Академический Документы

Профессиональный Документы

Культура Документы

12 Pinholes

Загружено:

vivek1312Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

12 Pinholes

Загружено:

vivek1312Авторское право:

Доступные форматы

70

Description of defects: Pinholes

71

Description of defects: Pinholes

Pinholes

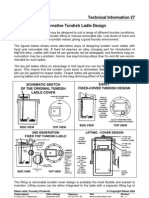

Assistance for decisions P. 154 Sand control P. 181

Pinhole porosity surface blowholes Differentiation is made between hydrogen pinholes, hydrogennitrogen pinholes and pinholes due to CO-slag reactions. Characteristic features Pores or small blowholes with a smooth surface. Sub-surface blowholes often contain a thin graphite lm. There is no differentiation between hydrogen and hydrogen-nitrogen pinholes. Pinholes due to CO-slag reaction also have smooth surfaces. The size of sub-surface blowholes can vary considerably. Blowholes occur in conjunction with oxygen-rich slag. Incidence of the defect Pinholes can appear individually or over an area. All areas of the casting can be affected. However, pinholes are more common in areas of the casting located away from the gate. Hydrogen and hydrogen-nitrogen pinholes occur in both grey and SG iron castings. Pinholes due to CO-slag reaction only occur in grey iron castings.

Explanations Hydrogen and hydrogen-nitrogen pinholes The formation of pinholes progresses in several stages: 1. The surface reaction of water vapour with other elements in the iron gives rise to metal oxides and atomic hydrogen which diffuses into the molten metal. Similarly, nitrogenhydrogen compounds dissociate on the hot metal surface and diffuse into the molten metal. Dissociation of molecular nitrogen and hydrogen does not take place at the prevailing casting temperatures. 2. Due to enrichments in the slag, the metal oxides react with the carbon in the melt to form CO molecules which are precipitated from the melt and form micro-blowholes. 3. Hydrogen, and sometimes nitrogen, diffuse from the liquid metal into the CO micro-blowholes and increase their size. Pinholes due to CO-slag reaction These occur due to the reaction of heavily oxidizing, molten slags (mostly MnO / MnS-rich slags) with the carbon in the melt to form CO. Later in the process, hydrogen can also diffuse into these blowholes.

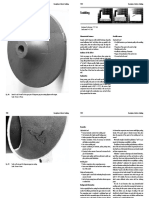

Fig. 32:

Large areas of surface blowholes/pinholes on a grey iron casting. Scale: 10 mm = 4 mm

72

Description of defects: Pinholes

73

Description of defects: Pinholes

Possible causes Metallurgical Ferrous metals Nitrogen content in the melt too high due to the charge composition. Proportion of oxides, hydroxides (rust) and other impurities in the charge materials too high Aluminium content in the melt too high Manganese and sulphur contents in the melt too high Clay-bonded sand Nitrogen content in the sand too high Moisture content of the sand too high Lustrous carbon production in the moulding sand too low Fig. 33: Section through the surface of a grey iron casting in the area of pinhole formation. Pinhole formation is promoted by surface oxidation, recognizable in the formation of ferrite. Scale: 10 mm = 0.08 mm Resin-bonded sand Nitrogen content in the core sand too high Proportion of nitrogen/hydrogen compounds in the core binder too high Gating and pouring practice Pouring passages too long Too much turbulence and slag formation during pouring

Remedies Metallurgical Use charge components with low nitrogen content, e.g. reduce the quantity of steel scrap. Use scrap and return material free of rust, water and oil impurities. Use circulating materials free of impurities adhering to sand and feeder auxiliaries. Use charge materials and especially inoculants and circulating materials with low aluminium and titanium contents. Deoxidize melts as well as possible. Avoid excessive supply of titanium or aluminium. Reduce the formation of slag, and particularly the formation of slags containing manganese sulphide, by adjusting the manganese and sulphur content. Clay-bonded sand Reduce nitrogen content in the sand. Reduce the quantity of inowing nitrogen-containing core sand. If necessary, add new sand to the circulating sand. Reduce the moisture content of the sand. Lower the bentonite content. Improve development of the moulding sand. If necessary, reduce inert dust content. Keep amount of lustrous carbon carrier at the minimum level. With an oxidizing atmosphere in the mould cavity, if necessary increase the quantity of lustrous carbon producer in the moulding sand. Avoid adding too much. Resin-bonded sand Reduce the amount of binder. Use binder with lower nitrogen content. Improve core venting, dress core if necessary. Add iron oxides to the core sand mixture. Gating and pouring practice Increase pouring temperature Reduce ow rate into the mould Avoid turbulence when pouring.

