Академический Документы

Профессиональный Документы

Культура Документы

Rtu Ind Engg Syllabus

Загружено:

manish_chaturvedi_6Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rtu Ind Engg Syllabus

Загружено:

manish_chaturvedi_6Авторское право:

Доступные форматы

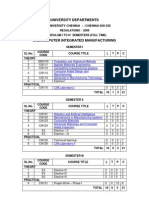

BRANCH: Industrial Engineering and Management YEAR: II THEORY S. No. 1. 2. 3. 4. 5. 6. Code No.

3IEM1 3IEM2 3IEM3 3IEM4 3IEM5 3IEM6 3IEM6.1 3IEM6.2 3IEM6.3 3IEM6.4 Subject Statistics and Probability Mechanics Of Solid Introduction to Industrial Management Manufacturing Processes and Materials Computer Programming Elective 1: (Any one of the Following) Engineering Mathematics and Numerical Analysis Environmental Sciences Entrepreneurship Development Electrical and Electronics Engineering Total 3 3 3 2 2 3 L

SEMESTER: III T 1 1 0 0 1 0 MM 100 100 100 100 100 100 Ex. Hrs. 3 3 3 3 3 3

16

600

PRACTICALS AND SESSIONALS S. No. 7. 8. 9. 10. 11. 12 13. Code No. 3IEM7 3IEM8 3IEM9 3IEM10 3IEM11 3IEM12 3IEMDC Subject Computer Lab -1 Material Science Lab Industrial Engineering Lab - 1 Production Practice -1 Strength of Materials Lab Statistics Lab - I Discipline and Extra Curricular Activities T/S 0 0 0 0 0 0 0 Total 0 P MM 50 50 75 50 50 75 50 400 1000

3 2/2 3 3 2/2 3 0 13 Grand Total

BRANCH: Industrial Engineering and Management YEAR: II THEORY S. Code No. No. 1. 4IEM1 2. 4IEM2 3. 4. 5. 6. 4IEM3 4IEM4 4IEM5 4IEM6 4IEM6.1 4IEM6.2 4IEM6.3 4IEM6.4 Subject Engineering Thermodynamics Managerial Accounting, Finance and Economics Theory of Machines Methods Engineering and Work Measurement Communications Skill Elective 1: (Any one of the Following) Measurements of Metrelogy Metallurgy and Heat Treatment Machine Design Advanced Mathematics Total 3 3 3 3 2 2 L

SEMESTER: IV T 1 1 1 0 1 0 MM 100 100 100 100 100 100 Ex. Hrs. 3 3 3 3 3 3

16

600

PRACTICALS AND SESSIONALS S. No. 7. 8. 9. 10. 11. 12 13. Code No. 4IEM7 4IEM8 4IEM9 4IEM10 4IEM11 4IEM12 4IEMDC Subject Computer Lab - II Thermal Engineering lab Industrial Engineering Lab - II Production Practice -II Theory of Machines Lab Communication Lab Discipline and Extra Curricular Activities T/S 0 0 0 0 0 0 0 Total 0 P MM 50 50 75 75 50 50 50 400 1000

3 3 3 3 2/2 2/2 0 13 Grand Total

BRANCH: Industrial Engineering and Management YEAR: III THEORY S. No. 1. 2. 3. 4. 5. 6. Code No. 5IEM1 5IEM2 5IEM3 5IEM4 5IEM5 5IEM6 Subject Operations Research - I Management Information System Quality Engineering and Management Strategic Management Materials Management Reliability and Maintainability Engineering Total 3 3 3 3 3 3 18 L

SEMESTER: V T 1 1 1 0 0 1 4 MM 100 100 100 100 100 100 600 Ex. Hrs. 3 3 3 3 3 3 -

PRACTICALS AND SESSIONALS S. No. 7. 8. 9. 10. 11. Code No. 5IEM7 5IEM8 5IEM9 5IEM10 5IEMDC Subject Operations Research Lab Industrial Engineering Lab - III Simulation Lab-1 Practical Training - 1 Discipline and Extra Curricular Activities T/S 0 0 0 0 0 Total 0 P MM 75 100 100 75 50 400 1000

