Академический Документы

Профессиональный Документы

Культура Документы

Assignment No. 4 - Oil Well Cement

Загружено:

Zang NguyenИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Assignment No. 4 - Oil Well Cement

Загружено:

Zang NguyenАвторское право:

Доступные форматы

King Saud University College of Engineering Petroleum & Natural Gas Engineering Department Drilling Engineering: PGE 472

Oil Well Cement: Assignment No. 4

_________________________________________________________

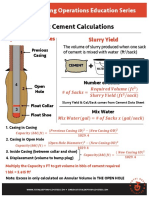

1) A string of 13-3/8, 48 lb/ft casing (thickness 0.32''), is to be cemented at 2000' with a 15 lb/gal slurry. Complete fill up is desired. Discuss the choice of displacing fluid. Maximum collapse pressure of 13-3/8, 48 lb/ft CSG is 740 psi. Float collar is 50' above shoe. 2) What surface pressure must be held to prevent cement back flow under the following conditions: mud 9 ppg, cement is 15 ppg, oil 30 API (used to displace cement), fill up 2000 ft well depth 6000'. 3) A well is to be cemented with 50-50 pozzolan cement containing 2% bentonite per weight and mixed with 5.75 gal of water per sack. The specific gravity of the cement is 3.14; of pozzolan 2.46 and of bentonite 2.65. Calculate the slurry volume yield. 4) A 9000 string of 7", 29 lb/ft casing is to be run in a 9-7/8" hole with float-collar placed 50' above shoe. 750 sacks of cement are to be mixed at a slurry weight of 15.5 lb/gal, with a yield of 1.2ft3 /Sack. Cement is mixed at a rate of 30 sacks/mim, the rig pump has 18" stroke with 6.5" liners and operates at 60 SPM and 95% volumetric efficiency. a) What will be the mixing and displacement time b) Calculate the fill up in the annulus. 5) A string of 13-3/8 CSG, 68 lb/ft is to be cemented at 3000' over 2000' of open hole. If slurry yield is 2 ft3/sack and excess factor is 100 in open hole. 20" casing is set at 1000', I.D. =18.5". Float collar is 80' above shoe .Find the number of sacks for this job and the amount of displacing fluid (bbls) to displace cement to float collar. What will be the final displacing pressure. 6) A 9-5/8" casing, ID. 8.5", is to be cemented in 12.25" hole from 9000 to surface. The shoe of the surface casing (13-5/8") was set at 4000', I.D. is 12.5". The float collar is placed 80' above the shoe of the 9-5/8" CSG. The cement to be used is API class with 3% attapulgite. The mixing water is salt saturated and is 44% by weight of dry cement, increased by 5% for each one percent of attapulgite. Mixing water weighs 10 ppg. a) What is the yield of dry cement b) Find the specific weight (ppg) of slurry. c) How many sacks of cement are required for this cement job, if 100% excess cement is used in open hole d) Check if a thickening time of 4.5 hours is adequate for this job. The slurry is pumped at the rate of 45 ft3/min and displaced at the rate of 50 ft3/min.

e) In case that the float valve fails to work effectively, estimate the minimum pressure to apply at the surface to prevent the slurry from returning to the inside of the casing. Mud weight is 90 lb/ft3 7) It is required to set 13-3/8 string (I.D. 12.4'') at 4000'. 20" casing is set at 1000' (I.D. of 20" is 18.5"). Average diameter of open hole below 20" casing is 18.5". The 13 -3/8" string should be cemented to the surface. Use 150% excess in open hole and 10% excess in the annular space between casing strings. Neglect the amount of cement left below the float collar. The yield of cement per sack is 2 ft3/sack a) Find the number of sacks of class G cement for this job. b) The minimum thickening time if mixing, pumping and displacement were conducted at 7 barrels per minute. c) If the float shoe and float collar failed to work what would be the minimum surface pressure into the casing? slurry = 12.8 ppg, m =90ppg 8) 7" casing to be lowered to 10,000' in 8 1/2" hole, 9 5/8" casing (ID 8.68") at 8,000'. Well is filled with 11.0 ppg mud. Casing is fitted with float shoe and lowered empty. Casing grade is N80 & 26 lb./ft. Assume no excess cement, CSG ID is 6.28". a. If casing string is to be cemented with 16.2 ppg slurry till the surface, draw a curve showing change in hook load with amount of cement pumped inside and outside casing. Hole size is 9" average diameter. Show the following points: (1) zero CMT pumped, (2) total volume of CMT pumped, (3) CMT reached shoe, (4) CMT equalized inside and outside, and (5) CMT is outside CSG except the last 80' of CSG. Draw force depth diagram for each case. b. Draw the variation of surface pressure assuming hydrostatic conditions.

