Академический Документы

Профессиональный Документы

Культура Документы

ITMF 2013 02 Setyawan ENU

Загружено:

bcqbaoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ITMF 2013 02 Setyawan ENU

Загружено:

bcqbaoАвторское право:

Доступные форматы

Presentation 02.

Maintenance Management on Current Transformer

Andhy Dharma Setyawan / Tanzil Ramadhan Aljufri, PLN, Indonesia thoroughly for the purpose of measurement and protection. In Java Bali system there are several level voltage used for electric power transmission systems, which are Extra High Voltage (500 kV) and High Voltage (150 kV & 70 kV). This paper covers the maintenance management on current transformer for electric power transmission systems on 500 kV, 150 kV and 70 kV. HV Apparatus Current transformer of PLN consists of more than 10 manufacturers and the total number of Current transformer are informed in table below : CT Total 500 kV 2325 150 kV 10431 70 kV 1803

Abstract

Current transformer are among the most commonly used items of electrical apparatus which reduce power system current to lower value for measurement or protection and insulate secondary circuits from primary. The importance of current transformers in the transmission and distribution of electrical energy cannot be over emphasized because it is effect the accuracy of protection and metering. For the availability of the electricity, each utility needs to settle their maintenance management for their operational and maintenance of the electrical apparatus device including current transformers. PLN Indonesia use Failure Mode Effect Analysis (FMEA) as a method for the operational and maintenance guidance. This method is the basic guidance for determining the component need to be monitor and maintained. The maintenance method of current transformer using in PLN are : 1. In service inspection - Dielectric - Mechanical Structure - CT Grounding 2. In service Measurement - Thermo vision 3. Shutdown Testing/Measurement - Insulation resistance - Tan Delta - Oil quality test (BDV, water content, acidity test, etc) - Dissolve Gas Analysis - Grounding resistance - Ratio - Excitation test / knee point 4. Shutdown treatment The maintenance schedule will be made based on above type of maintenance and as guidance for the Condition Based maintenance (CBM) of current transformers.

Tab.1 PLNs Current Transformer Population

Failure Mode and Effect Analysis (FMEA)

PLN Indonesia uses FMEA as a guideline for operational and maintenance of current transformer. FMEA is a method that intends to analyze the cause of the equipment failure. Those became a reference for determining the component should be checked or maintained FMEA made under several stages as follows: a. Define the system (equipment) and its function. Definition: a set of components that work together to form one or more functions. b. Determine subsystem and function for each subsystem. Definition: Equipment or component which form together as a one function. According to its function, subsystem is an independent unit in a system c. Determine functional failure for each subsystem Definition: Functional failure is the inability of an asset to work as properly base on the asset performance standard. d. Determine failure mode for each subsystem. Definition: Failure mode is every incident which caused functional failure

Introduction

Current Transformer is the equipment used to measure current value in power system on the primary side (EHV,HV and MV) and transform the current value into a small scale accurately and

OMICRON 2013 Instrument Transformer Measurement Forum

Presentation 02.2

Check the pressure of N2 gas through a manometer installed in CT (numeric indicator) Checking the SF6 gas pressure through a manometer installed in CT (numeric indicator) Seepage / leakage of oil CT. Do a visual inspection of the porcelain insulator. Observed insulator of cracks, blemishes, broken and other abnormalities. Mechanical Structure Mechanical structure is the equipment that supporting the eestablishment of the current transformer. Mechanical inspection conducted by checking equipment below:

Tab.2 FMEA of PLNs Current Transformer

Condition of core housing (house / tank cores) visually, whether the core housing in normal conditions, corrosion or cracking. Condition of the support structure. CT Grounding Inspections carried out by checking the CT grounding wire and grounding terminals by checking the connection between switchyard grounding terminal with mess grounding switchyard.

Maintenance Methods

In Service Measurement

In Service Measurement is the method measurement done under online operation.

Fig. 1 PLNs Maintenance Method

of

Current transformer maintenance guideline was made based on FMEA that have been developed, as follows: In Service Inspection In Service Measurement Shutdown Testing/Measurement Shutdown Treatment

In Service Inspection

In Service Inspection is a visual observation activities on parts of the equipment which potentially shows anomaly that could degrade the equipment performance or damage the whole or part of equipment. The activities conducted during the In Service Inspection are: Dielectric In service inspection held by viewing the visual adequacy of CT through dielectric media: Check the oil level height on the glass probe current transformer.