2 3 3 2 0 10 Grand Total

BRANCH: Industrial Engineering and Management YEAR: III THEORY S. Code No. No. 1. 6IEM1 2. 6IEM2 3. 6IEM3 4. 5. 6. 6IEM4 6IEM5 6IEM6 Subject Total Quality Management Network Flow Models and Applications Human Resource Management and Organizational Behaviour Marketing Management Design and Analysis of Experiments Working Capital Management 3 3 3 3 2 2 L

SEMESTER: VI T 1 1 0 0 1 0 3 MM 100 100 100 100 100 100 600 Ex. Hrs. 3 3 3 3 3 3 -

Total 16

PRACTICALS AND SESSIONALS S. No. 7. 8. 9. 12 13. Code No. 6IEM7 6IEM8 6IEM9 6IEM10 6IEMDC Subject Computer Lab III SQC Lab DOE Lab Statistics Lab -II Discipline and Extra Curricular Activities T/S 0 0 0 0 0 Total 0 P MM 75 100 100 75 50 400 1000

3 3 3 2 0 13 Grand Total

BRANCH: Industrial Engineering and Management YEAR: IV THEORY S. No. 1. 2. 3. 4. 5. 6. Code No. 7IEM1 7IEM2 7IEM3 7IEM4 7IEM5 7IEM6 Subject 3 3 3 3 2 2 L

SEMESTER: VII T 1 1 0 0 1 0 MM 100 100 100 100 100 100 Ex. Hrs. 3 3 3 3 3 3

Manufacturing Planning and Control Operations Research - II Computer Aided Manufacturing Supply-Chain Management Business Process Reengineering Elective: (Any one of the Following) 7IEM6.1 System Design 7IEM6.2 Neural Nets, Fuzzy systems and Applications 7IEM6.3 Optimization Techniques

Total 16

600

PRACTICALS AND SESSIONALS S. No. 7. 8. 9. 10 11. Code No. 7IEM7 7IEM8 7IEM9 7IEM10 7IEMDC Subject CAM Lab - I Simulation lab - II Minor Project Practical Training -II Discipline and Extra Curricular Activities T/S 0 0 0 0 0 Total 0 P MM 100 100 75 75 50 400 1000

3 3 4 3 0 13 Grand Total

BRANCH: Industrial Engineering and Management YEAR: IV THEORY S. Code No. No. 1. 8IEM1 2. 8IEM2 3. 8IEM3 Subject Modelling and Optimization in FMS Project Management Elective 1: i. World Class Manufacturing System ii. Research Methodology iii. Management of Intellectual Property Rights Elective 2: (Any one of the Following) Engineering Ethics and Leadership Artificial Intelligence Introduction to Stochastic Models 4 4 4 L

SEMESTER: VIII T 1 1 0 MM 100 100 100 Ex. Hrs. 3 3 3

4.

8IEM4

100

Total 16

400

PRACTICALS AND SESSIONALS S. No. 5. 6. 7. 8. 9 Code No. 8IEM5 8IEM6 8IEM7 8IEM8 8IEMDC Subject CAM Lab -II System Modeling lab Project Seminar Discipline and Extra Curricular Activities T/S 0 0 0 0 0 Total 0 P MM 100 100 200 200 50 600 1000

3 3 2 4 0 12 Grand Total

5IEM1: Operations Research - 1 3L + 1T

UNIT 1:Overview of Operations Research: Linear Programming: LP formulation, graphical method, simplex method, duality and Sensitivity analysis, Transportation Model, Assignment Model.

MM: 100

Ex. Hrs. 3

UNIT 2:Integer Linear Programming, Branch & Bound Algorithms zero one Implicit Enumeration cutting Plane Algorithms. Replacement Models: Capital equipment replacement with time, group replacement of items subjected to total failure.

UNIT 3:Queuing Theory: Analysis of the following queues with Poisson pattern of arrival and exponentially distributed service times, Single channel queue with infinite customer population, Multichannel queue with infinite customer population, Single channel queue with finite customer population, Multichannel queue with finite customer population, Analysis of the queue with unlimited and limited system capacity.

UNIT 4:Simulation: Need of simulation, advantages and disadvantages of simulation method of simulation. Generation of Random numbers, Generation of Normal Random numbers, Generation of random numbers with any given distribution. Use of random numbers for system simulation, Application of simulation for solving queuing Inventory Maintenance, Scheduling and other industrial problems.

