Академический Документы

Профессиональный Документы

Культура Документы

Cooler Efficiency

Загружено:

ayaskant751001Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cooler Efficiency

Загружено:

ayaskant751001Авторское право:

Доступные форматы

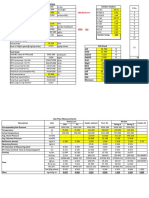

BEFORE OPTIMIZATION (AFTER MAY2009 BRICK LINING WORK)

Cooler heat balance Ref.Temp.(deg.C) 35 Heat in Clinker Cooling air

Date- 12-7-2008 Flow Flow kg/kg-cl, kg/kg-cl Nm3/kg-cl 1 2.37 1 3.06

Cp

Temp.

kcal/kg OC

OC

Heat kcal/kg-cl

0.26 0.24

1350 35 Total

343.08 0.00 343

100 0 100

Heat out Cooler vent Discharged clinker Radiation loss

1.50 1

1.93 1

0.24 0.19

336 106 Total

142.49 13.61 2.44 159

90 9 2 100

NOTE:

UNDER GRATE PRESSURE IS BETWEEN 450 TO 470 MM WG.

Cooler efficiency on heat loss basis= =

((heat in by clinker + cooling air) -(heat loss by vent air+ clinker + radiation))/( total heat in) 54 %

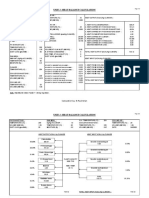

SAVING OF THERMAL ENERGY BY COOLER OPTIMIZATION = 27.38

K Cal/kg clinke

THERMAL ENERGY COST EFFICIENCY Energy cost Clinker production Heat saving saving p.a.cooler heat

SAVING BY INCREASING COOLER Rs/m kcal 650 Tonne p.a. 900000 k cal/kg.clk 27.38 Rs.p.a. 16014510 Cr.p.a. 1.601

SAVING OF HEAT BY PREHEATER EXHAUST GAS TEMP. REDU = 10 K Cal/kg clinke

THERMAL ENERGY COST SAVING BY REDUCING PH. EXHAUST TEMP. Energy cost Rs/m kcal 650 Clinker production Tonne p.a. 900000 Heat saving k cal/kg.clk 10.00 saving p.a.PH exhaust heat Rs.p.a. 5850000 Cr.p.a. 0.585

SAVING OF HEAT BY PREHEATER EXHAUST GAS TEMP. REDU = 10 K Cal/kg clinke

THERMAL ENERGY COST SAVING BY REDUCING PH. EXHAUST TEMP. Energy cost Rs/m kcal 650 Clinker production Tonne p.a. 900000 Heat saving k cal/kg.clk 10.00 saving p.a.PH exhaust heat Rs.p.a. 5850000 Cr.p.a. 0.585

ELECTRICAL ENERGY SAVING= ELECTRICAL ENERGY COST= CLINKER PRODUCTION = POWER COST SAVING =

1.3 3.2 900000 0.3744

Unit/tonne clk Rs/unit Tonne p.a. Cr.p.a.

TOTAL SAVING BY THERMAL AND ELECTRICAL ENERGY = 2.6 Cr.p.a.

AFTER OPTIMIZATION (AFTER NOVEEMBER 2009 BRICK LINING WORK)

emp.

OC

Heat kcal/kg-cl

Cooler heat balance Ref.Temp.(deg.C) 35 Heat in Clinker Cooling air

Date- 19-12-2008 Flow Flow Cp kg/kg-cl, kg/kg-cl kcal/kg OC Nm3/kg-cl 1 2.1 1 2.72 0.26 0.24

Temp.

OC

Heat kcal/kg-cl

350 35 otal

343.08 0.00 343

100 0 100

1350 35 Total

343.08 0.00 343

100 0 100

336 106

otal

142.49 13.61 2.44 159

90 9 2 100

Heat out Cooler vent Discharged clinker Radiation loss

1.28 1

1.65 1

0.24 0.19

325 96 Total

117.06 11.66 2.44 131

89 9 2 100

WG.

