Академический Документы

Профессиональный Документы

Культура Документы

Angle Type Blowdown Valve

Загружено:

rikumohan0 оценок0% нашли этот документ полезным (0 голосов)

193 просмотров7 страницghfghfgcjh

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документghfghfgcjh

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

193 просмотров7 страницAngle Type Blowdown Valve

Загружено:

rikumohanghfghfgcjh

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

1

BLOW DOWN VALVE

SIZE : 1,1-1/2

CLASS 1500,2000

INSTRUCTION MANUAL

Bharat Heavy Electricals Limited

Tiruchirapalli

PUB.NO.7048

2

HIGH PRESSURE BLOW DOWN VALVES

NOMINAL BORE: 1",1-1/2" RATING: Class 1500,2000

Orifice Sizes -. 1/8", 3/16",1/4",5/16",3/8",7/16" & 1/2" FOR 1"

3/8", 7/16", 1/2",5/8", 3/4", 7/8", 1" FOR 1-1/2".

1.GENERAL

The valve is operated easily by rotating the handle clockwise to close and counterclockwise to

open. Graduations are available in the dial to indicate 1/20th of the handwheel turn. This valve

recommended for blow-down service from very high pressure. Suitable orifice size is to be selected

based on the blow-down capacity required for the given pressure.

2. HANDLING

Care should be exercised when handling the valves to prevent damage to handle, stem, actuator or

other parts.

3. STORAGE

Valves should be stored under cover and protected from excessive dust and dirt. Ensure that valve

ports are properly closed with end caps.

4. PRE-INSTALLATION

Prior to installation, the following steps should be taken: (1) Keep the valve ends closed with end

caps till the time of installation. (11) Inspect valve flow passage and connecting pipeline for

obstructions or foreign materials. Clean where necessary. (111) Check packing gland bolting to

make sure that the packing is compressed. If the nuts are loose, tighten as per the procedure given

in this manual.

5. INSTALLATION

(1) Mount the valve in the line with pressure in the upper side. The flow direction in the high

Pressure Blow down Valve is from sidewards to bottom, which is also indicated by an arrow on the

valve to aid installation.

(11) Valves should be fully open prior to welding. Care should be taken not to ground to valve yoke,

stem or handwheel when welding.

For further instructions on storage and installation refer Publication No. 700 1.

6. OPERATION

The valve is operated by rotating the handle in clockwise direction to close and counter-clockwise

to open. If the valve does not shut off tightly when closed, opening the valve and re-closing may

flush out any foreign material entrapped in the seats. Do not use a wrench to close the valve. If there

3

is leakage through the seats, when seating surfaces are free of foreign material, the seats will have to

be refinished as per the procedure given in this manual.

When putting the valve in service and when the valve has been brought up temperature, the

packing should be checked for leakage. If leakage is noticed the packing gland should be adjusted

immediately. Continued leakage through the gland packings may damage the valve beyond repair.

The packing gland flange should be adjusted an equal amount on each side to ensure proper

compression of the packing and to avoid binding of the gland follower with the stem. If adjust-

ment of the packing does not eliminate leakage, additional packing rings should be inserted or the

valve should be completely repacked. Refer to the section entitled ,maintenance in this manual

for instructions on addition or replacement of packings. For extended packing life when the

valves are operated in open position, they should be fully opened and back seated.

7. MAINTENANCE

The valve can be easily disassembled for inspection, maintenance or replacement of internal parts

by using the procedure and tools outlined in this manual.

(i) Disassembly

Refer assembly cross-sectional drawing for part names. Open the valve until contact with the back

seat is felt. Turn the tee-handle in the closing direction through onefourth of a turn. Remove the

lock nut (015) and the tee-handle. The yoke bush (014) can now be removed. The rotation of yoke

bush is arrested by staking as shown in figure. The staking must be flattened or filed smooth to

enable the removal of yoke bush. After removing the staking, hold the stem by the pyramid to

prevent rotation and remove the yoke bush. Remove the packing gland studs(O 10) and nuts (0 11).

Lift the gland flange and remove the split type gland follower. Now pulling the Stem will remove

the packing ring alongwith the stop ring.

WARNING: The High Pressure Valve is designed with Loose Back Seat and hence is not suitable

for repacking of gland during service.Also since the flow is from top to bottom, the packings are

always under line pressure. Hence, no attempt shall be made either to remove the packings or add

additional packing during service.