UNIT 5:Competitive Situations and Solutions: Game theory, two person zero sum game, approximate solution, simplified analysis for other competitive situations. Theory of Decision-Making: Decision making under certainty, risk and uncertainty, decision trees.

3L + 1T

5IEM2: Management Information System MM: 100 Ex. Hrs. 3

Unit 1:Introduction: MIS and information systems; Management support system and classifications Unit 2:Role of MIS: Strategic advantage with MIS; Systems approach to problem solving; Business Process Reengineering (BPR); Internet worked enterprise in MIS: Internet, Intranet, Extranet; Enterprise communication and collaboration Unit 3:Decision support systems: MIS support for decision making; Decision support systems; Tools of business support systems: what if analysis, sensitivity analysis, goal seek analysis, optimisation analysis, data mining for decision support Unit 4:Developing MIS systems: System Development Cycle; System Analysis; System Design (DFD and ER diagrams)

Unit 5:Applications: Cross-functional MIS; ERP; CRM; SCM; Transaction processing; Artificial intelligent technologies in business: neural network, fuzzy logic, genetic algorithm, virtual reality; Executive Information System; Expert Support Systems; Security and Ethical challenges

5IEM3: Quality Engineering and Management 3L + 1T MM: 100 Ex. Hrs. 3

Unit 1:Quality: Quality conception, quality of design quality of conformance, cost of quality and value of quality, quality objectives, role of Statistical Quality Control for fulfilment of quality objectives; organisation for quality factors influencing quality. Zero defects. Control Chart philosophy: Statistical Concepts; frequency distributions: averages and measures of dispersion; statistics and parameters; normal curve; estimating parameters. Control-chart limit factors; Shewharts normal bowl; lack of control; interpreting patterns of variation. Unit 2:X bar and R control-chart : objectives; subgrouping; recording measurements; plotting control charts; drawing conclusions; revising control limits; use of computer software The Control Chart for Faction Rejected p chart; trial limits; standard values; revising control limits; steps for control-chart set-up; np chart; interpretation of lack of control. Unit 3:The control Chart for Nonconformity: c chart; u chart; probability limits; Demerit control chart. Pareto Analysis Cause and Effect Analysis; weighting non-conformities. Cumulative Sum Control Charts, mask construction; Average Run Length, EWMA control charts, comparison of X bar, CUSUM and EWMA control charts. Unit 4:Process Evaluation and Control by Designs of Experiment: Various basic designs; Special Methods like EVOP, RSM and ROBUST Designs Other statistical process control techniques : SPC for short production run; X bar & R chart, attribute control chart for short production run; modified control limits for for x bar chart, acceptance control chart; group control charts for multiple-stream processes; precontrol. Unit 5:Fundamental Concepts in Acceptance Sampling, operating characteristic curves; attribute and variable plans, design of sampling plans, single; double; and multilevel plans. BIS sampling standards IS 2500 Part I & II. Continuous Sampling plans, Sequential sampling plans.

3L

5IEM4: Strategic Management MM: 100

Ex. Hrs. 3

Unit 1:Introduction: Strategic management (SM) , Business Policy (BP) and Business Plan; Basic concepts of SM; Impact of Globalisation and e-Com; Theories of organisational adaptation; Creating a learning organisation; Basic model of SM; Strategic decision making; Impact of Internet; Firm and its environment.

Unit 2:Scanning the environment: Environmental scanning; Industry analysis; Competitive intelligence; Forecasting; Synthesis of external factors; ETOP Study. Internal scanning: Organisational analysis; resource-based approach; value chain analysis; Scanning functional resources; Strategic audit; Unit 3:Strategy formulation: Situational analysis: SWOT analysis, TOWS Matrix; Corporate strategy; Strategies for growth and diversification; Process of strategic planning; Stages of corporate development; Portfolio analysis; Corporate parenting; Functional strategy; Core competencies; Strategic choice.

