Академический Документы

Профессиональный Документы

Культура Документы

40 - 4 Swivel Base en 15373

Загружено:

salekojic5332Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

40 - 4 Swivel Base en 15373

Загружено:

salekojic5332Авторское право:

Доступные форматы

Howe A/S Att.

: Ruben Tychsen Mandal All 23 5500 Middelfart

Order no. Page Appendices Initials

352892E 1 of 1 2 laha/flg/hbs

Test Report

Material:

Model:

Type: Length: Weight: Materials:

40/4 with five star base

Conference chair 656 mm 11 kg Seat/back: Frame: Spindle: Five star base: 10 mm plastic 13 mm metal thread 28 mm metal Cast aluminium Width: 490 mm Lab.no.: Height: 352892 E 802/880 mm

Sampling:

The test material was sampled by the client and received at the Danish Technological Institute 25-05-2010. EN 15373:2007 Furniture - Strength, durability and safety - Requirements for non-domestic seating. Loading according to Test severity 3. Severe use. Clauses 5.1, 5.2.2, 5.2.3, 5.3.2, 5.4, 6.1.1, 6.1.2, 6.1.4, 6.1.10, 6.1.12, 6.1.16, 6.1.17, 6.1.19, 6.1.20, 6.2.

Method:

Period: Result:

The testing was carried out from 25-05-2010 to 06-07-2010. Model 40/4 with five star base fulfils the requirements in EN 15373:2007 Furniture - Strength, durability and safety - Requirements for non-domestic seating. Loading according to Test severity 3. Individual results appear from Appendix 1.

Storage: Terms:

The test material will be destroyed after 1 month, unless otherwise agreed.

The test has been performed according to the attached conditions, which are according to the guidelines laid down by DANAK (The Danish Accreditation). The testing is only valid for the tested specimen. The test report may only be extracted, if the laboratory has approved the extract. This report was generated by software version 2.05 of 2010-02-04.

Software:

07-07-2010, Danish Technological Institute, Wood Technology, Taastrup

Test responsible

\\dmwclus\dmw_docs\1214179\1315203_352892 EN 15373.doc

Co-reader

Report no. Appendix Page Initials

352892E 1 1 of 2 laha/flg/hbs

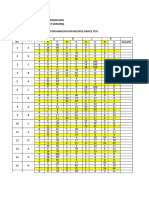

Test of model: 40/4 with five star base Lab. no.: 352892 E

Loading according to Test severity 3.

Test 5.1 General 5.2.2 Shear and squeeze points under influence of powered mechanisms 5.2.3 Shear and squeeze points during use 5.3.2 Swivelling chairs 5.3.3 Non swivelling chairs 5.4 Rolling resistance of the unloaded chair 6.1.1 Static Load - Seat and Back 6.1.2 Static Load of Seat Front Edge 6.1.3 Additional Static Load Test for Tilting Chairs and Intermediate Reclining Chairs 6.1.3 Additional Static Load Test for Fully Reclining Chairs 6.1.4 Vertical Static Load on Back 6.1.5 Static Load Test of Foot Rail/Foot Rest and Leg Rest 6.1.6 Sideways Static Load of Arms 6.1.7 Sideways Static Load of Wings 6.1.8 Downwards Static Load of Arms 6.1.9 Vertical Upwards Static Load on Arm Rests 6.1.10 Combined Seat and Back Fatigue Test 6.1.11 Seat and Back Fatigue Test for Tilting Chairs and Intermediate Reclining Chairs 6.1.11 Seat and Back Fatigue Test for Fully Reclining Chairs and Loungers 6.1.12 Seat Front Edge Fatigue Test 6.1.13 Arm Fatigue Test 6.1.14 Leg Rest Fatigue Test 6.1.15 Foot Rail Fatigue Test 6.1.16 Leg Forward Static Load Test 6.1.17 Legs Sideways Static Load Test