(ii) Renewal of Packing

The valve glands are packed with high quality asbestos rings having certain special features. Since

the use of the right packing is essential for proper performance of the valve, replacement packing

shall be procured only from BHEL or sources approved by BHEL.

The valve is NOT provided with a fixed back seat arrangement. These valves belong to the so-called

Loose Backseat design category and hence renewal of packing when valve is in service is strictly

prohibited. If it becomes absolutely necessary to add packings, the same shall be done by isolating

the line and then dismantling required parts.

(a) Adding Packing

After isolating from line and ensuring that there is no pressure, the following procedure shall be

adapted for addition of packing. Unscrew the gland nuts and remove them. Raise the gland flange

and remove the split type gland follower. The gland flange may be tied by a wire to the tee packing.

Additional rings may be added as required. When inserting new rings the slit in the rings shall be

staggered 90' apart. The gland follower can now be inserted and the gland nuts assembled. Tighten

4

the nuts on either side evenly and by an amount j . just sufficient to arrest leakage. Overcompression

of packings will reduce the life of packings and also make the operation of valve difficult.

(b) Replacement of Packing

If a valve is to be completely repacked, isolate the valve to relieve the pressure on the packing rings.

Turn the tee-handle counter-clockwise until the valve is fully opened. Remove the Tee-handle and

then the Yoke bush. Remove the gland nuts (0 11). Lift the gland flange and remove the split gland

follower. Wire the gland flange and follower to the handwheel to allow more room for changing the

packing. Now pull the Stem Assembly with a jerk. The packing rings followed by the metallic Stop

ring come out of the valve. Remove all old packing taking care not to damage the stem or the

stuffing box bore. Clean the stem, stop ring and stuffing box. Lap seat surfaces also if necessary.

Inspect the stem and stuffing box bore to ensure that there is no damage to the surfaces. Insert back

the Stop ring and then required number of newpacking rings over the Stem shank so that the slit in

the rings shall be staggered 90 apart. Now insert the Stem-Packing assembly back into the valve.

Sufficient number of rings shall be added to ensure that there will be provision for further tighten-

ing to arrest any leakage in service. Assemble the Gland follower and tighten the gland nuts evenly

on either side, taking care not to compress the packings too much. Open the valve fully. Now

assemble the Yoke Bush and tighten it. Fix the Tee-handle and the nut over it. Put the valve back in

service. Turn the tee-handle in the closing direction by /2 turn and check for leakage. If leakage

continues, tighten the nuts by another V2 turn. Turn tee-handle back and forth /2 turn to check

easeness of operation. If leakage has stopped, but the operation is difficult, loosen the gland nuts by

1/4 turn. Check for leakage and operational ease. The objective is to tighten the packing just suffi-

ciently to prevent leakage with a minimum amount of resistance to stem movement.

(iii) Reconditioning of seats

The valves have integral hard faced seats of stellite. The hard faced seats can be reconditioned as

follows:

(a) Assemble the re-seating tool and insert in the valve. A course 60 or 80 Grit abrasive cloth is

recommended.

(b) Drive the re-seating tool using an electric drill. Application of light pressure is recommended

(c) Replace the abrasive cloth frequently and check for a uniform finish over the entire seating

surface.

(d) Remove the reseating tool and lap the seating surfaces together using the stem assembly.

(iv) Assembly

The procedure as told in the section for replacement of packing shall be adapted.

STAKING DIMENSION

Lubricate the stem threads and the external thread on yoke bushing. Install the yoke bushing over

the stem and tighten on to the yoke. The yoke bushing must now be stake locked as shown in figure.

The packing gland nuts shall now be adjusted evenly on either side. Install the handle and lock nut

(183). Lubrication of threaded parts during assembly shall be done with molybdenum di-sulphide,

graphite and kerosene.

5

7

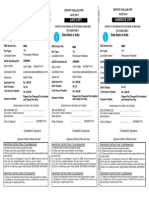

SIZE OF

VALVE

LOCK NUT

(015)

GLAND NUT

(011)

YOKE BRUSHING

(014)

1 14.27 19.05 41.3

1-1/2 26.97 28.58 54.0

SIZE OF

VALVE

OUTSIDE

DIA (OD)

INSIDE

DIA(ID)

THICKNESS

T

1 34. 1 17.4 7.9

1-1/2 46.7 27.15 9.5

INDEX

Вам также может понравиться

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareОт EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareОценок пока нет

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliДокумент7 страницInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYОценок пока нет