Unit 4:Strategy implementation and control: Organising for action; Developing programmes, budgets and procedures; How strategy to be implemented? Strategy implementation through structure, values, and ideologies; McKinseys 7s framework; Acquisition of resources and competence; Organization life cycle; Management & Control, Activitybased costing; Strategic Information Systems Unit 5:Other strategic issues: Strategic issues in managing technology and innovation; Strategic issues in entrepreneurial ventures and small businesses; Strategic issues in not-for-profit organisations

3L

5IEM5: Materials Management MM: 100

Ex. Hrs. 3

Unit 1:Materials Management Concepts and objectives for material function, Administrative practices, Purchasing system, Purchasing cycle, Make or buy decisions, Vendor development and evaluation, Reciprocity and ethics in purchasing. Unit 2:Inventory control and management, Purchase negotiations and pricing - purchase procedures, Policy and procedure manuals.

Unit 3:Demand Forecasting, Roles and Applications of management Science, Value analysis Unit 4:Import and canalisation, Legal aspects and considerations, Technological developments. Unit 5:Spare parts management, Store layout and management traffic and transportation, Physical distribution, Disposal of scrap, Standardisation, Computer applications in purchasing and Inventory control, Evaluating materials management function. MIS for materials management, Materials budgetory control.

5IEM6: Reliability and Maintainability Engineering 3L + 1T MM: 100 Ex. Hrs. 3

Unit 1:Maintenance in context: maintenance and profitability, terro-technology, application of terro-technology. Principles: the structure of plant, reason for nature of maintenance work, the production maintenance system a dynamic model. Unit 2:Establishing a maintenance plan-preliminary consideration: items, classification of items, maintenance procedure, guidelines for machine procedures to items. Maintenance planning and control: Basic requirements, Management information, labour costs, computer based Management information system, work planning and work control, basic rules for success. Unit 3:Introduction: Reliability concepts and patterns of failure, reliability Management, reliability, for system effectiveness. Reliability and hazard rates: Failure data, reliability function, failure rate and hazard rate, common distributions in failure mechanisms experimental, Welbull, gamma, Normal, log normal, extreme value, model selection for components failure, failure analysis. Unit 4:Reliability prediction and analysis: reliability prediction based on exponential distribution, system reliability analysis block diagram method, fault tree and success tree methods, event tree method, failure model, failure mechanism. Unit 5:Reliability design: Design for reliability, design process, assessment methodology, reliability allocation, reliability improvement, selection of components to improve system reliability.

Вам также может понравиться

- Instrumentation EngineeringДокумент34 страницыInstrumentation Engineeringvaithy1990Оценок пока нет

- Computer-Controlled Systems: Theory and Design, Third EditionОт EverandComputer-Controlled Systems: Theory and Design, Third EditionРейтинг: 3 из 5 звезд3/5 (4)

- M - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem) - 2Документ105 страницM - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem) - 2ProfessorTextech100% (1)

- DLL Eapp 3RDДокумент4 страницыDLL Eapp 3RDJf UmbreroОценок пока нет

- Sternberg Cognitive Psychology 2010-2011Документ26 страницSternberg Cognitive Psychology 2010-2011Kate Corrales100% (2)

- Performance TaskДокумент2 страницыPerformance TaskMelissaKarenNisolaVilegano67% (3)

- Cell Unit PlanДокумент7 страницCell Unit Planapi-354943357Оценок пока нет

- Command-Words-All 3 LevelsДокумент11 страницCommand-Words-All 3 LevelsSenumi Fonseka100% (1)

- Introduction EmceeДокумент4 страницыIntroduction Emceeversmajardo100% (2)

- Power SystemsДокумент47 страницPower Systemsmanish_chaturvedi_6Оценок пока нет

- Operation Research NotesДокумент98 страницOperation Research Notessagar kadam100% (2)

- Six Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneОт EverandSix Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneОценок пока нет

- Strategic Plan 2008 2016Документ158 страницStrategic Plan 2008 2016Kliu Senior Selestre VillanuevaОценок пока нет

- (B.E. Production Engineering Sem - VII & VIII) : Revised Syllabus ofДокумент41 страница(B.E. Production Engineering Sem - VII & VIII) : Revised Syllabus ofAbhinandan KolhapureОценок пока нет

- M.E. Industrial Engineering SyllabusДокумент46 страницM.E. Industrial Engineering SyllabusJoswa CaxtonОценок пока нет

- University of Kerala: Syllabus For Vii SemesterДокумент43 страницыUniversity of Kerala: Syllabus For Vii SemesterSreekanthKottavilayilОценок пока нет

- Mtech Iem 2013Документ12 страницMtech Iem 2013Jaykrishnan GopalakrishnanОценок пока нет

