Академический Документы

Профессиональный Документы

Культура Документы

What Our Customers Value: JUMO Metal Technology

Загружено:

Prasad MahajanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

What Our Customers Value: JUMO Metal Technology

Загружено:

Prasad MahajanАвторское право:

Доступные форматы

What our customers value

n n

Many years of experience

Metal technology is an important part of the JUMO production, which has more than 60 years of experience. Distinctive innovative strength and forward-looking technologies enable us to provide solutions optimally tailored to your requirements. Consistent service and established customer focus ensure reliability at all times.

Everything from a single source thanks to flexible combination of technologies Small-scale and medium-scale system supplier In-house prototype production Engineering (consulting, design) First-class quality

n n n n

Our references

JUMO production service ...

that everything fits.

Our key industries

n n n n n n

JUMO GmbH & Co. KG Moritz-Juchheim-Strae 1 36039 Fulda, Germany Phone: Fax: E-mail: Internet: +49 661 6003-712 +49 661 6003-9637 mail@jumo.net http://metal-technology.jumo-en.info

PR 10010 EN/2013-04-11/00600691

JUMO Metal Technology

Production Portfolio

The latest production technologies and uncompromising quality assurance

Medical technology Level measurement technology Hydraulic plants Optical industry Locks and fittings industry Measurement and control technology

www.jumo.net

Toolmaking Stamping and forming technology Flexible sheet metal processing Float production Welding, joining, and mounting technology Surface engineering

JUMO metal technology production portfolio

Module front Module Sheet metal/ bent parts Enclosure/bridge Enclosure cover Tool Floats Protection sleeves

Industry

Medical technology

Locks and fittings industry/electric motors 500 to 30,000 units Stainless steel Welding/joining technology Stamping Bending Riveting Pulse welding Electropolishing Mounting 100 to 500,000 units

Measurement and control technology 100 to 250,000 units

Cross-industry Optical industry as well as measurement and control technology 100 to 5,000 units Minimum one unit

Level measurement technology 5 to 50,000 units Stainless steel, titanium, Hastelloy Floats Stamping Drawing Welding (laser/ microplasma) Electropolishing / pickling Mounting Diameter: 20 mm to 200mm

Measurement and control technology 10 to 5,000 units Steel, stainless steel, brass Welding/joining technology Single/multipart sleeves Welding (TIG/laser) Certification DIN EN 10204 Coating CNC turning Pressure testing Diameter: 6 to 15mm, length: 100 to 400mm

Order quantity Material Technologies

3 to 15,000 units Zinc-plated steel, stainless steel Flexible sheet metal processing Laser cutting CNC bending Galvanizing Mounting

Steel, stainless steel, Zinc-plated steel non-ferrous metals Stamping, forming Stamping, forming

Stainless steel, Tool steel/powder polished on one side steel, carbides Flexible sheet metal processing Laser cutting Stamping CNC bending Punch laser combination Toolmaking Wire erosion Sink erosion Precision drilling Design in CATIA CNC turning/ milling/polishing

Stamping/drawing, Ready-to-use incl. ready to use thread forming and Progressive tool implementation of all countersinks Progressive tool

Dimensions

500 350 2mm

150 100 2 mm

10 15 0.5 mm 10 20 1 to 150 1502.5mm to 80 120 1mm

144 144 1 mm

1000600370mm

Вам также может понравиться

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОт EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Catalog: About Us Certification Services Contact Project InsuranceДокумент30 страницCatalog: About Us Certification Services Contact Project InsuranceNehaKarunyaОценок пока нет

- Carmex Catalogue WebДокумент203 страницыCarmex Catalogue WebPaisaje SilenciosoОценок пока нет

- Sultan Al Baqami Est. For TradingДокумент7 страницSultan Al Baqami Est. For Tradingsalman KhanОценок пока нет

- 2021 MicroplasmaДокумент20 страниц2021 MicroplasmatibisortОценок пока нет

- Technical Data About The Production of Steel StructuresДокумент2 страницыTechnical Data About The Production of Steel StructuresPress EscapeОценок пока нет