74

Description of defects: Pinholes

75

Description of defects: Pinholes

Background information A distinction is made between pinholes caused by hydrogen, nitrogen-hydrogen and sub-surface blowholes due to slag / CO reactions. Mechanism of pinhole formation Blowholes/pinholes arise in a melt under the following conditions: P = P0 + 2 r P P0 Fig. 34: Section through a surface pinhole in a grey iron casting, hydrogen-nitrogen defect recognizable by the graphite lm and the partial decarburization of the surface zones. Scale: 10 mm = 0.05 mm s r Necessary gas pressure to form a blowhole Atmospheric + metallostatic pressure Surface tension of the melt Radius of the blowhole

Surface tension [N / cm]

In the formation of CO bubbles, the surface tension of the melt is proportional to the work to be expended. According to Frenkel and Thompson, the intensity I of pinhole formation is described by the following equation:

I=Ae

Ak kT

The inuence of surface tension on the formation of pinholes has been investigated. Higher surface tension suppresses pinhole formation.1 Surface tension at 1400C

10,000 8,000 6,000 4,000

No pinholes

Calculations of the gas pressure at which blowholes/pinholes can occur shows that the melt must be considerably over-saturated with gases such as nitrogen and / or hydrogen. Sub-surface blowholes can form on solid reaction products in the melt at considerably lower gas pressures (phase boundaries). Similarly, where CO bubbles are formed through the reaction of oxides with the carbon in the melt, the dissolved gases (nitrogen, hydrogen) diffuse into the molecular gas pockets and form pinholes. Sufcient oxygen enrichment near the surface of the melt is necessary for the formation of CO bubbles. According to Gibbs, the formation of molecular CO blowholes is determined through the work to be expended: Ak = 4 r 3

Pinholes

2,000 0 0 0.1 0.2 0.3

No pinholes Pinholes

0.4

Aluminium content [%]

Fig. 35: Inuence of aluminium content on surface tension and pinhole occurence in grey cast iron.

76

Description of defects: Pinholes

77

Description of defects: Pinholes

Surface tension at 1400C

10,000

Surface tension [N / cm]

8,000 6,000 4,000 2,000 0 0

Tellurium

No pinholes

In addition to pure CO pinholes, molecular CO bubbles can be regarded as the nucleus for hydrogen and hydrogen-nitrogen pinholes. Hydrogen pinholes

Titanium Sulphur

Pinholes

Hydrogen is primarily introduced into a melt through the reaction of strong oxygen binding agents in the melt, e.g. aluminium, magnesium and titanium, with water vapour. Me + H2O MeO + 2H The atomic hydrogen is immediately absorbed by the melt. Water vapour is produced by moist refractories, rust-containing input materials and the binding clays used in the moulds, and is also present in the mould cavity air during pouring. Table 1 shows how long a melt absorbs hydrogen from the lining of a cupola. Tapping time 7.00 7.20 7.40 9.00 11.00 12.00 14.15 Hydrogen content [ppm] 5.6 4.2 3.0 2.2 1.8 1.4 1.6

0.1

0.2

0.3

0.4

Total of additives present [%] S No pinholes S Pinholes Te No pinholes Te Pinholes Ti No pinholes Ti Pinholes

Fig. 36:

Micrograph of a slag / gas defect in a grey iron casting. Scale: 10 mm = 0.1 mm

Fig. 37: Inuence of sulphur, titanium and tellurium content on surface tension and pinhole formation in grey cast iron. Pinholes due to CO-slag reactions In the formation of this defect, low-viscosity silicate slags rich in manganese oxide and enriched with manganese sulphide react with the carbon in the melt and form CO. With high manganese and low silicon contents, the manganese reduces silica from slags and the refractory lining, forming highly liquid manganese oxide slags. High sulphur contents enable the formation of MnS, which is enriched in the slag and makes the slags even more reactive.2

0.2

Pinholes

0.15

0.1

1350C

0.05

No defects

1280C

1200C

Cold blast test cupola, tap weight in each case 400 kg. Cupola diameter 140 cm Acid furnace lining The furnace was lined 24 hrs. previously.

1.6

Sulphur [%]

0

0

0.4

0.8

1.2

Manganese [%]

Fig. 38: Inuence of manganese and sulphur content and pouring temperature on the formation of pinholes.