Вам также может понравиться

- Drilling HomeworkДокумент10 страницDrilling HomeworkRaphael L Cotta MacedoОценок пока нет

- Porosity Problems SheetДокумент1 страницаPorosity Problems Sheetiscribdusername100% (1)

- Calculation For The Sucker Rod Design: Assumed DataДокумент5 страницCalculation For The Sucker Rod Design: Assumed DataMando U WKОценок пока нет

- 4ADworkbook9 DTS2 CementingДокумент6 страниц4ADworkbook9 DTS2 CementingSamad Ali SiddiquiОценок пока нет

- Porosity QuestionsДокумент3 страницыPorosity QuestionsAtahan AltayОценок пока нет

- 3.2 Reservoir Performance PDFДокумент23 страницы3.2 Reservoir Performance PDFMuhammad Amirullah SanadiОценок пока нет

- Chapter Two Reservoir Properties PorosityДокумент35 страницChapter Two Reservoir Properties Porositymohamed sadekОценок пока нет

- Beng Drilling Course Tutorials CementingДокумент2 страницыBeng Drilling Course Tutorials CementingTamkin TamrazliОценок пока нет

- PTRT2323 Chapter 3-6Документ52 страницыPTRT2323 Chapter 3-6Sig BahaОценок пока нет

- Well Control FdreДокумент27 страницWell Control FdreKhairi OmarОценок пока нет

- Cementing CalcДокумент68 страницCementing CalcEmad JamshidiОценок пока нет

- CementingДокумент9 страницCementingakshitppe11Оценок пока нет

- Types of Free PointДокумент19 страницTypes of Free Pointphucbm bmОценок пока нет

- Drilling 1 AutoRecoveredДокумент52 страницыDrilling 1 AutoRecoveredKhaled AdelОценок пока нет

- Balanced Cement Plug CalculationДокумент7 страницBalanced Cement Plug CalculationAlejandro ViscarraОценок пока нет

- DRLG 451 - Assignment #3 Well ControlДокумент6 страницDRLG 451 - Assignment #3 Well ControlnijamediaОценок пока нет

- Well CompletionДокумент82 страницыWell CompletionFlorian Ananias ByarugabaОценок пока нет

- Basic Cement CalculationsДокумент1 страницаBasic Cement Calculationsابوالحروف العربي ابوالحروفОценок пока нет

- Wait and Weight MethodДокумент2 страницыWait and Weight MethodMubin Ashraf Sheikh100% (1)

- Bahan Kuliah CementingДокумент22 страницыBahan Kuliah CementingRioPrawiraОценок пока нет

- Well DrillingДокумент390 страницWell DrillingfrmarzoОценок пока нет

- Setting & Thickening TimeДокумент10 страницSetting & Thickening TimeAlimahmood BahraniОценок пока нет

- Binder 1Документ50 страницBinder 1Hamed NazariОценок пока нет

- Round Trip Ton-Miles CalculationДокумент2 страницыRound Trip Ton-Miles CalculationKenaouia BahaaОценок пока нет

- Testing of Drilling Fluids: Mud DensityДокумент9 страницTesting of Drilling Fluids: Mud DensityMohammed Amin BenharkatОценок пока нет

- Driller MethodДокумент1 страницаDriller MethodReza AgungОценок пока нет

- Sand Content: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab ExperimentДокумент6 страницSand Content: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab Experimentايمن القنونيОценок пока нет

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageДокумент8 страницENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiОценок пока нет

- Leak Off TestДокумент80 страницLeak Off Testb4rfОценок пока нет

- TestsДокумент10 страницTestsShakeel AhmedОценок пока нет

- Diverter Equipment11Документ2 страницыDiverter Equipment11이동건Оценок пока нет

- Chapter4 (Drilling String Design)Документ13 страницChapter4 (Drilling String Design)Kalpana Venugopal100% (6)

- Quiz AITДокумент4 страницыQuiz AITazizsarshoghОценок пока нет

- Well Control Preparation Class Final-Test: Name: Badge: DateДокумент16 страницWell Control Preparation Class Final-Test: Name: Badge: DateBoedi SyafiqОценок пока нет

- Oil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepДокумент8 страницOil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepAli MahmoudОценок пока нет

- Drilling Engineering Labratory Manual - King FahadДокумент98 страницDrilling Engineering Labratory Manual - King FahadMarshal betaОценок пока нет

- Mud Engineer TrainingДокумент8 страницMud Engineer Trainingsanjeet giri100% (1)

- Lot & FitДокумент3 страницыLot & FithassansocОценок пока нет

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesОт EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesОценок пока нет

