Академический Документы

Профессиональный Документы

Культура Документы

GSPL-207-E-6108 Rev 0

Загружено:

Srikanth VoletiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GSPL-207-E-6108 Rev 0

Загружено:

Srikanth VoletiАвторское право:

Доступные форматы

PAGE No.

: 1 OF 11

VALDEL ENGINEERS & CONSTRUCTORS PVT LTD MEGHDOOTH MANSION 9, CIVIL STATION HOSUR ROAD BANGALORE-560025 (INDIA)

PROJECT

GAS COMPRESSOR SYSTEM

CLIENT/OWNER

GUJARAT STATE PETRONET LTD., GANDHINAGAR

CONTRACT No.

9500 VE

DOCUMENT No.

GSPL-207-E-6108

DOCUMENT TITLE

SPECIFICATION FOR LT CAPACITOR CONTROL PANEL WITH APFC

0 REV.

01.02.2012 DATE FV5001-1/10

ISSUED FOR BID REVISION DESCRIPTION

MMR PREPD.

SLC CHKD.

SLC APPD.

NRR P.M.

VALDEL ENGINEERS & CONSTRUCTORS PVT LTD DOCUMENT No.: GSPL-207-E-6108

REVISION STATUS SHEET

PAGE No. : CONTRACT No. : 0 REV . SIGN. : SHEET OF

REV. PAGE NO. 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144

2 OF 11 9500VE 01.02.2012 DATE :

DOCUMENT TITLE:

PAGE NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 REV. 0 0 0 0 0 0 0 0 0 0 0

SPECIFICATION FOR LT CAPACITOR CONTROL PANEL WITH APFC ADDL. PAGE ADDL.

PAGE NO. REV. NO. 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 REV. PAGE NO.

1

REV. ADDL. PAGE NO. REV.

NOTE: IF REVISION REQUIRES ADDITIONAL PAGES TO BE INSERTED IN BETWEEN THE DOCUMENT, THE NUMBER OF THE PAGE AT INSERTION SHALL BE NUMBERED WITH DECIMAL (e.g. INSERTION BETWEEN PAGE 10 AND 11 SHALL BE NUMBERED AS 10.1, 10.2 ........)

FV5046-1/7

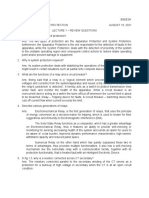

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 3 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

TABLE OF CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0

SCOPE ............................................................................................................................. 4 CODES AND STANDARDS .......................................................................................... 4 GENERAL REQUIREMENTS ..................................................................................... 4 CONSTRUCTION .......................................................................................................... 5 DESIGN FEATURES ..................................................................................................... 6 OPERATIONS ................................................................................................................ 6 EARTHING ..................................................................................................................... 7 DOCUMENTATION...................................................................................................... 7 INSPECTION, TESTING AND ACCEPTANCE ....................................................... 8 SYSTEM TESTS............................................................................................................. 8 SPARES ........................................................................................................................... 8 PACKING FOR TRANSPORT..................................................................................... 9 ATTACHMENT .............................................................................................................. 9

FV5062/2

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 4 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

1.0

SCOPE The scope of this specification covers design, manufacture, assembly, shop testing and delivery of low voltage shunt capacitors suitable for indoor locations along with complete accessories and parts necessary for safe and efficient operation.

2.0

CODES AND STANDARDS The equipment shall comply with the requirements of latest revision of the following standards issued by BIS (Bureau of Indian Standards) unless specified other wise: IS 8623 IS 2834 IS 4237 Faraday built assembly for switch gear & control gear Shunt capacitor for power system General requirement of switchgear & control gear for voltage not exceeding 1000V AC & 120 volt DC. Colors for ready mixed paints and enamels 5082 Wrought aluminium and aluminium alloy bars, rods, tubes and sections for electrical purpose Internal fuses and internal overpressure disconnectors for shunt capacitors.

