Академический Документы

Профессиональный Документы

Культура Документы

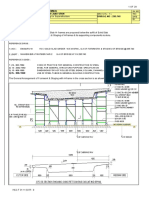

Analysis of structural frame with pinned base plate connection

Загружено:

waweng22Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Analysis of structural frame with pinned base plate connection

Загружено:

waweng22Авторское право:

Доступные форматы

Job No

Sheet No

Rev

1

Software licensed to Job Title Part Ref By Client File Date27-Feb-14 Chd

Structure1.std

Date/Time

27-Feb-2014 09:04

Job Information

Engineer Name: Date: Structure Type Number of Nodes Number of Elements Number of Basic Load Cases Number of Combination Load Cases Included in this printout are data for: The Whole Structure All Included in this printout are results for load cases: Type L/C Primary 1 LOAD CASE 1 27-Feb-14 SPACE FRAME 2 1 Highest Node Highest Beam 1 0 2 1 Checked Approved

Name

Print Time/Date: 27/02/2014 10:21

STAAD.Pro V8i (SELECTseries 4) 20.07.09.31

Print Run 1 of 5

Job No

Sheet No

Rev

2

Software licensed to Job Title Part Ref By Client File Date27-Feb-14 Chd

Structure1.std

Date/Time

27-Feb-2014 09:04

Connection Template : Pinned BP Connection ID : CB - N(1) - M(1) Design Code : AISC-ASD

GENERAL DATA Design axis : Major axis Cracked concrete : No Brittle steel : No Anchor bolts welded to base plate : Consider friction : No Pressure distribution : Uniform MEMBERS: Column Section bf = d = k = k1 = tf = tw = = W4X13 103.12 [mm] 105.66 [mm] 13.14 [mm] 7.94 [mm] 8.76 [mm] 7.11 [mm]

No

Material = STEEL Fy = 0.25 [KN/mm2] Fu = 0.41 [KN/mm2] Concrete base Longitudinal dimension = 1.83 Transversal dimension = 1.83 Thickness = 0.30 [m] Material = C 4-60 Fc = 0.03 [KN/mm2] CONNECTION(S): Base plate Plate Length = Width = Thickness 400.00 [mm] 400.00 [mm] = 13.00 [mm] [m] [m]

Material = A36 Fy = 0.25 [KN/mm2] Fu = 0.40 [KN/mm2] Weld D = Anchors Material = F1554 Gr36 = 5 E70XX [1/16 in]

Print Time/Date: 27/02/2014 10:21

STAAD.Pro V8i (SELECTseries 4) 20.07.09.31

Print Run 2 of 5

Job No

Sheet No

Rev

3

Software licensed to Job Title Part Ref By Client File Date27-Feb-14 Chd

Structure1.std

Date/Time

27-Feb-2014 09:04

Fy Fu

= =

0.25 0.40

[KN/mm2] [KN/mm2]

Geometry type = Longitudinal Anchor type = Headed Head type = Hexagonal D = 6.35 [mm] Effective length = 50.80 [mm] Total length = 72.18 [mm] Lev = 381.00 [mm] Longitudinal edge distance on the plate Leh = 381.00 [mm] Transverse edge distance on the plate Anchor Transverse [mm] [mm] 1 2 3 4 LOADS Members Load Type V2 V3 M33 [KN] [KN] [KN*m] LC-1 Design --M22 [KN*m] -Axial [KN] -35.00 181.00 181.00 -181.00 -181.00 181.00 -181.00 -181.00 181.00 Longitudinal

Column Design for major axis

Base plate (AISC 360-05 ASD) GEOMETRIC CONSIDERATIONS Dimensions Base plate Longitudinal dimension [mm] 400.00 121.54 Nmin = dc + 2*w = 105.66[mm] + 2*7.9375[mm] = 121.54[mm] Transversal dimension [mm] 400.00 119.00 Bmin = bc + 2*w = 103.12[mm] + 2*7.9375[mm] = 119[mm] Distance from anchor to edge [mm] 19.00 Lemin = edmin + C2 = 15.874999[mm] + 0[mm] = 15.874999[mm] Weld size wmin = wmin = 3 table J2.4 [1/16in] 5 3 --15.87 TablesJ3.4,J3.5 -Tables J3.4, Unit Value Min. value Max. value Sta. References

J3.5

table J2.4 --

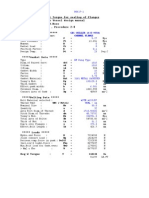

DESIGN CHECK Verification Concrete base Axial bearing [KN/mm2] 0.02 0.00 LC-1 0.00 DG1 Sec 3.1.1 Unit Capacity Demand Ctrl EQ Ratio References

