Академический Документы

Профессиональный Документы

Культура Документы

Cold Formed Bending

Загружено:

georgeispasoiuОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cold Formed Bending

Загружено:

georgeispasoiuАвторское право:

Доступные форматы

CALCULATION SHEET

Document Ref: Title

T3704_T3706-DFE

Sheet

of

Example: Design and serviceability limit state check of a cold-formed steel member in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Example: Design and serviceability limit state check of a cold-formed steel member in bending

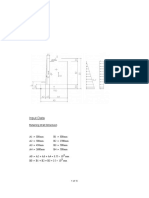

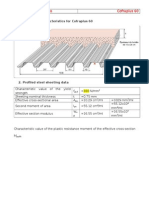

This example considers the design of a simply supported lipped channel section floor joist. It is assumed that the upper and bottom flanges are continuously laterally restrained. Serviceability limit state check is also considered. Basic Data Span of joist Spacing between joists

L=5m S = 0,6 m

qG,beam = 0,06 kN m 0,68 kN m 2

qG,slab = 0,68 0 ,6 = 0,41 kN m

Distributed loads applied to the joist: self-weight of the beam

lightweight slab

dead load

qG = qG,beam + qG,slab = 0,47 kN m 2,50 kN m 2 qQ = 2,50 0,6 = 1,50 kN m

imposed load

The dimensions of the cross-section and the material properties are: Total height

Total width of flange in compression Total width of flange in tension Total width of edge fold Internal radius Nominal thickness Steel core thickness Basic yield strength Modulus of elasticity Poissons ratio h = 200 mm

b1 = 74 mm

b2 = 66 mm

c = 20,8 mm r = 3 mm t nom = 2 mm t = 1,96 mm

f yb = 350 N mm 2

E = 210000 N mm 2

= 0,3

T3704_T3706-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3704_T3706-DFE

Sheet

of

Example: Design and serviceability limit state check of a cold-formed steel member in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Partial factors

M0 = 1,0

M1 = 1,0

EN1993-1-3 2(3) permanent loads variable loads EN1990

G = 1,35

Q = 1,50

Design of the joist for Ultimate Limit State

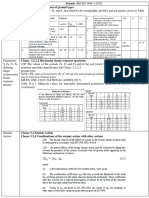

Effective section properties at the ultimate limit state

Second moment of area of cold-formed lipped channel section subjected I eff,y = 4139861 mm 4 to bending about its major axis: Position of the neutral axis: - from the flange in compression: - from the flange in tension: Effective section modulus: - with respect to the flange in compression: Weff,y,c = I eff,y zc

=

T3701a

zc = 102 ,3 mm z t = 95,7 mm

4139861 = 40463 mm3 102,3

- with respect to the flange in tension: Weff,y,t = I eff,y zt

=

4139861 = 43264 mm3 95,7

Weff,y = min(Weff,y,c ,Weff,y,t ) = 40463 mm 3

Applied loading on the joist at ULS

qd = G qG + Q qQ = 1,35 0,47 + 1,50 1,50 = 2,89 kN m Maximum applied bending moment (at midspan) about the major axis y-y: M Ed = qd L2 8 = 2,89 52 8 = 9,03 kNm

Check of bending resistance at ULS

EN1990

Design moment resistance of the cross-section for bending:

M c,Rd = Weff,y f yb M0 = 40463 10 9 350 103 1,0 = 14 ,16 kNm

EN1993-1-3 6.1.4.1(1)

T3704_T3706-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3704_T3706-DFE

Sheet

of

Example: Design and serviceability limit state check of a cold-formed steel member in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Verification of bending resistance:

M Ed 9 ,03 = = 0 ,638 < 1 M c,Rd 14 ,16

EN1993-1-1 OK 6.2.5(1)

Check of shear resistance at ULS

Design to shear force Maximum applied shear force VEd = qd L 2 = 2,89 5 2 = 7,225 kN Design plastic shear resistance