NOTE:

UNDER GRATE PRESSURE IS BETWEEN 570 TO 590 MM WG.

clinker + radiation))/( total heat in)

Cooler efficiency on heat loss basis= =

((heat in by clinker + cooling air) -(heat loss by vent air+ clinker + radiation))/( total heat in) 62 %

Y BY COOLER OPTIMIZATION = 27.38 K Cal/kg clinker

ING BY INCREASING COOLER

m kcal 650 e p.a. 900000 /kg.clk 27.38 .a. 16014510 .a. 1.601

TER EXHAUST GAS TEMP. REDUCTION = 10 K Cal/kg clinker

ING BY REDUCING PH. EXHAUST GAS 650 900000 10.00 5850000 0.585

m kcal e p.a. /kg.clk .a. .a.

TER EXHAUST GAS TEMP. REDUCTION = 10 K Cal/kg clinker

ING BY REDUCING PH. EXHAUST GAS 650 900000 10.00 5850000 0.585

m kcal e p.a. /kg.clk .a. .a.

1.3 3.2 900000 0.3744

Unit/tonne clk Rs/unit Tonne p.a. Cr.p.a.

AND ELECTRICAL ENERGY 2.6 Cr.p.a.

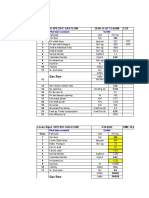

CK LINING WORK)

Temp.

OC

Heat kcal/kg-cl

1350 35 Total

343.08 0.00 343

100 0 100

325 96 Total

117.06 11.66 2.44 131

89 9 2 100

EEN 570 TO 590 MM WG.

eat loss by vent air+ clinker +

Вам также может понравиться

- Bestway Cement Limited heat balance and WHR analysisДокумент4 страницыBestway Cement Limited heat balance and WHR analysisKiran Veerubhotla100% (1)

- Heat Calculation by SG.Документ26 страницHeat Calculation by SG.TIRIANTO0% (2)

- Heat Balance-1Документ85 страницHeat Balance-1Ravi sharmaОценок пока нет

- Pheater Heat BalanceДокумент2 страницыPheater Heat BalanceRaji SuriОценок пока нет

- MASS BALANCE SUMMARYДокумент51 страницаMASS BALANCE SUMMARYirfan100% (1)

- Cement Kiln Pyro BalanceДокумент45 страницCement Kiln Pyro BalanceirfanОценок пока нет

- Cement Kiln Performance CalculationsДокумент9 страницCement Kiln Performance Calculationsvvijaybhan0% (2)

- Plant Kiln Fuel and Airflow ReportДокумент1 страницаPlant Kiln Fuel and Airflow ReportBùi Hắc HảiОценок пока нет

- Conversion Factor For NOx and SOx CalculationsДокумент2 страницыConversion Factor For NOx and SOx CalculationsvvijaybhanОценок пока нет

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesДокумент3 страницыRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliОценок пока нет

- Kiln Burner Flame Momentum CalculationДокумент6 страницKiln Burner Flame Momentum CalculationVijay BhanОценок пока нет

- Clinker CoolersДокумент74 страницыClinker Coolersemad sabri80% (5)

- Flame MomentumДокумент1 страницаFlame Momentumayaskant751001Оценок пока нет

- Cooler Balance 1Документ17 страницCooler Balance 1Tamer Fathy100% (1)

- Combustion Air Fan CalculationДокумент2 страницыCombustion Air Fan CalculationVijay BhanОценок пока нет

- AF Ash IncorporationДокумент7 страницAF Ash Incorporationirfan100% (1)

- Calculation of Flame MomentumДокумент1 страницаCalculation of Flame MomentumAnoop TiwariОценок пока нет

- Najran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportДокумент2 страницыNajran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportIrfan AhmedОценок пока нет

- Material Residence Time in KilnДокумент2 страницыMaterial Residence Time in KilnVijay Bhan100% (2)

- Clinker Production Kiln Surface Heat Loss FactorsДокумент2 страницыClinker Production Kiln Surface Heat Loss FactorsvvijaybhanОценок пока нет

- Heat Balance (Cooler 2)Документ4 страницыHeat Balance (Cooler 2)Junaid Mazhar100% (1)

- Clinker CoolersДокумент17 страницClinker Coolersemad sabri0% (1)

- ROTAFLAM Burner AdjustmentДокумент5 страницROTAFLAM Burner AdjustmentMuhammad Zaghloul100% (2)

- Cooler BalanceДокумент16 страницCooler BalanceIrfan Ahmed100% (1)

- FD Fan Efficiency CalculationДокумент6 страницFD Fan Efficiency CalculationPraveen VaratharajanОценок пока нет

- Overall Heat Balance - 11.08.2008Документ8 страницOverall Heat Balance - 11.08.2008Tamer FathyОценок пока нет

- LINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPAДокумент44 страницыLINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPAirfanОценок пока нет

- Separator Efficiency CalculationsДокумент13 страницSeparator Efficiency Calculationstricky7770% (1)

- Fine Coal Conveying Velocity in Kiln Firing SystemДокумент2 страницыFine Coal Conveying Velocity in Kiln Firing SystemVijay BhanОценок пока нет

- Heat BalanceДокумент33 страницыHeat BalanceIrshad Hussain100% (2)

- Raw Mill-Ball Mill Heat BalanceДокумент16 страницRaw Mill-Ball Mill Heat BalanceAbhishekОценок пока нет

- Cement Kiln Dust CKD Methods For ReductioДокумент21 страницаCement Kiln Dust CKD Methods For ReductiofaheemqcОценок пока нет

- Heat Balance For Kiln: Jasveer SinghДокумент4 страницыHeat Balance For Kiln: Jasveer SinghAlok RanjanОценок пока нет

- Fan Flow CalculationДокумент1 страницаFan Flow CalculationvvijaybhanОценок пока нет

- 3500TPD Cement Plant Heat BalanceДокумент2 страницы3500TPD Cement Plant Heat BalanceIrshad HussainОценок пока нет

- Rotary Kiln - Burning Zone Load CalculationДокумент2 страницыRotary Kiln - Burning Zone Load CalculationVijay BhanОценок пока нет

- HOCM MAR Fez CoolerHeatBalanceДокумент1 страницаHOCM MAR Fez CoolerHeatBalanceOUSSAMA LAKHILI100% (2)

- Useful Equations For Kiln & CoolerДокумент7 страницUseful Equations For Kiln & CoolerAbul Qasim100% (2)

- Heat Balance CalculationsДокумент29 страницHeat Balance CalculationsGuillermo Càceres100% (1)

- Vertical Raw Mill Heat Balance - SolutionДокумент3 страницыVertical Raw Mill Heat Balance - SolutionSai Sricharan Reddy80% (5)

- Cooler Air Flow Vs Kiln FeedДокумент2 страницыCooler Air Flow Vs Kiln FeedBùi Hắc HảiОценок пока нет

- Binani Cement kiln process diagram analysisДокумент99 страницBinani Cement kiln process diagram analysissaji kumar100% (5)

- Cooler Design and Operation CriteriaДокумент19 страницCooler Design and Operation Criteriatricky777100% (1)

- Fuel Analysis CalculationДокумент2 страницыFuel Analysis CalculationRamachandran Venkatesh100% (1)

- HOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSДокумент4 страницыHOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSMohd AliОценок пока нет

- AFR Profile 2003 GuidelinesДокумент13 страницAFR Profile 2003 Guidelinesshani5573Оценок пока нет

- Brick CaclulatorДокумент7 страницBrick CaclulatorAbul QasimОценок пока нет

- Fan Flow - CementДокумент5 страницFan Flow - CementharikrushnaОценок пока нет

- Kiln and Preheater Inspection Report: Area Status Remark of Condition (TUQEER ZAFAR)Документ33 страницыKiln and Preheater Inspection Report: Area Status Remark of Condition (TUQEER ZAFAR)Junaid MazharОценок пока нет

- Cement kiln heat balance and energy auditДокумент9 страницCement kiln heat balance and energy auditZia Khan100% (3)

- Plant Design of Cryogenic Distillation of Air To Oxygen and NitrogenДокумент34 страницыPlant Design of Cryogenic Distillation of Air To Oxygen and Nitrogenkumar100% (1)

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTДокумент2 страницыUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTjoe_kudoОценок пока нет

- Refrigeration problems COP calculations and refrigeration effectsДокумент7 страницRefrigeration problems COP calculations and refrigeration effectsAkash Bhange100% (1)

- 4.HVAC and Refrigeration SystemДокумент32 страницы4.HVAC and Refrigeration SystemPrudhvi RajОценок пока нет

- Mod 6Документ49 страницMod 6mkpq100% (1)

- Mass & Heat BalanceДокумент14 страницMass & Heat BalanceTruth SeekerОценок пока нет

- Grate Cooler Thermal AnalysisДокумент14 страницGrate Cooler Thermal Analysisaman131Оценок пока нет

- Rac Assignment (Sampurna Sahoo - 1702090077) PDFДокумент2 страницыRac Assignment (Sampurna Sahoo - 1702090077) PDFsambhav jainОценок пока нет

