Академический Документы

Профессиональный Документы

Культура Документы

Modern steam trap survey and leak calculation sheet reduces annual steam losses by 95,000 Rs

Загружено:

intania66Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modern steam trap survey and leak calculation sheet reduces annual steam losses by 95,000 Rs

Загружено:

intania66Авторское право:

Доступные форматы

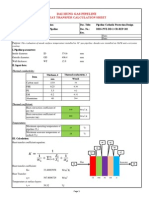

Input only in Yellow Cells Constant Leakage Hole Eq Dia Pipe Dia Orifice Constant Steam Pressure Steam

Temperature Beta M Rho Differential Head Q 19.63 1.0 0.04 50.0 0.62 34.0 #NAME? 0.020 1.00 #NAME? #NAME? #NAME? #NAME? Kg/M3 Feet M3/hr Kg/hr

mm mm Kg/cm2g C Or Bar

Steam Leakage is

Steam Price

#NAME?

0.7

Kg/hr

Rs./Kg $/Kg $/Yr

Annual Loss

#NAME?

Rs./Yr

September 16, 2008

Excel Sheet For Steam Leak Calculation

One of the most talked about energy wasters is steam leakage from "bad" steam traps and leaking fittings. Steam traps are blamed for being inefficien

I Recommend

Modern steam t G Stewart (Unkno

123>

Privacy

In general you can find many references where steam losses from different leak sizes at different steam pressures are listed. An example shows that

If condensate is recovered, leaking traps can cause an excessive return temperature and cause failure of the condensate return pumps. Severe water as hot steam contacts condensate that has cooled below the temperature of the steam The leakage rate can be easily calculated by using general orifice equation. Q = K x d^2 x H^0.5

Example template sheet in Excel is attached herewith for your easy use. In the said example steam of 34 bar can have a leakage rate of 17.0 Kg/hr fro

Download Excel Sheet Here

The following steps are recommended for saving energy in your steam condensate distribution system and starting an effective steam energy manage

Develop an estimate of the cost of steam leaks based upon your plant costs similar to other articles or references. A method for demonstrating visu Run a survey, recording all leaks, size, cost, and location.

Check the operation of all installed disc traps used for drips and steam tracing. If found leaking, consider replacing with a more efficient type trap. B Check installation and operation of steam traps used on equipment using the sound detection method, the pyrometer method, or the glove method. Check vent valves on steam jacketed equipment and kettles for proper operation (removal of inerts without steam loss).

Start a preventative maintenance program to maintain the steam distribution system in excellent condition. If manpower is not available in maintena

Steam trap manufacturers will be happy to furnish information to assist in your energy saving program to reduce steam losses, but use your own ec It is always beneficial to collect condensate at different pressures in different flash drums to recover flash steam . Also connect each high pressure drum liquid to subsequent low pressure drum

e blamed for being inefficient or worn out and causing as much as 10% of the generated heat from steam to be lost. Is this true or just a sales method to sell more tr

ed. An example shows that a 1-inch union was found leaking at a loss of $3000 per year. The repair cost was $50 or a six day payout. So the point is whatever be th

return pumps. Severe water hammer can occur

eakage rate of 17.0 Kg/hr from 1 mm hole. This is equal to Rs. 95000 / year in fuel loss. Normal repair cost can be only few thousand Rs. resulting in payback of few

ctive steam energy management program:

thod for demonstrating visually to plant people what these losses are can be made.

a more efficient type trap. Before replacing, check installation design and confirm trap size (not over or undersized).

ethod, or the glove method. The installation should be checked for proper trapping. Items checked include strainer, check valve, back pressure, orifice, and inert gas

is not available in maintenance, you can have the operating people maintain a simple log for their area of responsibility.

osses, but use your own economic costs to decide whether to replace, repair, or redesign the system.

a sales method to sell more traps? It turns out that steam leaks cause a significant energy loss.

So the point is whatever be the size of leaks or whatever be the pressure of steam the payback is generally in days compared to high fuel cost now a days.

s. resulting in payback of few days/months. Therefore a regular survey of such leakage systems is necessary for every process plant.

ressure, orifice, and inert gas venting. Improper venting can cause a severe reduction in heat transfer rate.

el cost now a days.