78

Description of defects: Pinholes

79

Description of defects: Pinholes

The precipitation of hydrogen is unlikely in a homogeneous melt. Where oxide nuclei or CO bubbles form, precipitation is more likely, due to the low pressure required. At high temperatures and pressures, the molecular hydrogen formed reacts with the carbon in the melt and forms methane, which breaks down to form graphite and hydrogen: Cdissolved + 2H2 CH4 CH4 Cgraphite + 2H2 Whilst the dissolved carbon reacts with hydrogen, the precipitated graphite is not dissolved by the superheated hydrogen in the formation of methane. As a result of these processes, hydrogen pinholes nearly always contain a thin graphite lm. The bubbles are surrounded by a pearlite-free ferrite layer. Hydrogen pinholes are normally round. Contrary to this, nitrogen pinholes have a dendritic shape. The explanation lies in the different rates of diffusion of the gases. Pure nitrogen blowholes/ pinholes contain no graphite lm. Avoidance of hydrogen pinholes Hydrogen is absorbed by an iron melt where the amounts of reactive elements are too high. Cast iron melts should be free of magnesium and, above all, aluminium. Aluminium contents as low as 0.01 0.1 % can lead to dangerous hydrogen absorption. Excessive titanium contents, as particularly found in circulating materials, promote the formation of pinholes. Since absorption of hydrogen usually occurs through the formation of water vapour, the content in the molten metal of hydroxides, rust, mould moisture, water combined in the clay etc. should be kept as low as possible.

The formation of pinholes can also be avoided if there is sufcient lustrous carbon producer in the mould. The reducing atmosphere prevents the formation of CO bubbles. Various authors have highlighted that admixtures of pit coal dust and other lustrous carbon producers can help to prevent pinholes.3 5 Nitrogen-hydrogen pinholes In addition to hydrogen pinholes, nitrogen-hydrogen pinholes occur where nitrogen-containing binding agents are used. Such defects are primarily generated through the use of binders containing urea. The nitrogen-hydrogen radicals are broken down near the surface of the melt, which immediately absorbs them in the atomic state. These surface blowholes often have a graphite lm and a ferrite seam like the hydrogen pinholes. They form in a similar way to that described under hydrogen pinholes. Many reports have been published on these pinhole phenomena. Avoidance of nitrogen-hydrogen pinholes These pinholes can occur where there is a high nitrogen content in the melt resulting from the use of charge materials such as steel scrap or nitrogen-containing carburizing compounds. Here, too, a crucial contribution is made by the combined action of gases from the mould cavity and the mould. High nitrogen contents in the melt (over 100 ppm), in the carburizing agent, in the core binder and in the bentonite-bonded sands should be avoided. The use of increased proportions of lustrous carbon producers in the moulding sand to achieve a reducing atmosphere has also proved to be effective. In the case of cores, the addition of iron oxides and barium sulphate will help to prevent this defect.

Fig. 39:

Blowholes/pinholes over the complete surface of a grey iron casting. Scale: 10 mm = 8 mm

80

Description of defects: Pinholes

81

Description of defects: Pinholes

Pinholes due to CO-slag reactions Under certain conditions, oxygen-rich slags can react with the carbon in the melt to form CO. Liquid iron oxide-rich slags also react this way: FeO + C Fe + CO The pinholes may be observed on the surface of the casting but are sometimes not visible until it is machined. All slags formed during melting and pouring can become highly uid through enrichment with FeO or MnO, and then react with carbon to form blowholes/pinholes. Pinholes of this type mostly have slag inclusions in the pockets, such inclusions often containing MnS precipitations. The large inuence of MnS on the formation of the pinhole can be traced back to the liquefaction of the slag and thus its increased reactivity. Hydrogen also negatively inuences this defect. Avoidance of slag-CO surface pinholes In order to avoid this surface defect, it is necessary to increase the pouring temperature, reduce the sulphur content and restrict the manganese content. BCIRA recommends foundries to keep to a 0.7 % manganese content. Other authors recommend that the manganese content be kept no higher than 0.4 % of the Si content. It is also recommended that the melt be given little opportunity to oxidize. Turbulence during lling should be avoided and liquidmetal ow paths kept short. As water vapour has a strongly negative effect, the bentonite content in the moulding sand should be as low as possible.

