Академический Документы

Профессиональный Документы

Культура Документы

HiLoad Simulations 68

Загружено:

sunqiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HiLoad Simulations 68

Загружено:

sunqiАвторское право:

Доступные форматы

Real time simulations using the HiLoad in tandem offloading operations

Simulating the HiLoad on a bridge simulator

Remora SA has developed the HiLoad Technology as an offshore loading system for crude oil. The HiLoad is an L-shaped body which can connect to other vessels in a similar way as a forklift picks up a pallet; it moves in underneath and lifts up using a ballast pump system. With its special attachment system (suction cup) it attaches itself to the keel of a ship. The propulsion system of the HiLoad consists of three thrusters. These thrusters are controlled by a dynamic positioning system. In this way the HiLoad can offer DP capability to conventional ships. In the beginning of 2011 the first HiLoad successfully completed an extensive sea trial program. Parallel to this development simulator research and training sessions were executed on MARINs bridge simulators. These sessions focused on offshore operations where normally tugs are used to position an offloading tanker in order to carry out offloading of oil from an FPSO. The objectives of the simulations were to: find the optimum position to connect the HiLoad to the tanker; find the optimum station relative to the FPSO in various environmental conditions; establish command and control procedures to work with the HiLoad.; find the limiting environmental conditions under which offloading operations can be executed using the HiLoad; simulate emergency situations and identify ways of recovery with the HiLoad.

Real time simulations

Simulations for different customers were carried out on MARINs bridge simulators. The simulations were carried out on full mission bridge I (FMB I) in combination with MARINs compact manoeuvring simulator (CMS). FMB I was used to simulate the bridge of the offloading tanker. On the compact simulator the bridge of the HiLoad was simulated. Data of wind tunnel tests, ship model tests and sea trials of the HiLoad were used to get a highly accurate manoeuvring model of a tanker with the HiLoad connected on its bow. The actual Kongsberg DP software and control panel were also integrated in the MARIN simulator environment. This ensured the most realistic behaviour during the simulations. The HiLoad was used to assist tandem offloading operations from an FPSO with and without the use of a hawser.

V. 2011/09/26/MSCN68

Tanker with Hiload attached to the bow

MARI N P.O. Box 28

6700 AA Wageningen The Netherlands

T +31 317 49 39 11 F +31 317 49 32 45

E info@marin.nl I www.marin.nl

The simulations were often setup as workshops in which engineers and nautical experts co-operated in an open minded atmosphere. The results of the first tests led to a good understanding of how the HiLoad could be used in tandem offloading operations. Alternatives were tried out and new ideas were quickly tested on the simulator. This way the operational philosophy of using the HiLoad in offloading operations was gradually developed. Nautical and communication procedures could be worked out in high detail.

Results

All objectives of the simulations could be met. This led to a thorough understanding of the effectiveness of the HiLoad and the way it can be utilised in complex operations. The HiLoad DP system is able to control the position of a certain part of the tanker. For example the connection point of the offloading hose, or the hawser. Since it is not possible to control the heading of the tanker with the HiLoad, the concept performs best when the tanker is allowed to weathervane. Stationing the offloading tanker more away from the FPSO proved to be effective in increasing the operability rate. Bringing DP capability to Suez-max and VLCC-size tankers is considered a huge improvement. Operations like approach, hook up and departure can be carried out much more controlled and (very important) with less effort. A simple and effective way of communicating with the HiLoad operators was developed. During offloading operations the position of the tanker is easily adjusted, allowing to station the tanker in the safest (down weather) position. Also during emergencies the HiLoad was very effective in saving the situation. The HiLoad technology is not limited to offshore loading operations, but can be used in numerous situations where add-on propulsion or DP capability is considered to be a plus. If you are keen to know what the HiLoad can mean for your operations, we will be more than happy to investigate this for you using our hightech bridge simulators. With our experience we are capable of providing you with a clear picture of the benefits the HiLoad may bring to your operations.

Tanker with HiLoad approaching offloading position

Set up of HiLoad bridge (including DP system)

View from tanker bridge

For more information please contact MARINs Nautical Centre MSCN, T +31 317 479 911 E MSCN@marin.nl

Вам также может понравиться

- Syncrolift Shiplifts and Transfer SystemsДокумент3 страницыSyncrolift Shiplifts and Transfer Systemsdanilo laraОценок пока нет

- Conceptual Planning of Jebel Ali New Container TerminalДокумент8 страницConceptual Planning of Jebel Ali New Container TerminalAlejandro GarnicaОценок пока нет

- 175 LNG19 04april2019 Morilhat Eric PaperДокумент7 страниц175 LNG19 04april2019 Morilhat Eric Paperivg8562Оценок пока нет