A2 = ((B/N)*Ncs)*Ncs = ((400[mm]/400[mm])*1828.8[mm])*1828.8[mm] = 3344509.23[mm2] A1 = B*N = 400[mm]*400[mm] = 160000[mm2] DG1 Sec 3.1.1

fp, max = (1/)*min(0.85*f'c*(A2/A1)1/2, 1.7*f'c) = 0.4*min(0.85*0.027579[KN/mm2]* Base plate

(20.903183) 1/2, 1.7*0.027579

Print Time/Date: 27/02/2014 10:21

STAAD.Pro V8i (SELECTseries 4) 20.07.09.31

Print Run 3 of 5

Job No

Sheet No

Rev

4

Software licensed to Job Title Part Ref By Client File Date27-Feb-14 Chd

Structure1.std [KN*m/m] = 6.279594[KN*m/m]

Date/Time

27-Feb-2014 09:04 LC-1 0.00

Flexural yielding (bearing interface) (1/)Mn = (1/)*Fy*tp2/4 = 0.598802*0.248211[KN/mm2]*13[mm]2/4

6.28Eq. 3.3.13 DG1 0.00 DG1 Eq. 3.3.13 6.28Eq. 3.3.13 DG1 7.70

Flexural yielding (tension interface) MpT = Mstrip/Beff = 1.222816[KN*m]/158.75[mm]

[KN*m/m]

LC-1

1.23

= 7.702759[KN*m/m]

(1/)Mn = (1/)*Fy*tp2/4 = 0.598802*0.248211[KN/mm2]*13[mm]2/4 = 6.279594[KN*m/m] DG1 Eq. 3.3.13 Anchor (s) in tension for maximum moment: #1 Column Weld capacity [KN/m] beff = 2*L = 2*182.16[mm] = 364.31[mm] 1218.98 DG1 p. 35 24.02 LC-1 DG1 p. 35, 0.02

Maximum weld load = T/beff = 8.750001[KN]/364.31[mm] = 24.017726[KN/m] LoadAngleFactor = 1 + 0.5*(sin())1.5 = 1 + 0.5*(sin(1.570796))1.5 = 1.5 Fw = 0.6*FEXX*LoadAngleFactor = 0.6*0.482633[KN/mm2]*1.5 = 0.43437[KN/mm2] p. 8-9 Sec. J2.5 Sec. J2.4

Aw = (2)1/2/2*(D/16)*[in]*L = (2)1/2/2*(5/16)*[in]*1000[mm] = 5612.66[mm2] (1/)Rw = (1/)*Fw*Aw/L = 0.5*0.43437[KN/mm2]*5612.66[mm2]/1000[mm] [KN/m]

= 1218.98[KN/m] 0.00 LC-1 p. 8-9, 0.00

Elastic method weld shear capacity fv = V/Lshear = 0[KN]/158.75[mm] = 0[KN/m]

812.66

LoadAngleFactor = 1 + 0.5*(sin())1.5 = 1 + 0.5*(sin(0))1.5 = 1

p. 8-9 Sec. J2.5 Sec. J2.4

Fw = 0.6*FEXX*LoadAngleFactor = 0.6*0.482633[KN/mm2]*1 = 0.28958[KN/mm2] Aw = (2)1/2/2*(D/16)*[in]*L = (2)1/2/2*(5/16)*[in]*1000[mm] = 5612.66[mm2]

(1/)Rw = (1/)*Fw*Aw/L = 0.5*0.28958[KN/mm2]*5612.66[mm2]/1000[mm] = 812.66[KN/m] Elastic method weld axial capacity fa = P/L = 35[KN]/380.75[mm] = 91.92481[KN/m] fb = M*c/I = 0[KN*m]*52.832[mm]/914572091.43[mm4] = 0[KN/m] f = fb + fa = 0[KN/m] + 91.92481[KN/m] = 91.92481[KN/m] LoadAngleFactor = 1 + 0.5*(sin())1.5 = 1 + 0.5*(sin(1.570796))1.5 = 1.5 Fw = 0.6*FEXX*LoadAngleFactor = 0.6*0.482633[KN/mm2]*1.5 = 0.43437[KN/mm2] Aw = (2)1/2/2*(D/16)*[in]*L = (2)1/2/2*(5/16)*[in]*1000[mm] = 5612.66[mm2] p. 8-9 Sec. J2.5 Sec. J2.4 [KN/m] 1218.98 91.92 LC-1 p. 8-9, 0.08