- Catalog Steel 2007 enДокумент57 страницCatalog Steel 2007 enVasilica BarbarasaОценок пока нет

- GTDMCДокумент9 страницGTDMCSaadFarooqОценок пока нет

- Laser Cutting Sheet Metal Fabrication Melior Laser Company Intro 05 2013Документ14 страницLaser Cutting Sheet Metal Fabrication Melior Laser Company Intro 05 2013Kirke71Оценок пока нет

- Precision Technologies: Industrial Supplier Since 1988Документ28 страницPrecision Technologies: Industrial Supplier Since 1988Paolo TempestaОценок пока нет

- Texas Technology PresentationДокумент9 страницTexas Technology PresentationRoberto SolorzanoОценок пока нет

- About SWDDPLДокумент10 страницAbout SWDDPLumasankar.jОценок пока нет

- AMADA Painutustooriistade Kataloog 2012Документ0 страницAMADA Painutustooriistade Kataloog 2012sssf-dobojОценок пока нет

- TBT Deep Hole Drilling Tools: Two Flute DrillsДокумент3 страницыTBT Deep Hole Drilling Tools: Two Flute Drillsparadoxid78Оценок пока нет

- Aluminium Glass and MetalsДокумент47 страницAluminium Glass and Metalssana shahzadiОценок пока нет

- 2013 01 15 Baoyuan RevisedДокумент37 страниц2013 01 15 Baoyuan RevisedVKTTOOLSОценок пока нет

- Pomina Steel enДокумент2 страницыPomina Steel enrazen_in0% (1)

- Company Profil Ver6.31Документ28 страницCompany Profil Ver6.31Tze YenОценок пока нет

- CatalogДокумент8 страницCatalogBarry KnightingОценок пока нет

- ESKATE China Ecatalogue PDFДокумент20 страницESKATE China Ecatalogue PDFMarlon BrandoОценок пока нет

- Powder Injection MouldingДокумент45 страницPowder Injection MouldingAmritanshu SharmaОценок пока нет

- Jumo Delos T: Electronic Temperature Switch With Display and Analog OutputДокумент17 страницJumo Delos T: Electronic Temperature Switch With Display and Analog OutputPraise Sam AbrahamОценок пока нет

- Seamless Tubes BrochureДокумент16 страницSeamless Tubes BrochureNisarg PandyaОценок пока нет

- Central Components Mfg. Company ProfileДокумент6 страницCentral Components Mfg. Company Profilewebmaster5813Оценок пока нет

- Catalogue - Cooper WireДокумент5 страницCatalogue - Cooper WiretrapistОценок пока нет

- Hoelzel Brochure enДокумент12 страницHoelzel Brochure enDVP EngineeringОценок пока нет

- Ifm International Short-Catalogue GB 05Документ29 страницIfm International Short-Catalogue GB 05cesar luis gonzalez rodriguez100% (1)

- SM Enterprises - ProileДокумент3 страницыSM Enterprises - ProileUday MahaleОценок пока нет

- Datron c5 BrochureДокумент2 страницыDatron c5 BrochurejcempoalSCОценок пока нет

- Sumitomo LinepipeДокумент46 страницSumitomo LinepipeMaqsoodAnwarОценок пока нет

- Data Sheet: W-Series WDU 2.5Документ8 страницData Sheet: W-Series WDU 2.5Hafiz YunusОценок пока нет

- TR Branded Products TR Fastenings Contact Us Application Engineering Service OverviewДокумент2 страницыTR Branded Products TR Fastenings Contact Us Application Engineering Service OverviewjuanmadjjОценок пока нет

- Midas C08 Pressure TXДокумент6 страницMidas C08 Pressure TXKamitkumar PatelОценок пока нет

- MTM BrochureДокумент2 страницыMTM BrochureRonny AndalasОценок пока нет

- 002 DEW Warmarbeitsstahl GB PDFДокумент76 страниц002 DEW Warmarbeitsstahl GB PDFSinan Yıldız100% (1)