Вам также может понравиться

- Condensate Line SizingДокумент2 страницыCondensate Line SizingAnonymous oVRvsdWzfBОценок пока нет

- CV - Orifice Diameter PDFДокумент8 страницCV - Orifice Diameter PDFManuelОценок пока нет

- Expansion Tank Capacity Calculation SheetДокумент5 страницExpansion Tank Capacity Calculation SheetDEX TERRОценок пока нет

- Vent Line Pressure Drop CalculationДокумент4 страницыVent Line Pressure Drop CalculationRubensBoerngenОценок пока нет

- Pressure Drop CalculatorДокумент26 страницPressure Drop CalculatorAnonymous 6S9tcbhОценок пока нет

- 2K Method Excess Head Loss in Pipe FittingsДокумент8 страниц2K Method Excess Head Loss in Pipe Fittingsjxd3261Оценок пока нет

- Fgas Refrigerant CalculatorДокумент10 страницFgas Refrigerant CalculatorKumar sssssОценок пока нет

- Condensate Tank - For 250Документ3 страницыCondensate Tank - For 250Sakthi VelОценок пока нет

- Plate Heat ExchangersДокумент4 страницыPlate Heat Exchangersamini_mohiОценок пока нет

- Tank Pressure Vacuum ReliefДокумент1 страницаTank Pressure Vacuum ReliefalmadhagiОценок пока нет

- Understanding NPSHДокумент34 страницыUnderstanding NPSHeliyanto budiartoОценок пока нет

- Orifice Flow Calculator For Gases, Steam, and VaporsДокумент2 страницыOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21Оценок пока нет

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesДокумент2 страницыNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009Оценок пока нет

- API 521 pressure relief analysisДокумент3 страницыAPI 521 pressure relief analysisDaniel Pastor OrtíОценок пока нет

- Tank Emisiion CalcДокумент16 страницTank Emisiion CalcAdhe GedeОценок пока нет

- Liquid Valve CV CalcДокумент4 страницыLiquid Valve CV Calcamit_kt1973Оценок пока нет

- Pressure Drop Calculation - ExampleДокумент1 страницаPressure Drop Calculation - ExampleBandi ThaguruОценок пока нет

- Heat Exchanger CalcДокумент34 страницыHeat Exchanger Calcميثة الغيثيةОценок пока нет

- ASME Venting Calculation FB-2007 - PDFДокумент3 страницыASME Venting Calculation FB-2007 - PDFjaganОценок пока нет

- Liquid Thermal Sizing SheetДокумент1 страницаLiquid Thermal Sizing SheetapgoslingОценок пока нет

- Calculate Pressure Drop in Filters and Strainers - Separation TechnologiesДокумент5 страницCalculate Pressure Drop in Filters and Strainers - Separation TechnologiesSumit Kaushik100% (1)

- Ognition PSV Sizing Calculation SpreadsheetДокумент2 страницыOgnition PSV Sizing Calculation Spreadsheetger80Оценок пока нет

- Water Sprayer Calculation For Vertical VesselДокумент11 страницWater Sprayer Calculation For Vertical VesselSdferwste Srqre0% (1)

- Surface Area Calculations Vessel TanksДокумент5 страницSurface Area Calculations Vessel Tanksdhavalesh1Оценок пока нет

- Section 17 - Fluid Flow and PipingДокумент11 страницSection 17 - Fluid Flow and PipingCHANADASОценок пока нет

- Heat HXerДокумент2 страницыHeat HXerGade JyОценок пока нет

- Ssags PSV SizingДокумент5 страницSsags PSV SizingEkundayo JohnОценок пока нет

- API 650 RF Pad Calculation PDFДокумент1 страницаAPI 650 RF Pad Calculation PDFBimal DeyОценок пока нет

- Pressure Relief Valve Data Sheet-Rev01Документ1 страницаPressure Relief Valve Data Sheet-Rev01thawdarОценок пока нет

- Hazen Williams EquationДокумент1 страницаHazen Williams EquationNur IzzaidahОценок пока нет

- Ekoplastik PPR Catalogue of Products PDFДокумент36 страницEkoplastik PPR Catalogue of Products PDFnamОценок пока нет

- Orifice Calc Gas Rev 0Документ1 страницаOrifice Calc Gas Rev 0edufragaОценок пока нет

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitДокумент9 страницHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeОценок пока нет

- NAFS 125 Technical DataДокумент6 страницNAFS 125 Technical DataRupon RupОценок пока нет

- Relief Valve CalculationsДокумент9 страницRelief Valve CalculationssegunoyesОценок пока нет

- Pressure Drop Calculation For Rect. DuctsДокумент2 страницыPressure Drop Calculation For Rect. Ductsmahmutovicm3488Оценок пока нет

- PSV data sheets for existing refinery steam boilerДокумент1 страницаPSV data sheets for existing refinery steam boilermaurya888Оценок пока нет

- API 2000 5th Vs 6th FinalДокумент20 страницAPI 2000 5th Vs 6th Finalbrujula24Оценок пока нет