- Cryogenic Air Separation Process Assignments SolutionsДокумент7 страницCryogenic Air Separation Process Assignments SolutionsShekhar GaikwadОценок пока нет

- Control Mine Climate Using Wet-Bulb Globe Temperature IndexДокумент3 страницыControl Mine Climate Using Wet-Bulb Globe Temperature IndexFaizal AkbarОценок пока нет

- AratiДокумент5 страницAratiayaskant751001Оценок пока нет

- Cial 2Документ1 страницаCial 2ayaskant751001Оценок пока нет

- SOP For Cleaning of Clinker Cooler DischargeДокумент3 страницыSOP For Cleaning of Clinker Cooler Dischargeayaskant751001Оценок пока нет

- SJN Weighfeeders Advantages TitleДокумент2 страницыSJN Weighfeeders Advantages Titleayaskant751001Оценок пока нет

- TO Head - Credicards Icici Creditcard Division Kind Attn. MR - Subrat Pani Dear Sir, Ref:: My Credit Card NoДокумент1 страницаTO Head - Credicards Icici Creditcard Division Kind Attn. MR - Subrat Pani Dear Sir, Ref:: My Credit Card Noayaskant751001Оценок пока нет

- Sand VikДокумент6 страницSand Vikayaskant751001Оценок пока нет

- Robes DesignДокумент6 страницRobes Designayaskant751001Оценок пока нет

- Belt Weigher Technical PDFДокумент4 страницыBelt Weigher Technical PDFKEERTHI INDUSTRIESОценок пока нет

- ABB Technical Guide 1 - Direct Torque ControlДокумент32 страницыABB Technical Guide 1 - Direct Torque ControlASM_213Оценок пока нет

- Kind Attn: Mr. S.K.Purohit, Sr.D.G.M. (MKTG.) /HMBPДокумент4 страницыKind Attn: Mr. S.K.Purohit, Sr.D.G.M. (MKTG.) /HMBPayaskant751001Оценок пока нет

- BrochureДокумент27 страницBrochureayaskant751001Оценок пока нет

- SFM With Binlevel MeasuringiДокумент7 страницSFM With Binlevel Measuringiayaskant751001Оценок пока нет

- VRM-Roller Seal-Of OCL PlantДокумент3 страницыVRM-Roller Seal-Of OCL Plantayaskant751001100% (1)

- Bharat Sanchar Nigam Limited Calcutta TelephonesДокумент2 страницыBharat Sanchar Nigam Limited Calcutta Telephonesayaskant751001Оценок пока нет

- BSP CraneДокумент1 страницаBSP Craneayaskant751001Оценок пока нет

- Flame MomentumДокумент1 страницаFlame Momentumayaskant751001Оценок пока нет

- SRF PresentationДокумент16 страницSRF Presentationayaskant751001Оценок пока нет

- Burner Calculation OCLДокумент4 страницыBurner Calculation OCLayaskant751001100% (1)

- Cooler EfficiencyДокумент58 страницCooler Efficiencyayaskant75100150% (2)

- 251BC1 R2 ModelДокумент1 страница251BC1 R2 Modelayaskant751001Оценок пока нет

- 5 Pillars of the Visual WorkplaceДокумент30 страниц5 Pillars of the Visual WorkplaceMayur12345dtОценок пока нет

- VRM-Roller Seal-Of OCL PlantДокумент3 страницыVRM-Roller Seal-Of OCL Plantayaskant751001100% (1)

- High Air To Cloth Ratio Bag FilterДокумент2 страницыHigh Air To Cloth Ratio Bag Filterayaskant751001Оценок пока нет

- O Sepa DimensionДокумент1 страницаO Sepa Dimensionayaskant751001Оценок пока нет

- Keyplan CCBCДокумент1 страницаKeyplan CCBCayaskant751001Оценок пока нет

- Heat BalanceДокумент3 страницыHeat Balanceayaskant751001Оценок пока нет

- Super Teams 5 S Game Hand OutДокумент22 страницыSuper Teams 5 S Game Hand Outayaskant751001Оценок пока нет

- Comparision Between Longitudinal Circular StockpileДокумент2 страницыComparision Between Longitudinal Circular Stockpileayaskant751001Оценок пока нет

- Flame MomentumДокумент1 страницаFlame Momentumayaskant751001Оценок пока нет