\\dmwclus\dmw_docs\1214179\1315203_352892 EN 15373.doc

Test Method EN 15373, 5.1 EN 15373, 5.2.2 EN 15373, 5.2.3 EN 15373, 5.3.2 EN 15373, 5.3.3 EN 15373, 5.4 EN 1728, 6.2.1 EN 1728, 6.2.2 EN 1728, 6.3.1 EN 1728, 6.3.2 EN 15373, A.2 EN 1728, 6.4 EN 1728, 6.5 EN 1728, 6.5 EN 1728, 6.6 EN 15373, A.1 EN 1728, 6.7 EN 1728, 6.9.1 EN 1728, 6.9.2 EN 1728, 6.8 EN 1728, 6.10 EN 1728, 6.11 EN 15373, A.5 EN 1728, 6.12 EN 1728, 6.13

Cycles

Load

Result Passed Passed Passed Passed N/A Passed

10 10 10

Seat: 2000 N Back: 700 N Seat: 2000 N

Passed Passed N/A N/A

10

Back: 900 N Seat: 1800 N

Passed N/A N/A N/A N/A N/A

200000 200000

Seat: 1000 N Back: 300 N

Passed N/A N/A

100000

1000 N

Passed N/A N/A N/A

10 10

Edge: 620 N) (Seat: 1800 N) Edge: 760 N)

Passed Passed

Report no. Appendix Page Initials

352892E 1 2 of 2 laha/flg/hbs

Test of model: 40/4 with five star base Lab. no.: 352892 E

Test 6.1.18 Diagonal Static Base Load Test 6.1.19 Seat Impact Test 6.1.20 Back Impact Test 6.1.21 Arm Impact Test 6.1.22 Drop Test (multiple seating) 6.1.23 Auxiliary writing surface static load test 6.1.24 Auxiliary writing surface fatigue test 6.2 Strength and durability requirements 7 Information for use Test Method EN 1728, 6.14 EN 1728, 6.15 EN 1728, 6.16 EN 1728, 6.17 EN 1728, 6.18 EN 15373, A.3 EN 15373, A.4 EN 15373, 6.2 EN 15373, 7 10 10 300 mm 620 mm / 68 Cycles Load (Seat: 1800 N) Result N/A Passed Passed N/A N/A N/A N/A Passed N/A

\\dmwclus\dmw_docs\1214179\1315203_352892 EN 15373.doc

Report no. Appendix Page Initials

352892E 2 1 of 1 laha/flg/hbs

Test of model: 40/4 with five star base Lab. no.: 352892 E

Photo

\\dmwclus\dmw_docs\1214179\1315203_352892 EN 15373.doc

The general conditions pertaining to assignments accepted by Danish Technological Institute shall apply in full to the technical testing and calibration at Danish Technological Institute and to the completion of test reports and calibration certificates within the relevant field. Danish Accreditation (DANAK) DANAK was established in 1991 in pursuance of the Danish Act No. 394 of 13 June 1990 on the promotion of Trade and Industry. The requirements to be met by accredited laboratories are laid down in the Danish Agency for Trade and Industrys ("Erhvervsfremme Styrelsens") Statutory Order on accreditation of laboratories to perform testing etc. and GLP inspection. The statutory order refers to other documents, where the criteria for accreditation are specified further. The standards DS/EN ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories and DS/EN 45002 General criteria for the assessment of testing laboratories describe fundamental criteria for accreditation. DANAK uses guidance documents to clarify the requirements in the standards, where this is considered to be necessary. These will mainly be drawn up by the European co-operation of Accreditation (EA) or the International Laboratory Accreditation Co-operation (ILAC) with the purpose of obtaining uniform criteria for accreditation. In addition, DANAK draws up Technical Regulations with specific requirements for accreditation that are not contained in the standards. In order for a laboratory to be accredited it is, among other things, required: - that the laboratory and its personnel are not subject to any commercial, financial or other pressures, which might influence their technical judgement - that the laboratory operates a documented quality system - that the laboratory has at its disposal all items of equipment, facilities and premises required for correct per formance of the service that it is accredited to perform - that the laboratory management and personnel have technical competence and practical experience in performing the service that they are accredited to perform - that the laboratory has procedures for traceability and uncertainty calculations - that accredited testing or calibration is performed in accordance with fully validated and documented methods - that the laboratory keeps records, which contain sufficient information to permit repetition of the accredited test or calibration - that the laboratory is subject to surveillance by DANAK on a regular basis - that the laboratory shall take out an insurance, which covers liability in connection with the performance of accredited services Reports carrying DANAKs logo are used, when reporting accredited services and show that these have been performed in accordance with the rules for accreditation.