IS 5 IS

IS 12672

In case Indian standards are not available for any equipment, standards issued by IEC/BS/VDE/IEEE/NEMA or equivalent agency shall be applicable.

3.0 3.1

GENERAL REQUIREMENTS The offered equipment shall be brand new with state of the art technology and a proven field track record. No prototype equipment shall be offered.

FV5062/2

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 5 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

3.2

The vendor shall be responsible for design, engineering and manufacturing of the complete capacitor bank to fully meet the intent and requirements of this specification and attached data sheets. All equipment shall be properly coordinated to ensure complete compatibility

4.0 4.1

CONSTRUCTION APFCR PANEL The housing of the capacitor banks shall be of open construction with free ventilation for capacitor units. The connections from the capacitor units to the control panel shall be carried in totally enclosed, dust-proof, vermin-proof busways or wire-ways. The unit shall be free standing, floor mounting & having sheet steel thickness of 2.0mm for load bearing members 1.6mm for doors & louvers & 3mm thick base channel. The control panel shall be fully compartmentalized and extensible for future expansion. Bus bars and feeder circuits shall be segregated. Single panel with all the capacitors, control & Relay can be also considered.

4.1.1

The bus-bar sizes and clearances shall be suitable for connection of cables through soldering sockets or crimping type cable lugs. Size of the cable will be specified in Purchase Data Sheets. Bus-bar chamber shall be extended suitably on one side to enable termination of cable. Undrilled removable gland plate and access covers shall be provided for cable entry required. 5.3 The capacitor banks shall comprise the following basic components. Other equipment, not specifically listed below but necessary for the safe and proper functioning of the capacitor bank shall be included: Capacitor units of appropriate kVAR rating Internal element fuses Bushings as per requirement Cable end boxes for cable termination PVC sleeved aluminium bus bars for interconnecting the units to form the capacitor bank Discharge resistors Incoming isolator, if specified

FV5062/2

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 6 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

5.0 5.1 5.1.1

DESIGN FEATURES Capacitor Units The dielectric used in the capacitors shall be all polypropylene or mixed dielectric or Gas filled with low watt loss. The impregnate in the capacitors shall be non-toxic, nonPCB (Poly chlorinated bi-phenyl) based, and biodegradable. The capacitor units shall be assembled such that the capacitor banks are capable of withstanding the electro-dynamic and thermal stresses caused by transient over currents during switching. The capacitor units shall have overload capacity as per IS 13925. Protection for capacitor banks using internal element fuses shall conform to the following requirements:

5.1.2

5.1.3

5.1.3.1 In internal element fuse design, the internal design of series and parallel arrangement of elements shall be such that: In the case of one element failure, there is no harmful over voltage across the remaining elements and no appreciable change in the operation of the capacitor bank. Operation of a single fuse element does not cause cascade fuse bowling. Permissible over voltages and surges do not cause fuse bowling.

5.1.4 Discharge Resistors Discharge Resistors shall be provided to reduce the capacitor bank terminal voltage to a value equal to or less than 50V within 10 minutes after capacitor is disconnected from the electrical system.

6.0 6.1

OPERATIONS Power Factor Improvement Relay (PFIR) capable of automatic switching of the capacitor units shall be provided. The relay shall have minimum 12 steps. The relay shall measure KVAR of the system and shall be actuated by current signal of 1 Amp from secondary side of CT provided on incomer of Main PDB. 415 Voltage signal shall be trapped from incomer of APFIR. Essentially PFCR shall be able to achieve the following functions / features:

6.2

FV5062/2

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 7 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

Consistently high power factor under fluctuating load conditions. Automatically switch ON and OFF (self-adjustment) relevant capacitor steps to ensure consistent power factor Ensure user interface for enabling reliable understanding of system operation, such as display of power factor, number of switching operations carried out, pre-set parameters, etc. Protect against any electrical faults (surge protection, unbalance, etc.) in a manner that will ensure safe isolation of the power factor correction equipment i.e., capacitors. No-volt release feature, to disconnect the capacitor in the event of power supply failure. Digital setting of parameters like target PF, switching time, step limit, etc. Visual display of target power factor. Indication for switching of banks per step. Switch ON and OFF the capacitors in rotation so that individual capacitor bank shall not be in continuous used and unused condition for a long time. Normally one capacitor unit of 5 KVAR shall be kept ON & balance shall be variable as per requirement. Minimum Sensing current shall be 1%.

