Short Stories: Take Your Vocabulary and Culture Awareness to the Next LevelОценок пока нет

- Essential Spanish in 2 hours with Paul Noble: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachОт EverandEssential Spanish in 2 hours with Paul Noble: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachРейтинг: 4.5 из 5 звезд4.5/5 (49)

- Automatic Fluency Latin American Spanish for Conversation: Level 2: 4 Hours of Intense Spanish Fluency InstructionОт EverandAutomatic Fluency Latin American Spanish for Conversation: Level 2: 4 Hours of Intense Spanish Fluency InstructionРейтинг: 4.5 из 5 звезд4.5/5 (11)

- Easy Spanish Phrase Book NEW EDITION: Over 700 Phrases for Everyday UseОт EverandEasy Spanish Phrase Book NEW EDITION: Over 700 Phrases for Everyday UseРейтинг: 3 из 5 звезд3/5 (5)

- Learn Spanish - Level 1: Introduction to Spanish: Volume 1: Lessons 1-25От EverandLearn Spanish - Level 1: Introduction to Spanish: Volume 1: Lessons 1-25Рейтинг: 5 из 5 звезд5/5 (4)

- Learn Spanish For Beginners: 30 Days of Language Lessons- Rapidly Improve Your Grammar, Conversations& Dialogue+ Short Stories& Learn 1001 Common Phrases In Your Car& While You SleepОт EverandLearn Spanish For Beginners: 30 Days of Language Lessons- Rapidly Improve Your Grammar, Conversations& Dialogue+ Short Stories& Learn 1001 Common Phrases In Your Car& While You SleepОценок пока нет

- Spanish for Beginners: Learn the Basics of Spanish in 7 DaysОт EverandSpanish for Beginners: Learn the Basics of Spanish in 7 DaysРейтинг: 4 из 5 звезд4/5 (11)

- The Tragedy Of Romeo And Juliet: Bilingual Edition (English – Spanish)От EverandThe Tragedy Of Romeo And Juliet: Bilingual Edition (English – Spanish)Оценок пока нет

- Spanish for Beginners: Learn the Basics of Spanish in 7 DaysОт EverandSpanish for Beginners: Learn the Basics of Spanish in 7 DaysРейтинг: 5 из 5 звезд5/5 (3)

- Next Steps in Spanish with Paul Noble for Intermediate Learners – Complete Course: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachОт EverandNext Steps in Spanish with Paul Noble for Intermediate Learners – Complete Course: Spanish Made Easy with Your 1 million-best-selling Personal Language CoachРейтинг: 5 из 5 звезд5/5 (54)

- Learn Spanish: 3000 essential words and phrasesОт EverandLearn Spanish: 3000 essential words and phrasesРейтинг: 5 из 5 звезд5/5 (1)

- Real Spanish 102: 5 Hours of Intermediate, Real-Life Spanish Learning with the Language Guy® & His Native Spanish SpeakersОт EverandReal Spanish 102: 5 Hours of Intermediate, Real-Life Spanish Learning with the Language Guy® & His Native Spanish SpeakersРейтинг: 4.5 из 5 звезд4.5/5 (13)