Академический Документы

Профессиональный Документы

Культура Документы

DKSKV MTK 204

Загружено:

Izzah AmalinaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DKSKV MTK 204

Загружено:

Izzah AmalinaАвторское право:

Доступные форматы

DECEMBER Edition 2013

MINISTRY OF EDUCATION, MALAYSIA VOCATIONAL COLLEGE STANDARD CURRICULUM COURSE INFORMATION

COURSE NAME CODE NAME LEVEL CREDIT UNIT CONTACT HOUR

: : : : :

QUALITY CONTROL / INSPECTION 1 MTK 204 1 SEMESTER 2 2.0 FACE TO FACE NON FACE TO FACE : 3.0 HOURS / : EEK

COURSE TYPE PREREQUISITE CORE REQUISITE

: : :

VOCATIONAL MTK 203: SMA # !SHIELDED METAL ARC ELDING" PROCESS 1

Last Edited Course Page

10-13 November 2013 1/11 Document Page 1

DECEMBER Edition 2013

COURSE OUTCOMES: At the end of the course, the students should be able to:1. !. #. $. &. '. (. Check welding against drawing and welding procedure specification (WPS Check di"ension on prepared speci"ens Check inter-pass irregularities and clean Prepare welded %oint for inspection Check di"ension, penetration, reinforce"ent, height, surface irregularities and "isalign"ent Prepare speci"en for "echanical test Conduct "echanical test )ace *end ()* , +oot *end (+* and ,ick *reak (,* -ests

COURSE DESCRIPTION : -his unit identifies the co"petence re.uired to check welding against drawing and welding procedure specification, "aterial di"ension and interpass irregularities /isuall0, clean welded %oint to check di"ension, penetration, reinforce"ent, height, surface irregularities and "isalign"ent using gauges and inspection tools so that the surface ph0sical condition and profile of the weld"ent is obtained and co"pared against the drawing 1 procedure. 2t also identifies the co"petence re.uired to check, prepare speci"en for "echanical test and conduct "echanical test ()ace *end ()* , +oot *end (+* And ,ick *reak (,* -ests b0 preparing test blue print, carr0ing the tests and e/aluating test results so that the test is conducted according to procedure and the .ualit0 of the weld is deter"ined against the codes re.uire"ent

Last Edited Course Page

10-13 November 2013 2/11 Document Page 2

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD 1. CHECK ELDING AGAINST DRA ING AND ELDING PROCEDURE QUALIFICATION 1.1

LEARNING STANDARD 2dentif0 welding code re.uire"ent 34a"ine weld"ent b0 /isual inspection "ethod

PERFORMANCE CRITERIA 1.1.1 2dentif0 t0pe of weld irregularities 1.1.! 5escribe acceptance and re%ection criteria with respect to specified code and standards. 1.!.1 1.!.! 1.!.# 1.!.$ 1.!.& 2dentif0 t0pe of "aterial defects. 5escribe 6eat Affected 7one in welding "aterial. 2dentif0 "ethode of surface inspection. 2dentif0 t0pe of tools and instru"ent for surface inspection. 2nspect root pass, fill and capping pass using inspection tools according to *S1AWS codes and standards. 1.!.' Perfor" and 2nspect back gouging on welding %oint according to *S1AWS codes and standards. 1.!.( +ecord and interpret finding for surface inspection. 1.!.8 Practice safet0 consciousness, cautious, alertness and patience according to standard safet0 procedures.

1.!

Last Edited Course Page

10-13 November 2013 3/11 Document Page 3

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD 2. CHECK DIMENSION ON PREPARED SPECIMENS

LEARNING STANDARD !.1 Clean the surface of the speci"en !.1.1

PERFORMANCE CRITERIA 2dentif0 techni.ue and tools used for cleaning surface in welding work. !.1.! 5escribe t0pe of surface i"purities1unwanted "aterials in welding process. !.1.# 9se tools to re"o/e unwanted surface "aterials before welding. 2nterpret drawing re.uire"ent to inspect speci"en. 2dentif0 and use "easuring tools and instru"ent to check work piece di"ension. 2dentif0 unit of "easure"ent, fraction and deci"al. Conduct and record "easure"ent in inspection process. Practise alertness, care and neatness according welding procedures, codes and standard.