(1/)Rw = (1/)*Fw*Aw/L = 0.5*0.43437[KN/mm2]*5612.66[mm2]/1000[mm] = 1218.98[KN/m] Notes.- Anchors only designed for LRFD code Critical strength ratio 1.23 Major axis analysis Maximum compression and tension (LC-1)

Print Time/Date: 27/02/2014 10:21

Maximum Minimum Maximum Minimum Neutral Bearing

bearing pressure : 0.00000 [KN/mm2] bearing pressure : 0.00000 [KN/mm2] anchor tension : 8.75000 [KN] anchor tension : 8.75000 [KN] axis angle : 0.00000 V8i (SELECTseries 4) 20.07.09.31 length STAAD.Pro : -1E303 [mm] Tension

Print Run 4 of 5

Anchors tensions Anchor Transverse Longitudinal Shear [mm] [mm] [KN] [KN]

Job No

Sheet No

Rev

5

Software licensed to Job Title Part Ref By Client File Date27-Feb-14 Chd

Structure1.std

Date/Time

27-Feb-2014 09:04

3 4 NOTATION A1: A2: Aw: A2/A1: B: bc: beff: Beff: Bmin: C2: c: dc: D: fa: fb: f'c: f: FEXX: fp, max: fv: Fw: Fy: I: L: Lemin: L: Lshear:

-181.00 -181.00

-181.00 181.00

0.00 8.75 0.00 8.75

Base plate area

Maximum area of portion of the concrete supporting surface that is geometrically similar to an Effective area of the weld Ratio between the concrete support area and the base plate area Base plate design width Width of column section Effective width of the compression block Controlling ffective width Minimum base plate width perpendicular to moment direction Edge distance increment Distance to weld group Column depth Number of sixteenths of an inch in the weld size Axial stress on welds Bending stress on welds Specified compressive strength of concrete Combined stress on welds Electrode classification number Maximum uniformly bearing stress under base plate Vertical shear force on weld Nominal strength of the weld metal per unit area Specified minimum yield stress Inertia of weld group Distance from the anchor rod to the column Minimum edge distance Length of weld Length of weld receiving shear

LoadAngleFactor: Load angle factor M: MpT: Mstrip: Bending required Plate bending moment per unit width at tension unstiffened strip interface Maximum bending moment at the strip Maximum weld load

Maximum weld load: edmin: N: Ncs: Nmin: P: (1/): (1/)Mn: (1/)Rw: T: tp: : V:

Print Time/Date: 27/02/2014 10:21

Minimum edge distance Base plate design length Length of the concrete supporting surface or pier parallel to moment design direction Minimum base plate length parallel to moment direction Required axial force Design factors Design or allowable strength per unit length Fillet weld capacity per unit length Anchor rod tensile strength required Plate thickness Load angle Shear load STAAD.Pro V8i (SELECTseries 4) 20.07.09.31

Print Run 5 of 5

Вам также может понравиться

- Anchor Bolt DesignДокумент15 страницAnchor Bolt Designamit8808Оценок пока нет

- Shutter DesignДокумент28 страницShutter DesignRajendra Prasad GubbalaОценок пока нет

- Flange Asme ViiiДокумент21 страницаFlange Asme Viiizahidwahla1Оценок пока нет

- NCHRP-98-Manual For Bridge Rating Through Load TestingДокумент150 страницNCHRP-98-Manual For Bridge Rating Through Load TestingJuniorz Zavaleta100% (1)

- Mechanical Vibrations Lecture NotesДокумент133 страницыMechanical Vibrations Lecture NotesHarrison AdemuОценок пока нет

- Structural Calculation for Glass BalustradeДокумент47 страницStructural Calculation for Glass Balustradewaweng22Оценок пока нет

- DSM Holes AISI Draft R1Документ509 страницDSM Holes AISI Draft R1christos032Оценок пока нет

- Plate Girders - I: Fig. 1 Typical Plate Girder With Intermediate and End StiffenersДокумент47 страницPlate Girders - I: Fig. 1 Typical Plate Girder With Intermediate and End StiffenersNaveen NunnaОценок пока нет

- Initial Verification for Glass Panel Wind Load CalculationДокумент5 страницInitial Verification for Glass Panel Wind Load Calculationwaweng22Оценок пока нет

- Single Shear Steel ConnectionДокумент36 страницSingle Shear Steel ConnectionNatalie WestОценок пока нет