7.0

EARTHING Enclosure of individual capacitors unit shall be provided with two numbers 10 mm dia. earth terminals, each complete with two plain and one spring washers, nuts, etc. These terminals shall be effectively bonded to the common sheet steel framework. Each bank shall have two external earth terminals on the bus-bar chamber, complete with hardware.

8.0

DOCUMENTATION The vendor / manufacturer shall perform the engineering for the capacitor bank and shall submit to Owner / RGTIL for review / reference, as per enclosed documentation schedule.

FV5062/2

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 8 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

9.0

INSPECTION, TESTING AND ACCEPTANCE All necessary routine and acceptance tests as per IS 13925 shall be performed on the capacitor bank / capacitor units in the presence of purchasers representative. Two weeks advance notice shall be given to the purchaser to enable him or his authorized representative to witness the tests. During the course of manufacturing, the purchaser or his authorized representative to witness the tests. During the course of manufacturing, the purchaser or his authorized representative shall be free to visit the works and assess the progress of work and the manufacturer shall render him all possible assistance to do so.

10.0

SYSTEM TESTS Insulation resistance test. Functional test including simulation test on relay.

10.1.1 Capacitor Bank Following routine test as per IS: 13340/13441 shall be carried out on the Capacitor Bank: Visual Examination Test for output / Capacitance Voltage test between terminals High Voltage Test Voltage test between terminals & earth (for capacitor bank) Insulation resistance test Test for efficiency of discharge test

11.0 11.1 11.2 11.3

SPARES A priced list of recommended operating spares and maintenance spares for two years operation shall be provided with the Tender. Spares shall be purchased at the discretion of the Purchaser. Commissioning spares shall be provided by the Vendor.

FV5062/2

PAGE No. SPECIFICATION FOR LT CAPACITOR CONTROL PANEL

: 9 OF 11 9500 VE 0 GSPL-207-E-6108

Contract No. : Revision No. : Doc. No. : Date

PROJECT: GAS COMPRESSOR SYSTEM

: 01.02.2012

12.0

PACKING FOR TRANSPORT Capacitor banks along with the panel shall be packed and forwarded in accordance with the Packing and Shipping Instructions.

13.0

ATTACHMENT Data sheet for LT capacitor control panel.9500-75-1055

FV5062/2

VALDEL ENGINEERS & CONSTRUCTORS PVT LTD

DOC. No. : PROJECT :

1 1.1 2 2.1 2.2 2.3 2.4 2.5 3 3.1 3.2 3.3 3.4 4 4.1 4.2 4.3 4.4 4.5 5 5.1 5.2 5.3 5.4 6 6.1 6.2 6.3 6.4 6.5 6.60 6.7 6.8 6.9 6.10 6.11 6.12 6.13

DATA SHEET FOR LT CAPACITOR CONTROL PANEL

PAGE No. : 10 OF 11 CONTRACT No.: 9500 VE 2 REV. 0 QTY.:

9500-75-1055 GAS COMPRESSOR PROJECT

SHT. 2 OF ITEM. No.: REQN. No.: GSPL-207-E-6108

40 C

DESIGNATION DESIGN AMBIENT TEMPERATURE SYSTEM PARTICULARS Voltage Frequency No of Phases / Wire System Grounding Fault Level Control / Auxiliary Supply Contactor Coil Potential Indicating Lights Other Indicating Meters & Lights Space Heaters CONSTRUCTION TYPE / MOUNTING NO. OF FRONTS BASE FRAME DEGREE OF PROTECTION COLOUR CONTACTORS TYPE DUTY CLASS RATING AUX. CONTACTS TECHNICAL PARTICULARS OF CAPACITOR BANK TYPE CONNECTION RATED VOLTAGE RATED CURRENT FREQUENCY OUTPUT KVAR MICROFARAD DUTY DISCHARGE RESISTOR VALUE NO. OF PHASES TOTAL HIGHT SUITABLE FOR PANEL MOUNTING MAX. TEMP. RISE PERMISSIBLE Air Break Capacitor Duty 1.2 times Feeder Rating (Min) 2 N.O and 2 N. C Compartmentalised / Free Standing Single Front Integral Indoor, IP 41(Min) * 240V, 1 Ph, AC Supply 240V, 1 Ph, AC Supply 240V, 1 Ph, AC Supply 240V, 1 Ph, AC Supply 415 10% 50 5% 3 Phase, 4 Wire Solidly Earth 10kA, Symmetrical

* * * * * * * * * * * * *

NOTE :

1. 2.

DATA MARKED ` * ' IS TO BE FILLED UP BY VENDOR ALONG WITH BID. THE RATING OF TRANSFORMER INDICATED IS TENTATIVE.THE EXACT RATING DURING DETAIL ENGINEERING. SHALL BE WORKED OUT

0 REV.

FV7555-1/2

01.02.12 DATE

ISSUED FOR BID DESCRIPTION

MMR PREPD.

SLC CHKD.

SLC APPD.

VALDEL ENGINEERS & CONSTRUCTORS PVT LTD

DOC. No. : 9500-75-1055 PROJECT : GAS COMPRESSOR PROJECT

6.14 6.15 6.16 6.17 6.18 CONSTRUCTION INSULATION LEVEL

DATA SHEET FOR LT CAPACITOR CONTROL PANEL

PAGE No. :11 OF 11 CONTRACT No.: 9500 VE 2 REV. 0 QTY.:

SHT. 2 OF ITEM. No.: REQN. No.: GSPL-207-E-6108

* * *

TYPE OF MOUNTING ARRANGEMENT THE PANEL CAPACITOR DISCHARGE TIME CAPACITOR MODULE FOR EWPL TOP-2 (50 KVAR) (a) 5 kVAR (a) 2 kVAR (a) 1 kVAR

* * *

7 7.1 7.2 7.3 7.4 7.5 7.6

APFC PANEL AUXI. SUPPLY LEVEL NO. OF CHANNEL AUTO / MANUAL SELECTION DISPLAY TYPE DEGREE PROTECTION TYPE * * * * * *

8 8.1 8.2 9 9.1 9.1.1 9.1.2 9.1.3 9.1.4 9.1.5 9.2 9.2.1 9.2.2 9.3 9.3.1 9.3.2 9.4 9.5 9.5.1 9.6 9.6.1 9.7 9.8 9.9 9.10

SINGLE PHASE PREVENTION SPP Hooter COMPONENTS Bus Bar Material Heat Shrinkable PVC Sleeve Rating Main Bus bar Position Material of Bus bar Support Earth Bus Material Min Size Isolators Make /Type Rating Accuracy Class of Instruments MCB's make MCB's Rating ELCB's Make ELCB's Rating / No of Poles MCCB Cable Entry Cable Glands & Lugs Spare Feeders * * * * * * * * * Aluminium 50 * 6 Aluminium Required * * * * *

FV7555-2/2

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Th63-5WM SchematicДокумент2 страницыTh63-5WM Schematicssinokrot67% (3)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- User's Manual: PMC Programmable Motion ControllerДокумент122 страницыUser's Manual: PMC Programmable Motion ControllerSdiri OumaimaОценок пока нет

- 236b3 Esquema Electrico Mini Cargador CatДокумент29 страниц236b3 Esquema Electrico Mini Cargador Cathenry laviera100% (2)

- Microondas Ms-0744aДокумент33 страницыMicroondas Ms-0744aJhony GuitarzuОценок пока нет