!.! 34a"ine weld speci"ens b0 /isual inspection "ethod

!.!.1 !.!.! !.!.# !.!.$ !.!.&

Last Edited Course Page

10-13 November 2013 /11 Document Page

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD 3. INSPECT INTER# PASS IRREGULARITIES/ ELD DEFECT

LEARNING STANDARD #.1 34a"ine the welded surface #.1.1

PERFORMANCE CRITERIA 2dentif0 t0pe of surface irregularities1weld defects, inclusions i"purities and describe it causes according to *S1AWS codes and standards.

#.! +e"o/e surface irregularities1 weld defect

#.!.1 2dentif0 tools and procedures for cleaning surface irregularities1weld defects. #.!.! +e"o/e surface irregularities1 weld defects carefull0 #.!.# Appl0 safet0 precaution while cleaning according to standard safet0 procedures.

Last Edited Course Page

10-13 November 2013 !/11 Document Page !

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD 4. PREPARE ELDED $OINT FOR INSPECTION

LEARNING STANDARD $.1 Select weld %oint $.! Clean weld surface $.1.1 $.!.1 $.!.! $.!.#

PERFORMANCE CRITERIA 2dentif0 t0pe of weld %oints in welding work. 5escribe "ethods of cleaning weld surface prior for testing procedure. 9se tools for cleaning and re"o/ing weld slag according to standards oerational procedures. Appl0 safet0 precaution while cleaning according to standard safet0 procedures.

Last Edited Course Page

10-13 November 2013 "/11 Document Page "

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD %. CHECK DIMENSION, PENETRATION, REINFORCEMENT, HEIGHT, SURFACE IRREGULARITIES / ELD DEFECT AND MISALIGNMENT

LEARNING STANDARD &.1 2nspect the weld penetration

PERFORMANCE CRITERIA &.1.1 ;i/e definition and identif0 for weld penetration in welding work. &.1.! 2dentif0 "ethod of checking weld penetration. &.1.# 2dentif0 lack of penetration in accordance to *S1AWS codes and standard. &.!.1 ;i/e definition for weld reinforce"ent. &.!.! 2dentif0 tools for checking weld reinforce"ent. &.!.# 5escribe "ethod of checking weld reinforce"ent. &.#.1 2dentif0 t0pe of surface irregularities1 weld defects in accordance to *S1AWS codes and standard. &.#.! 5escribe "ethod of checking surface irregularities1 weld defects &.$.1 2dentif0 weld "isalign"ent and causes in accordance to *S1AWS, codes and standard. &.$.! 2dentif0 "ethods of checking weld "isalign"ent of weld &.$.# 2dentif0 "isalign"ent in welding work. &.&.1 )ill and co"plete inspection report for" to record all data.

&.! :easure weld reinforce"ent

&.# 5etect weld for surface irregularities1weld defects &.$ 2nspect weld for "isalign"ent

&.& Prepare inspection report for"

Last Edited Course Page

10-13 November 2013 #/11 Document Page #

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD &. PREPARE SPECIMEN FOR MECHANICAL TEST

LEARNING STANDARD '.1 2dentif0 t0pe of "echanical test to be conducted '.1.1 '.1.! '.! :easure and "ark welded "aterial '.!.1 '.!.! '.!.# '.#.1 '.#.! '.#.# '.$ 2dentif0 si<e of %ig re.uired '.& Set speci"en onto test %ig '.$.1 '.$.! '.&.1 '.&.! '.&.#

