Академический Документы

Профессиональный Документы

Культура Документы

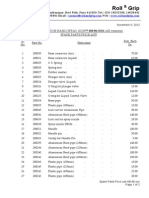

ServeCAST - Non-Fe - Sand, Die Casting - Input Data Format

Загружено:

Vaibhav ShuklaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ServeCAST - Non-Fe - Sand, Die Casting - Input Data Format

Загружено:

Vaibhav ShuklaАвторское право:

Доступные форматы

ServeCAST: SoftCAST Casting Simulation and Methoding Services

Non-Ferrous

Use additional sheets as necessar !

Die Casting, Sand Casting

Note: All Dimensions - mm.

Co. Name: Hind Metal & Allied Inds. Casting Ref. /No. /ID: HMI/3" Flange

Casting Name: 3" Flange Method Dra ing Ref. /No. /ID: !!!!!!!!!!!!!!!!!!

A! Casting and "#isting Method Files:

If available, 3D Models:

". 3D Models of the Casting and the e#isting Method $a%o&t: Format: !$%T &$ro'"( or !ST$ &ST"$ format( or !)*T &$arasolids file( or !N"U

+%

If 3D Models are not available, please send us the Drawings:

'. Casting and Method ( 'D dra ings )se*tional dra ings in*l&ded+ ith dimensions in all the ,ie s. -Format: .D./0 .1DF0 s*anned image ).21/0 .3M10 et*+0 or 1a4er5. If Method dra ing is not a,aila6le0 a *lear s7et*h ith all details sho&ld 6e 4ro,ided.

In both cases, please also provide the following:

a+ 1hotogra4hs of the *asting and method la%o&t0 and of the defe*ts -8ario&s ,ie s5. 6+ A dra ing /s7et*h of the 9#isting Method0 sho ing the *hills0 ins&lating 4ads0 and other method feat&res ) ith details of material and si:e+. ;o& sho&ld also mar7 the defe*ts in this s7et*h itself.

,! For SoftCAST Simulation, Anal sis - Design:

3. Metal / Allo% -- Cast metal s4e*ifi*ation: a+ 3road Categor% )A$ allo%0 3rass0 3ron:e0 other Co44er 6ased allo%0 <in* allo%0 Magnesi&m allo%0 Cerami*0 =ther+ 6+ >&6 Categor% )/&n Metal0 A$ 3ron:e0 $M? allo%0 et*.+ *+ Com4osition. $iB&id densit% of the allo% )gms/**+ at 1o&r Cem4. >olid densit% of the allo% )gms/**+ at Room Cem4. $iB&id&s Cem4. )FC+: >olid&s Cem4. )FC+: ".@-".EH 3rass DC-3' of I>: "'@A Atta*hed File

@. D. E. ?. "G. "". "'. "3.

8ol&metri* shrin7age of the allo% )Hage+0 if 7no n. 1attern Ma7erIs shrin7age )$inear Contra*tion+ of the allo% )Hage+0 if 7no n 1attern alread% made / to 6e madeJ Ma*hining Allo an*es 4ro,ided )mm+. -Mar7 the ma*hining s&rfa*es on the *asting dra ing /s7et*h5 "A. Casting 4ro*ess ->and Casting0 /ra,it% Die0 Cilt /DC0 $1DC0 H1DC5 "K. F&rna*es &sed -Ind&*tion0 Ar*0 and C&4ola5. "@. Ca4a*it% of F&rna*e )Connes+: )Main0 Holding+: "D. If Ind&*tion F&rna*e0 hat freB&en*%J Nos. 4er Heat: M=riental >oft are >er,eCA>C In4&t Data Format: non-Fe: Die />and Casting

Cilt /DC Ind&*tion 'GG Lg. 'GGG H:

1age: " of 3

"E. 1rod&*tion N&antit%: "?. =rientation0 1arting -indi*ate on dra ing5

Nos. 4er 3at*h: Nos. 4er Ann&m:

'G. No. of *astings 4er Mold 3o# / Ca7e / Flas7 /Die: Indicate Parting Type: Horizontal / Vertical: If Horizontal: If Vertical: '". >i:e of Mold 3o# / Die /Flas7 /Ca7e: .#3 3#H Co4e Height .idth Drag Height '3. Material of: Mold / Die: -/reen sand0 s7in-dried green sand0 dr% sand0 C=' sand0 *ement sandO Cores: =li,ine sand / :ir*on0 *hromite / gra4hite / C.I.0 steel0 et*.5 Chills: Ins&lating 1ads: Mold /Die Coat: =ther 1aints /Coats: '?. 1ro*ess )C='0 No 3a7e0 ...+ Molding: Coring:

Hori:ontal DK#"KG D' D' Mild >teel Molasses >and Core None None $iB. /ra4hite 3ath None

Cilt /ra,it% Die Casting Man&al Molasses

1ermanent Man&al ;es "GG degrees Centigrade

3". )>and+ Mold-ma7ing: Hand molding0 ma*hine molding )H1M/2olt-sB&ee:e/P+J 3'. Core-ma7ing: )Core shoot0 et*.+J 33. Mold /Die 1re-HeatedJ 3A. Mold /Die 1re-Heat />ta6le Cem4: "st mold in the 3at*h: 3K. 1o&ring Cem4. )FC+: $ast mold in the 6at*h: A,erage for the 6at*h: "st mold in the 3at*h: 3@. 1o&ring time )se*s.+: $ast mold in the 6at*h: A,erage for the 6at*h: 3D. If 9#othermi* / Ins&lating >lee,e Feeders are &sed0 the follo ing data: a+ Ma7e -Fose*o0 Cerafl� Ine#o0 .estern0 et*.5 6+ M9F )Mod&l&s 9#tension Fa*tor+ -if 7no n5 *+ Feeding 9ffi*ien*% )if 7no n+ AG. An% A1C / HCC &sedJ If ;es0 hat material and B&antit%0 if 7no nJ A". If *hills &sed0 indi*ate lo*ation -on dra ing5. >i:eJ: Chi*7ness0 $&3 or Dia. C%4e )$i4 1o&r0 3ottom 1o&r0 Cea >4o&t0 P+: A'. $adle /1o&ring 3asin: >i:e )Dia. or 3 # .O Ht.+: Height a6o,e Mold0 hen 4o&ring )a44ro#.+: A3. >i:es of the follo ing0 if an%: -also0 mar7 them in the dra ing /s7et*h5 Core 1rints: 8ents/3leeders: Flo -offs: Ma#im&m: Minim&m: A,erage:

"GKG degrees *entigrade

E se* No No No

No >4oon 4o&r Dia. KGmm0Ht.:DKmm "Kmm

A@. Casting Cime )from 1o&r *om4letion to remo,al from the Mold+ -se*s.5: AD. Me*hani*al 4ro4erties of the *asting AE. Cests 4erformed: RC0 QC0 D1I0 M1I0 1ress&re Cest0 8is&al0 et*. A?. A**e4tan*e N&alit% $e,el )A>CM $e,el '0 P+ KG. Defe*ts ith this Method. M=riental >oft are >l. No. Defe*t Hage defe*ti,e >e,erit% $e,el

"3 se*onds 1ress&re : 3G Lg/sB. *m 8is&al for defe*ts

Consistent =R >4oradi*J

$o*ations )also0 mar7 in *asting dra ing+ 1age: ' of 3

>er,eCA>C In4&t Data Format: non-Fe: Die />and Casting

-1l. 4ro,ide 1hotogra4hs of *asting from all angles0 R-ra% images5

Note:

". Data m&st 6e 4ro,ided at least for the Items in Red. '. Che dra ings and models sho&ld 6e *om4lete0 i.e. the% sho&ld in*l&de all details and dimensions. Che method dra ing / s7et*h sho&ld in*l&de all details of the *om4lete feeding / gating s%stem. 3. Do not include non-4art items of the method )*ores0 ins&lation 4ads0 *hill0 et*.+ hen ma7ing the 3D Models of the *asting and the method. A. Defe*t Codes: >1 )>hrin7age 1orosit% or >hrin7age+0 /1 )/as 1orosit% / Air 9ntra4ment+0 13 )1inholes / 3lo holes+0 >I )>and /Cerami* In*l&sion+0 C&C )Cears & Cra*7s+0 DD )Dimensional Distortion+0 = )=ther+. K. Note: Che term SDefe*ti,esT in*l&des all *astings that are not "GGH =L or of a**e4ta6le B&alit%O this term in*l&des 6oth SreUe*tedT and Sre- or7a6leT *ategories. @. >e,erit% $e,el: state as A>CM )le,el "0 'P+ or 6% an% other ind&str%-standard B&alif%ing 4arameter. D. Hage defe*ti,e V "GG # No. of *astings of the s4e*ified defe*t Cotal 4rod&*ed