- Syncrolift 20130206Документ6 страницSyncrolift 20130206George GougoulidisОценок пока нет

- Valencia ConfДокумент6 страницValencia Confvran77100% (1)

- OTC-26575-MS Safe LNG Loading of Conventional LNG Carriers in Severe Open Sea EnvironmentsДокумент23 страницыOTC-26575-MS Safe LNG Loading of Conventional LNG Carriers in Severe Open Sea Environmentsthlim19078656Оценок пока нет

- Solutions: HelicopterДокумент4 страницыSolutions: HelicopterMohit SharmaОценок пока нет

- R78 - p11 - SHIPMA 6.0Документ1 страницаR78 - p11 - SHIPMA 6.0godfreyreggioОценок пока нет

- Optimising The Operational Front LineДокумент18 страницOptimising The Operational Front LineJose Mendelle Murry TombadoОценок пока нет

- Study of Influence On Port ScaleДокумент4 страницыStudy of Influence On Port ScalebrufpotОценок пока нет

- Green Line TelemetryДокумент18 страницGreen Line Telemetryshadow_x3xОценок пока нет

- Mar in 2Документ1 страницаMar in 2Omar OgbaОценок пока нет

- The Insertion of A Satellite Terminal in Port Operations - Port Economics, Management and PolicyДокумент5 страницThe Insertion of A Satellite Terminal in Port Operations - Port Economics, Management and PolicymerrwonОценок пока нет

- AMC FacilitiespdfДокумент12 страницAMC FacilitiespdfgodfreyreggioОценок пока нет

- L9 - Future Port TechnologiesДокумент91 страницаL9 - Future Port TechnologiesIseei RoxОценок пока нет

- Shuttle GustavsenДокумент41 страницаShuttle GustavsenXa MauОценок пока нет

- OTC 24330 - T Terpstra E A Hellinga HC Leerdam FINAL PDFДокумент19 страницOTC 24330 - T Terpstra E A Hellinga HC Leerdam FINAL PDFParvathy ReviОценок пока нет

- Spe-170600-Ms Floating LNG Chain - Finally A Reality: Michael S. Choi, ConocophillipsДокумент11 страницSpe-170600-Ms Floating LNG Chain - Finally A Reality: Michael S. Choi, Conocophillipsthlim19078656Оценок пока нет

- Hazop ProcedureДокумент14 страницHazop ProcedureAnh Hai100% (1)

- MUNIN Final BrochureДокумент12 страницMUNIN Final BrochureMyo Zin AungОценок пока нет

- Pu BL Ications: Practical Aspects of Ride Control Systems For MGH Speed Ferries Ajan J HaywoodДокумент7 страницPu BL Ications: Practical Aspects of Ride Control Systems For MGH Speed Ferries Ajan J HaywoodsirousОценок пока нет

- RORO CH Ph1Документ35 страницRORO CH Ph1mmishra914Оценок пока нет

- MaritimeNews2012web PDFДокумент36 страницMaritimeNews2012web PDFChander MehtaОценок пока нет

- Autonomous Equipment - QueensMineDesignWikiДокумент5 страницAutonomous Equipment - QueensMineDesignWikiRMRE UETОценок пока нет

- D1 IHC Training Simulators For Dredging and OffshoreДокумент3 страницыD1 IHC Training Simulators For Dredging and OffshoreSig Baha100% (1)

- The Role of Private Off Dock Terminals On Port Efficiency (A Study of Sifax Off Dock Nig, LTD.)Документ11 страницThe Role of Private Off Dock Terminals On Port Efficiency (A Study of Sifax Off Dock Nig, LTD.)IJEMR JournalОценок пока нет

- Liebherr LHM Mobile Harbour Cranes Brochure en 8568-0Документ36 страницLiebherr LHM Mobile Harbour Cranes Brochure en 8568-0Chusnadi100% (1)

- Role of Private Off Dock Terminals On Port EfficiencyДокумент11 страницRole of Private Off Dock Terminals On Port EfficiencyRyan MinaОценок пока нет

- Onshore Well Sites & Offshore Platforms: Slickline Connected TrainingДокумент14 страницOnshore Well Sites & Offshore Platforms: Slickline Connected Trainingikram khanОценок пока нет

- Simulation Modelling For Automated Guided Vehicle Introduction To The Loading Process of Ro-Ro ShipsДокумент12 страницSimulation Modelling For Automated Guided Vehicle Introduction To The Loading Process of Ro-Ro ShipsHo Van RoiОценок пока нет

- Ship Maneuvering Under Human ControlДокумент106 страницShip Maneuvering Under Human ControlAnil Kumar DashОценок пока нет

- Manoeuvring Criteria - More Than IMO A751 Requirements AloneДокумент8 страницManoeuvring Criteria - More Than IMO A751 Requirements Alonemfazioli0% (1)