PERFORMANCE CRITERIA 2dentif0 t0pe of "echanical tests according to the *S1AWS code and standards. 5escribe test instruction1procedure = t0pe of test and nu"ber of speci"en re.uired according to standard perational procedures. 2dentif0 si<e of speci"en to be tested. 2dentif0 cutting allowances in "easuring in cutting process. 2dentif0 and use proper "easuring and "arking tools according to standards operational procedures. Appl0 safet0 precaution related to handling and using of cutting tools 5escribe "ethods of cutting speci"en >perate and use cutting tools and e.uip"ent safel0 according to standard operational procedures. 2dentif0 "ain features of %igs for face, root and nick break tests. 2dentif0 and use proper %igs carefull0 for bend and nick break tests Appl0 safet0 precaution related to setting up speci"en onto test %ig. 2dentif0 setting procedure Asse"ble speci"en on test %ig.

'.# Cut welded "aterial into test speci"en and clean

Last Edited Course Page

10-13 November 2013 $/11 Document Page $

DECEMBER Edition 2013

CONTENT AND LEARNING STANDARDS PROGRAMME COURSE NAME CODE NAME : : : ELDING TECHNOLOGY QUALITY CONTROL/INSPECTION 1 MTK 204

CONTENT STANDARD '. CONDUCT MECHANICAL TEST: FACE (END, ROOT (END AND NICK (REAK TEST

LEARNING STANDARD (.1 Prepare test blue print (.! Carr0 out "echanical test = face, root bend and nick break tests. (.1.1 (.1.! (.!.1 (.!.! (.!.# (.!.$ (.!.& (.# 3/aluate test piece (.#.1 (.#.! (.#.#

PERFORMANCE CRITERIA 2nterpret welding codes and standards according to *S1AWS. Produce test blue print according to work re.uire"ent. 5escribe "ethods of "echanical tests for welded %oints Appl0 safet0 pracaution related to testing according to standard operational procedures. 2dentif0 t0pe of %igs for test. 2dentif0 and appl0 correct tests procedure1instruction for "echanical test. 9se test %igs according to "anufacturer reco""endation 5escribe cceptance and re%ection criteria based on codes and standards. 2dentif0 t0pe of discontinuities for acceptance and re%ection according to *S1AWS codes and standard. Co"plete test report.

Last Edited Course Page

10-13 November 2013 %/11 Document Page %

Вам также может понравиться

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Документ17 страницMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- Refining Corrosion Technologist NACE-RCT-001: NACE Coating Inspector Level 2 Written Exam NACE-CIP2-001Документ10 страницRefining Corrosion Technologist NACE-RCT-001: NACE Coating Inspector Level 2 Written Exam NACE-CIP2-001EvoMene100% (2)

- Nace Cip Level I Guide PDFДокумент2 страницыNace Cip Level I Guide PDFGouse PashaОценок пока нет

- CIP1 Exam Preparation Guide PDFДокумент10 страницCIP1 Exam Preparation Guide PDFrjnerdОценок пока нет

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Документ20 страницMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Frosio PDFДокумент568 страницFrosio PDFdang217201490% (10)

- DKSKV Welding Technology MWT 202 AliДокумент15 страницDKSKV Welding Technology MWT 202 AliAli la NieОценок пока нет

- 01-Visual Inspection & Welding InspectorsДокумент7 страниц01-Visual Inspection & Welding InspectorsSaif UllahОценок пока нет

- MES - Construction Quality Manual - Rev - 0Документ55 страницMES - Construction Quality Manual - Rev - 0Ishaan ThakerОценок пока нет

- H-023-4 M15 KP03Документ5 страницH-023-4 M15 KP03Eizanie MuhamadОценок пока нет

- Module 1 PDFДокумент19 страницModule 1 PDFHardeep Singh100% (1)

- Jphil Bolting and Unbolting Procedure Rev 1Документ21 страницаJphil Bolting and Unbolting Procedure Rev 1Mark Darrel AranasОценок пока нет

- Oluwajana's CVДокумент6 страницOluwajana's CVBolu KennethОценок пока нет

- CIP 1 Preparation GuideДокумент10 страницCIP 1 Preparation GuideSabrina RodriguezОценок пока нет