- S, I A M P: Gate Valve "O.S." & "Y"Документ6 страницS, I A M P: Gate Valve "O.S." & "Y"Hafiz Ali AlviОценок пока нет

- Valve MaintenanceДокумент6 страницValve Maintenancemoorthymech1979Оценок пока нет

- TBV Series 21 20 Cryogenic Flanged Ball ValveДокумент5 страницTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranОценок пока нет

- Jamesbury Butterfly Valves 8000 and 8200Документ8 страницJamesbury Butterfly Valves 8000 and 8200Uday GokhaleОценок пока нет

- Maintenance Instruction Manual: Severe Service Control ValvesДокумент9 страницMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقОценок пока нет

- Valve Operation Manula-KINKAДокумент30 страницValve Operation Manula-KINKAyosОценок пока нет

- Valve Installation and Operation ManualДокумент1 страницаValve Installation and Operation ManualStateОценок пока нет

- 8in Wafer Ball Vale IMOДокумент2 страницы8in Wafer Ball Vale IMOw4uengineerОценок пока нет

- Tube Turns Hinged ClosureДокумент8 страницTube Turns Hinged ClosureMarcelino Torres RenjfoОценок пока нет

- Gate ValveДокумент1 страницаGate ValveStateОценок пока нет

- Gate Valve "O.S." & "Y"Документ1 страницаGate Valve "O.S." & "Y"StateОценок пока нет

- Farris Valve ManualДокумент11 страницFarris Valve ManualsumsolcaggОценок пока нет

- Unidad Rotacion Serie l30Документ22 страницыUnidad Rotacion Serie l30Raphael Ruiz RamosОценок пока нет

- 755Документ19 страниц755JOHNОценок пока нет

- Tilt CylinderДокумент7 страницTilt Cylinderluis tocoraОценок пока нет

- 1" Angle Valves: Installation Operation Inspection MaintenanceДокумент12 страниц1" Angle Valves: Installation Operation Inspection MaintenanceLucas MonteОценок пока нет

- Maintenance and Troubleshooting: 6.1 Lubrication OilДокумент7 страницMaintenance and Troubleshooting: 6.1 Lubrication Oilabdullatif_asОценок пока нет

- 1 Thru 6in E Series Globe Valves ED ET PDFДокумент16 страниц1 Thru 6in E Series Globe Valves ED ET PDFakhileshkuniyilОценок пока нет

- 2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideДокумент2 страницы2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideLucianОценок пока нет

- Sherwood Valves Cylinder ValvesДокумент17 страницSherwood Valves Cylinder Valvesklr_sean100% (1)

- Installation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate ValveДокумент6 страницInstallation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate Valveعبدالرحمن عمرОценок пока нет

- FCV COMBO Manual ABZ Valve W Actuator J032Документ28 страницFCV COMBO Manual ABZ Valve W Actuator J032corasaulОценок пока нет

- Yoke Type Hinged Closures Installation, Operation & MaintenanceДокумент8 страницYoke Type Hinged Closures Installation, Operation & MaintenanceRamОценок пока нет

- 2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuideДокумент2 страницы2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuidemajoОценок пока нет

- Tank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsДокумент4 страницыTank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDanielle JohnsonОценок пока нет

- Valvula DireccionДокумент8 страницValvula DireccionVictor Manuel Lozada ObessoОценок пока нет

- Weflo Nrs Gate Op and MaintДокумент5 страницWeflo Nrs Gate Op and MaintyusufОценок пока нет

- Series 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsДокумент3 страницыSeries 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsluchitocapoОценок пока нет

- Cam-Tite Ball Valve Operating Instructions: WarningДокумент3 страницыCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarОценок пока нет

- Dive Scubapro - Tank Valves - Maintenance ProcedureДокумент4 страницыDive Scubapro - Tank Valves - Maintenance ProceduremanonpomОценок пока нет

- Installation - Maintenance Manual F15 and F30 Series 150 and 300 Lb. Flanged Full Port Ball ValvesДокумент5 страницInstallation - Maintenance Manual F15 and F30 Series 150 and 300 Lb. Flanged Full Port Ball ValvesBureau VeritasОценок пока нет

- Kennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualДокумент11 страницKennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualttyОценок пока нет

- DAKE Press Model 75 H - 907003Документ6 страницDAKE Press Model 75 H - 907003mark_dayОценок пока нет

- WNCO Valve's WN-1 Valve MaintenanceДокумент5 страницWNCO Valve's WN-1 Valve MaintenancethritaОценок пока нет

- Valtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyДокумент4 страницыValtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyEduardo Landa GonzalezОценок пока нет

- Llave de Varillas de BombeoДокумент28 страницLlave de Varillas de BombeoGianna Frola100% (1)

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsДокумент4 страницыCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezОценок пока нет

- Needle Valve Maintenance Instructions - Alco Valves PM-221Документ5 страницNeedle Valve Maintenance Instructions - Alco Valves PM-221AzaelОценок пока нет

- Grid Coupling Installation InstructionsДокумент2 страницыGrid Coupling Installation Instructionsakashwsl92Оценок пока нет

- Flush Bottom Valve Installation-Maintenance-Manual PDFДокумент12 страницFlush Bottom Valve Installation-Maintenance-Manual PDFtuscan23Оценок пока нет

- Worcester Cryogenic Manual WceimstemДокумент15 страницWorcester Cryogenic Manual Wceimstem윤병택Оценок пока нет

- MT 170Документ4 страницыMT 170mafambaОценок пока нет

- Butterfly Valves Waferdesign Manual O&mДокумент17 страницButterfly Valves Waferdesign Manual O&mMilu OberoiОценок пока нет

- Manual Mantenimiento Cuadradas Rev.1Документ10 страницManual Mantenimiento Cuadradas Rev.1pelaeztemplarioОценок пока нет

- Balance Disk Replacement PDFДокумент8 страницBalance Disk Replacement PDFOscar Araya RojasОценок пока нет

- Catálogo Anderson Greenwood 400sДокумент32 страницыCatálogo Anderson Greenwood 400sDaniela BeltranОценок пока нет

- Operation & Maintenance of Plug Valves PDFДокумент5 страницOperation & Maintenance of Plug Valves PDFعزت عبد المنعمОценок пока нет

- Air CylinderДокумент4 страницыAir Cylindersimbua720% (1)

- Yarway Blow Off Valves Operation ManualДокумент4 страницыYarway Blow Off Valves Operation ManualLeoОценок пока нет

- Agco Serie 800 PDFДокумент24 страницыAgco Serie 800 PDFJohnny VargasОценок пока нет

- Pratt - Bfv-14 Triton XR, XL, Hp-250Документ14 страницPratt - Bfv-14 Triton XR, XL, Hp-250tiago_mozartОценок пока нет

- Iom WKM 310FДокумент4 страницыIom WKM 310FNasir NaqviОценок пока нет

- Remove & Install Bucket CylinderДокумент8 страницRemove & Install Bucket CylinderchanlinОценок пока нет

- Ex Reg2ndДокумент57 страницEx Reg2nddaviddealbaОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- A598H84Cp ( JyjhallanДокумент1 страницаA598H84Cp ( JyjhallanrikumohanОценок пока нет

- Junction Box Drawings PDFДокумент14 страницJunction Box Drawings PDFrikumohanОценок пока нет

- 25-06-2009 09:02:31 This Drawing Is Printed From Engineering Digital Archive System (EDAS) - Therefore Signatures Are Not Essentially RequiredДокумент1 страница25-06-2009 09:02:31 This Drawing Is Printed From Engineering Digital Archive System (EDAS) - Therefore Signatures Are Not Essentially RequiredrikumohanОценок пока нет

- 08-07-2009 10:09:18 This Drawing Is Printed From Engineering Digital Archive System (EDAS) - Therefore Signatures Are Not Essentially RequiredДокумент1 страница08-07-2009 10:09:18 This Drawing Is Printed From Engineering Digital Archive System (EDAS) - Therefore Signatures Are Not Essentially RequiredrikumohanОценок пока нет

- Boiler Installation and Maintenance Manual: Oil and Gas Fired Cast Iron Boiler Logano G115 USДокумент56 страницBoiler Installation and Maintenance Manual: Oil and Gas Fired Cast Iron Boiler Logano G115 USrikumohanОценок пока нет

- Power Engineering International - Article On SWASДокумент7 страницPower Engineering International - Article On SWASshameer_febiОценок пока нет

- Ppchem Free 9 2004 2Документ0 страницPpchem Free 9 2004 2rikumohanОценок пока нет

- Cofferdams Uwsh Manual Training & OperationsДокумент18 страницCofferdams Uwsh Manual Training & OperationsBudi SatrioОценок пока нет

- Actuator InformationДокумент4 страницыActuator InformationFajar DwikurniaОценок пока нет

