Академический Документы

Профессиональный Документы

Культура Документы

Acrolein

Загружено:

Elok Faiqotul UmmaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Acrolein

Загружено:

Elok Faiqotul UmmaАвторское право:

Доступные форматы

ACROLEIN

99

5. PRODUCTION, IMPORT/EXPORT, USE, AND DISPOSAL

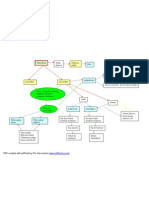

5.1 PRODUCTION

Acrolein was first produced commercially in the 1930s through the vapor phase condensation of acetaldehyde and formaldehyde (Etzkorn et al. 2002). A second method was developed in the 1940s, which involved the vapor phase oxidation of propylene; however, this method was not used at first due to the poor performance of cuprous oxide catalysts. During the 1960s, propylene oxidation was greatly enhanced by the introduction of bismuth molybdate-based catalysts and has since become the primary method used for the commercial production of acrolein. Acrylic acid and carbon oxides are the major byproducts produced during this reaction. Minor byproducts are acetaldehyde, acetic acid, formaldehyde, and polyacrolein.

Companies located in the United States that currently produce acrolein are: Baker Petrolite Corporation, Taft, California; Degussa Corporation, Theodore, Alabama; and Dow Chemical U.S.A., Taft, Louisiana (SRI 2006). Annual production capacities reported during the year 2000 were 110,000 metric tons/year (242 million pounds/year) for the Degussa Corporation and 72,000 metric tons/year (159 million pounds/year) for Dow Chemical (Etzkorn et al. 2002). Production capacity data were not provided for the Baker Petrolite Corporation. In 1978, domestic manufacturing plants produced approximately 354 million pounds of acrolein (EPA 1983). The production volumes of acrolein reported by manufacturers in 1986, 1990, 1994, 1998, and 2002 were within the ranges of >1050 million pounds, >50100 million pounds, >50100 million pounds, >100500 million pounds, and >100500 million pounds, respectively (IUR 2002).

Table 5-1 summarizes information on companies that reported the production, import, or use of acrolein for the Toxics Release Inventory in 2004 (TRI04 2006). The TRI data should be used with caution since only certain types of facilities are required to report. This is not an exhaustive list.

5.2

IMPORT/EXPORT

Current information regarding the import or export of this compound could not be located.

ACROLEIN 5. PRODUCTION, IMPORT/EXPORT, USE, AND DISPOSAL

100

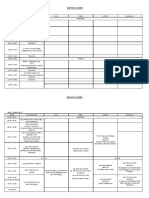

Table 5-1. Facilities that Produce, Process, or Use Acrolein

Minimum Number of amount on site facilities in poundsb

5 2 4 3 2 2 1 2 14 1 2 4 1 4 2 1 1 1 1 44 2 3 2 0 0 0 0 0 0 10,000 100 0 0 0 0 0 0 100 1,000,000 1,000 0 100,000 0 0 0 0

Statea

AL AR CA GA IA IL IN KS LA ME MI MN MS NC NE NY OH OR TN TX VA WI WV

a b

Maximum amount on site in poundsb

999,999 9,999 999,999 9,999 9,999 999 99,999 9,999 10,000,000,000 99 9,999 999,999 99 9,999 9,999 9,999,999 9,999 99 999,999 9,999,999 99,999 9,999 9,999

Activities and usesc

1, 3, 5, 6, 13 1, 5, 12 1, 2, 4, 5, 9, 12 1, 5 1, 5, 13 1, 5 6 1, 13 1, 3, 4, 5, 6, 7, 8, 12, 13 1, 5 1, 5, 12 1, 5, 13, 14 1, 5 1, 5 1, 5, 13 12 1, 13 1, 5, 13 8, 9 1, 3, 4, 5, 6, 7, 9, 10, 12, 13 1, 5 1, 5, 13, 14 1, 5, 6

Post office state abbreviations used Amounts on site reported by facilities in each state c Activities/Uses: 1. Produce 6. Impurity 2. Import 7. Reactant 3. Onsite use/processing 8. Formulation Component 4. Sale/Distribution 9. Article Component 5. Byproduct 10. Repackaging Source: TRI04 2006 (Data are from 2004)

11. 12. 13. 14.