- Puter Integrated Manufacturing SyllabusДокумент41 страницаPuter Integrated Manufacturing SyllabusJoswa CaxtonОценок пока нет

- Mechanical Engineering: University of CalicutДокумент20 страницMechanical Engineering: University of CalicutJacob JoseОценок пока нет

- Rajasthan Technical University (RTU) : M. Tech Program in Mechanical Engineering With Specialization inДокумент6 страницRajasthan Technical University (RTU) : M. Tech Program in Mechanical Engineering With Specialization invipinyadavkumarОценок пока нет

- Cse Vi Operations Research (10cs661) NotesДокумент98 страницCse Vi Operations Research (10cs661) NotesRajesh KannaОценок пока нет

- University Departments: Anna University Chennai:: Chennai 600 025Документ42 страницыUniversity Departments: Anna University Chennai:: Chennai 600 025Jeyaram KumarОценок пока нет

- Advanced Manufacturing SystemsДокумент23 страницыAdvanced Manufacturing SystemsDhanish KumarОценок пока нет

- SchemeДокумент2 страницыSchemesshridhar2008Оценок пока нет

- M.e.,cim SyllabusДокумент44 страницыM.e.,cim SyllabusSiva PrakashОценок пока нет

- 4-1 Syllabus PDFДокумент8 страниц4-1 Syllabus PDFJohn CenaОценок пока нет

- I 0 PrinciplesAutomationTechnology PDFДокумент5 страницI 0 PrinciplesAutomationTechnology PDFZoran LalkovicОценок пока нет

- M.E Cse PDFДокумент51 страницаM.E Cse PDFLatha MugunthanОценок пока нет

- Lbs College of Engineering: KasaragodДокумент14 страницLbs College of Engineering: KasaragodshobithОценок пока нет

- A Simulation Approach For Productivity Improvement of An IC FactoryДокумент8 страницA Simulation Approach For Productivity Improvement of An IC Factorycsrajmohan2924Оценок пока нет

- B.Tech 4 1syllabus 1 PDFДокумент60 страницB.Tech 4 1syllabus 1 PDFGm LakshmanОценок пока нет

- Research Reprot 1Документ7 страницResearch Reprot 1Siyeon YeungОценок пока нет

- Mtech Se July2011 PDFДокумент50 страницMtech Se July2011 PDFsavitrinaikОценок пока нет

- s7 Mechnical Strem Production Eng1479454356Документ59 страницs7 Mechnical Strem Production Eng1479454356Manjunath NadarajanОценок пока нет

- CRP 7th 8th Syllabus..Документ34 страницыCRP 7th 8th Syllabus..Archana MaskeОценок пока нет

- Manufact Engg FДокумент31 страницаManufact Engg FtskcbeОценок пока нет

- ManfДокумент34 страницыManfAnantha NarayananОценок пока нет

- Cse VI Operations - Research - 10cs661 Notes - Unlocked PDFДокумент98 страницCse VI Operations - Research - 10cs661 Notes - Unlocked PDFNagarjuna JОценок пока нет

- T.E.printing SyllabusДокумент30 страницT.E.printing Syllabusmayur13Оценок пока нет

- Thesis Index MyPhDvol1Документ8 страницThesis Index MyPhDvol1amittechnosoftОценок пока нет

- knrS7 & S8Документ94 страницыknrS7 & S8Raavan LankaОценок пока нет

- 7th 8th Syll With Objectivesa21.11.09acmДокумент36 страниц7th 8th Syll With Objectivesa21.11.09acmKiran KumarОценок пока нет

- 3 Sem Mtech Cad Cam MpccetДокумент5 страниц3 Sem Mtech Cad Cam MpccetEL-Sayed HamedОценок пока нет

- FYCSДокумент10 страницFYCSrehan shaikhОценок пока нет

- SeДокумент3 страницыSeAnju SainiОценок пока нет

- 4278 JNTUA CSE 3-1 R15 Syllabus PDFДокумент22 страницы4278 JNTUA CSE 3-1 R15 Syllabus PDFDasari ChanduОценок пока нет

- Semester 4 McaДокумент9 страницSemester 4 McaSreekanth JayanОценок пока нет

- Course Curriculum of The Department of Industrial and Production EngineeringДокумент24 страницыCourse Curriculum of The Department of Industrial and Production EngineeringRashedul Islam RanaОценок пока нет