Vpl,Rd = Av f yb

M0

) = sin t ( f

hw

yb

M0

EN1993-1-1 6.2.6(2)

where: Av hw = h t nom is the shear area is the web height is the slope of the web relative to the flanges. sin 90 3

= 90

Vpl,Rd =

(200 2) 10 3 1,96 10 3 (350 103

1,0

= 78,42 kN

Design shear buckling resistance

Vb,Rd = hw tf bv sin

M0

is the shear strength, considering buckling

EN1993-1-3 6.1.5

where: f bv

For a web with stiffening at the support: f bv = 0,58 f yb

f bv = 0,48 f yb w

if if

w 0,83 w > 0,83

T3704_T3706-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3704_T3706-DFE

Sheet

of

Example: Design and serviceability limit state check of a cold-formed steel member in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

The relative slenderness w for webs without longitudinal stiffeners:

w = 0,346

sw t

f yb E

= 0,346

h t nom t

f yb E

0,346

200 2 350 = 1,427 1,96 210000

w = 1,427 > 0,83

so:

f bv = 0 ,48 f yb w = 0 ,48 350 1,427 = 117 ,73 N mm 2

Vb,Rd =

(200 2) 103 1,96 10 3 117 ,73 103

sin 90 1,0

= 45,7 kN

Design shear resistance

Vc,Rd = min(Vpl,Rd ,Vb,Rd ) = min(78,42 ; 45,7 ) = 45,7 kN

Verification of shear resistance

VEd 7 ,225 = = 0 ,158 < 1 Vc,Rd 45,7

OK

EN1993-1-1 6.2.6(1)

Check of local transverse resistance at ULS

Support reaction: FEd = qd L 2 = 2,89 5 2 = 7,225 kN To obtain the local transverse resistance of the web for a cross section with a single unstiffened web, the following criteria should be satisfied: hw t

r t

EN1993-1-3 6.1.7.2 (1)

200

6

198 1,96 = 101,02 < 200 OK 3 1,96 = 1,53 < 6 OK

45

90

where is the slope of the web relative to the flanges: = 90

OK

T3704_T3706-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3704_T3706-DFE

Sheet

of

Example: Design and serviceability limit state check of a cold-formed steel member in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

The local transverse resistance of the web The bearing length is: ss = 80 mm EN1993-1-3 6.1.7.2 (2) Figure 6.7

For ss t = 80 1,96 = 40,816 < 60 the local transverse resistance of the web Rw,Rd is: h t s k1k 2 k3 5,92 w 1 + 0,01 s t 2 f yb 132 t =

Rw,Rd

M1

where:

k1 = 1,33 0,33k

with

k = f yb 228 = 350 228 = 1,535

k1 = 1,33 0,33 1,535 = 0,823 k 2 = 1,15 0,15 r t = 1,15 0,15 3 1,96 = 0,92 k3 = 0,7 + 0,3( 90 ) = 0,7 + 0,3 (90 90 ) = 1

2 2

EN1993-1-3 6.1.7.2(3)

Rw,Rd

198 1,96 80 2 0,823 0,92 1 5,92 1 + 0,01 1,96 350 132 1 , 96 = 7396 N = 1,0

Rw,Rd = 7,396 kN Verification of local transverse force FEd = 7,225 kN < Rw,Rd = 7,396 kN OK

EN1993-1-3 6.1.7.1(1)

Verification for Serviceability Limit State

Applied loading on the joist at SLS (frequent combination)

qd,ser = qG + qQ = 0,47 + 1,50 = 1,97 kN m The maximum applied bending moment:

M Ed,ser = qd,ser L2 8 = 1,97 52 8 = 6 ,16 kNm

EN1990

T3704_T3706-DFE.doc

CALCULATION SHEET

Document Ref: Title

T3704_T3706-DFE

Sheet

of

Example: Design and serviceability limit state check of a cold-formed steel member in bending EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Effective section properties at the serviceability limit state

