Академический Документы

Профессиональный Документы

Культура Документы

Fluid Power Application - 004 Hydraulic Actuators Color

Загружено:

Hakimi BobАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fluid Power Application - 004 Hydraulic Actuators Color

Загружено:

Hakimi BobАвторское право:

Доступные форматы

Fluid Power Application

(Hydraulic Actuators)

Hydraulics & Pneumatics KMD 3133

By, Mohd Darnalis A.Rahman

Learning Objectives

Upon completing this chapter, students should be able to:

1. Describe the construction and design features of hydraulic cylinders. 2. Identify the various types of hydraulic cylinder mountings and mechanical linkages. 3. Explain the operation and features of double-rod cylinders and telescopic cylinders. 4. Explain the operation of gear, vane , and piston hydraulic motors.

Introduction

Actuators and motors act the opposite to pump functions (extract energy from a fluid and convert it to mechanical energy to perform useful work). Transmitted through either linear or rotary motion by hydraulic cylinders or motors. Cylinders extend & retract to perform a complete cycle of operation. Motors known as rotary actuators, rotate a shaft to provide a torque driving load along a rotary path.

3

Hydraulic Cylinder

Operating Features

Consist of a piston inside a cylindrical housing (barrel). A rod is attached to one end of the piston. Other end (blank end) is a port for the entrance & exit of oil.

Single-Acting Cylinder

Single Acting Hydraulic Cylinder

Exert force in only the extending direction. Retract by means of gravity or by a compression spring. 5

Double-Acting Cylinder

Double Acting Cylinder

Extend & Retract hydraulically. Force exerted through out extension & retraction. High pressure rating with respect to small size of bore. Made of ductile iron, polished bore surface, and hydro dynamically sealed between piston & barrel. Cushioned at both end to provide smooth deceleration of each stroke.

6

Double-Acting Cylinder

Click to add an outline

Cylinder Mountings

Various mountings are provided to permit versatility of applications. Rod ends are usually threaded so they could be attached directly to the load. Such load are,

Clevis Yoke Other mating devices

8

Cylinder Mountings

Mechanical Linkages

There are various mechanical linkages application which could benefit hydraulic advantages. It is limited to the ingenuity of the fluid power designer. Linkages can transform linear motion into either an oscillating or rotary motion. Can also be used to increase or decrease effective leverage & stroke of a cylinder.

10

Mechanical Linkages

Click to add an outline

11

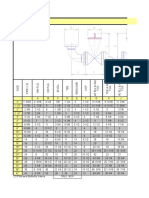

Cylinder Force & Velocity

Output force (F) & piston velocity (v) of doubleacting cylinders are not the same for extension & retraction strokes. Extension stroke,

Fluid enters the blank end of the cylinder through the entire circular area of the piston. Fluid enters the rod end through smaller annular area between the rod and cylinder bore.

12

Retraction stroke,

Cylinder Force & Velocity

13

Special Cylinder Designs

Double-Rod Cylinder

Force & speed are the same for both ends. Used when same task needed to perform on both ends.

14

Special Cylinder Designs

Telescopic Cylinder

Contains multiple cylinders that slide inside each other. Used when long work strokes are required with retraction length must be kept minimum. Such application using this cylinder is high-lift fork truck.

15

Special Cylinder Designs

Figure 6-10

16

Вам также может понравиться

- Options Playback TestingДокумент12 страницOptions Playback TestingHakimi Bob100% (1)

- Supply and DemandДокумент82 страницыSupply and DemandHakimi Bob94% (16)

- The Dynamics of Financial Markets: Fibonacci Numbers, Elliott Waves, and SolitonsДокумент27 страницThe Dynamics of Financial Markets: Fibonacci Numbers, Elliott Waves, and SolitonsHakimi BobОценок пока нет

- Thales A400M Press Kit 151209Документ4 страницыThales A400M Press Kit 151209Hakimi Bob100% (2)

- Lead Lead Lag CompensatorДокумент11 страницLead Lead Lag CompensatorHakimi BobОценок пока нет

- TABLE 1 Laplace Transform For Both MCS CSДокумент2 страницыTABLE 1 Laplace Transform For Both MCS CSHakimi BobОценок пока нет

- Root Locus NotesДокумент27 страницRoot Locus NotesHakimi BobОценок пока нет

- WHO Declares Ebola Epidemic An International Health Emergency. - by Kate KellandДокумент5 страницWHO Declares Ebola Epidemic An International Health Emergency. - by Kate KellandHakimi BobОценок пока нет

- CHAPTER 2 A New Product DevelopmentДокумент21 страницаCHAPTER 2 A New Product DevelopmentHakimi BobОценок пока нет

- Identifying Variables: Step 4: Test Your HypothesisДокумент6 страницIdentifying Variables: Step 4: Test Your HypothesisHakimi BobОценок пока нет

- SIRIM QAS Intl. Corporate ProfileДокумент32 страницыSIRIM QAS Intl. Corporate ProfileHakimi BobОценок пока нет