- API577 IDC Weld Inspect Aug15 PDFДокумент7 страницAPI577 IDC Weld Inspect Aug15 PDFMohamad AzuwanОценок пока нет

- Tuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & MetallurgyДокумент5 страницTuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & Metallurgyzulfadli izaraeeОценок пока нет

- Cswip 3.0 SyllabusДокумент2 страницыCswip 3.0 SyllabusAbu HurairaОценок пока нет

- Qa - QC Welding Inspector - Shaikh Mohammed TabishДокумент7 страницQa - QC Welding Inspector - Shaikh Mohammed TabishAurangzeb MalikОценок пока нет

- Dowell QA QC InspectorДокумент9 страницDowell QA QC InspectorSuhail NilОценок пока нет

- Brochure API 510 (150128)Документ4 страницыBrochure API 510 (150128)wisnu_bayusaktiОценок пока нет

- Piping Fabrication L4Документ134 страницыPiping Fabrication L4OLiver Robert100% (1)

- WMS (Method Statement For Concrete Repair Works)Документ6 страницWMS (Method Statement For Concrete Repair Works)PUI CHEE KHIANОценок пока нет

- WI & CERT Kelas EДокумент22 страницыWI & CERT Kelas EKevin ArmandoОценок пока нет

- TP-25 For 115kv GIS SystemДокумент8 страницTP-25 For 115kv GIS SystemsathiyaseelanОценок пока нет

- Dutyies of Welding InspectorДокумент30 страницDutyies of Welding InspectorMorg Actus100% (1)

- Ebs1 Aaaa00 Saqa Prqa 0016Документ7 страницEbs1 Aaaa00 Saqa Prqa 0016SERT-QA/QC- BUZОценок пока нет

- API653 Feb12Документ4 страницыAPI653 Feb12Amair CoolОценок пока нет

- S1501 Piping SpecДокумент33 страницыS1501 Piping SpecLiou Will SonОценок пока нет

- NSE Report 1Документ10 страницNSE Report 1PROFADEV RESOURCESОценок пока нет

- Asset Integrity EngineerДокумент4 страницыAsset Integrity Engineerlaz_kОценок пока нет

- Suvidya Book1Документ113 страницSuvidya Book1amankodi50% (2)

- CV FormateДокумент8 страницCV Formatetariq_hussain_20Оценок пока нет

- Course Plan Details For The Subject: Software Quality AssuranceДокумент5 страницCourse Plan Details For The Subject: Software Quality AssuranceAnonymous TxPyX8cОценок пока нет

- O - (TOC) - SOP - 011 - R0 - SOP For External Painting and CoatingДокумент10 страницO - (TOC) - SOP - 011 - R0 - SOP For External Painting and CoatingMDhana SekarОценок пока нет

- Curriculum Vitae: Udo-Umoren, Mbetobong Umoren Nace Certified Coating, Lining & Insulation Inspector. Career ObjectiveДокумент5 страницCurriculum Vitae: Udo-Umoren, Mbetobong Umoren Nace Certified Coating, Lining & Insulation Inspector. Career ObjectiveSamuel AnemeОценок пока нет

- Fabrication TechnologyДокумент11 страницFabrication Technologyhiren mandaliaОценок пока нет

- TVL-Shielded Metal Arc Welding 12 Third: PanimulaДокумент3 страницыTVL-Shielded Metal Arc Welding 12 Third: PanimulaFlorinda Gagasa100% (1)

- 100690-MEC-QW-E-2006: Site QA/QC ManagerДокумент6 страниц100690-MEC-QW-E-2006: Site QA/QC ManagerAhmed GamalОценок пока нет

- Scope of Work (Sow)Документ10 страницScope of Work (Sow)Asongwe HansОценок пока нет

