Академический Документы

Профессиональный Документы

Культура Документы

Synopsis

Загружено:

Darshak GowdaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Synopsis

Загружено:

Darshak GowdaАвторское право:

Доступные форматы

M y s o r e P o l y m e r s & R u b b e r Pr o d u c t s P v t . Lt d .

, MYSORE

Company Profile INTRODUCTION:

Mysore Polymers and Rubbers Products (P) Ltd., was started in the year 1981.The company commenced its commercial production in the year 198 . !t is a pri"ate l i m i t e d c o m p a n y. !t has obtained has !#$ T# 1%9&9 ' into (( the c e r t i ) i c a t e . T h e c o m p a n y maintains *ood relationship with its customers by supplyin* +uality products. The c o m p a n y 0ast 1)rica, 2orth o) and #outh 1merica. also entered ensures ) o r e i * n m a r , e t i n 1 9 9 & - 1 9 9 . b y e / p o r t i n * i t s products to )ar 0ast, Middle M3P$L The ma/imum in utili4ation a"ailable resources. company belie"es

m a i n l y promotin* )rom within and encoura*es its people to stri"e )or h i * h e r m a n a * e m e n t stability. The setup also allows them to ta,e the ad"anta*e o) common pool o) technical and mar,etin* talent o) the hi*hest +uality.

LOCATION OF THE COMPANY:

M3P$L is located 5ust % ,ms )rom historical city o) Mysore in the state o) 6 a r n a t a , a . !t is about 1( ,ms )rom 6.R. #a*ar dam. The m a n u ) a c t u r i n * ) a c i l i t y o ) laboratory and head o))ice is housed o"er an area o) 1 ,1.7 s+uare )eet.

PRODUCT PROFILE:

Products manu)actured at M3P$L are8 9 9 9 9 9 :utyl 1utomoti"e !nner Tubes Moulded Rubber ;omponents <i))user Membrane #pon*e Rubber ;omponents =aws and other en*ineerin* rubber products

Introd !tion

D e p t of Mec h a nic al En gin e e ri n g, SJCE, Mys or e Pa g e 1

M y s o r e P o l y m e r s & R u b b e r Pr o d u c t s P v t . Lt d . , MYSORE >i"en today?s competiti"e business en"ironment and thin mar*ins, plants simply can?t a))ord to wait )or critical e+uipment to )ail be)ore ma,in* repairs. 2or can they rely on time-based pre"enti"e maintenance to minimi4e downtime. @hile less costly than brea,down maintenance, repairin* or replacin* components, 5ust because the cloc, or counter says to do the wor,, is not cost-e))ecti"e. The *old standard )or e))ecti"e maintenance is a predicti"e approach that *uides decisions about production assets. !t monitors each asset?s condition to determine its )itness )or continued operation and initiates repairs only when the machine itsel) starts cryin* )or help. Predicti"e maintenance uses non-in"asi"e techni+ues to monitor the pulse o) a manu)acturin* plant. !t chec,s, )or e/ample, the usability o) *reases and oils. !t ,eeps trac, o) "ibration. !t correlates abnormal temperatures with mechanical problems. Predicti"e maintenance re)ers to the periodical inspection on the e+uipment without stoppin* it, in which e"ery inspection allows the comprehension o) the e+uipment?s operatin* condition, so it is possible to ,now which part o) the e+uipment is out o) order, based on which prediction o) operable time is made. L "e analy#i# $il or *rease between mechanical components minimi4es heat-producin* )riction and cools the parts. #uch lubricants consist o) a base stoc, )orti)ied with a "ariety o) additi"es that stabili4e the lubricant?s physical and chemical properties to maintain its hi*h per)ormance. Aowe"er, any lubricant will succumb to the ri*ors o) e/tended use and its protecti"e properties will de*rade o"er time. $il analysis alerts a plant that such de*radation is occurrin*. The techni+ue in"ol"es sub5ectin* a lubricant sample to laboratory testin* that re"eals, amon* other thin*s, how well it can neutrali4e acids and resist o/idation that brea,s the lube into small, ine))ecti"e molecules. $i"ration analy#i# Many pieces o) plant hardware )eature rotatin* elements. 0/amples include compressors, )ans, turbines, *earbo/es and pumps with their motors, bearin*s, rotors, )an wheels, impellers and seals. <ependin* on its speed and de*ree o) imbalance, a rotatin* element can *enerate a "ibration that sha,es the machine, its )oundation and, perhaps, the buildin* structure itsel). Recordin* "ibration si*nals pro"ides "iew o) the bearin*?s time-domain "ibratory si*nature. <i*ital processin* con"erts data points to a )re+uency-domain si*nal, which re"eals the source and ma*nitude o) the "arious superposed "ibrations. Thus, "ibration D e p t of Mec h a nic al En gin e e ri n g, SJCE, Mys or e Pa g e 2