- Enhancing Container Terminal Productivity: A Co-Maker Approach Between Carriers and OperatorsДокумент3 страницыEnhancing Container Terminal Productivity: A Co-Maker Approach Between Carriers and OperatorsAdn AdinaОценок пока нет

- Tractor Tug Training As Published in Marine LogДокумент6 страницTractor Tug Training As Published in Marine Logfeng8618Оценок пока нет

- Syncro LiftДокумент3 страницыSyncro Liftjoshivishal800Оценок пока нет

- Advanced Offshore Engineering Notes For Petrochem BranchДокумент91 страницаAdvanced Offshore Engineering Notes For Petrochem BranchVikas Katiyar100% (1)

- Jack Ups in Operation - Types and DifferencesДокумент16 страницJack Ups in Operation - Types and Differencesibnuhary100% (1)

- DP Operations Part 2 Paper NIДокумент4 страницыDP Operations Part 2 Paper NIparareceberspamsОценок пока нет

- A New Combined Seakeeping and Manoeuvring BasinДокумент12 страницA New Combined Seakeeping and Manoeuvring BasinibadurrahmanОценок пока нет

- Improving Productivity of Yard Trucks in Port ContДокумент9 страницImproving Productivity of Yard Trucks in Port Contandinet betreОценок пока нет

- Offshore Facilities: Technology FocusДокумент14 страницOffshore Facilities: Technology FocusSarah MandasariОценок пока нет

- Tank Storage Marine Gangway ArticleДокумент2 страницыTank Storage Marine Gangway ArticleRaed Naim KhammashОценок пока нет

- Siwertell Ship Unloaders Original 33001Документ6 страницSiwertell Ship Unloaders Original 33001alireza_vatandoustОценок пока нет

- Simulation-Based Operational Control of A Dry BulkДокумент8 страницSimulation-Based Operational Control of A Dry BulkJorge Vieira LeiteОценок пока нет

- Development of A Load Moment Indicator System For Heavy Load CraneДокумент4 страницыDevelopment of A Load Moment Indicator System For Heavy Load CranedanilynjoyaquinoОценок пока нет

- Schroder Applying 2014Документ62 страницыSchroder Applying 2014Rachit DhondОценок пока нет

- Designing A Container Terminal YardДокумент108 страницDesigning A Container Terminal Yardlim kang hai100% (5)

- Autonomous Safety On Vessels - WebbДокумент55 страницAutonomous Safety On Vessels - WebbClarence Pietersz100% (1)

- Chapter 3.4 - Container Terminal Design and Equipment - Port Economics, Management and PolicyДокумент21 страницаChapter 3.4 - Container Terminal Design and Equipment - Port Economics, Management and PolicymerrwonОценок пока нет

- Tanker Terminal and Liquid Cargo CourseДокумент4 страницыTanker Terminal and Liquid Cargo CourseAnonymous yJ7VjL28iОценок пока нет

- Helipad SpecsДокумент123 страницыHelipad SpecsAhmedОценок пока нет

- 5.13.shipyard InfrastructureДокумент7 страниц5.13.shipyard Infrastructureaimri_cochin100% (1)

- 2009 Oasis of The Seas Hydrodynamics Model Test MARINДокумент2 страницы2009 Oasis of The Seas Hydrodynamics Model Test MARINgnd100Оценок пока нет

- Transport Fluvial de CalatoriДокумент8 страницTransport Fluvial de CalatoriCristian LuncasuОценок пока нет

- The Fleet of The Future - DNVДокумент8 страницThe Fleet of The Future - DNVMeleti Meleti MeletiouОценок пока нет

- ITS 2016 Boston - Tugconomy PaperДокумент6 страницITS 2016 Boston - Tugconomy PaperPietGebruikerОценок пока нет

- Dynamic PositioningДокумент31 страницаDynamic PositioningU Zaw Aung100% (3)

- R0 Procedure Cendor BridgeДокумент65 страницR0 Procedure Cendor BridgeBoyОценок пока нет

- Collapsible Baton - Technical Report - CPRCДокумент22 страницыCollapsible Baton - Technical Report - CPRCsunqiОценок пока нет

- CIMAC SH SEPTEMBER 2010 v3 Hatzigrigoris PDFДокумент16 страницCIMAC SH SEPTEMBER 2010 v3 Hatzigrigoris PDFsunqiОценок пока нет

- Talon Batons SsДокумент2 страницыTalon Batons SssunqiОценок пока нет

- Advanced Series On Ocean EngineeringДокумент4 страницыAdvanced Series On Ocean EngineeringsunqiОценок пока нет

- Type Document Expires Modified ActionДокумент3 страницыType Document Expires Modified ActionsunqiОценок пока нет