- 13 - Gas Lift - 2007 - Petroleum Production Engineering PDFДокумент26 страниц13 - Gas Lift - 2007 - Petroleum Production Engineering PDFmissaouiОценок пока нет

- Oil Well DesigningДокумент15 страницOil Well DesigningShashank SacamuriОценок пока нет

- Primary Cementing CalculationsДокумент40 страницPrimary Cementing CalculationsMostafa ElghifaryОценок пока нет

- Case Study of Core and Pluge PreparationДокумент9 страницCase Study of Core and Pluge PreparationSpeculeОценок пока нет

- ENPE 515 W 2013 Assignment 3.313Документ2 страницыENPE 515 W 2013 Assignment 3.313ench501Оценок пока нет

- Drilling Engineering SyllabusДокумент3 страницыDrilling Engineering SyllabusbrigitteОценок пока нет

- Solids Induced Pack-Off Packing Off - First ActionsДокумент4 страницыSolids Induced Pack-Off Packing Off - First ActionsBhagwal TravelsОценок пока нет

- CH 5 Formation Pressures PDFДокумент121 страницаCH 5 Formation Pressures PDFtashh raoОценок пока нет

- Mitchell-Advanced Oil Well Drilling EngineeringДокумент626 страницMitchell-Advanced Oil Well Drilling EngineeringYASSER_MAОценок пока нет

- Mud Viscosity and RhelogyДокумент8 страницMud Viscosity and RhelogyHafizszul FeyzulОценок пока нет

- TUTORIAL 1 Drilling EngineerДокумент4 страницыTUTORIAL 1 Drilling EngineerAnonymous AkV8maWxGNОценок пока нет

- Drilling With Casing Promises Major BenefitsДокумент12 страницDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaОценок пока нет

- Perf - Presentation AiymДокумент32 страницыPerf - Presentation AiymNaief Javaheri100% (1)

- Well ControlДокумент5 страницWell ControlMostafa IbrahimОценок пока нет

- Annular VelocityДокумент4 страницыAnnular VelocityMiguel VelazcoОценок пока нет

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsОт EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsОценок пока нет

- Cement Plug Balanced GuideДокумент9 страницCement Plug Balanced GuideemiljuchiacОценок пока нет

- HW 8 CementingДокумент1 страницаHW 8 CementingAli AL-ghareebОценок пока нет

- Instructions: Well Cementing Trainint-Project WorkДокумент4 страницыInstructions: Well Cementing Trainint-Project WorkTariqОценок пока нет

- Drilling Eng. II CH 5 CalculationДокумент6 страницDrilling Eng. II CH 5 CalculationShakerMahmood100% (3)

- BlakeДокумент13 страницBlakeZang NguyenОценок пока нет

- Entropy: Geometric Interpretation of Surface Tension Equilibrium in Superhydrophobic SystemsДокумент17 страницEntropy: Geometric Interpretation of Surface Tension Equilibrium in Superhydrophobic SystemsZang NguyenОценок пока нет

- Experimental and Numerical Study of Two-Phase Flows in Arrays of CylindersДокумент13 страницExperimental and Numerical Study of Two-Phase Flows in Arrays of CylindersZang NguyenОценок пока нет

- MOdelling of Wake-Induced Transition With Dynamic PDFДокумент163 страницыMOdelling of Wake-Induced Transition With Dynamic PDFZang NguyenОценок пока нет

- Apartment Rental AgreementДокумент2 страницыApartment Rental AgreementZang NguyenОценок пока нет

- How To: Use Basic C++, Syntax and OperatorsДокумент13 страницHow To: Use Basic C++, Syntax and OperatorsSatryo WibisonoОценок пока нет

- Gas Fluidized BedДокумент87 страницGas Fluidized BedZang NguyenОценок пока нет

- Chuong Trinh Hoi Nghi 15 FullДокумент4 страницыChuong Trinh Hoi Nghi 15 FullZang NguyenОценок пока нет

- Washburn EquationДокумент2 страницыWashburn EquationZang NguyenОценок пока нет

- Compiled ErrorДокумент1 страницаCompiled ErrorZang NguyenОценок пока нет

- Presentation 160603191325Документ110 страницPresentation 160603191325Ngô Ích SơnОценок пока нет

- Casing Design Manual - BG (2001)Документ51 страницаCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- Hydraulic Fracture Models Abc D PDFДокумент23 страницыHydraulic Fracture Models Abc D PDFZang NguyenОценок пока нет

- De Cuong Tai Lieu Tham Khao Do An Ky Thuat ViaДокумент5 страницDe Cuong Tai Lieu Tham Khao Do An Ky Thuat ViaZang NguyenОценок пока нет