M=riental >oft are

>er,eCA>C In4&t Data Format: non-Fe: Die />and Casting

1age: 3 of 3

Вам также может понравиться

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- 1 en 3 Chapter AuthorДокумент14 страниц1 en 3 Chapter AuthorVaibhav ShuklaОценок пока нет

- Standard Astm b456Документ11 страницStandard Astm b456Vaibhav ShuklaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Esi ProCAST PDFДокумент16 страницEsi ProCAST PDFanwarsitangangОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Progress Test 18Документ8 страницProgress Test 18Vaibhav ShuklaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Procast Manual PDFДокумент471 страницаProcast Manual PDFPhan Dinh Sy0% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Ubc 1997-0068Документ123 страницыUbc 1997-0068Vaibhav ShuklaОценок пока нет

- Metals 10 01418Документ24 страницыMetals 10 01418Vaibhav ShuklaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Ubc 1997-0068Документ123 страницыUbc 1997-0068Vaibhav ShuklaОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Effect of Heat Transfer Coefficient and Cooling Schedule On Porosity Sizes of Low Pressure Die Casting Aluminium Alloy WheelsДокумент8 страницThe Effect of Heat Transfer Coefficient and Cooling Schedule On Porosity Sizes of Low Pressure Die Casting Aluminium Alloy WheelsVaibhav ShuklaОценок пока нет

- GST Chapter Wise RateДокумент213 страницGST Chapter Wise RateMoneycontrol News92% (280)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- HTC CoefficientДокумент20 страницHTC CoefficientVaibhav ShuklaОценок пока нет

- FORM ED1 Invest PunjabДокумент1 страницаFORM ED1 Invest PunjabVaibhav ShuklaОценок пока нет

- FORM ED1 Invest PunjabДокумент1 страницаFORM ED1 Invest PunjabVaibhav ShuklaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Grohe Cat 03Документ144 страницыGrohe Cat 03FERCOОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- ANSI ASME B1.20.1, NPT Pipe Threads PDFДокумент31 страницаANSI ASME B1.20.1, NPT Pipe Threads PDFVaibhav Shukla75% (4)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Disclosure To Promote The Right To InformationДокумент21 страницаDisclosure To Promote The Right To InformationVaibhav ShuklaОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- GST Chapter Wise RateДокумент213 страницGST Chapter Wise RateMoneycontrol News92% (280)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- HIWINДокумент1 страницаHIWINVaibhav ShuklaОценок пока нет

- Brass MachiningДокумент68 страницBrass MachiningVaibhav ShuklaОценок пока нет

- BS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Документ20 страницBS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Vaibhav ShuklaОценок пока нет

- Exploded View & Part List HB-86-XxxДокумент3 страницыExploded View & Part List HB-86-XxxVaibhav ShuklaОценок пока нет

- BS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Документ20 страницBS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Vaibhav ShuklaОценок пока нет

- FP241 1Документ4 страницыFP241 1Vaibhav ShuklaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- User Guide Dual Action Hand Spray Gun HB-86, HB-35 & DJ-10Документ12 страницUser Guide Dual Action Hand Spray Gun HB-86, HB-35 & DJ-10Vaibhav ShuklaОценок пока нет

- Spares Pricelist HB-86Документ2 страницыSpares Pricelist HB-86Vaibhav ShuklaОценок пока нет

- Technical data on carbide end mills and drillsДокумент1 страницаTechnical data on carbide end mills and drillsenricoОценок пока нет

- Speedchart For MachiningДокумент1 страницаSpeedchart For MachiningVaibhav ShuklaОценок пока нет

- General Casting ToleranceДокумент2 страницыGeneral Casting ToleranceMuhammad M ElhafidОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Foundry Pouring LabДокумент26 страницFoundry Pouring LabMuhd MuzafarОценок пока нет

- Metal Stamping Dies GuideДокумент7 страницMetal Stamping Dies GuideedpsousaОценок пока нет

- ch11Документ12 страницch11Kirat KambozОценок пока нет

- Castings Vs Forging Comparison ChartДокумент1 страницаCastings Vs Forging Comparison Charta_c_eОценок пока нет