References 1 Hernandesz, B.; Wallace, J. F. Mechanismus der Randblasenbildung in Gueisen mit Lamellengraphit AFS 1979 Research Reports, Des Plaines / Il 1979, P. 39 52 (English) Henke, F. Mangan im Gueisen Giess.-Prax. 1970, P. 281 294 Dawson, J. V.; Kilshaw, J. A.; Morgan, A. D. Art und Entstehung von Gasblasen in Gueisenteilen Mod. Cast. 47, 1965, P. 144 160 Bauer, W. Einu der chemischen Zusammensetzung und der Formstoffe auf Gasblasenfehler im Gueisen Gieerei-Rundschau 31, 1984, P. 7 13 Giess.-Prax. 1984, P. 198 205 Fujio, S.; Yamada, J.; Mizuno, K.; Yamauchi, Y.; Tanimura, H. Vermeidung von Pinhole-Bildung bei Gueisen mit Kugelgraphit Imono 56, 1984, P. 212 218 (Jap. w. Engl. summary)

Additional references Orths K.; Weis W.; Lampic, M. Verdeckte Fehler bei Gustcken aus Gueisen Giess.-Forsch. 27, 1975, P. 103 111 Orths K.; Weis, W.; Lampic, M. Gesetzmigkeiten und Zusammenwirken von Regelgren bei der Entstehung verdeckter Fehler bei Gueisen Giess.-Forsch. 28, 1976 , P. 15 26 Greenhill, J. M. Fehlerdiagnose in Gueisenstcken Foundry 99, 1971, P. 56 60 (English) Author not named Guoberchen verdeckte Blschen im Zusammenwirken mit MnS-Ausscheidungen Mod. Castings 1978, P. 53 Gittus, J. Randblasen im Gueisen mit Kugelgraphit BCIRA Journal 5, 1933, P. 394 & P. 603 Dawson, J. V.; Smith, L. W. L. Pinholes-Bildung in Gusseisen und ihre Abhngigkeit von der Wasserstoffabgabe aus dem Formsand BCIRA Journal 6, 1956, P. 226 Dawson, J. V. Untersuchungen ber die Randblasenbildung in Gueisen BCIRA Journal 8, 1960, P. 805 811 Murray, W. G. Randblasen in Gueisen mit Kugelgraphit Brit. Foundryman 55, 1962, P. 85 93 Pidgeon, C. L. Einu der Zusammensetzung von Grnsandformen auf die Bildung von Pinholes BCIRA Journal 11, 1963, P. 319 335 Dawson, J. V. Pinholes BCIRA Journal 10, 1962, P. 433 437 Vogel, D. Beabsichtigte Erzeugung von Pinholes im Gueisen mit Kugelgraphit und seine Entstehung Staatl. Ing. Schule Duisburg 1964, Diplomarbeit Berndt, H. Die Pinhole-Bildung von Gueisen mit Lamellengraphit bei Verwendung von Hot-Box-Kernen Gieerei 52, 1965, P. 548 555 Berndt, H.; Unger, D. Prfung von Formsandmischungen f. das Hot-Box-Verfahren Gieerei 53, 1966, P. 96 105 Nipper, H. A.; Knig, R.; Gries, H. Zur Begasung u. Entgasung von schmelzssigem Gueisen Buderus techn. Bl., Febr. 62, P. 60 Patterson, W; v. Gienanth Dipl.-Arbeit ber Nadelstichporositten im Gueisen TH Aachen, May 1962 Author not named Pinholes im Graugu Foundry, 1965, P. 162

82

Description of defects: Pinholes

83

Description of defects: Pinholes

Chen, F.; Keverian, J. Einu v. Stickstoff auf die Randblasenbildung bei Stahlgu Mod. Cast. 50, 1966, P. 95 103 Frommhagen, A. Pinholes in Graugustcken Giess.-Prax. 1964, P. 123 126 Schitikow W. S.; Schulte G.; Gederewitsch, N. A.; Tschebotar L. K. Die Pinholesbildung in GGL Lit. Proisv. 1973, P. 18 Gieereitechnik 22, 1974, P. 320 Kokonov, A. T. Einu der Desoxidation auf die Pinholesbildung bei Stahlgustcken beim Gieen in kunstharzgebundene Formen Lit. proisv. 1979, P. 9 Carter, S. F.; Evans, W. J.; Harkness, J. C.; Wallace, J. F. Einugren bei der Pinhole-Bildung in Gueisen mit Lamellengraphit und Gueisen mit Kugelgraphit Amer. Foundrym. Soc. 87, 1979, P. 245 268 (English) Giess. Prax. 1980, P. 219 246 VDG Fachbibliographie Nr. 352 Wasserstoffgehalte im Gueisen (67 literature references) VDG Fachbibliographie Nr. 74 Gase im Gueisen (78 literature references)