Thermovision Thermovision used to see hot spots in electrical installations, with Infra red thermovison we can see losses that occur in the network, the higher the temperature hotspot that happens, the greater the losses that occurred. Losses can be caused by a lack of connection. The thermovison check is used to see the connection points on the current transformer. Thermovision performed on: Conductor and CT clamps. It aims to determine the temperature difference between the conductor and the clamp CT Isolator and housing CT. It aims to detect abnormalities / hotspots in the CT. Thermovision performed every 3 months, except for the 500 kV CT performed every 2 weeks.

Shutdown Testing/Measurement

Shutdown testing / measurement is the methods of measurement done under offline/outages operation. This work was carried out during routine maintenance or during the investigation of abnormalities.

OMICRON 2013 Instrument Transformer Measurement Forum

Presentation 02.3

Insulation Resistance Insulation resistance test using a 5 kV insulation resistance test for the primary side and 500 V for the secondary side. Serves to determine the quality of the insulation resistance of the current transformer. Recording the results of measurements performed at the time of 60 seconds. Tan Delta Tan delta testing is done to determine the value of dissipation factor (tan delta) and a capacitance value of CT. Increase in the value of capacitance will indicate a paper insulation contaminated by moisture, contamination or deterioration in the insulation system CT. Insulating Oil Quality Test Based on the standard IEC 60422 Mineral insulating oils in electrical equipment supervision and maintenance guide , Current transformer (CT) in the category D (instrument / protection transformers> 170 kV) and category E (instrument / 170 kV transformer protection). Quality testing instrument transformer oil can only be done on the type of instrument transformer none hermetically sealed. Insulation quality testing is done based on time based maintenance is every 10 years (after 5 times of every 2 year's maintenance) or if the tan delta test results badly. Sampling needs to be done a second time prior consultation with the manufacturer or refer to the instruction manual of each manufacturer. Current transformer insulating oil quality testing according to IEC 60422 standard covers: Break Down Voltage (BDV) test Water Content test Acidity test Dielectric Disspation Factor test Interfacial Tension test Sediment dan Sludge test Flash point test Dissolved Gas Analysis (DGA) Dissolved Gas Analysis (DGA) is a diagnostic tool to detect and evaluate a damages on electric power equipment by measuring multiple gas content in the insulating oil, include gas: Nitrogen (N2), Oxygen (O2), Hydrogen (H2), Carbon monoxide (CO), Carbon dioxide (CO2), Methane (CH4), Ethane (C2H6), Ethylene (C2H4) and Acetylene (C2H2). According to the standart IEC 60599 "Mineral oil-impragnated electrical equipment in service-Guide to the interpretation of dissolved and free gases analysis", abnormalities in equipment instrument transformers can be detected by using DGA.

Grounding Resistance Measurement of the amount of ground resistance using ground resistance tester. Grounding resistance value affects current the safety condition of the maintenance personnel. Ratio Ratio measurements aimed to compare the ratio value measured by the value on the nameplate. This test uses current injection test equipment (high current test injection), done by adjusting the supply from the test injection refer to the value specified and record the current test result at the secondary side of current transformer. The ct ratio value equals with reference CT value multiply by secondary current value of the tested CT. The equation is:

NT: NR: IR: IT :

Tested CT Ratio Reference CT Ratio Current of reference CT Nominal Current of tested CT

Excitation Testing (kneepoint voltage) The aim of excitation testing is to determining the characteristics of the excitation current transformer. Characteristic of the excitation current transformer is a curve illustrating the relationship between the excitation current and rms voltage applied to the secondary side of the current transformer in the primary side open circuit condition. In the excitation characteristic curve can be determine kneepoint voltage of current transformer.

Shutdown Treatment

Shutdown treatment is an activity to solve the problems/anomaly found during in service inspection/measurement or shutdown testing / measurement.

Strategy of Maintenance Management

The transmission system of Java Bali is managed by 16 operational units (APP) which responsible of the substation and transmission performance. This situation needs tight and effective coordination.

OMICRON 2013 Instrument Transformer Measurement Forum

Presentation 02.4

are developing / optimizing maintenance programs and improve quality of condition assessment. The maintenance schedule will be made based on the above-mentioned types of maintenance activities and as guidance for the Condition-Based maintenance (CBM) of Current Transformers.