- Foundry Hand ToolsДокумент83 страницыFoundry Hand ToolsKiran MunavalliОценок пока нет

- IE 337: Materials & Manufacturing Processes: Metal Forming Operations 2Документ31 страницаIE 337: Materials & Manufacturing Processes: Metal Forming Operations 2silverknights007Оценок пока нет

- MP ppt1Документ224 страницыMP ppt1गिरीधर सदानंद चव्हाण100% (1)

- Presentation Sand CastingДокумент23 страницыPresentation Sand CastingAbdul RazzaqОценок пока нет

- LAB SESSION NO 3 Material and ManufacturingДокумент9 страницLAB SESSION NO 3 Material and Manufacturingm.sheraz malikОценок пока нет

- Metal Casting Process and Equipment - PPT - FinalДокумент19 страницMetal Casting Process and Equipment - PPT - Finalchandika herathОценок пока нет

- Gating SystemДокумент69 страницGating SystemSaurabh ThakurОценок пока нет

- Sheet Metal OperationsДокумент3 страницыSheet Metal OperationsDineshОценок пока нет

- Casting: Workshop Practice ME-105Документ20 страницCasting: Workshop Practice ME-105Mazahir habib100% (1)

- Sheet Metal Operation MCQ (Free PDF) - Objective Question Answer For Sheet Metal Operation Quiz - Download Now!Документ7 страницSheet Metal Operation MCQ (Free PDF) - Objective Question Answer For Sheet Metal Operation Quiz - Download Now!Prashant SinghОценок пока нет

- Found AryДокумент30 страницFound AryKawish TamourОценок пока нет

- Special Casting ProcessДокумент9 страницSpecial Casting ProcessChaitanya SadhanОценок пока нет

- Casting ProcessДокумент72 страницыCasting ProcessFRO MusicОценок пока нет

- Pattern AllowanceДокумент14 страницPattern AllowancesudhirОценок пока нет

- Various Types of CastingДокумент146 страницVarious Types of CastingKaushik SreenivasОценок пока нет

- MP-II COPYRIGHT PPT by SJYДокумент177 страницMP-II COPYRIGHT PPT by SJYMohit GajaralwarОценок пока нет

- Tharaj Castings PVT - ltd.-1st & 2nd Phase PresentationДокумент58 страницTharaj Castings PVT - ltd.-1st & 2nd Phase PresentationAnkur DhirОценок пока нет

- Interview QuestionДокумент22 страницыInterview QuestionsugeshОценок пока нет

- Cross Reference-Electroswitch To Shallco RevBДокумент31 страницаCross Reference-Electroswitch To Shallco RevB4Chat GptОценок пока нет

- Gauge THKДокумент2 страницыGauge THKYisel GomezОценок пока нет

- Fundamental of Metal Casting 2018Документ69 страницFundamental of Metal Casting 2018Mohd MuhaiminОценок пока нет

- Ch16 - Sheet-Metal Forming Processes and EquipmentДокумент42 страницыCh16 - Sheet-Metal Forming Processes and Equipmentlam minhОценок пока нет

- Press Working Operations Types Cutting FormingДокумент2 страницыPress Working Operations Types Cutting FormingCecil Thompson100% (1)

- METAL CASTING PROCESS OPTIMIZATIONДокумент10 страницMETAL CASTING PROCESS OPTIMIZATIONcarrespmОценок пока нет

- Assignment IДокумент23 страницыAssignment I016 ARUNACHALAM S R MОценок пока нет

- Playful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsОт EverandPlayful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Bulletproof Seduction: How to Be the Man That Women Really WantОт EverandBulletproof Seduction: How to Be the Man That Women Really WantРейтинг: 4.5 из 5 звезд4.5/5 (168)

- The Basics of Corset Building: A Handbook for BeginnersОт EverandThe Basics of Corset Building: A Handbook for BeginnersРейтинг: 4.5 из 5 звезд4.5/5 (17)

- Famous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsОт EverandFamous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsРейтинг: 4 из 5 звезд4/5 (4)

- DIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!От EverandDIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Рейтинг: 3.5 из 5 звезд3.5/5 (7)

- Knitting for Anarchists: The What, Why and How of KnittingОт EverandKnitting for Anarchists: The What, Why and How of KnittingРейтинг: 4 из 5 звезд4/5 (51)