Second moment of area for SLS: I fic = I gr with:

I gr = 4495921 mm 4 is the second moment of area of the gross cross-section

gr (I I ( )eff ) gr

EN1993-1-3 7.1(3)

gr maximum compressive bending stress in SLS

zc,gr = 96,88 mm position of the centroidal axis with regard to the compressed flange

gr =

M Ed,ser M Ed,ser 6 ,16 106 = = = 132,74 N mm 2 Wgr I gr z c,gr 4495921 96,88

= f yb = 350 N mm 2

I ( )eff = I eff,y = 4139861 mm 4

I fic = 4495921

132 ,74 (4495921 4139861) = 4360883 mm 4 350

Deflection check

Deflection of the joist:

4 5 qd,ser L 5 1,97 5000 4 = = 17,51 mm 384 EI fic 384 210000 4360883

The deflection is L/286 OK

Note 1: the limits of deflection should be specified by the client. The National Annex may specify some limits. Here the result may be considered as fully satisfactory.

EN 1993-1-1 7.2.1

Note 2: concerning the vibration, the National Annex may specify limits EN 1993-1-1 concerning the frequency. Here the total deflection is acceptably low, for this 7.2.3 reason there is no problem of vibration.

T3704_T3706-DFE.doc

Example: Design and serviceability limit state check of a cold-formed steel member in bending T3704_T3706-DFE.doc

Quality Record

RESOURCE TITLE Example: Design and serviceability limit state check of a cold-formed steel member in bending

Reference(s) ORIGINAL DOCUMENT Name Created by Technical content checked by Editorial content checked by Technical content endorsed by the following STEEL Partners: 1. UK 2. France 3. Sweden 4. Germany 5. Spain Resource approved by Technical Coordinator TRANSLATED DOCUMENT This Translation made and checked by: Translated resource approved by: SCI CTICM SBI RWTH Labein Company Date

Page 7

Example: Design and serviceability limit state check of a cold-formed steel member in bending T3704_T3706-DFE.doc

Wrapper Information

Title* Series Description* This example considers the design of a simply supported lipped channel section floor joist. It is assumed that the upper and bottom flanges are continuously laterally restrained. Serviceability limit state check is also considered. Expertise Filename C: T3704_T3706-DFE.doc Microsoft Office Word; 8 Pages; 589kb; Resource Type Viewpoint Subject* Dates Application Area(s) Created Date Last Modified Date Checked Date Valid From Valid To Language(s)* Contacts Author Checked By Approved by Editor Last Modified By Keywords* See Also Ultimate limit state, serviceability limit state, bending, lipped channel section, cold-formed, joist Eurocode Reference Worked Example(s) Commentary Discussion Other Coverage Special Instructions National Applicability Europe Residential buildings 25/12/2005 Worked example Example: Design and serviceability limit state check of a cold-formed steel member in bending

Access Level* Identifiers* Format Category*

Page 8

Вам также может понравиться

- PGHU-EH-CSPDS-000103 Rev 0 - Design Loads For StructuresДокумент10 страницPGHU-EH-CSPDS-000103 Rev 0 - Design Loads For StructuresGiovanni AlfieriОценок пока нет

- Proracun - Example Cold Formed SteelДокумент10 страницProracun - Example Cold Formed SteelpedjaОценок пока нет

- Ec3 Kolon HesabıДокумент5 страницEc3 Kolon HesabınaimalimliОценок пока нет

- Eurocode 3 steel joint design guideДокумент2 страницыEurocode 3 steel joint design guideneverreturnОценок пока нет

- Fatigue Resistant DesignДокумент190 страницFatigue Resistant DesignHomero Silva100% (6)

- Example Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingДокумент10 страницExample Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Bendingcbler100% (10)

- Steel Beam DesignДокумент26 страницSteel Beam DesignWazini D. Izani100% (1)

- Worked Examples Ec2 Def080723Документ120 страницWorked Examples Ec2 Def080723dan_ospir67% (3)

- Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsДокумент5 страницExample - Buckling Resistance of A Pinned Column With Intermediate RestraintsAndreea NanОценок пока нет

- SX001a en EU Example Simply Supported Laterally UnrestrainedДокумент9 страницSX001a en EU Example Simply Supported Laterally UnrestrainedJamesОценок пока нет

- Bracing Connection EC3Документ9 страницBracing Connection EC3Mustafa AyşeОценок пока нет

- Example Simply Supported IPE Profile PurlinДокумент10 страницExample Simply Supported IPE Profile PurlinAjay GargОценок пока нет

- Wind Loading-Base Station Antennas White Paper TP - 103194Документ13 страницWind Loading-Base Station Antennas White Paper TP - 103194nakkipatty100% (2)

- QAP - LT Panel PDFДокумент8 страницQAP - LT Panel PDFAkshay Ajay100% (2)

- Unrestrained Beam With End MomentsДокумент9 страницUnrestrained Beam With End MomentsNikos StathoulopoulosОценок пока нет

- Richard A. Nyquist and Ronald O. Kagel (Auth.) - Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts. Infrared Spectra of Inorganic Compounds-Academic Press (1971)Документ499 страницRichard A. Nyquist and Ronald O. Kagel (Auth.) - Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts. Infrared Spectra of Inorganic Compounds-Academic Press (1971)Patrícia Bodanese PratesОценок пока нет

- KLCC EAST STATION STRUTTING DESIGN CALCULATIONSДокумент319 страницKLCC EAST STATION STRUTTING DESIGN CALCULATIONSalexanderОценок пока нет

- TGN 1 25 Introduction To FatigueДокумент2 страницыTGN 1 25 Introduction To FatigueMuhammad ImranОценок пока нет

- Design of Three Span Steel Composite FlyoverДокумент85 страницDesign of Three Span Steel Composite FlyoverStructural SpreadsheetsОценок пока нет

- Simply Supported Secondary Composite BeamДокумент11 страницSimply Supported Secondary Composite BeamgeorgeispasoiuОценок пока нет

- Eurocode 1-Snow InformationДокумент46 страницEurocode 1-Snow InformationKelvin BongОценок пока нет

- MathCAD - Retaining Wall FoundationДокумент6 страницMathCAD - Retaining Wall FoundationValentinОценок пока нет

- NCCI: Determination of Non-Dimensional Slenderness of I and H SectionsДокумент11 страницNCCI: Determination of Non-Dimensional Slenderness of I and H SectionslingchenhОценок пока нет

- Example Beam Simply Supported With Lateral RestraintДокумент11 страницExample Beam Simply Supported With Lateral RestraintjplezpОценок пока нет

- Simply Supported Primary Composite BeamДокумент17 страницSimply Supported Primary Composite BeamPaul Marceti100% (2)

- Example-Simply Supported Laterally Unrestrained BeamДокумент9 страницExample-Simply Supported Laterally Unrestrained BeamBejan Claudiu100% (2)

- Brochure WaterstopДокумент52 страницыBrochure WaterstopbabuliuОценок пока нет

- Brochure WaterstopДокумент52 страницыBrochure WaterstopbabuliuОценок пока нет

- Mathcad - Design Resistance For Individual FastnersДокумент3 страницыMathcad - Design Resistance For Individual FastnersValentinОценок пока нет

- Accidental Loading On BuildingsДокумент22 страницыAccidental Loading On Buildingssubin_mampallyОценок пока нет

- Open Hole Logs Introduction GR SP CALДокумент21 страницаOpen Hole Logs Introduction GR SP CALmagedОценок пока нет

- 03 1 Weynand Moment Resistant JointsДокумент71 страница03 1 Weynand Moment Resistant Jointsdeepak_dce_meОценок пока нет

- AD385 - Robustness SCI P391Документ2 страницыAD385 - Robustness SCI P391mdavies20Оценок пока нет