- 07-GB Column BasesДокумент14 страниц07-GB Column BasesAUNGPSОценок пока нет

- Bolt Torq. (Moss+Farr)Документ9 страницBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- FlangeДокумент12 страницFlangeGabriel RodríguezОценок пока нет

- PROFIS Anchor 2.2.0: WWW - Hilti.deДокумент6 страницPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguОценок пока нет

- Fin Plate - Beam To ColumnДокумент78 страницFin Plate - Beam To ColumnHemant Ramesh NarkarОценок пока нет

- Screw ConveyorДокумент5 страницScrew ConveyorEDUARDO100% (3)

- M2-CV-RC-D-005 (R1)Документ22 страницыM2-CV-RC-D-005 (R1)ksshashidharОценок пока нет

- Progressive Tool Design and Analysis For 49 Lever 5 Stage ToolsДокумент10 страницProgressive Tool Design and Analysis For 49 Lever 5 Stage ToolsseventhsensegroupОценок пока нет

- Davit Arm Support Plate CheckДокумент56 страницDavit Arm Support Plate CheckHafizi HZnumismatic100% (5)

- Anchor Chair Design CheckДокумент5 страницAnchor Chair Design CheckHomer SilvaОценок пока нет

- Bolt BendingДокумент1 страницаBolt Bendingwaweng22Оценок пока нет

- PE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Документ33 страницыPE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Virginia Elena Iordache67% (3)

- Typ Base PlateДокумент19 страницTyp Base PlateumeshОценок пока нет

- Base Ring and SkirtДокумент8 страницBase Ring and Skirtduazo2009Оценок пока нет

- Flange KOD Vessel Calculation - Actual ConditionДокумент21 страницаFlange KOD Vessel Calculation - Actual ConditionPeter PerezОценок пока нет

- Offcon DNV Zorro SkidДокумент7 страницOffcon DNV Zorro SkidRAMSINGH CHAUHANОценок пока нет

- Structural Calculations ST04 AMD 4th FL BEAMДокумент35 страницStructural Calculations ST04 AMD 4th FL BEAMSun PonloeuОценок пока нет

- Bolted Connection ToolДокумент56 страницBolted Connection ToolPrakash Singh RawalОценок пока нет

- Conceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. RamegoudaДокумент4 страницыConceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. Ramegoudaaravindan476Оценок пока нет

- Bracket CheckДокумент3 страницыBracket Checkwaweng22Оценок пока нет

- CFD Design TemplateДокумент5 страницCFD Design TemplateEm MarОценок пока нет

- Doubler Plate CheckДокумент3 страницыDoubler Plate CheckkarthickОценок пока нет

- Properties of Concrete As Construction MaterialДокумент22 страницыProperties of Concrete As Construction MaterialEdisonОценок пока нет

- MOMENT EndplateДокумент8 страницMOMENT Endplatemoseslugtu6324Оценок пока нет

- Convergence - Confinement MethodДокумент0 страницConvergence - Confinement MethodNguyễn HòaОценок пока нет

- Client Project Drain Vessel DesignДокумент16 страницClient Project Drain Vessel DesignLaxmikant ChauhanОценок пока нет

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcДокумент8 страницPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalОценок пока нет

- Design CalcДокумент308 страницDesign CalcPeja Jusoh100% (1)

- Aspen HX Design ReportДокумент78 страницAspen HX Design ReportberylqzОценок пока нет

- Analysis of Integral Abutment Bridge Using FEA SoftwareДокумент71 страницаAnalysis of Integral Abutment Bridge Using FEA Softwarerabiatuladda92Оценок пока нет

- Apron FeederДокумент7 страницApron FeederEDUARDO0% (1)

- Company Name: Job InformationДокумент9 страницCompany Name: Job InformationdpkОценок пока нет

- 3.2. Design of Glass: ElevationДокумент3 страницы3.2. Design of Glass: Elevationwaweng22Оценок пока нет

- Gusset Plate Design for Cleveland Clinic Abu DhabiДокумент4 страницыGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- STR Report 1Документ9 страницSTR Report 1firasslmn50% (2)

- QRod Pump Design SoftwareДокумент40 страницQRod Pump Design SoftwareRodrigo DacolОценок пока нет

- Company Name: Job InformationДокумент6 страницCompany Name: Job InformationAlvin LeongОценок пока нет

- Job Information: Engineer Checked ApprovedДокумент3 страницыJob Information: Engineer Checked ApprovedRantharu AttanayakeОценок пока нет