Berndt, H.; Unger, D.; Rde, D. Die Bedeutung der Eisenoxidzugabe zum Formstoff Gieerei 59, 1972, P. 61 71 Author unknown Ein Fall von Randblasen (Pinholes) in der Oberche von GG Fonderie, Fondeur aujourdhui 1986, P. 27 Poyet, P.; Elsen, F.; Bollinger, E. Einu von Zustzen an Eisenoxid zum Formsand in der Stahlgieerei Hommes et Fonderie 161, 1986, P. 11 22 (French) Hner, K. E. Zum Einu des Stickstoffs auf die Gasblasenbildung im Stahlgu Gieerei 62, 1975, P. 6 12 Middleton, J. M. Einige Pros und Contras zu tongebundenen Formsanden Proc. Annu. Conf. Steel Cast. Res. & Trade Assoc. Harrogate 1970, Vol. 1, 1970 Pap. 6, P. 8 Habibullah, P. Allgemeine Betrachtungen ber Blasenbildung bei Stahlgustcken infolge der Metall-Formstoff-Reaktion 43me Congrs International de Fonderie, Bucuresti 1976 Paper No. 13., 7 P. (English) Yamauchi, Y.; Yamada, J.; Mizuno, K.; Fujio, S.; Tanimura, H. Pinholes bei Gustcken aus Gueisen mit Kugelgraphit (Nagusand) und Manahmen zu deren Vermeidung 4th International Conference for Licensees of the GF Converter Process, Schaffhausen 1981, Paper No. 7, P. 14

Levi, L. I.; Grigorjan, S. A.; Dybenko, I. V. Einu von Mn auf den Stickstoffgehalt im Gueisen und dessen Bestimmungsverfahren Izvestija vyssich. ucebnych. zavedenij, cernaja metallurgija 1977, P. 155 157 (Russian) Strong, G. R. Stickstoff in Tempergu Ein Literaturberblick Trans. Amer. Foundrym. Soc. 85, 1977, P. 29 36 (Engl.) Winterhager, H.; Koch, M. Untersuchungen zur Vakuumentgasung von AluminiumSchmelzen. Gieerei 65, 1978, P. 505 510 Stransky, K. Thermodynamische Bedingungen fr die Pinhole-Bildung in Stahlgu Slevarenstvi 28, 1980, P. 373 377 (Czech) Mechanisms of Pinhole Formation in Gray Iron AFS Gray Iron Research Committee 5-C AFS Research Reports 1979, P. 37

Вам также может понравиться

- Casting Defect - Fissure DefectsДокумент3 страницыCasting Defect - Fissure Defectsvivek1312Оценок пока нет

- Common Metallurgical Defects in Grey Cast IronДокумент9 страницCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- FP 238Документ32 страницыFP 238Mahmoud Atia100% (2)

- Positioning Ceramic Foam Filters in Gating SystemsДокумент8 страницPositioning Ceramic Foam Filters in Gating SystemsSiddharth GuptaОценок пока нет

- Filtration of Iron and Steel Castings PDFДокумент24 страницыFiltration of Iron and Steel Castings PDFbvphimanshu100% (1)

- Surface Graphite Degeneration in Ductile Iron CastДокумент8 страницSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarОценок пока нет

- Common Metallurgical Defects in Ductile Iron EnglishДокумент1 страницаCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessОценок пока нет

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeОт EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeОценок пока нет

- Causes and Remedies of Blow Holes in SanДокумент33 страницыCauses and Remedies of Blow Holes in SanNikhil KumarОценок пока нет

- Cored Wires for Iron Foundry TreatmentДокумент6 страницCored Wires for Iron Foundry TreatmentamitkkambleОценок пока нет

- Shrinkage in Iron CastingsДокумент10 страницShrinkage in Iron CastingskarthikkandaОценок пока нет

- Cast IronДокумент15 страницCast IronJohnОценок пока нет

- Seminar S.G IronДокумент32 страницыSeminar S.G Ironravikataria02Оценок пока нет

- AFS Thermal Analysis of CupsДокумент12 страницAFS Thermal Analysis of Cupsyash_ganatraОценок пока нет

- Offsetting Macro-Shrinkage in Ductile IronДокумент13 страницOffsetting Macro-Shrinkage in Ductile IronmetkarthikОценок пока нет