- Toyota Corolla Repair Manual: Precaution: Sell Medical Equipment OnlineДокумент1 страницаToyota Corolla Repair Manual: Precaution: Sell Medical Equipment Onlinebasheer almetwakelОценок пока нет

- Manual TZ100-TZ600 REV.5-MITCHELL PDFДокумент44 страницыManual TZ100-TZ600 REV.5-MITCHELL PDFBrian KomivesОценок пока нет

- Qx189860 Lb185-275-Lb185-275 Screw Air Compressor - Origional User ManualДокумент50 страницQx189860 Lb185-275-Lb185-275 Screw Air Compressor - Origional User Manualabdur rohmanОценок пока нет

- En137 1993Документ24 страницыEn137 1993TammanurRaviОценок пока нет

- ACRD20x Fluid Cooled InstallationДокумент44 страницыACRD20x Fluid Cooled InstallationNelson Arturo GarciaОценок пока нет

- SUNWARD MEDIUM EXCAVATOR Hydraulic SystemДокумент146 страницSUNWARD MEDIUM EXCAVATOR Hydraulic SystemAlbeiro Rodriguez100% (11)

- Manual Sillon Olsen PDFДокумент14 страницManual Sillon Olsen PDFbrisaОценок пока нет

- Zdree 2XДокумент16 страницZdree 2XTayfun GunalОценок пока нет

- BalClor BWMS Trouble ShootingДокумент41 страницаBalClor BWMS Trouble ShootingIgor Doroshchuk67% (6)

- Section15 MAINTENANCE.Документ20 страницSection15 MAINTENANCE.Mithilesh YadavОценок пока нет

- Safety Precautions and Engine DataДокумент44 страницыSafety Precautions and Engine DataJagmohan SinghОценок пока нет

- SUFA AJS Ball Valve Catalogue 03Документ33 страницыSUFA AJS Ball Valve Catalogue 03JasperTanОценок пока нет

- 100T Pump Parts List PDFДокумент30 страниц100T Pump Parts List PDFGabriel Andres ValenciaОценок пока нет

- Tower Light Manual..Документ29 страницTower Light Manual..abdallah badrОценок пока нет

- Roke Needle Valves NewДокумент8 страницRoke Needle Valves NewBay SetyaОценок пока нет

- Cat Forklift Nr4000p 36v Schematic Operation Maintenance ManualДокумент27 страницCat Forklift Nr4000p 36v Schematic Operation Maintenance Manualrodneycox060901aqk100% (122)

- Valve Material Specification A1MДокумент9 страницValve Material Specification A1Mchintan100% (1)

- WHAT - Subsea All Electric SystemsДокумент5 страницWHAT - Subsea All Electric SystemsvigneshnrynnОценок пока нет

- Paratherm Heat TransferДокумент9 страницParatherm Heat TransferWagus GinanjarОценок пока нет

- Lampiran Fire Fighting Pltu BelitungДокумент2 страницыLampiran Fire Fighting Pltu BelitungDangolОценок пока нет

- Water Mist Fire Protection Systems - System Design, Installation and Commissioning - Code of PracticeДокумент36 страницWater Mist Fire Protection Systems - System Design, Installation and Commissioning - Code of PracticeInyamul HasanОценок пока нет

- R220LC 9S+Swing+MotorДокумент27 страницR220LC 9S+Swing+MotorRamiro Castro Pacheco100% (1)

- Technical Specification EPC RFP EGPP v.1 19JUN2018 - CleanДокумент80 страницTechnical Specification EPC RFP EGPP v.1 19JUN2018 - Cleandgalindo1Оценок пока нет

- China Tariffs ListДокумент28 страницChina Tariffs ListBrett LoGiurato100% (17)

- Gambro BCT Trima Apheresis System - Service ManualДокумент27 страницGambro BCT Trima Apheresis System - Service ManualMagdiОценок пока нет

- Operational Flow Description: Sheet No. 2 Operational Flow Chart Fuel Gas CompressorДокумент2 страницыOperational Flow Description: Sheet No. 2 Operational Flow Chart Fuel Gas CompressorjeromejoeОценок пока нет

- G35 Series: Versatile, Reliable Pumps For A Wide Range of ApplicationsДокумент8 страницG35 Series: Versatile, Reliable Pumps For A Wide Range of ApplicationsHugo José Abreu de SouzaОценок пока нет

- BOP STACK All Phases of Drilling A 4CP WellДокумент6 страницBOP STACK All Phases of Drilling A 4CP WellPartha Sarathi ChatterjeeОценок пока нет