Literature

[1] [2]

Fig. 2 PLNs Inspection dan Assesment System

Pedoman Pemeliharaan Trafo Arus PT. PLN (Persero) 2009 IEC 60422: Mineral insulating oils in electrical equipment supervision and maintenance guidance IEC 60599: Mineral oil-impragnated electrical equipment in service-Guide to interpretation of Dissolved and free gas analysis, 1996 IEEE Std C57.13-1993: Standard Requirements for Instrument Transformers. Paper IEEE: A Tool for Realibity and Safety: Predict and Prevent Equipment failures with Thermography , Copyright material IEEE Paper No. PCIC-97-06

on HV Apparatus Level-1 inspection means in service inspection to detect any abnormalities or anomalies on the equipment and initiate follow-up inspection (Inspection Level 2 and Level 3). The purpose of Level-1 inspection is getting an early indication of abnormal equipment (anomaly). This inspection was conducted by maintenance personnel in substation. Level-2 Inspection means in service measurement (on-line measurement). This inspection was also conducted by maintenance personnel in substation or operational unit. Level-3 inspection means shutdown testing or measurement (off-line measurement). The activity was conducted by specialized and trained maintenance personnel of operational unit. The maintenance personnel in substation is also processing the result of level-1 inspection (anomali) as trigger for follow up action /treatment. Level-A diagnostic is conducted by skilled and trained assessment engineers of operational units with output condition assessment of the hv apparatus. Level-B diagnostic is conducted by skilled and trained assessment engineers of head office with outputs life assessment. And also levelC diagnostic is conducted by skilled and trained assessment engineers of head office with outputs risk assessment of hv apparatus.

[3]

[4] [5]

About the Authors

Andhy Dharma Setyawan was born in Indonesia on May 30th, 1979. He received her bachelor degree in Electrical Engineering from Brawijaya University. With 2 years experiences in Matsushita Lighting Indonesia as Maintenance Engineer, since 2006 he joined PT. PLN (Persero) Transmission and Load Dispatch Center Java Bali, Indonesia as Substation O&M Engineer. Tanzil Ramadhan Aljufri was born in Indonesia on June 06, 1985. He received her bachelor degree in Electrical Engineering from Muhammadiyah Semarang University. Since 2009, he is currently employment of PT. PLN (Persero) Transmission and Load Dispatch Center Java Bali, Indonesia as Protection Operation & Maintenance Engineer.

Conclusion

Various type and manufacturer of current transformer which are installed in Java Bali system need an effective strategy of maintenance management to assess the condition of the Current transformer so the breakdown incident or rapid deterioration that would lead to malfunction of potection system could be avoided. Implementation of FMEA method as the basic guidance for determining the failure path of each component and combine with statistical operational data could be a tool to analyse critical parts in a component. The next steps from this point of view

OMICRON 2013 Instrument Transformer Measurement Forum

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Astm A 240-18Документ12 страницAstm A 240-18Giann' Andreh'xd100% (2)

- DOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportДокумент323 страницыDOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportGustavo AguayoОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- PF-DF From MeggerДокумент74 страницыPF-DF From Meggerbcqbao100% (1)

- Basic Concepts of ChemistryДокумент31 страницаBasic Concepts of ChemistryMohammadHussainKhan100% (1)

- Pe Fir Handbook 1 2Документ237 страницPe Fir Handbook 1 2Salman JoОценок пока нет

- Manual Compresor Sullair PDFДокумент68 страницManual Compresor Sullair PDFKevin J. Peña CabarcasОценок пока нет

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceДокумент36 страницCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoОценок пока нет

- IEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsДокумент37 страницIEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsbcqbaoОценок пока нет

- 2 - 14 Experiences EuroDoble MeetingsДокумент22 страницы2 - 14 Experiences EuroDoble Meetingsbcqbao100% (1)

- Sweep Frequency Response Analysis SFRA TrainingДокумент82 страницыSweep Frequency Response Analysis SFRA Trainingbcqbao100% (1)

- Chapter 1 - Introduction To Well Planning & Design PDFДокумент47 страницChapter 1 - Introduction To Well Planning & Design PDFAkrem Hkimi100% (6)

- Test Voltages For CablesДокумент3 страницыTest Voltages For CablesMahmoud EidОценок пока нет

- Guide To Low Resistance Booklet-CROPICOДокумент39 страницGuide To Low Resistance Booklet-CROPICObcqbaoОценок пока нет

- Measurement of Earthing Systems PDFДокумент45 страницMeasurement of Earthing Systems PDFMostafa AliОценок пока нет