- PETE403 FinalДокумент2 страницыPETE403 FinalZang NguyenОценок пока нет

- 03 Inflow Control DevicesДокумент8 страниц03 Inflow Control DevicesZang Nguyen100% (1)

- Conference Name, SPE Number Conference Name, SPE Number: Vol. X EditionДокумент1 страницаConference Name, SPE Number Conference Name, SPE Number: Vol. X EditionZang NguyenОценок пока нет

- EclipseДокумент3 страницыEclipseZang NguyenОценок пока нет

- EOR Screening CriteriaДокумент7 страницEOR Screening CriteriaMuhammad WibisonoОценок пока нет

- Our Office Is Near To Surasak StationДокумент1 страницаOur Office Is Near To Surasak StationZang NguyenОценок пока нет

- Directional Drilling PDFДокумент15 страницDirectional Drilling PDFsyed Shaiq100% (1)

- 873 72100e Casing Reaming ToolДокумент2 страницы873 72100e Casing Reaming ToolZang NguyenОценок пока нет

- Lanko 753 - TdsДокумент1 страницаLanko 753 - TdskalslingamОценок пока нет

- Bicmos InvertersДокумент10 страницBicmos InvertersLily SharmaОценок пока нет

- Electrostatic Powder PaintingДокумент9 страницElectrostatic Powder PaintingfirdausОценок пока нет

- SAIC-Q-1043 Asphalt Core Density Testing InspectionДокумент3 страницыSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanОценок пока нет

- Civil Works BuildingДокумент22 страницыCivil Works BuildingSarinОценок пока нет

- MESCO News January 2016Документ4 страницыMESCO News January 2016GoriZakirSalimОценок пока нет

- SA35AC E01 MergedДокумент87 страницSA35AC E01 MergedClassyОценок пока нет

- Microsoft SQL Server 2005 Express Edition &Документ95 страницMicrosoft SQL Server 2005 Express Edition &lgmep350Оценок пока нет

- 03 Vetotouch Europa - Group 170821Документ2 страницы03 Vetotouch Europa - Group 170821HalaОценок пока нет

- WPH02 01 Que 20160120Документ24 страницыWPH02 01 Que 20160120Omar HashemОценок пока нет

- Interurban RMC Rail Bus ManualДокумент4 страницыInterurban RMC Rail Bus ManualSteven GardnerОценок пока нет

- Chemistry Practicals Class 12Документ32 страницыChemistry Practicals Class 12Eshan Trivedi40% (5)

- Aerobic Respiration in PeasДокумент2 страницыAerobic Respiration in PeasMatt Schiavo100% (1)

- Cama Stryker Sv2-Service ManualДокумент117 страницCama Stryker Sv2-Service ManualjoelpalzaОценок пока нет

- Analysis and Design of Gravity Retaining Structures PDFДокумент37 страницAnalysis and Design of Gravity Retaining Structures PDFChin Tiong LeeОценок пока нет

- GSM 06 InterfacesДокумент17 страницGSM 06 Interfacesamitcool26Оценок пока нет

- Design CalculationДокумент13 страницDesign CalculationSunil KumarОценок пока нет

- Pvu-L0880er GaДокумент1 страницаPvu-L0880er GaarunghandwalОценок пока нет

- How To Install Openbravo ERP On Debian LennyДокумент4 страницыHow To Install Openbravo ERP On Debian LennyfromemОценок пока нет

- Standard Rain GaugeДокумент43 страницыStandard Rain GaugeAku PalsuОценок пока нет

- Final Fine Black Sport 06.12.23Документ15 страницFinal Fine Black Sport 06.12.23NATWAR PRAJAPATIОценок пока нет

- PMAC720Документ3 страницыPMAC720felipeОценок пока нет

- TSI 271210 GHH Two-Stage Compressor Repair InstructionsДокумент18 страницTSI 271210 GHH Two-Stage Compressor Repair InstructionsMax HudsonОценок пока нет

- Instructions VbamДокумент2 страницыInstructions VbamAustin Yu LiuОценок пока нет

- Catalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionДокумент4 страницыCatalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionShalika SinhaОценок пока нет

- Optical FibreДокумент17 страницOptical Fibreshah alomОценок пока нет

- Intro To Neutron ScatteringДокумент191 страницаIntro To Neutron ScatteringEleni MitsiОценок пока нет

- ChemicalEq DroppersДокумент13 страницChemicalEq DroppersUtkarsh SharmaОценок пока нет

- Calculating The Volume of A Stainless Steel WeldДокумент6 страницCalculating The Volume of A Stainless Steel WeldOkayОценок пока нет

- Free Spanning Analysis of Offshore PipelinesДокумент14 страницFree Spanning Analysis of Offshore PipelinesMaringan JuliverОценок пока нет