- Cast Iron BrochureДокумент12 страницCast Iron BrochureFlamarion BadaroОценок пока нет

- Common Metallurgical Defects in Grey Cast Irons 2Документ1 страницаCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiОценок пока нет

- O HC HCДокумент101 страницаO HC HCIndustrial Infra Jobs100% (1)

- Gas Defects:: These Are Spherical, Flattened or Elongated CavitiesДокумент3 страницыGas Defects:: These Are Spherical, Flattened or Elongated CavitiesmaniОценок пока нет

- AntiSegregation HopperДокумент5 страницAntiSegregation Hoppermecaunidos7771Оценок пока нет

- Home About Us Products Quality Control Representation Useful Links Contact UsДокумент5 страницHome About Us Products Quality Control Representation Useful Links Contact Ustushak mОценок пока нет

- Recovery of Magnesium in A Ductile Iron Process.: AbstractДокумент8 страницRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazОценок пока нет

- Back to BASICS: Nitrogen fissures defects in iron castingsДокумент2 страницыBack to BASICS: Nitrogen fissures defects in iron castingsJustin DixonОценок пока нет

- Carbon Dioxide Moulding ProcessДокумент17 страницCarbon Dioxide Moulding ProcessqwertyuioОценок пока нет

- 26-ELKEM Poster-Graphite Structures in Cast IronsДокумент1 страница26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENОценок пока нет

- Effect of Bismuth in Ductile IronДокумент4 страницыEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Composition of Grey Cast IronДокумент2 страницыComposition of Grey Cast IronPranil GhatageОценок пока нет

- Carbide Dissolution in Thin Wall Ductile Iron PDFДокумент8 страницCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdОценок пока нет

- Chunky GraphiteДокумент16 страницChunky GraphitesachinguptachdОценок пока нет

- Thermal Analysis Optimization of Gray and Ductile Iron ProductionДокумент18 страницThermal Analysis Optimization of Gray and Ductile Iron ProductionslagmercuryОценок пока нет

- Late Metal Stream InoculationДокумент2 страницыLate Metal Stream Inoculationarnaldorcr8646Оценок пока нет

- Ferroalloy Storage Bin DesignДокумент2 страницыFerroalloy Storage Bin Designarnaldorcr8646Оценок пока нет

- Control of SlagДокумент12 страницControl of SlagVinay RajputОценок пока нет

- Cold Mounting EnglishpdfДокумент6 страницCold Mounting EnglishpdfJorge BonillaОценок пока нет

- Identifying Casting Defects - AFSДокумент3 страницыIdentifying Casting Defects - AFSnddkОценок пока нет

- GAS PROBLEM in Steel Sand CastingsДокумент7 страницGAS PROBLEM in Steel Sand CastingsVasu RajaОценок пока нет

- 229-01 Dross Inclusions in An Iron FoundryДокумент4 страницы229-01 Dross Inclusions in An Iron Foundryjlplazaola100% (1)

- Alternative Tundish Ladle DesignДокумент2 страницыAlternative Tundish Ladle Designarnaldorcr8646Оценок пока нет

- ELMAGДокумент2 страницыELMAGthomazfabricioОценок пока нет

- RECHUPEДокумент7 страницRECHUPEmarcotulio123Оценок пока нет

- Improving Die Casting Melt QualityДокумент12 страницImproving Die Casting Melt QualityCsaba WalczerОценок пока нет

- BCIRA Broadsheet 41Документ4 страницыBCIRA Broadsheet 41Justin Dixon100% (1)

- Sampling of Liquid Cast IronДокумент2 страницыSampling of Liquid Cast Ironarnaldorcr8646Оценок пока нет

- Metallography and Microstructures of Copper and Its AlloysДокумент12 страницMetallography and Microstructures of Copper and Its Alloysmartin_jaitmanОценок пока нет

- Cast Iron SolidificationДокумент12 страницCast Iron Solidificationkatchani123100% (1)

- FFPMДокумент171 страницаFFPMGulyam Maribasappa Rajendra PrasadОценок пока нет

- Why Primary Graphite Is Bad!Документ4 страницыWhy Primary Graphite Is Bad!qwsx123Оценок пока нет

- Metallographic Printing Methods for Detecting ImpuritiesДокумент3 страницыMetallographic Printing Methods for Detecting ImpuritiesAnup Tigga100% (1)

- Update of Blow Holes: What Causes Blowholes?Документ2 страницыUpdate of Blow Holes: What Causes Blowholes?Kruti PatelОценок пока нет