- Line Sizing For Liquid, (DO IT OWN)Документ11 страницLine Sizing For Liquid, (DO IT OWN)sumitОценок пока нет

- Maxi ManualДокумент47 страницMaxi ManualB Gary AcostaОценок пока нет

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsДокумент3 страницыSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Htri 105 PDFДокумент1 страницаHtri 105 PDFhirenpatel_62Оценок пока нет

- Pipeline Heat Transfer CalculationДокумент2 страницыPipeline Heat Transfer CalculationErica MartinОценок пока нет

- Gas Line Pressure LossesДокумент4 страницыGas Line Pressure Lossesyash saragiyaОценок пока нет

- Thermal 3TPH 12Kg FO Fired Boiler R0Документ6 страницThermal 3TPH 12Kg FO Fired Boiler R09913489806Оценок пока нет

- IR HL Heatless DryerДокумент1 страницаIR HL Heatless DryerYing Kei ChanОценок пока нет

- PSV SIZING CALCULATIONSДокумент3 страницыPSV SIZING CALCULATIONSAthiphap SrisupareerathОценок пока нет

- Jet Mixing CalculationДокумент3 страницыJet Mixing CalculationRachel FloresОценок пока нет

- Control Valve Failure Relief Rate - Gas ServiceДокумент3 страницыControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Heat Loss From An Insulated Pipe: ParametersДокумент4 страницыHeat Loss From An Insulated Pipe: ParametersMohan BabuОценок пока нет

- Underground Steam & Condensate Piping PDFДокумент26 страницUnderground Steam & Condensate Piping PDFZacky JoeОценок пока нет

- Flare Calc Sheet API - RP 521Документ13 страницFlare Calc Sheet API - RP 521ionutlaur86100% (1)

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellДокумент9 страницF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLEОценок пока нет

- Ventilation DesignДокумент4 страницыVentilation DesignPhyu Mar Thein KyawОценок пока нет

- Modern steam trap monitoring and steam leakage calculation Excel sheetДокумент3 страницыModern steam trap monitoring and steam leakage calculation Excel sheetvazzoleralex6884Оценок пока нет

- Efficient Uses of Steam EnergyДокумент67 страницEfficient Uses of Steam EnergytojinboОценок пока нет

- Boiler UtilizationДокумент24 страницыBoiler UtilizationLarisa Viorica FlorianОценок пока нет

- PTQ Q2 - Spirax PT 1Документ6 страницPTQ Q2 - Spirax PT 1Pop-Coman Simion100% (1)

- Boost Boiler Efficiency & Steam System PerformanceДокумент29 страницBoost Boiler Efficiency & Steam System Performancemadan karkiОценок пока нет

- Major Opportunities of Energy Savings - BoilersДокумент2 страницыMajor Opportunities of Energy Savings - BoilersDebasis MisraОценок пока нет

- BS en 10001-1991 (1999) PDFДокумент14 страницBS en 10001-1991 (1999) PDFBravo RdОценок пока нет

- ASGMT2004 Overviewof AGA TechWhitepaperДокумент9 страницASGMT2004 Overviewof AGA TechWhitepaperAbdelrhman MamdouhОценок пока нет

- Thermal Stress Limits in Cryogenic PipelinesДокумент8 страницThermal Stress Limits in Cryogenic Pipelinesintania66Оценок пока нет

- Impact Load FactorsДокумент13 страницImpact Load FactorsMuralidharan ShanmugamОценок пока нет

- Condensate Line SizingДокумент2 страницыCondensate Line Sizingemmanuilmoulos6339100% (1)

- Line SizeДокумент3 страницыLine Sizeintania660% (1)

- Calculation and Design of Packed Column For AcidДокумент14 страницCalculation and Design of Packed Column For AcidDavid LambertОценок пока нет

- C1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesДокумент37 страницC1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesAnonymous mcHqIfbnV1Оценок пока нет

- Convert Common UnitsДокумент31 страницаConvert Common Unitsintania66Оценок пока нет

- Reactor Particle SizingДокумент4 страницыReactor Particle SizinggrabettyОценок пока нет

- Steam TracingДокумент45 страницSteam Tracingwylie01Оценок пока нет

- Flare Stack CalculationsДокумент1 страницаFlare Stack CalculationsZeeshan Adeel Khan100% (1)

- Vapor Pressure of A Liquid SolutionДокумент40 страницVapor Pressure of A Liquid Solutionintania660% (1)

- Experienced Based Rules of Chemical EngineeringДокумент33 страницыExperienced Based Rules of Chemical Engineeringintania66Оценок пока нет

- Velocity of SoundДокумент6 страницVelocity of SoundWalter RigamontiОценок пока нет