- Cargo Oil SystemДокумент1 страницаCargo Oil SystemsunqiОценок пока нет

- 05-Towing Bracket TB-50 Side PDFДокумент1 страница05-Towing Bracket TB-50 Side PDFsunqiОценок пока нет

- Hiload DP FinalДокумент2 страницыHiload DP FinalsunqiОценок пока нет

- L-Type - Anchor Handling Tug Supply VesselДокумент8 страницL-Type - Anchor Handling Tug Supply VesselsunqiОценок пока нет

- Research in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TДокумент13 страницResearch in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDessy ParamitaОценок пока нет

- Grade 7 Hazards and RisksДокумент27 страницGrade 7 Hazards and RisksPEMAR ACOSTA75% (4)

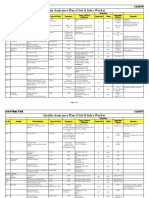

- Quality Assurance Plan - CivilДокумент11 страницQuality Assurance Plan - CivilDeviPrasadNathОценок пока нет

- PUBLIC - Axie Origins Changelogs - Season 4Документ2 страницыPUBLIC - Axie Origins Changelogs - Season 4Alef CarlosОценок пока нет

- New KitДокумент195 страницNew KitRamu BhandariОценок пока нет

- ICON Finals Casebook 2021-22Документ149 страницICON Finals Casebook 2021-22Ishan ShuklaОценок пока нет

- Basics of Petroleum GeologyДокумент23 страницыBasics of Petroleum GeologyShahnawaz MustafaОценок пока нет

- Final Grade 7 Lesson Plan REGULAR CLASSДокумент10 страницFinal Grade 7 Lesson Plan REGULAR CLASSCarla SheenОценок пока нет

- Gender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected PlaysДокумент6 страницGender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected Playsতন্ময়Оценок пока нет

- Reviewer CSCДокумент22 страницыReviewer CSCChristopher CocalОценок пока нет

- Malaybalay CityДокумент28 страницMalaybalay CityCalvin Wong, Jr.Оценок пока нет

- (LaSalle Initiative) 0Документ4 страницы(LaSalle Initiative) 0Ann DwyerОценок пока нет

- Self-Efficacy and Academic Stressors in University StudentsДокумент9 страницSelf-Efficacy and Academic Stressors in University StudentskskkakleirОценок пока нет

- Exam Ref 70 483 Programming in C by Wouter de Kort PDFДокумент2 страницыExam Ref 70 483 Programming in C by Wouter de Kort PDFPhilОценок пока нет

- An Analysis of The Cloud Computing Security ProblemДокумент6 страницAn Analysis of The Cloud Computing Security Problemrmsaqib1Оценок пока нет

- 1.12 Properties of The Ism - FlexibilityДокумент4 страницы1.12 Properties of The Ism - FlexibilityyomnahelmyОценок пока нет

- Aits 2122 PT I Jeea 2022 TD Paper 2 SolДокумент14 страницAits 2122 PT I Jeea 2022 TD Paper 2 SolSoumodeep NayakОценок пока нет

- Interceptor Specifications FinalДокумент7 страницInterceptor Specifications FinalAchint VermaОценок пока нет

- Promoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefДокумент52 страницыPromoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefEduardo Antonio Molinari NovoaОценок пока нет

- Nodal Analysis Collection 2Документ21 страницаNodal Analysis Collection 2Manoj ManmathanОценок пока нет

- D2E133AM4701 Operating Instruction UsДокумент9 страницD2E133AM4701 Operating Instruction UsMohamed AlkharashyОценок пока нет

- Define Variable and ConstantДокумент17 страницDefine Variable and ConstantSenthil MuruganОценок пока нет

- Opening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayДокумент3 страницыOpening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayAlven BlancoОценок пока нет

- Python Programming Laboratory Manual & Record: Assistant Professor Maya Group of Colleges DehradunДокумент32 страницыPython Programming Laboratory Manual & Record: Assistant Professor Maya Group of Colleges DehradunKingsterz gamingОценок пока нет

- Mufti ReligionMilitancy WebДокумент0 страницMufti ReligionMilitancy WebAyaz Ahmed KhanОценок пока нет

- T2 Group4 English+for+BusinessДокумент8 страницT2 Group4 English+for+Businessshamerli Cerna OlanoОценок пока нет

- FBISE Grade 10 Biology Worksheet#1Документ2 страницыFBISE Grade 10 Biology Worksheet#1Moaz AhmedОценок пока нет

- MGT403 Slide All ChaptersДокумент511 страницMGT403 Slide All Chaptersfarah aqeelОценок пока нет

- Jurnal Direct and Indirect Pulp CappingДокумент9 страницJurnal Direct and Indirect Pulp Cappingninis anisaОценок пока нет