- E PR 250 PDFДокумент30 страницE PR 250 PDFAmirhosein605334Оценок пока нет

- Editable Welding Resume TemplateДокумент6 страницEditable Welding Resume TemplatejeyesbelmenОценок пока нет

- Brochure API 570 (150129)Документ4 страницыBrochure API 570 (150129)Andri Dwi MaryantoОценок пока нет

- NDT ProceduresДокумент7 страницNDT ProceduresDavid DaemmejОценок пока нет

- Akhtar Ansari - TPI - FRT PDFДокумент5 страницAkhtar Ansari - TPI - FRT PDFAkhtar AnsariОценок пока нет

- What Is Welding Inspector ?: DefinisiДокумент20 страницWhat Is Welding Inspector ?: DefinisiBagasAdiNugroho100% (1)

- Abdelatif Belmamoune - CV - Feb 2023Документ6 страницAbdelatif Belmamoune - CV - Feb 2023Abdelatif BelmamouneОценок пока нет

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Документ4 страницыCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)nike_y2k85% (13)

- 11-Quality Assurance - HariharanДокумент29 страниц11-Quality Assurance - Hariharanabhinay soniОценок пока нет

- Aramco Specific Evaluations For WeldingДокумент6 страницAramco Specific Evaluations For WeldingSiddiqui Abdul Khaliq89% (9)

- Plant InspectorДокумент7 страницPlant Inspectornaveed7861Оценок пока нет

- Welding Insp Part 4Документ3 страницыWelding Insp Part 4irwanОценок пока нет

- Apcs 113a Rev 3 Pid ApprovalДокумент19 страницApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- NDT ProceduresДокумент2 страницыNDT Proceduresyeezee100% (1)

- Rediographic Examination ProcedureДокумент6 страницRediographic Examination ProcedureAbank RoonyОценок пока нет

- Kalyanasundaram Palaniappan BLK 468A Admiralty Drive, #04-129 SINGAPORE - 751468. H/P: 81691165 Singapore PR (S7564808A)Документ7 страницKalyanasundaram Palaniappan BLK 468A Admiralty Drive, #04-129 SINGAPORE - 751468. H/P: 81691165 Singapore PR (S7564808A)GomathyselviОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Engineering Applications: A Project Resource BookОт EverandEngineering Applications: A Project Resource BookРейтинг: 2.5 из 5 звезд2.5/5 (1)

- Implementation Rules For Compulsory Certification of Electrical and Electronic ProductsДокумент24 страницыImplementation Rules For Compulsory Certification of Electrical and Electronic ProductsIzzah AmalinaОценок пока нет

- Fastener Material SelectionДокумент3 страницыFastener Material SelectionIzzah AmalinaОценок пока нет

- Proses Reka Cipta: Kenal Pasti Keperluan/Masalah Spesifikasi Reka Bentuk Penjanaan IdeaДокумент10 страницProses Reka Cipta: Kenal Pasti Keperluan/Masalah Spesifikasi Reka Bentuk Penjanaan IdeaIzzah AmalinaОценок пока нет

- Factor of Cloth Choosing Male Rating Female Rating Range IndexДокумент14 страницFactor of Cloth Choosing Male Rating Female Rating Range IndexIzzah AmalinaОценок пока нет

- 70ft X 30ft 2100 FT .: Floor Plan Total Area Lenght X WidthДокумент1 страница70ft X 30ft 2100 FT .: Floor Plan Total Area Lenght X WidthIzzah AmalinaОценок пока нет

- Cover Report KimpalanДокумент1 страницаCover Report KimpalanIzzah AmalinaОценок пока нет

- SQP Proftest English XДокумент6 страницSQP Proftest English Xsavita_nagleОценок пока нет

- 2nd Year PhoneticsДокумент4 страницы2nd Year Phoneticskhadidja bnh0% (1)

- Estimator - Final LoresДокумент36 страницEstimator - Final Loresramachandran_ca8060Оценок пока нет

- Application Form For Flight Instructor RatingsДокумент1 страницаApplication Form For Flight Instructor RatingsNitesh PalОценок пока нет