- Buckling of Steel Shells European RecommendationsДокумент136 страницBuckling of Steel Shells European RecommendationsJoao AlvesОценок пока нет

- Crack Width - BS en 1992 Base SlabДокумент3 страницыCrack Width - BS en 1992 Base SlabVinoth KumarОценок пока нет

- SCI PUBLICATION P387 Steel Building Desi PDFДокумент106 страницSCI PUBLICATION P387 Steel Building Desi PDFSabarishwaran SabariОценок пока нет

- Connection Design According To en 1993-1-8Документ74 страницыConnection Design According To en 1993-1-8Marius Hirtopanu0% (2)

- Maccaferri Solution GuideДокумент32 страницыMaccaferri Solution Guideptopic10Оценок пока нет

- 07 Sx007a en Eu BeamДокумент11 страниц07 Sx007a en Eu BeamMic PaulaОценок пока нет

- Blast Resistant Roof Design ThesisДокумент124 страницыBlast Resistant Roof Design ThesisYam BalaoingОценок пока нет

- Woodbased Panels SelectionДокумент16 страницWoodbased Panels SelectionEbisugawaОценок пока нет

- RC Design EC2 v1.8Документ43 страницыRC Design EC2 v1.8NELSONHUGO100% (1)

- Binder Modul WMS 10Документ52 страницыBinder Modul WMS 10sandhiakhmadОценок пока нет

- Design BasisДокумент1 страницаDesign BasisAnonymous YDwBCtsОценок пока нет

- Setra Prestress Concrete BridgeДокумент291 страницаSetra Prestress Concrete BridgepsinguliОценок пока нет

- Anchor Calculation - Case 2Документ10 страницAnchor Calculation - Case 2MdShahbazAhmedОценок пока нет

- Background To EurocodesДокумент106 страницBackground To EurocodeshmoncktonОценок пока нет

- Bending and Compression To BS 5950 and BS en 1993-1-1Документ5 страницBending and Compression To BS 5950 and BS en 1993-1-1voegelchОценок пока нет

- 06 Eurocodes Steel Workshop WALDДокумент136 страниц06 Eurocodes Steel Workshop WALDIonut SavaОценок пока нет

- LT Buckling Beam Design - Simple Method - 2upДокумент5 страницLT Buckling Beam Design - Simple Method - 2upberto2008Оценок пока нет

- Connection No.: 66: Load Ver. Brace L120X120X10 AxialДокумент5 страницConnection No.: 66: Load Ver. Brace L120X120X10 Axialrts123Оценок пока нет

- Mathcad V1 BДокумент11 страницMathcad V1 BDoğan ArslanОценок пока нет

- Numerical and Experimental Study of Vibration Mitigation For Highway Light PolesДокумент11 страницNumerical and Experimental Study of Vibration Mitigation For Highway Light Poleszfk1982Оценок пока нет

- Reinforced Concrete Early Thermal Crack CheckДокумент7 страницReinforced Concrete Early Thermal Crack CheckklynchelleОценок пока нет

- Wind Loads On A Medium-Rise Building by Using FiveДокумент13 страницWind Loads On A Medium-Rise Building by Using FiveMadura JobsОценок пока нет

- SN017a-En-EU-Shear Resistance of A Fin Plate ConnectionДокумент13 страницSN017a-En-EU-Shear Resistance of A Fin Plate Connectionravi balajiОценок пока нет

- Clause For Seismic DesignДокумент10 страницClause For Seismic DesignFarhanah Binti FaisalОценок пока нет

- Hollo-Bolts in Idea Statica: SCI P358Документ3 страницыHollo-Bolts in Idea Statica: SCI P358MartinОценок пока нет

- Structural calculations for purlin sizingДокумент1 страницаStructural calculations for purlin sizing_jessecaОценок пока нет

- 1.choosing Steel Sub GradeДокумент7 страниц1.choosing Steel Sub GradeFlorin MatisОценок пока нет