- GTMA Member Pages A-ZДокумент124 страницыGTMA Member Pages A-ZGTMAonlineОценок пока нет

- Innovative: Foundry SolutionsДокумент6 страницInnovative: Foundry SolutionsInnovative Foundry SolutionsОценок пока нет

- PipeTec eДокумент20 страницPipeTec erahman_1904Оценок пока нет

- (A Govt. of India Society, Ministry of MSME) ISO 9001:2000 & ISO 14001:2004 ORGANISATIONДокумент36 страниц(A Govt. of India Society, Ministry of MSME) ISO 9001:2000 & ISO 14001:2004 ORGANISATIONSomnath RangrejОценок пока нет

- P/M (Powder Metallurgy) : Joseph Tunick StraussДокумент41 страницаP/M (Powder Metallurgy) : Joseph Tunick StraussAnonymous oTrMzaОценок пока нет

- TECSIS Serie P1705-P1706-P1709Документ3 страницыTECSIS Serie P1705-P1706-P1709Nebojsa IvinОценок пока нет

- The Complete EngineeringДокумент8 страницThe Complete EngineeringRafeek AliОценок пока нет

- WPC Company Profile 2012Документ18 страницWPC Company Profile 2012api-209859919Оценок пока нет

- H GuruДокумент4 страницыH GuruAvneet MaanОценок пока нет

- Catalog DatronДокумент136 страницCatalog DatrongeorgegvrОценок пока нет

- Transmisor de Presión Modelo MIDAS C08 Marca JUMO (Alemania)Документ10 страницTransmisor de Presión Modelo MIDAS C08 Marca JUMO (Alemania)Danielote1984Оценок пока нет

- About M.O.C Dies and MouldsДокумент11 страницAbout M.O.C Dies and Mouldsnagarajan224100% (1)

- GMH Produktgruppenbroschuere Blankstahl en R02Документ6 страницGMH Produktgruppenbroschuere Blankstahl en R02Chau BaoОценок пока нет

- Data KingДокумент16 страницData KingPriyanka ChaudharyОценок пока нет

- EUROFER Brochure Quality Tracking FinalДокумент4 страницыEUROFER Brochure Quality Tracking FinalmgalltestОценок пока нет

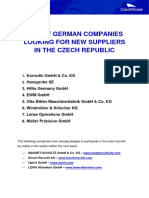

- Seznam Nemeckych FiremДокумент9 страницSeznam Nemeckych Firemkaushal kumarОценок пока нет

- Canbody WeldersДокумент6 страницCanbody WeldersPeyman KhОценок пока нет

- Company Introduction - Quadrant EngineeringДокумент32 страницыCompany Introduction - Quadrant EngineeringMitul Patel100% (1)

- Ceratizit ToolsДокумент340 страницCeratizit ToolsguimaslipaОценок пока нет

- Industrial Type Pressure GaugeДокумент4 страницыIndustrial Type Pressure GaugeSandi AslanОценок пока нет

- 750 HSS enДокумент20 страниц750 HSS enPascu Tiberiu CiprianОценок пока нет

- Gama de Produse - UKДокумент2 страницыGama de Produse - UKColta VictorОценок пока нет

- Datenblatt: W-Series Wdu 4Документ8 страницDatenblatt: W-Series Wdu 4Ernesto OlacheaОценок пока нет

- Engineering Applications: A Project Resource BookОт EverandEngineering Applications: A Project Resource BookРейтинг: 2.5 из 5 звезд2.5/5 (1)

- Position Control Unit: Specification SheetsДокумент16 страницPosition Control Unit: Specification SheetsmohammadОценок пока нет

- Operator'S Manual: FANUC FAST Ethernet FANUC FAST Data ServerДокумент240 страницOperator'S Manual: FANUC FAST Ethernet FANUC FAST Data ServerSergio Trujillo CerroОценок пока нет