M y s o r e P o l y m e r s & R u b b e r Pr o d u c t s P v t . Lt d . , MYSORE analysis distin*uishes the sha,in* that ori*inates with a )aulty bearin* rotor.

Pro"lem Definition:

!n M3P$L, Mysore maintenance acti"ity that has been carried out are Pre"enti"e, :rea,down, #hutdown and #cheduled type o) Maintenance, e"en then there are brea,downs which leads production interruption and lon* idle time due to spares a"ailability especially )or critical machines. !t is a mass production company and sometimes due to time constraints in production pre"enti"e maintenance acti"ities are s,ipped which leads to brea,down. These problems can be tac,led or impro"ed by usin* predicti"e maintenance techni+ues.

O%&ECTI$E':

To establish maintenance operations at the Bopportune momentB be)ore ha"in* the e+uipment to be deteriorated durin* a production operation. To impro"e the reliability and producti"ity o) the machines. To reduce number o) brea,down which in"ol"e the production?s interruption and hi*h costs o) maintenance. To accomplish e))ecti"e dia*nosis on dama*ed or worn parts to pre"ent the drawbac, o) o"er-maintenance

METHODOLO(Y:

Master list o) machines. ;ollectin* the in)ormation about the maintenance acti"ity carried out. D e p t of Mec h a nic al En gin e e ri n g, SJCE, Mys or e Pa g e 3

M y s o r e P o l y m e r s & R u b b e r Pr o d u c t s P v t . Lt d . , MYSORE Master list o) a ;ritical Machines based on production and spares a"ailability. <etermine )re+uency o) predicti"e maintenance and prepare predicti"e maintenance schedule. ;ollect critical machine history report recappin* total e+uipment history includin* all components. o 0/truder o o o !ntermi/ Rubber mi/in* mill Press

;alculatin* the reliability and producti"ity o) the critical machine by usin* obtained data and identi)y symptoms o) deterioration. !mplement predicti"e maintenance techni+ues such as "ibration analysis and lube analysis to critical machines and record the data. 1naly4e the obtained data. Ta,e counter measures. ;hec, the result )or impro"ement. Thesis wor,.

Po##i"le O t!ome8

:y applyin* these predicti"e maintenance techni+ues the possible brea, down, idle time can be reduced by increasin* the producti"ity and reliability.

D e p t of Mec h a nic al En gin e e ri n g, SJCE, Mys or e Pa g e 4

Вам также может понравиться

- Materials ManagementДокумент41 страницаMaterials ManagementDarshak Gowda100% (1)

- Reliabilty Prediction and AnalysisДокумент10 страницReliabilty Prediction and AnalysisDarshak GowdaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Shaft FailuresДокумент12 страницShaft FailuresDarshak GowdaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- CBMДокумент19 страницCBMDarshak GowdaОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Condition Based MonitoringДокумент10 страницCondition Based MonitoringDarshak GowdaОценок пока нет

- In-Plant Training at Government Tool Room & Training CentermysoreДокумент42 страницыIn-Plant Training at Government Tool Room & Training CentermysoreDarshak GowdaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 2M050: Computer Graphics: Jack Van Wijk Vanwijk@win - Tue.nl HG6.71Документ76 страниц2M050: Computer Graphics: Jack Van Wijk Vanwijk@win - Tue.nl HG6.71goldfish_meena5465Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Internship at GTTC, MysoreДокумент57 страницInternship at GTTC, MysoreDarshak Gowda44% (9)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Gate2012 1037959Документ5 страницGate2012 1037959Darshak GowdaОценок пока нет