- Casting Defects Guide - Identification and CausesДокумент10 страницCasting Defects Guide - Identification and CausesAbhinav Pratap MauryaОценок пока нет

- 09 Cast IronДокумент34 страницы09 Cast IronyogeshmangulkarОценок пока нет

- Observation of Defects in Cast Iron Castings by Surface AnalysisДокумент19 страницObservation of Defects in Cast Iron Castings by Surface Analysisgonzalo gimenez100% (1)

- Casting DefectsДокумент49 страницCasting Defectsgopi.nryn100% (2)

- Casting Defects in SteelsДокумент4 страницыCasting Defects in SteelsShamsur Rahman Russell100% (1)

- Effect of Minor and Trace Elements in Cast IronДокумент2 страницыEffect of Minor and Trace Elements in Cast IronsachinguptachdОценок пока нет

- Mixer Efficiency. Wenniger FormulaДокумент16 страницMixer Efficiency. Wenniger FormulacqigОценок пока нет

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFДокумент23 страницы1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Fading of InoculationДокумент2 страницыFading of Inoculationarnaldorcr8646Оценок пока нет

- Casting Defect Causes RemediesДокумент22 страницыCasting Defect Causes RemediesDeepakKaushik100% (1)

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsОт EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsОценок пока нет

- Sand Testing ProcedureДокумент34 страницыSand Testing Procedurevivek1312100% (5)

- Thermal Analysis of Cast Iron PDFДокумент27 страницThermal Analysis of Cast Iron PDFRasoul SadeghiОценок пока нет

- HIC Conveyor Belts Product SpecificationsДокумент8 страницHIC Conveyor Belts Product SpecificationsShravan VogulamОценок пока нет

- AFS Effects of Hot SandДокумент10 страницAFS Effects of Hot Sandvivek1312Оценок пока нет

- E 6aДокумент12 страницE 6aDamanveerОценок пока нет

- 592Документ4 страницы592vivek1312Оценок пока нет

- PAC4200 DatatsheetДокумент4 страницыPAC4200 DatatsheetmringkelОценок пока нет

- ALSTOM Different-Types-of-Mills PDFДокумент39 страницALSTOM Different-Types-of-Mills PDFvivek1312100% (1)

- Final Kanban Dr. Tammy SagastizadoДокумент71 страницаFinal Kanban Dr. Tammy Sagastizadovivek1312Оценок пока нет

- Green Sand, MouldingДокумент92 страницыGreen Sand, MouldingKrishna Deo100% (1)

- 16 ScabbingДокумент4 страницы16 Scabbingvivek13120% (1)

- Cold Box Binder UseДокумент3 страницыCold Box Binder Usevivek1312Оценок пока нет

- Influence MN S Properties Cast IronДокумент14 страницInfluence MN S Properties Cast Ironvivek1312Оценок пока нет

- The Oolitization Rate Determination of Bentonite Moulding MixturesДокумент4 страницыThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312Оценок пока нет

- Takt TimeДокумент17 страницTakt Timevivek1312Оценок пока нет

- Toyota PDFДокумент8 страницToyota PDFOHОценок пока нет

- 4 OEE ExampleДокумент8 страниц4 OEE Examplevivek1312Оценок пока нет

- Quality ManualДокумент36 страницQuality Manualvivek1312Оценок пока нет

- FIPSДокумент23 страницыFIPSvivek1312Оценок пока нет

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFДокумент23 страницы1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- 11x17 Lost Foam Brochure LFBv1201405 DraftДокумент2 страницы11x17 Lost Foam Brochure LFBv1201405 Draftvivek1312Оценок пока нет

- Common Metallurgical Defects in Ductile IronДокумент1 страницаCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- Nov Sand DataДокумент12 страницNov Sand Datavivek1312Оценок пока нет

- Gating System DesignДокумент8 страницGating System Designvivek1312Оценок пока нет

- ISO 9000 Awareness Presentation 8-27-15Документ19 страницISO 9000 Awareness Presentation 8-27-15mahinda100% (1)

- $ix $igma: Remarkable Results and Rave ReviewsДокумент29 страниц$ix $igma: Remarkable Results and Rave ReviewsdSolarianОценок пока нет

- Gating System DesignДокумент11 страницGating System DesignChinmay Das95% (19)

- Yogyata VikasДокумент11 страницYogyata Vikasvivek1312Оценок пока нет

- GREEN SAND PREPARATION Manufacturing Lab Foundry PDFДокумент21 страницаGREEN SAND PREPARATION Manufacturing Lab Foundry PDFvivek1312100% (1)