- Getting Value From Transformer Sfra: TransformersДокумент7 страницGetting Value From Transformer Sfra: Transformersbcqbao100% (1)

- 8 SfraДокумент81 страница8 Sfrabcqbao100% (1)

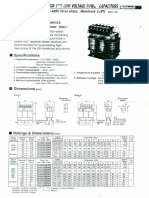

- Series Reactor Lok' V TAG Capacitors: 200 230V / 380-460V Three Phase Eact Nce L 6%Документ2 страницыSeries Reactor Lok' V TAG Capacitors: 200 230V / 380-460V Three Phase Eact Nce L 6%bcqbaoОценок пока нет

- Product Catalog: Smart Test Devices For Reliable Electric Power SystemsДокумент32 страницыProduct Catalog: Smart Test Devices For Reliable Electric Power SystemsbcqbaoОценок пока нет

- Viking Sprinkler Shield & GuardДокумент4 страницыViking Sprinkler Shield & Guardshankar_04Оценок пока нет

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationДокумент3 страницыPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesОценок пока нет

- YLAA InstallationДокумент62 страницыYLAA InstallationJoe YoungОценок пока нет

- Experimental Detemination of Crystal StructureДокумент40 страницExperimental Detemination of Crystal StructureAASHIR AHMAD JASKANIОценок пока нет

- Kaowool Board Low Temperature PDFДокумент2 страницыKaowool Board Low Temperature PDFmaxibarrios72Оценок пока нет

- Chemistry March 2008 EngДокумент7 страницChemistry March 2008 EngPrasad C M0% (2)

- DNA-protein Interactions: Methods For Detection and AnalysisДокумент31 страницаDNA-protein Interactions: Methods For Detection and AnalysisAhsan Arshad BSIT-F16-LC-008Оценок пока нет

- Technological Advancements in The Drying of Fruits and Vegetables: A ReviewДокумент14 страницTechnological Advancements in The Drying of Fruits and Vegetables: A ReviewMaria MadanОценок пока нет

- E Shield6421 Datasheet PDFДокумент1 страницаE Shield6421 Datasheet PDFYo AОценок пока нет

- Jurnal International AmilumДокумент17 страницJurnal International AmilumGhiyatsKalukuОценок пока нет

- TIAC TechnologyДокумент13 страницTIAC TechnologyPaul SunnyОценок пока нет

- TDS OF H-408 Silicone Adjuvant For AgricultureДокумент2 страницыTDS OF H-408 Silicone Adjuvant For AgricultureAda FuОценок пока нет

- Influence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloyДокумент8 страницInfluence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloywicaksonoОценок пока нет

- Back To Basics ... : Material Selection and Heat TreatmentДокумент8 страницBack To Basics ... : Material Selection and Heat TreatmentMuhammad Faisal FirdausОценок пока нет

- Experiment No. 2 Classes of Chemical Reactions BackgroundДокумент5 страницExperiment No. 2 Classes of Chemical Reactions BackgroundjonastolentinoОценок пока нет

- Tech-Venting HCL TanksДокумент2 страницыTech-Venting HCL TanksDHAVALESH AMОценок пока нет

- Koerner. On The Creep GeosynteticДокумент6 страницKoerner. On The Creep GeosynteticSergio Xexo Gonzalez RuizОценок пока нет

- DesalinationTechnologiesforDevelopingCountriesAReview PDFДокумент22 страницыDesalinationTechnologiesforDevelopingCountriesAReview PDFlebob12Оценок пока нет

- Latihan Industri UiTM PDFДокумент28 страницLatihan Industri UiTM PDFzzОценок пока нет

- Operator'S Manual Px01X-Xxx-Xxx-Axxx: 1/4" Diaphragm PumpДокумент12 страницOperator'S Manual Px01X-Xxx-Xxx-Axxx: 1/4" Diaphragm PumpAir PumpingОценок пока нет

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosДокумент4 страницыSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosSyafrian AzmiОценок пока нет

- NuclearДокумент10 страницNuclearUsman MunirОценок пока нет

- National Core Manual - Chapter 5 Pesticide Hazards and First AidДокумент55 страницNational Core Manual - Chapter 5 Pesticide Hazards and First AidMarvinGarciaОценок пока нет

- GPRSДокумент6 страницGPRSRoberto CapchaОценок пока нет

- 7th Physical and Chemical Changes Lesson PlanДокумент2 страницы7th Physical and Chemical Changes Lesson PlanAnkita DiverОценок пока нет