- Company Name: Job InformationДокумент7 страницCompany Name: Job InformationAlvin LeongОценок пока нет

- Building 7 TesДокумент11 страницBuilding 7 TesFauzankalibataОценок пока нет

- Nan Mudhalvan Project Report Batch 8Документ46 страницNan Mudhalvan Project Report Batch 8Visa Meena2351Оценок пока нет

- Beam - Roof Beam - GM1Документ20 страницBeam - Roof Beam - GM1FrederickV.VelascoОценок пока нет

- Fixed column base design analysisДокумент8 страницFixed column base design analysisinoОценок пока нет

- Simply Supported Beam AnalysisДокумент7 страницSimply Supported Beam AnalysisArunkumar AKОценок пока нет

- (GVДокумент10 страниц(GVRobinReyndersОценок пока нет

- Jhapa DDE Pedestral DesignДокумент24 страницыJhapa DDE Pedestral DesignPrakash Singh RawalОценок пока нет

- ETABS 2013 Concrete Frame Design: ETABS 2013 13.1.3 License # 1LF5NDQJQA7GDJ5Документ2 страницыETABS 2013 Concrete Frame Design: ETABS 2013 13.1.3 License # 1LF5NDQJQA7GDJ5Jorge TabarezОценок пока нет

- Autodesk Robot Structural Analysis Professional 2015 column designДокумент16 страницAutodesk Robot Structural Analysis Professional 2015 column designHimura_Оценок пока нет

- Roof truss design report for churchДокумент7 страницRoof truss design report for churchm2kalОценок пока нет

- Stückliste / Parts List: KlempelДокумент2 страницыStückliste / Parts List: KlempelJean Grey ValerОценок пока нет

- Base CHS X 10tДокумент7 страницBase CHS X 10tCollin NguОценок пока нет

- Peikko Designer, Printing-20140828Документ6 страницPeikko Designer, Printing-20140828Filipe FeioОценок пока нет

- PROFIS Anchor 2.4.6: WWW - Hilti.luДокумент6 страницPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliОценок пока нет

- Beam - Main Beam - GM7Документ87 страницBeam - Main Beam - GM7FrederickV.VelascoОценок пока нет

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsОт EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoОценок пока нет

- Bolt capacity and bending checks as per BS EN-1993-1-8Документ2 страницыBolt capacity and bending checks as per BS EN-1993-1-8waweng22Оценок пока нет

- Job Information: Engineer Checked Approved Name: Date: Project IDДокумент8 страницJob Information: Engineer Checked Approved Name: Date: Project IDwaweng22Оценок пока нет

- Loads and stresses on FEM glass panel modelДокумент3 страницыLoads and stresses on FEM glass panel modelwaweng22Оценок пока нет

- Parameters Screw Parameter (As Per AAMA TIR A9-14)Документ5 страницParameters Screw Parameter (As Per AAMA TIR A9-14)waweng22Оценок пока нет

- Vertical Post With Glass Door: Page 32Документ3 страницыVertical Post With Glass Door: Page 32waweng22Оценок пока нет

- Screw Capacity According To Aama Tir-A9 and Tir-A9-Add: Material ParametersДокумент2 страницыScrew Capacity According To Aama Tir-A9 and Tir-A9-Add: Material Parameterswaweng22Оценок пока нет

- Aluminum Hook Design ParametersДокумент2 страницыAluminum Hook Design Parameterswaweng22Оценок пока нет

- Top Bracket (Fin) Extended - Zeb2Документ6 страницTop Bracket (Fin) Extended - Zeb2waweng22Оценок пока нет

- Check For Glass Fins and Continuous Channel: Page 8Документ2 страницыCheck For Glass Fins and Continuous Channel: Page 8waweng22100% (1)

- Kids Pool: IntrodutionДокумент2 страницыKids Pool: Introdutionwaweng22Оценок пока нет

- Glass Check TrofisolДокумент2 страницыGlass Check Trofisolwaweng22Оценок пока нет

- Thermal Break CheclДокумент1 страницаThermal Break Checlwaweng22Оценок пока нет

- Intermediate Bracket CheckДокумент2 страницыIntermediate Bracket Checkwaweng22Оценок пока нет

- Window TransomДокумент1 страницаWindow Transomwaweng22Оценок пока нет

- 3.3. Design of Aluminium Framing Members: Reference Drawing: AJB ZEB BM Z Z Z SD FAC 42078 00Документ3 страницы3.3. Design of Aluminium Framing Members: Reference Drawing: AJB ZEB BM Z Z Z SD FAC 42078 00waweng22Оценок пока нет