- Determination Active Clay Percentage of Moulding Sand by Using Methylene BlueДокумент9 страницDetermination Active Clay Percentage of Moulding Sand by Using Methylene Bluevivek1312100% (2)

- Work Method Statement of RCP Works Pipe LayingДокумент6 страницWork Method Statement of RCP Works Pipe LayingLod.N.S100% (3)

- Bt2-Exam-Questions 4Документ26 страницBt2-Exam-Questions 4Traven SagravОценок пока нет

- Estimation and PlanningДокумент151 страницаEstimation and Planningfirojji panchtilakОценок пока нет

- 770SS DrawingДокумент2 страницы770SS DrawingSanggar WaringinОценок пока нет

- Progress in Additive Manufacturing New MaterialsДокумент50 страницProgress in Additive Manufacturing New Materialsdebisi14140Оценок пока нет

- How To Line The Burner Pipe PDFДокумент19 страницHow To Line The Burner Pipe PDFMustafa Ramadan100% (2)

- Ethacure 300Документ12 страницEthacure 300scorpionbadshahОценок пока нет

- Catch Up Plan Nha Format r.0001Документ2 страницыCatch Up Plan Nha Format r.0001Anthony Alvarez50% (6)

- Structural Steel Design SpecificationДокумент8 страницStructural Steel Design SpecificationNassim SabriОценок пока нет

- Comparison of CFRP Strips With Conventional Retrofitting Steel PlatesДокумент3 страницыComparison of CFRP Strips With Conventional Retrofitting Steel PlatesM.Ahmad RazaОценок пока нет

- Minor TalibДокумент24 страницыMinor TalibArsalan Moin (FC105)Оценок пока нет

- A Study in The Effect of Different Nozzle Shapes and Fibre Reinforcement in 3D Pritable MortarДокумент23 страницыA Study in The Effect of Different Nozzle Shapes and Fibre Reinforcement in 3D Pritable MortarManu K MohanОценок пока нет

- Evans Korir Cost Schedule FinalДокумент4 страницыEvans Korir Cost Schedule FinalBernie Quep100% (1)

- LAYING TECHNIQUES FOR MURAL WALL COVERINGSДокумент2 страницыLAYING TECHNIQUES FOR MURAL WALL COVERINGScorzeaОценок пока нет

- Ut Velocity Table: Material L-Wave Velocity M/s S-Wave Velocity In/ms S-Wave Velocity M/sДокумент1 страницаUt Velocity Table: Material L-Wave Velocity M/s S-Wave Velocity In/ms S-Wave Velocity M/sprakashОценок пока нет

- KNPC Deluge2 PDFДокумент12 страницKNPC Deluge2 PDFNarendra Reddy BhumaОценок пока нет

- Material and Construction CA1Документ20 страницMaterial and Construction CA1Amit DharaОценок пока нет

- Dartar Berat BesiДокумент12 страницDartar Berat BesiIskak UnoОценок пока нет

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaДокумент21 страницаThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanОценок пока нет

- Ship Windows BOHAMET PDFДокумент28 страницShip Windows BOHAMET PDFKartikОценок пока нет

- Format BillДокумент8 страницFormat BillJunaid KhanОценок пока нет

- Comparing Quality & Yield Performance in January 2019Документ7 страницComparing Quality & Yield Performance in January 2019Aris SusantoОценок пока нет

- World Refining-Rocket ScienceДокумент3 страницыWorld Refining-Rocket ScienceIndunil WarnasooriyaОценок пока нет

- Boehler CN 13 4-MC FДокумент1 страницаBoehler CN 13 4-MC FFilipe CordeiroОценок пока нет

- Material Selection For Sour Service EnvironmentДокумент10 страницMaterial Selection For Sour Service EnvironmentIdris Siddiqui100% (3)

- Grid slab design for 10x12m panelДокумент5 страницGrid slab design for 10x12m panelNeeta RautelaОценок пока нет

- 3D Slot-Anchor SystemДокумент54 страницы3D Slot-Anchor SystemStelian ConstantinescuОценок пока нет

- Axle Shaft Strength ChartДокумент1 страницаAxle Shaft Strength CharthavvkxjОценок пока нет

- Nitriding of Aluminum Extrusion Die: Effect of Die GeometryДокумент13 страницNitriding of Aluminum Extrusion Die: Effect of Die GeometryRaj Kumar GiriОценок пока нет