\\dmwclus\dmw_docs\1214179\1315203_352892 EN 15373.doc

Page 1 of 1

Вам также может понравиться

- Safety of Household and Similar Electrical Appliances Part 2:particular Requirements For HumidifiersДокумент157 страницSafety of Household and Similar Electrical Appliances Part 2:particular Requirements For HumidifiersFemko CorporationОценок пока нет

- API 510 Authorised Pressure Vessel InspectorДокумент5 страницAPI 510 Authorised Pressure Vessel InspectormjranjbarnОценок пока нет

- ADA5000 - K45603 - K45604 - K45703-TS - K45704-TS Manual REV BДокумент26 страницADA5000 - K45603 - K45604 - K45703-TS - K45704-TS Manual REV Bmoh_ichwanuddin100% (1)

- Strong SRT8500-IEC60065Документ54 страницыStrong SRT8500-IEC60065Valentin ZayikaОценок пока нет

- Ada5000 Manual Rev AДокумент23 страницыAda5000 Manual Rev AMARDEL2409Оценок пока нет

- Emc Test Report: Cerpass Technology CorpДокумент5 страницEmc Test Report: Cerpass Technology CorpAnonymous gX0jFSXОценок пока нет

- IPP STATEMENT SSP Duolok Swagelok Interchange Intermix Pages From ASTM F1387 GE 362A2915 Test PlanДокумент5 страницIPP STATEMENT SSP Duolok Swagelok Interchange Intermix Pages From ASTM F1387 GE 362A2915 Test PlanAnonymous otUd3TzIОценок пока нет

- K45910 Operation ManualДокумент10 страницK45910 Operation ManualSUDLAB Suporte TécnicoОценок пока нет

- Koehler Heated Oil Test CentrifugeДокумент14 страницKoehler Heated Oil Test CentrifugeRamirez FrancisОценок пока нет

- Khulna 150MW PPP Exhaust Stack Data BookДокумент26 страницKhulna 150MW PPP Exhaust Stack Data BookNgô Văn Dũng50% (2)

- WC059 AMG Metal Non Drainable Louver Test - MSRKДокумент9 страницWC059 AMG Metal Non Drainable Louver Test - MSRKAMG Co.Оценок пока нет

- Lab38 Acred. de Labs. Microbiológicos PDFДокумент30 страницLab38 Acred. de Labs. Microbiológicos PDFIBIB12Оценок пока нет

- Australian StandardДокумент5 страницAustralian StandardAgus Be Pe0% (1)

- 7697A Headspace Samplers Site Preparation ChecklistДокумент7 страниц7697A Headspace Samplers Site Preparation ChecklistnileshdhamorikarОценок пока нет

- K33850 Steam Boiler Manual REV AДокумент10 страницK33850 Steam Boiler Manual REV ASUDLAB Suporte TécnicoОценок пока нет

- TL 82002 enДокумент14 страницTL 82002 enIvan PerezОценок пока нет

- Efsh18042095 Ie 02 L01Документ150 страницEfsh18042095 Ie 02 L01Felix ZhuОценок пока нет

- 2414 IEC 61850 SEL Conformance Certs 20081125Документ3 страницы2414 IEC 61850 SEL Conformance Certs 20081125Augusto César MarianoОценок пока нет

- Training Program For Urea Engineers Jan 2013 v2 PDFДокумент16 страницTraining Program For Urea Engineers Jan 2013 v2 PDFfinne floresОценок пока нет

- MHI Electrical 1st Comment RSAE-MTS-QA-EL-009 MTS For MotorsДокумент17 страницMHI Electrical 1st Comment RSAE-MTS-QA-EL-009 MTS For MotorskamilОценок пока нет

- FirstPower 2012 PDFДокумент20 страницFirstPower 2012 PDFmvitavaresОценок пока нет

- LAPPKABEL DNV Certificate - OLFLEX PETRO FD 865 CPДокумент4 страницыLAPPKABEL DNV Certificate - OLFLEX PETRO FD 865 CPAndrew LowОценок пока нет

- Is Your Condition Monitoring Specialist 360° Certified?: SKF Reliability SystemsДокумент3 страницыIs Your Condition Monitoring Specialist 360° Certified?: SKF Reliability Systemsboodi_eidОценок пока нет