- Notes 1a Ammonia and UreaДокумент14 страницNotes 1a Ammonia and UreaHakimi BobОценок пока нет

- Surveillance of Drinking Water Quality For Safe Water Supply-A Case Study From Shillong, IndiaДокумент22 страницыSurveillance of Drinking Water Quality For Safe Water Supply-A Case Study From Shillong, IndiaHakimi BobОценок пока нет

- Technology Profiles-Precise Biometrics-Ensuring Integrity With Fingerprint VerificationДокумент5 страницTechnology Profiles-Precise Biometrics-Ensuring Integrity With Fingerprint VerificationHakimi BobОценок пока нет

- Fluid Power Application - 006 Hydraulic Ancillary DevicesДокумент7 страницFluid Power Application - 006 Hydraulic Ancillary DevicesHakimi BobОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Maintaining Valves: Module 08408-07Документ16 страницMaintaining Valves: Module 08408-07cjcp04Оценок пока нет

- Bombas OBL XRNДокумент8 страницBombas OBL XRNJ Ferreyra LibanoОценок пока нет

- SKF Hydraulic Pump-Oil InjectorДокумент1 страницаSKF Hydraulic Pump-Oil InjectorEko PrabowoОценок пока нет

- Rexroth Flush ValveДокумент2 страницыRexroth Flush ValveanandsubbiahОценок пока нет

- Above Ground VFD Constant Pressure Systems: MyersДокумент2 страницыAbove Ground VFD Constant Pressure Systems: Myersnicoi adoyОценок пока нет

- Sistem Perpipaan: Darcy-Weisbach Diagram MoodyДокумент32 страницыSistem Perpipaan: Darcy-Weisbach Diagram MoodyRezi OktaviandriОценок пока нет

- Directional Control Valve WM WN WP WHD Mechanical Manual. Pneumatic Hydraulic Actuated Re22331 PDFДокумент12 страницDirectional Control Valve WM WN WP WHD Mechanical Manual. Pneumatic Hydraulic Actuated Re22331 PDFRS Rajib sarkerОценок пока нет

- Group 2 Main Control Valve: 1. StructureДокумент26 страницGroup 2 Main Control Valve: 1. StructurePower MobileОценок пока нет

- Plastic Push in FittingsДокумент8 страницPlastic Push in FittingssujoyludОценок пока нет

- Piping Valve Flange DimensionsДокумент252 страницыPiping Valve Flange DimensionschadОценок пока нет

- Antishiphon ValveДокумент1 страницаAntishiphon ValveRoshan ShanmughanОценок пока нет

- REXROTH Service Manual PVC PSSFДокумент6 страницREXROTH Service Manual PVC PSSFRaghavendra DeshpandeОценок пока нет

- Pressure Reducing ValveДокумент3 страницыPressure Reducing ValveSasa JadrovskiОценок пока нет

- Control Valve CharacteristicsДокумент3 страницыControl Valve CharacteristicsgifitrianggraeniОценок пока нет

- Ihp QP Nov - 2022Документ3 страницыIhp QP Nov - 2022ranjitrvyavahareОценок пока нет

- CNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Документ3 страницыCNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Wibowo ArieОценок пока нет

- CC Pump Isolation & PurgingДокумент2 страницыCC Pump Isolation & PurgingSunilKChandilaОценок пока нет

- Allied Autovent 2000 3000 ManualДокумент28 страницAllied Autovent 2000 3000 ManualwiroarОценок пока нет

- Valve Range SupplierДокумент8 страницValve Range Suppliercuongnv_19Оценок пока нет

- W07. Open Centre Control ValvesДокумент3 страницыW07. Open Centre Control ValvesMohamed BakheetОценок пока нет

- General Pumping System and The Net Head Developed by A PumpДокумент14 страницGeneral Pumping System and The Net Head Developed by A PumpMohit SharmaОценок пока нет

- Chapter II - Review of Related LiteratureДокумент14 страницChapter II - Review of Related Literaturebryesanggalang80% (10)

- Siemens CNC Programming ExamplesДокумент2 страницыSiemens CNC Programming ExamplesAhmedSalahОценок пока нет

- Practical Task 1 Pneumatik June 2018Документ20 страницPractical Task 1 Pneumatik June 2018Zuhaila MohammadОценок пока нет

- Diagramas HidraulicoДокумент2 страницыDiagramas HidraulicoAlonso MtZОценок пока нет

- Intro To Pumps 2.1 Complete ManualДокумент140 страницIntro To Pumps 2.1 Complete ManualZaynfrivoОценок пока нет

- Danfoss 520L0889 Series 90 55cc Pump Parts Manual 2015Документ164 страницыDanfoss 520L0889 Series 90 55cc Pump Parts Manual 2015juanchis650Оценок пока нет

- Jet PumpsДокумент7 страницJet PumpsNazeeh Abdulrhman AlbokaryОценок пока нет

- Pressure Relief ValveДокумент20 страницPressure Relief ValveshaikhОценок пока нет

- Lab Manual - 1-5 - 2019-20Документ8 страницLab Manual - 1-5 - 2019-20ashishОценок пока нет