- Part 1-8 Joint DesignДокумент8 страницPart 1-8 Joint DesignChweОценок пока нет

- (PPT) Fire Resistance Assessment of Concrete StructuresДокумент81 страница(PPT) Fire Resistance Assessment of Concrete StructuresGregory Simmon100% (2)

- SN002a (NCCi - Determination of Non-Dimensional Slenderness of I and H Sections)Документ11 страницSN002a (NCCi - Determination of Non-Dimensional Slenderness of I and H Sections)Hamati RamiОценок пока нет

- SX011a en GB Example Unrestrained Beam With End MomentsДокумент9 страницSX011a en GB Example Unrestrained Beam With End MomentsBenediktas DervinisОценок пока нет

- NCCI PN 001a - Stud StrengthДокумент7 страницNCCI PN 001a - Stud StrengthravisbadryОценок пока нет

- Lateral-torsional buckling of beamsДокумент27 страницLateral-torsional buckling of beamsYoussef AliОценок пока нет

- ECCS Releases Fatigue Design ManualДокумент2 страницыECCS Releases Fatigue Design ManualKoh Wei SangОценок пока нет

- Link Look UpДокумент7 страницLink Look UpValerioZucchelliОценок пока нет

- Beam UnrestrainedДокумент9 страницBeam Unrestrainedgorgika papandОценок пока нет

- Active Vs Passive Earth PressureДокумент2 страницыActive Vs Passive Earth PressuregeorgeispasoiuОценок пока нет

- Active Vs Passive Earth PressureДокумент1 страницаActive Vs Passive Earth Pressuregeorgeispasoiu100% (1)

- 2D Frame KM 31+170Документ6 страниц2D Frame KM 31+170georgeispasoiuОценок пока нет

- Active Vs Passive Earth PressureДокумент1 страницаActive Vs Passive Earth Pressuregeorgeispasoiu100% (1)

- MacLoop 100 ENG Rev01 Dec2013Документ1 страницаMacLoop 100 ENG Rev01 Dec2013georgeispasoiuОценок пока нет

- Tutorial For Temperature Effects in Bridge DecksДокумент1 страницаTutorial For Temperature Effects in Bridge DecksgeorgeispasoiuОценок пока нет

- 1 s2.0 S1687404814000996 Main PDFДокумент16 страниц1 s2.0 S1687404814000996 Main PDFgeorgeispasoiuОценок пока нет

- Presiuni Fundatie KM 21+050 3DДокумент2 страницыPresiuni Fundatie KM 21+050 3DgeorgeispasoiuОценок пока нет

- Armare - 2D Frame KM 33+720Документ6 страницArmare - 2D Frame KM 33+720georgeispasoiuОценок пока нет

- ACEMДокумент21 страницаACEMvahap_samanli4102Оценок пока нет

- ACEMДокумент21 страницаACEMvahap_samanli4102Оценок пока нет

- Simply Supported Primary Composite BeamДокумент17 страницSimply Supported Primary Composite BeamgeorgeispasoiuОценок пока нет

- Composite Floors - Cofraplus60Документ1 страницаComposite Floors - Cofraplus60georgeispasoiuОценок пока нет

- En Upc3 L6Документ3 страницыEn Upc3 L6georgeispasoiuОценок пока нет

- Course4 Plotting Drawings Model and Paper SpacesДокумент21 страницаCourse4 Plotting Drawings Model and Paper SpacesgeorgeispasoiuОценок пока нет

- Angel in AДокумент3 страницыAngel in AdimogrecОценок пока нет

- Course4 Plotting Drawings Model and Paper SpacesДокумент21 страницаCourse4 Plotting Drawings Model and Paper SpacesgeorgeispasoiuОценок пока нет

- Loads On TunnelsДокумент29 страницLoads On TunnelsAmrend Prasad ShahОценок пока нет

- Course6 Dimensioning in AutocadДокумент20 страницCourse6 Dimensioning in AutocadgeorgeispasoiuОценок пока нет