- S8 Industrial Syllabus (2007-2011 Batch)Документ5 страницS8 Industrial Syllabus (2007-2011 Batch)PraveenCETОценок пока нет

- Karanataka State Open University: M Tech in Mechanical (Computer Integrated Manufacturing)Документ35 страницKaranataka State Open University: M Tech in Mechanical (Computer Integrated Manufacturing)nav1278Оценок пока нет

- MechanicalДокумент4 страницыMechanicalAnish SukumarОценок пока нет

- VTU 5th Sem SyllabusДокумент27 страницVTU 5th Sem SyllabusSubash PrakashОценок пока нет

- B.tech-Cse (Bs Abdurahman Univ)Документ127 страницB.tech-Cse (Bs Abdurahman Univ)Mohd Faizan AhmadОценок пока нет

- MRSPTU 8th Sem Syllabus 2020Документ4 страницыMRSPTU 8th Sem Syllabus 2020PiyushОценок пока нет

- UVCE CSE SyllabusДокумент55 страницUVCE CSE Syllabusaryan171100% (2)

- Faculty of Engineering, University of Pune Mca 2008 Course Structure For Third Year Semister VДокумент17 страницFaculty of Engineering, University of Pune Mca 2008 Course Structure For Third Year Semister Va_sumant4uОценок пока нет

- MCA CourseДокумент44 страницыMCA CourseChandrakant ChatterjeeОценок пока нет

- M.E. Software Engineering SyallabusДокумент34 страницыM.E. Software Engineering SyallabusDarwin V TomyОценок пока нет

- VII Semester Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsДокумент22 страницыVII Semester Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsMurali Krishna GbОценок пока нет

- IT Course Syllabus For DIT UniversityДокумент68 страницIT Course Syllabus For DIT UniversitykaashОценок пока нет

- VTH Sem Ece 2006 SYLLABUSДокумент91 страницаVTH Sem Ece 2006 SYLLABUSSanketh GowdaОценок пока нет

- Modern Data Mining Algorithms in C++ and CUDA C: Recent Developments in Feature Extraction and Selection Algorithms for Data ScienceОт EverandModern Data Mining Algorithms in C++ and CUDA C: Recent Developments in Feature Extraction and Selection Algorithms for Data ScienceОценок пока нет

- Design Automation of Cyber-Physical SystemsОт EverandDesign Automation of Cyber-Physical SystemsMohammad Abdullah Al FaruqueОценок пока нет

- Ph.D. Pre Synopsis Seminar Examination ReportДокумент4 страницыPh.D. Pre Synopsis Seminar Examination Reportmanish_chaturvedi_6Оценок пока нет

- PHD Thesis Format and GuidelinesДокумент15 страницPHD Thesis Format and GuidelinesPranayОценок пока нет

- Ph.D. Pre Synopsis Seminar Examination ReportДокумент4 страницыPh.D. Pre Synopsis Seminar Examination Reportmanish_chaturvedi_6Оценок пока нет

- PHD Oral Defence Evaluation FormДокумент2 страницыPHD Oral Defence Evaluation Formmanish_chaturvedi_6Оценок пока нет

- PHD Thesis Evaluation FormДокумент2 страницыPHD Thesis Evaluation Formmanish_chaturvedi_6Оценок пока нет

- Half Yearly Exam - Class3 - ComputerДокумент5 страницHalf Yearly Exam - Class3 - Computermanish_chaturvedi_6Оценок пока нет

- Half Yearly Exam English - IДокумент2 страницыHalf Yearly Exam English - Imanish_chaturvedi_6Оценок пока нет

- Half Yearly Exam - Class 3 - English 1Документ3 страницыHalf Yearly Exam - Class 3 - English 1manish_chaturvedi_6Оценок пока нет

- Ist Year Branchwise Batch AllottmentДокумент1 страницаIst Year Branchwise Batch Allottmentmanish_chaturvedi_6Оценок пока нет

- Half Yearly Exam English - IДокумент2 страницыHalf Yearly Exam English - Imanish_chaturvedi_6Оценок пока нет

- Department of Biochemical Engineering and Biotechnology Indian Institute of Technology Delhi Hauz Khas, New Delhi 110 016Документ2 страницыDepartment of Biochemical Engineering and Biotechnology Indian Institute of Technology Delhi Hauz Khas, New Delhi 110 016manish_chaturvedi_6Оценок пока нет