- Oil Refinery Process Flow DiagramДокумент1 страницаOil Refinery Process Flow DiagramDharyl Libarra BardelasОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Chemical Reactor Design-CHEM-E7135: Yongdan LiДокумент56 страницChemical Reactor Design-CHEM-E7135: Yongdan LiVaseline RobinsonОценок пока нет

- Aerodynamics 1Документ512 страницAerodynamics 1bitchwhorecuntОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Lecture 1 SeriesДокумент43 страницыLecture 1 SerieschetsОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Catalyst DefinitionДокумент17 страницCatalyst DefinitionTRIBRATA BASKOROОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Adaptive Identification of A Pneumatic Pump: Diploma ThesisДокумент86 страницAdaptive Identification of A Pneumatic Pump: Diploma Thesisandreas vavatsikosОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- WLMONO024Документ5 страницWLMONO024Michał BorzemskiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Basic Principles and DefectsДокумент18 страницBasic Principles and DefectsAkshaj NevgiОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Nuclear power plant valve data sheetsДокумент7 страницNuclear power plant valve data sheetspoojarimayurОценок пока нет

- Airfoil Wake SurveyДокумент12 страницAirfoil Wake SurveyCalvin LauОценок пока нет

- CALIB053 - Mathcad 15 EquationsДокумент8 страницCALIB053 - Mathcad 15 Equationsilie_vlassaОценок пока нет

- Sullair Compressor 7500 2017Документ104 страницыSullair Compressor 7500 2017JoNathanGranatoCaldeiraОценок пока нет

- Vogt Valves Catalog and Application ManualДокумент53 страницыVogt Valves Catalog and Application ManualRomner CordovaОценок пока нет

- Interval/Frequency and Extent of Inspection: Piping InstallationДокумент4 страницыInterval/Frequency and Extent of Inspection: Piping InstallationMuhammad BilalОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Flushing Oil Flooded Rotary Screw Air Compressors Procedure enДокумент2 страницыFlushing Oil Flooded Rotary Screw Air Compressors Procedure enSergiSerrano100% (1)

- Heat ExchangerДокумент11 страницHeat ExchangerSyafiyatulMunawarahОценок пока нет

- Combined Convection and Radiation PDFДокумент2 страницыCombined Convection and Radiation PDFAlexis0% (1)

- Gas Absorption: Based On Mccabe, Smith, Harriott 7 EdДокумент22 страницыGas Absorption: Based On Mccabe, Smith, Harriott 7 EdnazrinОценок пока нет

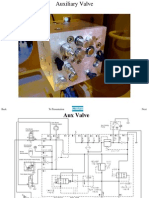

- Aux Valve Brakes ST710Документ16 страницAux Valve Brakes ST710Jose VegaОценок пока нет

- Brochure Air Application Map Fisher en 138202Документ1 страницаBrochure Air Application Map Fisher en 138202Habib A. IslamОценок пока нет

- SCIENCE IV 3rd Quarter TestДокумент2 страницыSCIENCE IV 3rd Quarter Test엘라엘라100% (5)

- Re90220 01 - 2011 10Документ6 страницRe90220 01 - 2011 10Parmasamy SubramaniОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Guide To Registration Rev 9 - February 2014Документ5 страницGuide To Registration Rev 9 - February 2014Anton WelgemoedОценок пока нет

- Low Flow Relief Valves and Pressure Controls Parts ListДокумент3 страницыLow Flow Relief Valves and Pressure Controls Parts ListMuh IchsanudinОценок пока нет

- Chapter 13 Tubing DesignДокумент16 страницChapter 13 Tubing DesignByron GonzalezОценок пока нет

- What Is Blunt BodyДокумент17 страницWhat Is Blunt Bodyankush2020Оценок пока нет

- Choked FlowДокумент14 страницChoked FlowParesh GujaratiОценок пока нет

- Determination of Thermo-Physical Properties of Food Through Transient CoolingДокумент5 страницDetermination of Thermo-Physical Properties of Food Through Transient CoolingshahamОценок пока нет