- Thumb Rules - Xls For Chemical EngineerДокумент46 страницThumb Rules - Xls For Chemical EngineerAnuj KaliyerОценок пока нет

- Volumes AndweightsДокумент2 страницыVolumes AndweightsmohdnazirОценок пока нет

- BMW B46TU Engine Technical TrainingДокумент41 страницаBMW B46TU Engine Technical TrainingLauri MäkinenОценок пока нет

- Functional location mapping of Cikampek tissue mill siteДокумент24 страницыFunctional location mapping of Cikampek tissue mill siteRian AprianaОценок пока нет

- 3.9L - Terraza & UplanderДокумент776 страниц3.9L - Terraza & UplanderKJ CARGOОценок пока нет

- ABS Piping GroupsДокумент5 страницABS Piping Groupsking852Оценок пока нет

- 02 - Progressing Cavity Pumps, Downhole Pumps and MudmotorsДокумент6 страниц02 - Progressing Cavity Pumps, Downhole Pumps and MudmotorsramОценок пока нет

- Section 14 (Water Distribution Systems)Документ88 страницSection 14 (Water Distribution Systems)badrul79Оценок пока нет

- Air Filling and SoundingДокумент20 страницAir Filling and Soundingsathish_sbit100% (2)

- SSTPS LMI On Optimaization of Ash Water Utilaization Revision-2 - Agupta SirДокумент18 страницSSTPS LMI On Optimaization of Ash Water Utilaization Revision-2 - Agupta SirGautamupadhyayОценок пока нет

- Smart Monitoring Sytem of Underwater EnivornmentДокумент5 страницSmart Monitoring Sytem of Underwater Enivornmentshakeel ahmedОценок пока нет

- High Pressure Water Jetting FormatДокумент35 страницHigh Pressure Water Jetting Formatboypardede100% (1)

- Noida MMD Viva QuestionsДокумент61 страницаNoida MMD Viva QuestionsSameerFernandezОценок пока нет

- GE Troubleshooting Guide EC2+ MarineДокумент76 страницGE Troubleshooting Guide EC2+ MarineJeremy TravisОценок пока нет

- Paper - Lufkin - Beam Pumping System Efficiency ImprovementДокумент13 страницPaper - Lufkin - Beam Pumping System Efficiency ImprovementhichemОценок пока нет

- Jeep Cj3a Manual Do Proprietario (Jipenet)Документ74 страницыJeep Cj3a Manual Do Proprietario (Jipenet)tr4n00Оценок пока нет

- Catalogo ContinentalДокумент255 страницCatalogo ContinentalGabriel Castillo MuñozОценок пока нет

- Check List Start Up and Comissioning of Fire Pumps 2Документ6 страницCheck List Start Up and Comissioning of Fire Pumps 2ismail_khansОценок пока нет

- The Function and Structure of Water PumpsДокумент570 страницThe Function and Structure of Water PumpsRogerio Francisco Dos Santos100% (1)

- 320C - Esquema de Lubrificação 3066Документ3 страницы320C - Esquema de Lubrificação 3066Marcus ViníciusОценок пока нет

- Industrial Training Report: Indian Oil, Barauni RefineryДокумент39 страницIndustrial Training Report: Indian Oil, Barauni RefineryPriyanshu PrakashОценок пока нет

- 721 MA-01 Finished PlansДокумент39 страниц721 MA-01 Finished PlansДмитрий ВоронинОценок пока нет

- NalsДокумент148 страницNalsKartik BhararaОценок пока нет

- Resume of Md. Selim MiahДокумент3 страницыResume of Md. Selim MiahNusmus TinuОценок пока нет

- Maersk Intrepid PDFДокумент8 страницMaersk Intrepid PDFMauricio RicardezОценок пока нет

- Stihl Ts500i Service Manual-StihlДокумент118 страницStihl Ts500i Service Manual-StihlCarl Carlson63% (8)

- Operation ManualДокумент156 страницOperation ManualJans Manaek Carlos SitorusОценок пока нет

- Sewerage Manual Part 2 - With EurocodesДокумент94 страницыSewerage Manual Part 2 - With EurocodesParani DharanОценок пока нет

- Stepless Drive-1Документ3 страницыStepless Drive-1Mehul BawaОценок пока нет

- 988K Wheel Loader LWX PDFДокумент4 страницы988K Wheel Loader LWX PDFandreina nuñezОценок пока нет

- Troubleshooting - MaceratorsДокумент11 страницTroubleshooting - MaceratorsBeni SaputraОценок пока нет

- Id HMДокумент8 страницId HM성동Оценок пока нет