Chemical Processing Aid Manufacturing Aid Ancillary/Other Uses Process Impurity

ACROLEIN 5. PRODUCTION, IMPORT/EXPORT, USE, AND DISPOSAL

101

5.3

USE

The largest single use for acrolein is as an unisolated intermediate in the manufacture of acrylic acid, most of which is converted to its lower alkyl esters (IARC 1995). Acrolein is also used as a herbicide and algicide in irrigation waters and drainage ditches; as a biocide in the control of algae, weeds, and mollusks in recirculating process water systems; as a slimicide in the paper industry; as a biocide in oil wells and liquid petrochemical fuels; in the cross-linking of protein collagen in leather tanning; as a tissue fixative in histological samples; in the manufacture of colloidal forms of metals; in the production of perfumes; as a warning agent in methyl chloride refrigerant; and as an intermediate in the manufacture of methionine and its hydroxyl analogue, glutaraldehyde, ally1 alcohol, pyridines, and tetrahydrobenzaldehyde (Arntz et al. 2002; Baker Petrolite 2005; Etzkorn et al. 2002; Hess et al. 1978; HSDB 2007; IARC 1995; Lewis 1997; ONeil 2001; Windholz et al. 1983). Isolated, refined acrolein is used mainly as a biocide and as an intermediate in the production of methionine, which is a protein supplement used in animal feed (Arntz et al. 2002; IARC 1995). Acrolein has been used to make modified food starch, synthetic glycerine, acrolein polymers, polyurethane, and polyester resins (Arntz et al. 2002; HSDB 2007; Lewis 1997). It has also been used in military poison gas mixtures (IARC 1995).

5.4

DISPOSAL

Prior to implementing land disposal of waste residues (including waste sludge), environmental regulatory agencies should be consulted for guidance on acceptable disposal practices (HSDB 2007). Materials containing concentrated acrolein may be incinerated by: rotary kiln incineration, with a temperature range of 8201,600 C and a residence time of seconds; fluidized bed incineration, with a temperature range of 450980 C and a residence time of seconds; and liquid injection, with a temperature range of 6501,600 C and a residence time of 0.12 seconds (HSDB 2007). Materials containing small amounts of acrolein may be disposed of by neutralization (if needed), followed by secondary biological treatment or by submerged combustion (to concentrate the waste) followed by incineration (Hess et al. 1978; OHMTADS 1988). On-site combustion is an option for disposal if the spill site is in a very remote, inaccessible area, and there is danger of subsequent discharge if other methods of disposal are attempted. Local, state, and federal Resource Conservation and Recovery Act (RCRA) approval must be obtained before burning on site (OHM-TADS 1988).

Acrolein has been identified as a hazardous waste by the EPA, and the disposal of this compound is regulated under RCRA. Specific information regarding federal regulations concerning disposal of

ACROLEIN 5. PRODUCTION, IMPORT/EXPORT, USE, AND DISPOSAL

102

hazardous wastes through land treatment, landfilling, incineration, thermal treatment, chemical/physical/ biological treatment, underground injection, and deep sea injection are provided in the Code of Federal Regulations (40 CFR 190399). Release of acrolein in waste water is regulated under the Clean Water Act by the National Pollutant Discharge Elimination System (NPDES).

Information regarding effluent guidelines and standards for acrolein may be found in 40 CFR 122, 40 CFR 125, 40 CFR 268, 40 CFR 413, 40 CFR 423, and 40 CFR 433.

Pursuant to RCRA Section 3004(g)(5), EPA has proposed to restrict the land disposal of acrolein (EPA 1989b). Acrolein may be land disposed only if prior treatment standards have been met, or if disposal occurs in units that satisfy the statutory no migration standard (EPA 1989b). Proper guidelines and standards are outlined in the Federal Register (EPA 1989b).