- EKA3 - 1 Pag.20Документ30 страницEKA3 - 1 Pag.20Razvan MaresОценок пока нет

- RENSON Fixscreen EngДокумент20 страницRENSON Fixscreen Engwww.profilalouminio.comОценок пока нет

- Shaft Current Protection: Tin RabuzinДокумент79 страницShaft Current Protection: Tin RabuzinNaresh PattanaikОценок пока нет

- Eaton - Gen 3 (Auto & UltraShift) .13 Speed With Push Button (UltraShift)Документ5 страницEaton - Gen 3 (Auto & UltraShift) .13 Speed With Push Button (UltraShift)Diego LiraОценок пока нет

- litIndustrialCat PDFДокумент124 страницыlitIndustrialCat PDFNermeen ElmelegaeОценок пока нет

- This Typical Is Also Valid For:: 03 06/2020 BSP AS BUILT JZB JZB Ismail IsmailДокумент56 страницThis Typical Is Also Valid For:: 03 06/2020 BSP AS BUILT JZB JZB Ismail IsmailMohammed AltafОценок пока нет

- TESAR Installation Use and Maintenance EngДокумент20 страницTESAR Installation Use and Maintenance EngPatran ValentinОценок пока нет

- Car SoftДокумент5 страницCar Softembajador2010Оценок пока нет

- Frigidaire Refrigerator SXS 2001 Next Gen Service Manual - 5995352423Документ100 страницFrigidaire Refrigerator SXS 2001 Next Gen Service Manual - 5995352423lamiradaОценок пока нет

- Triton Relays Normally Open Vs Normally Closed PDFДокумент2 страницыTriton Relays Normally Open Vs Normally Closed PDFMariane LopesОценок пока нет

- FCM 1Документ2 страницыFCM 1Peter Chua0% (1)

- Monera - John Philip M - Bsee4a - Lecture 1 - Review QuestionsДокумент1 страницаMonera - John Philip M - Bsee4a - Lecture 1 - Review QuestionsJohn Philip MoneraОценок пока нет

- L KaramaДокумент3 страницыL KaramaMostafa MohmmedОценок пока нет

- EN VEGAVIB 61 63 VEGAWAVE 61 63 Level Detection in Bulk Solids PDFДокумент20 страницEN VEGAVIB 61 63 VEGAWAVE 61 63 Level Detection in Bulk Solids PDFRyfaldiОценок пока нет

- Emr 4Документ39 страницEmr 4RaulОценок пока нет

- Etap Solutions Overview PDFДокумент29 страницEtap Solutions Overview PDFAndreyDhoОценок пока нет

- KS40 - 1Документ60 страницKS40 - 1adyro12Оценок пока нет

- Commisioning Check ListДокумент21 страницаCommisioning Check Listgst ajahОценок пока нет

- Manual SeriaT 3 - RadiocomandaДокумент123 страницыManual SeriaT 3 - RadiocomandaJitarciuc Ionut-AlexandruОценок пока нет

- Ijetae 0416 05Документ4 страницыIjetae 0416 05Rahul ShrivastavaОценок пока нет

- Chapter 15Документ40 страницChapter 15ovidiu_blnОценок пока нет

- FS20X Detector FlamaДокумент4 страницыFS20X Detector FlamaEduardo Diaz PichardoОценок пока нет

- HYDAC Understanding Proportional Hydraulics JAN 2015Документ3 страницыHYDAC Understanding Proportional Hydraulics JAN 2015marc271986Оценок пока нет

- LuckyIndiaPowerSolutions LV SWGR Price List Oct2011Документ48 страницLuckyIndiaPowerSolutions LV SWGR Price List Oct2011Sharafat AliОценок пока нет

- Installation and Maintenance InstructionsДокумент12 страницInstallation and Maintenance InstructionsabdellahОценок пока нет

- Murphy.40 ASM150.instДокумент4 страницыMurphy.40 ASM150.instS M NaveedОценок пока нет