- As NZS 5000.1 Standard For Earthing CableДокумент20 страницAs NZS 5000.1 Standard For Earthing CableKamlesh VaishnavОценок пока нет

- Spar PlatformДокумент34 страницыSpar PlatformAmir HazimОценок пока нет

- Test-Report-3594895 - 副本Документ25 страницTest-Report-3594895 - 副本Wei ChenОценок пока нет

- Safety of Household and Similar Electrical Appliances Part 2: Particular Requirements For Massage ApplianceДокумент10 страницSafety of Household and Similar Electrical Appliances Part 2: Particular Requirements For Massage ApplianceFemko CorporationОценок пока нет

- PY SeriesДокумент47 страницPY SeriesFareeha A K0% (1)

- Air Purifier CE Test ReportДокумент36 страницAir Purifier CE Test ReportMArcelaОценок пока нет

- DA18K4 Class-D Power Amplifier CE-EMC Test ReportДокумент44 страницыDA18K4 Class-D Power Amplifier CE-EMC Test ReportJL EN CONCIERTOОценок пока нет

- Thermo Scientific SL40 Thermo Scientific SL40RДокумент56 страницThermo Scientific SL40 Thermo Scientific SL40RJesus Rafael MarcanoОценок пока нет

- ADR10000 - I&M MANUAL - 8.2.4 - 253456107 - Ed01Документ398 страницADR10000 - I&M MANUAL - 8.2.4 - 253456107 - Ed01Sidy Elbechir DrameОценок пока нет

- Audio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsДокумент114 страницAudio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsMohamed HusseinОценок пока нет

- Operation and Instruction Manual: K60094 Portable Heated Oil Test CentrifugeДокумент14 страницOperation and Instruction Manual: K60094 Portable Heated Oil Test CentrifugeWILMARОценок пока нет

- Calibrating DurometersДокумент14 страницCalibrating DurometersmaheshОценок пока нет

- Ascott Manual S Ip RangeДокумент80 страницAscott Manual S Ip Rangejeremias100% (1)

- Fugative EmmissionДокумент35 страницFugative EmmissionAhmed MansourОценок пока нет

- A770 A790 Ce Emi ReportДокумент56 страницA770 A790 Ce Emi ReportthanatitosОценок пока нет

- Ul Iec 62561 2Документ17 страницUl Iec 62561 2Snezhana YurkinaОценок пока нет

- SMT-2233 CB - 4Документ9 страницSMT-2233 CB - 4Bel BarretoОценок пока нет

- Offshore Mooring Steel Wire Ropes and Sockets: Standard For CertificationДокумент11 страницOffshore Mooring Steel Wire Ropes and Sockets: Standard For CertificationJason RobertsОценок пока нет

- Leonova Condmaster ManualДокумент172 страницыLeonova Condmaster ManualThomas BembeОценок пока нет

- Muk PDFДокумент162 страницыMuk PDFSosialОценок пока нет

- Bosiet Huet FoetДокумент56 страницBosiet Huet FoetsumnertingОценок пока нет

- Audit & Certification History: CoolerДокумент72 страницыAudit & Certification History: CoolerYahaya Mahabubu AdedotunОценок пока нет

- Ce Nnaa FSDFSDFДокумент54 страницыCe Nnaa FSDFSDFer_wenОценок пока нет

- Hm150 08EДокумент13 страницHm150 08EYoni EhmОценок пока нет

- Pub002 131 00 - 1013Документ5 страницPub002 131 00 - 1013Jim OhОценок пока нет

- Calculation of Contact StressДокумент23 страницыCalculation of Contact StressDaniel Popa100% (1)

- 2885 5-2012Документ8 страниц2885 5-2012toddfly0% (2)

- Australian/New Zealand Standard: Vehicle Support StandsДокумент17 страницAustralian/New Zealand Standard: Vehicle Support StandsRiski FebriantoОценок пока нет

- Manual de Mantenimiento BS2640.180Документ28 страницManual de Mantenimiento BS2640.180Roberto Daniel Sanchez MelgarejoОценок пока нет

- How Vestas Manufacture Wind Turbine NacellesДокумент67 страницHow Vestas Manufacture Wind Turbine NacellestpzunigaОценок пока нет