Вам также может понравиться

- Icd 10 Diagnosa GigiДокумент2 страницыIcd 10 Diagnosa GigiElok Faiqotul UmmaОценок пока нет

- Curaprox BrochureДокумент68 страницCuraprox BrochureElok Faiqotul UmmaОценок пока нет

- Child Dental Examination FormДокумент1 страницаChild Dental Examination FormElok Faiqotul Umma100% (2)

- Jadwal AcaraДокумент2 страницыJadwal AcaraElok Faiqotul UmmaОценок пока нет

- A Review On Peppermint OilДокумент7 страницA Review On Peppermint OilElok Faiqotul UmmaОценок пока нет

- Product Knowledge - Espe Sil Ifu WeДокумент2 страницыProduct Knowledge - Espe Sil Ifu WeElok Faiqotul UmmaОценок пока нет

- Tongue DisordersДокумент68 страницTongue DisordersSiskaJanerОценок пока нет

- Dental FormДокумент1 страницаDental FormElok Faiqotul UmmaОценок пока нет

- In Most Patients With Frictional KeratosisДокумент1 страницаIn Most Patients With Frictional KeratosisElok Faiqotul UmmaОценок пока нет

- Contoh Rundown Basic Life SupportДокумент2 страницыContoh Rundown Basic Life SupportElok Faiqotul Umma100% (1)

- Acrylic AcidДокумент7 страницAcrylic AcidElok Faiqotul Umma0% (1)

- Medicallycompromised 1233751509281867 3Документ31 страницаMedicallycompromised 1233751509281867 3Wafa AL-sooryОценок пока нет

- Comprehensive Periodontal Exam GuideДокумент40 страницComprehensive Periodontal Exam GuideKavin SandhuОценок пока нет

- Gambaran Tumpatan Amalgam Dan Semen Ionomer Kaca Pada Masyarakat Kelurahan Kalumpang Kecamatan Ternate TengahДокумент2 страницыGambaran Tumpatan Amalgam Dan Semen Ionomer Kaca Pada Masyarakat Kelurahan Kalumpang Kecamatan Ternate TengahElok Faiqotul UmmaОценок пока нет

- Gambaran Tumpatan Amalgam Dan Semen Ionomer Kaca Pada Masyarakat Kelurahan Kalumpang Kecamatan Ternate TengahДокумент2 страницыGambaran Tumpatan Amalgam Dan Semen Ionomer Kaca Pada Masyarakat Kelurahan Kalumpang Kecamatan Ternate TengahElok Faiqotul UmmaОценок пока нет

- Local Anesthesia in Pediatric DentistryДокумент31 страницаLocal Anesthesia in Pediatric DentistryMohamed Beshi100% (1)

- SPSS Step-by-Step Tutorial: Part 2Документ48 страницSPSS Step-by-Step Tutorial: Part 2Elok Faiqotul UmmaОценок пока нет

- E Book OdontologyДокумент347 страницE Book OdontologyElok Faiqotul UmmaОценок пока нет

- Konservasi GigiДокумент1 страницаKonservasi GigisofiandwimardiantoОценок пока нет

- 119-137 DR Agus Sel Squamosa CarsinomaДокумент19 страниц119-137 DR Agus Sel Squamosa CarsinomaElok Faiqotul UmmaОценок пока нет

- Materi SEMINAR FixДокумент5 страницMateri SEMINAR FixElok Faiqotul UmmaОценок пока нет

- Burning Mouth Syndrome: Symptoms, Causes and Treatment of Burning TongueДокумент4 страницыBurning Mouth Syndrome: Symptoms, Causes and Treatment of Burning TongueElok Faiqotul UmmaОценок пока нет

- Evaluation of Consistency in Dosing Directions and Measuring Devices For Pediatric Nonprescription Liquid MedicationsДокумент8 страницEvaluation of Consistency in Dosing Directions and Measuring Devices For Pediatric Nonprescription Liquid MedicationsElok Faiqotul UmmaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Introduction To The Philosophy of Science First PartДокумент138 страницIntroduction To The Philosophy of Science First PartChandra Sekhar Sahu100% (1)