- Assignment Recruit, Selection & RetentionДокумент11 страницAssignment Recruit, Selection & RetentionBalasubramanian Subramanian100% (1)

- Aarohan: Leadership Development Programme at Engineers India LimitedДокумент19 страницAarohan: Leadership Development Programme at Engineers India Limitedsandeep singhОценок пока нет

- Cracking CSS English EssayДокумент3 страницыCracking CSS English EssayAli WassanОценок пока нет

- MBTI Distribution RateДокумент54 страницыMBTI Distribution RateVania FlorensiaОценок пока нет

- OK Sa DepEd Policy and GuidelinesДокумент22 страницыOK Sa DepEd Policy and GuidelinesMarie Antonette A. RomasantaОценок пока нет

- About Asnt Certification ExamsДокумент2 страницыAbout Asnt Certification ExamsKhezzari MerwenОценок пока нет

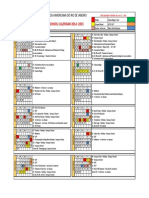

- CalendarДокумент1 страницаCalendarapi-277854872Оценок пока нет

- Course Outline in Life and Works of RizalДокумент2 страницыCourse Outline in Life and Works of RizalJeffthy S. JudillaОценок пока нет

- PRP 2016Документ5 страницPRP 2016umair100% (1)

- TIS Bulletin 041122 CДокумент70 страницTIS Bulletin 041122 COge MoghaluОценок пока нет

- BSA Business Policy and StrategyДокумент11 страницBSA Business Policy and StrategyNikki SaysonОценок пока нет

- Longman Érettségi Handbook For English TeachersДокумент6 страницLongman Érettségi Handbook For English TeachersFrank Cooper100% (1)

- Syllabus Econtwo 2Документ5 страницSyllabus Econtwo 2Holly AlexanderОценок пока нет

- Reaction PaperДокумент10 страницReaction Paperwilliam FELISILDAОценок пока нет

- CSTP 5 Thomas 4Документ7 страницCSTP 5 Thomas 4api-571036019Оценок пока нет

- APICS CSCP2014 Learning System SmartStudy ToolДокумент3 страницыAPICS CSCP2014 Learning System SmartStudy ToolpraveenjuturОценок пока нет

- William Horsman CVДокумент3 страницыWilliam Horsman CVWilliam David HorsmanОценок пока нет

- Lahore University of Management Sciences EE558 - Battery Energy Storage SystemsДокумент5 страницLahore University of Management Sciences EE558 - Battery Energy Storage SystemsIqra FarhanОценок пока нет

- The Social Work Services, Processes, and MethodsДокумент6 страницThe Social Work Services, Processes, and Methodsupperhand consultancyОценок пока нет

- Example e Mail Template From Supervisor Inviting ExaminerДокумент2 страницыExample e Mail Template From Supervisor Inviting ExaminerLucas Fernando Santos de JesusОценок пока нет

- First Sampl Test 2 Writ02&03Документ1 страницаFirst Sampl Test 2 Writ02&03Janine De Oliveira FontenlaОценок пока нет

- 9700 s08 QP 31Документ12 страниц9700 s08 QP 31Daniel ConwayОценок пока нет

- Three Domains of Learning - Cognitive, Affective, PsychomotorДокумент11 страницThree Domains of Learning - Cognitive, Affective, PsychomotorRoselie Manansala CastilloОценок пока нет

- PNP QS For All Ranks (February 2010)Документ2 страницыPNP QS For All Ranks (February 2010)Leon GuerreroОценок пока нет

- Why Have The Sales of Sharma Restaurant Declined in The 2008-2011 Period ?Документ18 страницWhy Have The Sales of Sharma Restaurant Declined in The 2008-2011 Period ?Shashi Shekhar MahajanОценок пока нет

- Math Researh PaperДокумент10 страницMath Researh PaperCaereel LopezОценок пока нет