- Mobile Anti Ragging SquadДокумент1 страницаMobile Anti Ragging Squadmanish_chaturvedi_6Оценок пока нет

- List of Recognised Supervisor 2015-16Документ3 страницыList of Recognised Supervisor 2015-16manish_chaturvedi_6Оценок пока нет

- Curricula in Islamic SciencesДокумент10 страницCurricula in Islamic SciencesismailОценок пока нет

- It - New CompleteДокумент15 страницIt - New CompleteIlayaraja ChinnasamyОценок пока нет

- Topic: Difference Between: Inferential Research, Unlike DescriptiveДокумент2 страницыTopic: Difference Between: Inferential Research, Unlike DescriptiveEric CasanasОценок пока нет

- सी एस शेषाद्रीДокумент5 страницसी एस शेषाद्रीसौर काशीОценок пока нет

- Book Clubs: 5th Grade Reading LessonДокумент8 страницBook Clubs: 5th Grade Reading Lessonapi-572009901Оценок пока нет

- Self-Assessment For Leading As A ManagerДокумент6 страницSelf-Assessment For Leading As A Managerbaodai85Оценок пока нет

- Summer Internship Program at Roverco Apparel Company PVTДокумент11 страницSummer Internship Program at Roverco Apparel Company PVTNagasai ReddyОценок пока нет

- QUESTION DJJ1043 EOC 2docx - NAME MATRIC BORANG KELULUSAN PENILAIAN BERTERUSANДокумент11 страницQUESTION DJJ1043 EOC 2docx - NAME MATRIC BORANG KELULUSAN PENILAIAN BERTERUSANFariz ApexОценок пока нет

- NSG 300c Rs ClinicalevaluationtoolДокумент9 страницNSG 300c Rs Clinicalevaluationtoolapi-496082612Оценок пока нет

- Seminars and Field TripsДокумент2 страницыSeminars and Field TripsShadôw ChasêrОценок пока нет

- AMU PHD Admission Test List 2010Документ5 страницAMU PHD Admission Test List 2010Azam SikandarОценок пока нет

- Shashankgprollno112 130507091013 Phpapp01Документ62 страницыShashankgprollno112 130507091013 Phpapp01Dola SahaОценок пока нет

- Board of Intermediate Education Karachi: Registration /application Form For Assignment of Examination DutiesДокумент2 страницыBoard of Intermediate Education Karachi: Registration /application Form For Assignment of Examination DutiesAbrar FaqeehОценок пока нет

- Employee Self & Peer-Assessment Works 2 Semester: Sunshine Joy DG. ChiapcoДокумент5 страницEmployee Self & Peer-Assessment Works 2 Semester: Sunshine Joy DG. ChiapcoAna Theresa TadeoОценок пока нет

- Science 5 Q1 WK7Документ12 страницScience 5 Q1 WK7ivy loraine enriquezОценок пока нет

- Siyanda Ntombela 222035138 (EDHS LSSN 2Документ7 страницSiyanda Ntombela 222035138 (EDHS LSSN 2silondilenoxolo85Оценок пока нет

- Name of Applicant: Personal DetailsДокумент4 страницыName of Applicant: Personal DetailsBALACHANDAR SОценок пока нет

- Info 1Документ2 страницыInfo 1IanEmmanuel PomzОценок пока нет

- Janice Pinote ReactionДокумент18 страницJanice Pinote ReactionjaniceОценок пока нет

- Object Oriented Project On Online Registrar SystemДокумент30 страницObject Oriented Project On Online Registrar SystemMasrie HabtieОценок пока нет

- Lesson Plan 1 2Документ6 страницLesson Plan 1 2api-299108629Оценок пока нет

- Senior Accountant Auditor MBA in Houston TX Resume Rochelle ButlerДокумент3 страницыSenior Accountant Auditor MBA in Houston TX Resume Rochelle ButlerRochelleButlerОценок пока нет

- Week 6 DAILY LESSON LOG IN EARTH AND LIFE SCIENCEДокумент3 страницыWeek 6 DAILY LESSON LOG IN EARTH AND LIFE SCIENCEBrufal Michael AngeloОценок пока нет