- Aasen, B. - Eurocode 3 - Design of Joints (2010)Документ18 страницAasen, B. - Eurocode 3 - Design of Joints (2010)dhf_pereiraОценок пока нет

- SUSCOS M General Introduction PresentationДокумент35 страницSUSCOS M General Introduction Presentationda_116107118Оценок пока нет

- MSB01 Architect S Guide 2010-08-05Документ75 страницMSB01 Architect S Guide 2010-08-05Sencu Razvan100% (1)

- T24 IN2 RoutinesДокумент29 страницT24 IN2 RoutinesKhalil ArifiОценок пока нет

- 9 CE AmplifierДокумент5 страниц9 CE AmplifierAnsh PratapОценок пока нет

- Selection: Open-Type Reciprocating Compressors: Input ValuesДокумент1 страницаSelection: Open-Type Reciprocating Compressors: Input ValuesYuli RahmawatiОценок пока нет

- Battery Testing, Test Methods and ProceduresДокумент8 страницBattery Testing, Test Methods and ProceduresMuraliKrishnaОценок пока нет

- ME4111 Engineering and Mechanical PrinciplesДокумент5 страницME4111 Engineering and Mechanical PrinciplesEdvard StarcevОценок пока нет

- B. Solving Quadratic EquationsДокумент23 страницыB. Solving Quadratic EquationsHasnain -GamerОценок пока нет

- Antenna Specifications Electrical PropertiesДокумент2 страницыAntenna Specifications Electrical PropertiesLuis Adolfo Mazini RodriguesОценок пока нет

- Virtual Retinal DisplayДокумент17 страницVirtual Retinal Displaysaket_mnОценок пока нет

- OptQuest User ManualДокумент190 страницOptQuest User ManualYamal E Askoul TОценок пока нет

- State Standards: Common CoreДокумент24 страницыState Standards: Common CoreEddy R. VélezОценок пока нет

- Eca Lab Record PDFДокумент71 страницаEca Lab Record PDFAlokОценок пока нет

- Ch01Документ33 страницыCh01sakali aliОценок пока нет

- NTSE 2015 Stage I Official Result Karnataka PDFДокумент10 страницNTSE 2015 Stage I Official Result Karnataka PDFAnnu NaikОценок пока нет

- Failure Mode For Gas CHromatographДокумент2 страницыFailure Mode For Gas CHromatographardi-Оценок пока нет

- Complete trip-free loop, PFC and PSC testerДокумент2 страницыComplete trip-free loop, PFC and PSC testerGermanilloZetaОценок пока нет

- CC5291-Design For Manufacture Assembly and Environments QBДокумент11 страницCC5291-Design For Manufacture Assembly and Environments QBYuvaraj Yuvi0% (1)

- 16 RMM Spring Edition 2020 Solutions CompressedДокумент83 страницы16 RMM Spring Edition 2020 Solutions CompressedKhokon GayenОценок пока нет

- Inductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Документ27 страницInductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Rodz Gier JrОценок пока нет

- No.1 PrestressedДокумент10 страницNo.1 PrestressedKristin ArgosinoОценок пока нет

- Iygb Gce: Mathematics MP2 Advanced LevelДокумент7 страницIygb Gce: Mathematics MP2 Advanced Levelsingh cos tanОценок пока нет

- Hargreaves 2007Документ15 страницHargreaves 2007Sam GonçalvesОценок пока нет

- Cisco Certified Network Associate - CCNA (200-301) : Building Blocks of NetworkingДокумент5 страницCisco Certified Network Associate - CCNA (200-301) : Building Blocks of NetworkingShahnawaz SiddiqueОценок пока нет

- TDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemДокумент12 страницTDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemKermess McОценок пока нет

- DebugДокумент14 страницDebugMigui94Оценок пока нет

- XI-Opt. Syllabus (2023-24)Документ29 страницXI-Opt. Syllabus (2023-24)INDERDEEPОценок пока нет