- Cad Cam LP 19Документ12 страницCad Cam LP 19raviteja tankalaОценок пока нет

- BuselattoДокумент4 страницыBuselattoMilanko MarjanovicОценок пока нет

- System Renishaw For Machine ToolДокумент56 страницSystem Renishaw For Machine ToolIlija SisoskiОценок пока нет

- PEP5 Instructions 2016 PDFДокумент31 страницаPEP5 Instructions 2016 PDFWei FangОценок пока нет

- ECNG3004 Control System ApplicationsДокумент7 страницECNG3004 Control System ApplicationsMarlon BoucaudОценок пока нет

- Milling and Machining CentersДокумент5 страницMilling and Machining CentersJose JulianОценок пока нет

- TNN CNC Lathe Machine CatalogueДокумент3 страницыTNN CNC Lathe Machine Catalogueneda100% (1)

- Internship Report (Chai)Документ26 страницInternship Report (Chai)sai chaithanyaОценок пока нет

- DDCS V4.1 Users Manual in English V1Документ89 страницDDCS V4.1 Users Manual in English V1pelebotiniОценок пока нет

- Tribology July 2018 (2010 Scheme)Документ39 страницTribology July 2018 (2010 Scheme)Gopal KumarОценок пока нет

- Machine Manuals For ALARM MessagesДокумент29 страницMachine Manuals For ALARM Messagesanas mohammedОценок пока нет

- Douce Hydro Jarret 2012 GBДокумент46 страницDouce Hydro Jarret 2012 GBAurica DanielОценок пока нет

- Increase Efficiency With The NX-to-VERICUT InterfaceДокумент4 страницыIncrease Efficiency With The NX-to-VERICUT InterfaceTRUNG QUOC LEОценок пока нет

- 15' Sales Manual MEGA100 (En)Документ60 страниц15' Sales Manual MEGA100 (En)277702715Оценок пока нет

- SIN WF5 0913 enДокумент140 страницSIN WF5 0913 envozoscribdОценок пока нет

- Engineering Workshop Pre FeasibilityДокумент8 страницEngineering Workshop Pre FeasibilityengrzishОценок пока нет

- P51Документ8 страницP51asitzone4u100% (1)

- CNC Writing MachineДокумент9 страницCNC Writing MachineANKITОценок пока нет

- Hurco VM2 ProposalДокумент14 страницHurco VM2 ProposalRonza129Оценок пока нет

- JANUARY 2020 Surplus Record Machinery & Equipment DirectoryДокумент717 страницJANUARY 2020 Surplus Record Machinery & Equipment DirectorySurplus RecordОценок пока нет

- Solidcam 2014 Modules Overview PDFДокумент106 страницSolidcam 2014 Modules Overview PDFMirza CaticОценок пока нет

- Dec 2014Документ1 694 страницыDec 2014Avadhoot JoshiОценок пока нет

- Cad/ Cam Prof. P. V. Madhusudhan Rao Department of Mechanical Engineering Indian Institute of Technology, Delhi Lecture No. # 03 What Is CAD/ CAMДокумент16 страницCad/ Cam Prof. P. V. Madhusudhan Rao Department of Mechanical Engineering Indian Institute of Technology, Delhi Lecture No. # 03 What Is CAD/ CAMDhanaraj RamachandranОценок пока нет

- XPTHC-100II Instruction Manual PDFДокумент19 страницXPTHC-100II Instruction Manual PDFEliane Souza0% (1)

- 2018 Salman Sarfraz Implementinga Preventive Maintenance Planning ModelДокумент5 страниц2018 Salman Sarfraz Implementinga Preventive Maintenance Planning ModelRudi SuherlanОценок пока нет

- Cad Cam ModuleДокумент105 страницCad Cam ModuleNyashadzamwari GadzaiОценок пока нет

- Ump PDFДокумент9 страницUmp PDFSurah Al Kahfi mmjОценок пока нет

- Milling MachineДокумент11 страницMilling MachineAnil Deshpande100% (2)