- Window Mullion FullДокумент1 страницаWindow Mullion Fullwaweng22Оценок пока нет

- Window Mullion NotchedДокумент1 страницаWindow Mullion Notchedwaweng22Оценок пока нет

- Glass Check P1Документ1 страницаGlass Check P1waweng22Оценок пока нет

- Window Mullion SmallДокумент1 страницаWindow Mullion Smallwaweng22Оценок пока нет

- JORDAHL - JTA-CE Katalog - EnglДокумент24 страницыJORDAHL - JTA-CE Katalog - Englwaweng22Оценок пока нет

- maၐԂ҄ - 01 - 01 - Effective Thickness of Laminated Glass of (GL-104)Документ3 страницыmaၐԂ҄ - 01 - 01 - Effective Thickness of Laminated Glass of (GL-104)waweng22Оценок пока нет

- Glass Check P3Документ1 страницаGlass Check P3waweng22Оценок пока нет

- Load Combination As Per Nys 2010 Building CodeДокумент2 страницыLoad Combination As Per Nys 2010 Building Codewaweng22Оценок пока нет

- Check For BendingДокумент1 страницаCheck For Bendingwaweng22Оценок пока нет

- Trosifol® - World of Interlayers - Glass Calculator112mm PVBДокумент2 страницыTrosifol® - World of Interlayers - Glass Calculator112mm PVBwaweng22Оценок пока нет

- MB41Документ6 страницMB41GERARDO TORRES RUIZОценок пока нет

- WRT 3 Reinforcement of OpeningsДокумент1 страницаWRT 3 Reinforcement of OpeningsShyam BambalОценок пока нет

- Math Forbidden JutsuДокумент6 страницMath Forbidden Jutsuimo konsensyaОценок пока нет

- NTPC SyllabusДокумент3 страницыNTPC SyllabusVimleshKumarSharma100% (1)

- Rigidez A FlexiónДокумент13 страницRigidez A FlexiónJosé Cabrera100% (1)

- L07 Compatibility Mode 1645956007946Документ97 страницL07 Compatibility Mode 1645956007946Saini boyОценок пока нет

- Rahul VyasДокумент48 страницRahul VyasRahul VyasОценок пока нет

- Materials Classification, Properties and ApplicationsДокумент76 страницMaterials Classification, Properties and ApplicationsgatproОценок пока нет

- Analysis, Design and Construction of Ferrocement Water Tanks in CubaДокумент9 страницAnalysis, Design and Construction of Ferrocement Water Tanks in CubaJamielah MacadatoОценок пока нет

- Traction VectorsДокумент8 страницTraction VectorsBrajesh kumarОценок пока нет

- Cracks in Concrete Core Due To Fire or Thermal Heating ShockДокумент6 страницCracks in Concrete Core Due To Fire or Thermal Heating ShockaravindtankОценок пока нет

- Finite Element Modeling of Contact ProblemsДокумент1 страницаFinite Element Modeling of Contact ProblemsMubeenОценок пока нет

- A Material Model For Flexural Crack Simulation in Reinforced Concrete Elements Using ABAQUS - Wahalathantri2011Документ7 страницA Material Model For Flexural Crack Simulation in Reinforced Concrete Elements Using ABAQUS - Wahalathantri2011marcilio1986Оценок пока нет

- Mos QBДокумент4 страницыMos QBJaishree ChauhanОценок пока нет

- 1Документ13 страниц1ihpeterОценок пока нет

- Stress-Strain ChapterДокумент37 страницStress-Strain ChapterRose EizzaОценок пока нет

- Biomechanics of CartilageДокумент14 страницBiomechanics of CartilageEric Urbina SantibañezОценок пока нет

- CV7001 Part 1 NoteДокумент267 страницCV7001 Part 1 NoteasdasОценок пока нет

- Manufacturing Technology (ME361) - Lecture 3: Shantanu BhattacharyaДокумент20 страницManufacturing Technology (ME361) - Lecture 3: Shantanu BhattacharyaSahil SundaОценок пока нет

- Hilti HCC-B For Concrete Overlays: Fastening Technology ManualДокумент39 страницHilti HCC-B For Concrete Overlays: Fastening Technology ManualPablo Martinez FesserОценок пока нет

- Side Discharge Loader PDFДокумент2 страницыSide Discharge Loader PDFraneshОценок пока нет