- JAN LOHFELDT vs. NEDBANK LTD - Cape Town High Court Judge Goliath (24.02.2014) & Judge Zondi (25.02.2014)Документ24 страницыJAN LOHFELDT vs. NEDBANK LTD - Cape Town High Court Judge Goliath (24.02.2014) & Judge Zondi (25.02.2014)willОценок пока нет

- AWWA Bacterial Regrowth in Distr Sys PDFДокумент368 страницAWWA Bacterial Regrowth in Distr Sys PDFsaishankarlОценок пока нет

- Hoa ReviewerДокумент3 страницыHoa ReviewerRachel Mae BahoyОценок пока нет

- DCT PIR insulation technical data sheetДокумент4 страницыDCT PIR insulation technical data sheetHenky MantophaniОценок пока нет

- Word Trek Lesson OutlinesДокумент8 страницWord Trek Lesson Outlinesapi-289048378Оценок пока нет

- Megger FORMДокумент1 страницаMegger FORMCOSMOPOLITAN M&EОценок пока нет

- Operator Identities 2Документ3 страницыOperator Identities 2jasmonОценок пока нет

- Co2 OrderДокумент2 страницыCo2 OrderRamakant PatelОценок пока нет

- Adept Conveyor Technologies Product ManualДокумент32 страницыAdept Conveyor Technologies Product ManualBagus Eko BudiyudhantoОценок пока нет

- Comp7 - Answer Key - Dec. Exam - 1st SetДокумент2 страницыComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaОценок пока нет

- Porphyria's Lover - Robert BrowningДокумент9 страницPorphyria's Lover - Robert Browningdearkatie6688Оценок пока нет

- RDT Steering System Pressure ChartДокумент118 страницRDT Steering System Pressure ChartAnonymous 340A7vnwV1100% (2)

- Sports AcousticsДокумент43 страницыSports Acousticssiddhant raoОценок пока нет

- Ruby and Pink Sapphire - IntroДокумент3 страницыRuby and Pink Sapphire - Introrazanym100% (1)

- Toxicology Compendium PDFДокумент602 страницыToxicology Compendium PDFJUANОценок пока нет

- Countable UncountableДокумент4 страницыCountable UncountablePaoLo Mena la TorreОценок пока нет

- Actividad 3.1B-Xport-Model-Exercises-SCMДокумент5 страницActividad 3.1B-Xport-Model-Exercises-SCMDante Rivera SalinasОценок пока нет

- RFIAДокумент11 страницRFIAMary Joy TorresОценок пока нет

- 6013 GCS-CONTROLS enДокумент5 страниц6013 GCS-CONTROLS enMuhammad SyaqirinОценок пока нет

- BT Word FormsДокумент11 страницBT Word FormsNguyên TrungОценок пока нет

- Anotações - Seminários em Língua Inglesa - Discurso LiterárioДокумент17 страницAnotações - Seminários em Língua Inglesa - Discurso LiterárioAline MoraisОценок пока нет

- Improving MV Underground Cable Performance - Experience of TNB MalaysiaДокумент4 страницыImproving MV Underground Cable Performance - Experience of TNB Malaysialbk50Оценок пока нет

- WK-3508F IPTV Gateway DatasheetДокумент7 страницWK-3508F IPTV Gateway DatasheetComunidad Tecnolibre.netОценок пока нет

- EM 385-1-1 Chapters 20-26Документ179 страницEM 385-1-1 Chapters 20-26MusabОценок пока нет

- Self EducationДокумент21 страницаSelf EducationSwami VedatitanandaОценок пока нет

- Potensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliДокумент8 страницPotensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliNuyul FaizahОценок пока нет

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENДокумент2 страницыData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasОценок пока нет

- CH 01Документ24 страницыCH 01Gabriel FlorêncioОценок пока нет

- Kodak Film StructureДокумент40 страницKodak Film StructureThu Thu SheinОценок пока нет