- Model 7620 Hypotultra Iii Model 7650 Hypotultra Iii: ModelsДокумент139 страницModel 7620 Hypotultra Iii Model 7650 Hypotultra Iii: ModelszolrkОценок пока нет

- Ee03100 Low Voltage SwitchboardДокумент25 страницEe03100 Low Voltage SwitchboardDeepak Verma100% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- Quality Assurance and Quality Control in Neutron Activation Analysis: A Guide to Practical ApproachesОт EverandQuality Assurance and Quality Control in Neutron Activation Analysis: A Guide to Practical ApproachesОценок пока нет

- Need Networking Help - 2 Routers, Can't Reach Other Subnet - Verizon FiOS - DSLReports ForumsДокумент4 страницыNeed Networking Help - 2 Routers, Can't Reach Other Subnet - Verizon FiOS - DSLReports Forumssalekojic5332Оценок пока нет

- Vera Zvonareva (Rus) : Order of Play Wednesday, 15 February 2012Документ1 страницаVera Zvonareva (Rus) : Order of Play Wednesday, 15 February 2012salekojic5332Оценок пока нет

- Testo 512 BrochureДокумент1 страницаTesto 512 Brochuresalekojic5332Оценок пока нет

- Network Guide For CanonДокумент200 страницNetwork Guide For Canonjazz0222Оценок пока нет

- Gasmet - BioRes 05-1-0135 Zhang CGHYWZ Exper Study BioOil Pyrol Gas 517Документ12 страницGasmet - BioRes 05-1-0135 Zhang CGHYWZ Exper Study BioOil Pyrol Gas 517salekojic5332Оценок пока нет

- Ground Impedance Tests - FOP Vs SGMДокумент6 страницGround Impedance Tests - FOP Vs SGMsalekojic5332Оценок пока нет

- Tie A Necktie - Half-Windsor..Документ3 страницыTie A Necktie - Half-Windsor..salekojic5332Оценок пока нет

- ReadmeДокумент2 страницыReadmeJonatas PinheiroОценок пока нет

- Flash Facts About LightningДокумент3 страницыFlash Facts About Lightningsalekojic5332Оценок пока нет

- Testo 511 BrochureДокумент1 страницаTesto 511 Brochuresalekojic5332Оценок пока нет

- Test Report - CE - LED Tube 60598-2-1Документ26 страницTest Report - CE - LED Tube 60598-2-1salekojic5332Оценок пока нет

- VS 101.51Документ4 страницыVS 101.51salekojic5332Оценок пока нет

- ACDSeePrint JobДокумент1 страницаACDSeePrint Jobsalekojic5332Оценок пока нет

- HP Color Laserjet CP1515nДокумент4 страницыHP Color Laserjet CP1515nsalekojic5332Оценок пока нет

- Demonstrationthermographyreportcomparisonbetween320x240versus160x120pixelconfiguration 120206093759 Phpapp01Документ10 страницDemonstrationthermographyreportcomparisonbetween320x240versus160x120pixelconfiguration 120206093759 Phpapp01salekojic5332Оценок пока нет

- Lightning SafetyДокумент1 страницаLightning Safetysalekojic5332Оценок пока нет

- Demonstrationthermographyreport2radiatorpowerflushing 120206093755 Phpapp01Документ21 страницаDemonstrationthermographyreport2radiatorpowerflushing 120206093755 Phpapp01salekojic5332Оценок пока нет

- Arc WeldingДокумент12 страницArc Weldingsalekojic5332100% (1)

- List of Activities Which May Effect The EnvironmentДокумент0 страницList of Activities Which May Effect The Environmentsalekojic5332Оценок пока нет

- Import and Export of Spectra FilesДокумент21 страницаImport and Export of Spectra Filessalekojic5332Оценок пока нет

- Electric MotorsДокумент25 страницElectric Motorsnikorn123Оценок пока нет

- Yara U T2 N2O F: Erification EportДокумент35 страницYara U T2 N2O F: Erification Eportsalekojic5332Оценок пока нет

- CDS Wave Wound Armature PDFДокумент1 страницаCDS Wave Wound Armature PDFsalekojic5332Оценок пока нет

- 2007 Neutral ZoneДокумент3 страницы2007 Neutral ZoneAle MariaОценок пока нет

- Combined Cast Risers and Involuted Equalizers PDFДокумент5 страницCombined Cast Risers and Involuted Equalizers PDFsalekojic5332Оценок пока нет

- CDS Diamond Coils PDFДокумент1 страницаCDS Diamond Coils PDFsalekojic5332Оценок пока нет

- Electrodynamic Forces On Busbars in LV SystemsДокумент20 страницElectrodynamic Forces On Busbars in LV SystemsJose SanchezОценок пока нет

- CDS Lap Wound Armature PDFДокумент1 страницаCDS Lap Wound Armature PDFsalekojic5332Оценок пока нет

- CDS Hairpin Coils PDFДокумент1 страницаCDS Hairpin Coils PDFsalekojic5332Оценок пока нет

- SQA Week 1Документ15 страницSQA Week 1sabaОценок пока нет

- Quality in Health Care PDFДокумент102 страницыQuality in Health Care PDFjeetОценок пока нет

- Quality QДокумент3 страницыQuality Qaryanboxer786Оценок пока нет

- Daily Plan of ActivityДокумент4 страницыDaily Plan of ActivityEnohoj YamОценок пока нет

- Principles of Language Testing Rita GreenДокумент32 страницыPrinciples of Language Testing Rita GreenKhairun Nisa100% (1)

- CSEC Physics Record of MarksДокумент2 страницыCSEC Physics Record of MarkseddmanОценок пока нет

- First Women Bank Assessment Tender Dec 2019 PDFДокумент25 страницFirst Women Bank Assessment Tender Dec 2019 PDFSweetieShahОценок пока нет

- PDFДокумент12 страницPDFrubel-buОценок пока нет

- Acpa Ethical Principals and StandardsДокумент7 страницAcpa Ethical Principals and Standardsapi-310813184Оценок пока нет

- Continuing Nursing EducationДокумент24 страницыContinuing Nursing EducationSathish Rajamani100% (3)

- Change Management On Royal MailДокумент16 страницChange Management On Royal Mailshibin21100% (2)

- Identifying Family PrioritiesДокумент4 страницыIdentifying Family Prioritiesemrod1185Оценок пока нет

- Assessing Student Learning EffectivelyДокумент3 страницыAssessing Student Learning EffectivelyDhon ValeОценок пока нет

- Unit-9 Job Analysis, Recruitment and Selection PDFДокумент15 страницUnit-9 Job Analysis, Recruitment and Selection PDFbhar4tpОценок пока нет

- Training & DevelopmentДокумент21 страницаTraining & Developmentdoremi7880% (5)

- DLP Week 9 OnwardsДокумент4 страницыDLP Week 9 OnwardsSteffiОценок пока нет

- RRS LocaleДокумент2 страницыRRS LocaleAnonymous OxMAxCHОценок пока нет

- Simulator Training Course STW 43-3-4 - Model Course - Train The Simulator Trainer and Assessor (Secretariat)Документ125 страницSimulator Training Course STW 43-3-4 - Model Course - Train The Simulator Trainer and Assessor (Secretariat)geims1180% (5)

- Critical Thinking WorkbookДокумент14 страницCritical Thinking WorkbookLa Roi Williams100% (10)

- It HubДокумент11 страницIt Hubjobel colleraОценок пока нет

- Chapter-5 103338Документ11 страницChapter-5 103338WONDYE DESTAОценок пока нет

- Vendor Development FinalДокумент15 страницVendor Development FinalYYASEER KAGDIОценок пока нет

- Rubric For Portfolio Evaluation (Updated)Документ1 страницаRubric For Portfolio Evaluation (Updated)Daniella Daniella67% (3)

- 2014 - Academics - Sport and Development in AfricaДокумент171 страница2014 - Academics - Sport and Development in AfricatiaОценок пока нет

- 3A00812Документ6 страниц3A00812Faraz AnsariОценок пока нет

- Implementing A Performance Management SystemДокумент25 страницImplementing A Performance Management SystemSuryansh Gupta50% (2)

- Screening Who Instructions PDFДокумент72 страницыScreening Who Instructions PDFpbta punjabОценок пока нет

- Item Analysis - Research Final 2nd QuarterДокумент16 страницItem Analysis - Research Final 2nd Quarterbernadette domoloanОценок пока нет

- IVV HandbookДокумент390 страницIVV HandbookkingmajorОценок пока нет